RIO-D Installation manual doc. R18

Remote setting

Full opening [Op] press SEL until LED G flashes,

then press remote control button.

Pedestrian open [Pe] press SEL until LED F flashes,

then press remote control button.

150 fixed or rolling code remotes can be set. See

also remotes function.

Quick setup

This is a simple setup for a functional test. Run time

is set to 30 sec default suitable for limit switch

motors. Auto-close, PSR, and photo test are

disabled. You will need 1 remote set.

1. Reset - Press SET & SEL for 2secs.

2. Phototest –Press SEL until no Leds are flashing.

Hold SET until Leds A&B are flashing

alternately. Press SEL until Led G flashes. Press

SET. Led G stays on.

3. Exit - Wait for 30 secs to exit programming.

4. Run –If possible, close gates by hand. Press

remote. The gates will start to open. After 2

secs, adjust FORZA for minimum power

required to open the gate reliably.

IMPORTANT

For safety, the PHOTOTEST is enabled

on delivery. When enabled, the function

tests devices in Fo and St before each

gate run. If the test fails, all 8 LEDs flash

3 times. Step 2 above disables the test.

Enable phototest aftersetup as required.

Timedfunctions

There are 4 timer settings.

Run times The quick setups have preset run times

for limit switches motors. Op runs for 30

secs. Pe runs for 10 secs. Menu 1D and 1C

allow run times and slow down times to be

set dynamic-ally. See page for instructions.

Pause sets the time before the gates are re-

closed. The time is set dynamically via menu

1B up to 240 secs. Setting to zero disables

auto-close. See page 4.

Shorten pause This function enabled on menu 3H

shortens the programmed Pause time to 5

secs after a car passes through the Fo

photobeam.

Interleaf delay For curved drives, motor2 may be

required to start closing after motor1. Menu

1B sets this interleaf delay dynamically in the

same way as Pause.

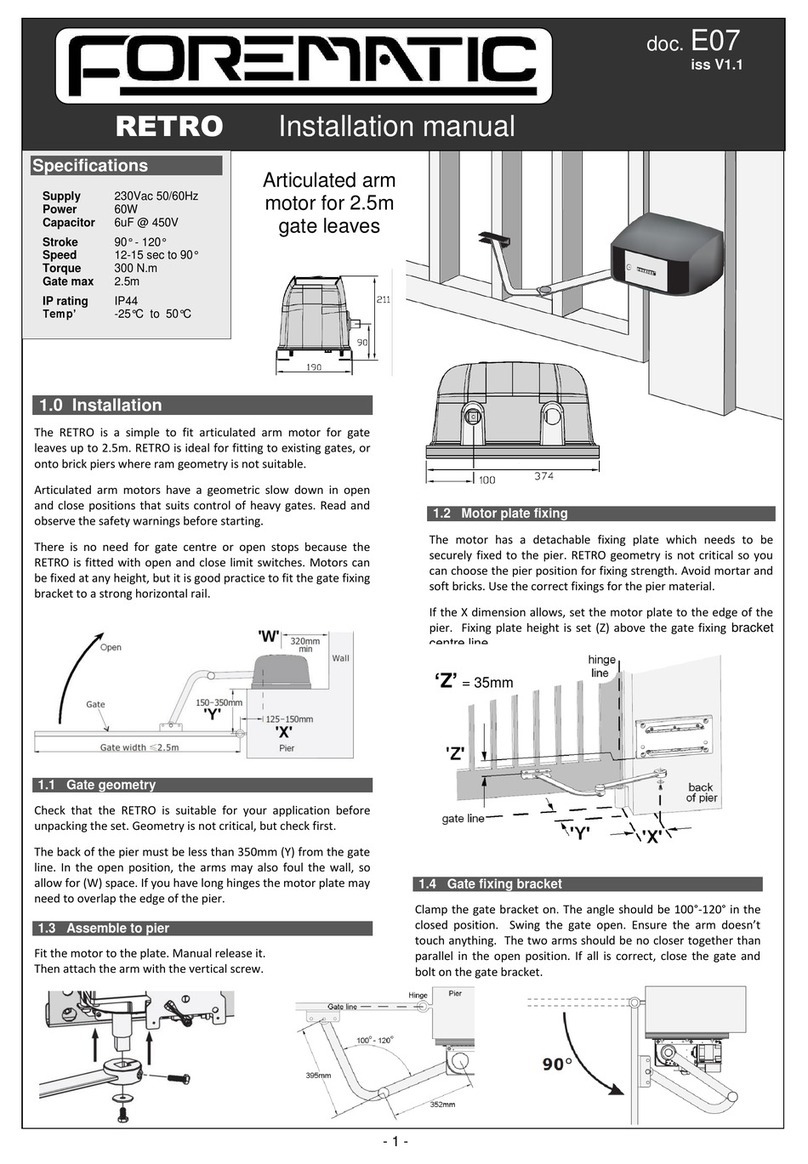

Terminal description

All low voltage inputs and outputs have the same

common Crepeated on 4 terminals.

[AC] Accessory supply 24Vac, 3W max. Can be set

as a switched supply for Cat2 testing.

[Lk] Electric lock terminal.

[Op] Open input. A momentary activation starts an

opening cycle. Holding the input ON keeps

the gate open by disabling auto re-close.

[Pe] Input for partially opening Motor1 for

pedestrian use. Programming can set this

input to operate the lock only.

[Fo] Photobeam input, re-opens the gates if

interrupted while gates are closing. No effect

while the gates are closing.

[St] Safety input with programmable options. The

default setting is to pause the gates while

opening then continue when cleared. On

closing, the gate stops & re-opens.Menu 2C

changes St to stop the gate then to wait for

the next input to re-start.

Function options

The controller has optional functions that need

some extraexplanation.

Lamp output is on while motors are running. There

are 2 options. Menu 3F enables lamp to also

stay on during the pause period. Menu 3G

allows a 3 sec pre-flash, or stay on 3 minutes

after closing (courtesy light), or both.

[Op] input. Menu 1H sets Op for 4 step automatic

(open-stop-close-stop). Menu 1E sets Op to

“open only” used typically with exit loops, or

on busy sites with several opening devices.

[Pe] input. Menu 3D sets Pe to release the lock on

Lk independent of the motors, eg a separate

pedestrian gates. Menu 3C sets Pe as a close

input used when Op is the open only input.

[Lk] lock has 3 function options. Menu 2D enables

an extra push at the end of the close cycle to

ensure a lock is fully latched. Menu 2E helps

release vertical bolts. It gives a short closing

pressure just before a lock pulse. Menu 2F

gives a closing pulse every 2 hours to ensure

the gate stays closed (for hydraulic openers)

Remotes. Menu 2H enables new remotes to be

learned without access to the PCB. Press

any existing remote for 10 secs, then press

the new remote button to be added.

Soft start. Menu 3E enables soft start. Power is

gently increased over the first 2 secs of run.

1 2 3 4 5 6 7 8 9 10 11 12

Foto

Foto

Lock

Opn

Ped

Foto

Stop

Board features

Connectors

The board is connected entirely thru 5 plug on

connectors on the front edge. Boards are easy to

change with all plug in blocks.

Power & lamp are on a 4 way plug. There is a

separate 3 way plug in earth block.

Motors are connected on a three way plug.

Motor plugs may be swapped over, but not

reversed. A capacitor may need to be wired

between the outer two terminals.

Controls are connected on two low voltage 6

way plugs. Button and safety inputs are 5V active

low to any common terminal. Safety inputs are

NC (normally connected).

Fuses F1 is the mains input fuse - 6.3A

F2 transformer primary –T50mA.

Receiver

The plug in receiver card set for 433MHz does

not store codes. The main processor stores up

to150 codes, fixed or rolling

Adjustments

SENSIBILITA sets the motor PSR limit (pressure

sensitive reversal). The setting is the total

permitted time motor force may exceed a force

limit set automatically during the run time

setting. Fully CCW disables PSR.

Unless soft start is enabled the first 2 secs motor

running is set to maximum power. The rest of

the run power is set by FORZA. Slow down

power is set on menu 4 as a lower proportion.

LEDs and buttons

Each input has an LED above the

terminal that is on when the input

is active (connected to common).

8 LEDs in the corner of the board

marked A-H are used with the SET

and SEL buttons

for programming.

See programming.