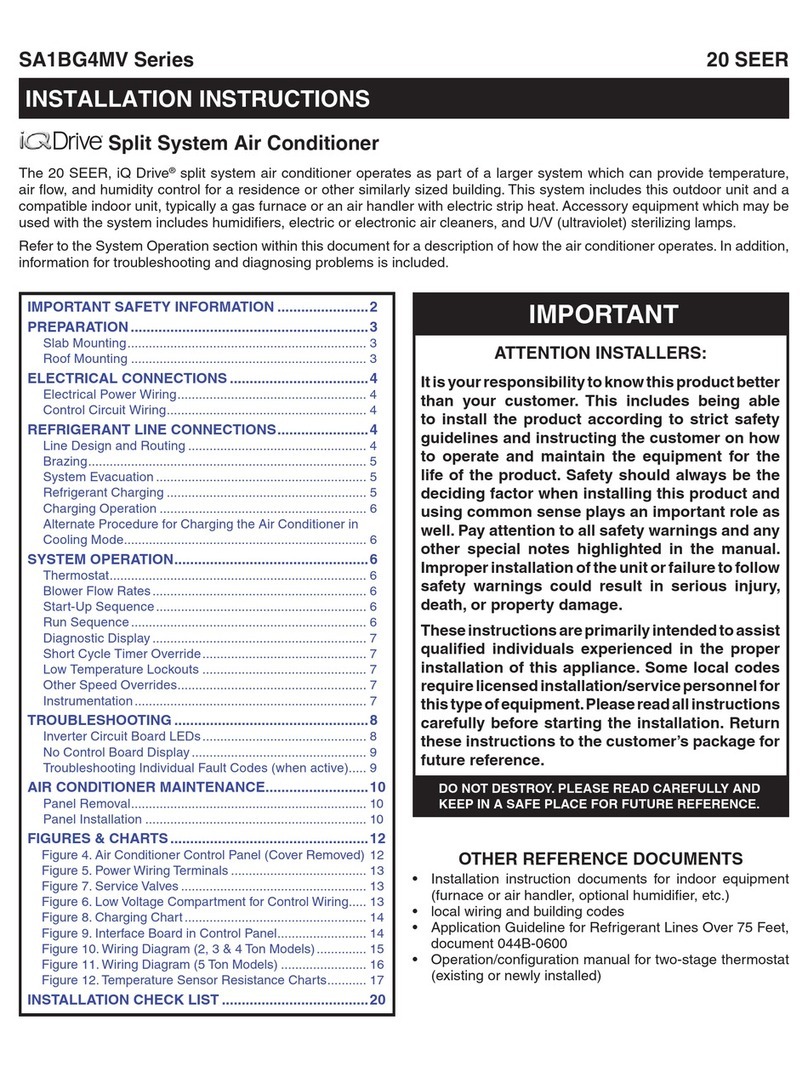

Important Safety Instructions

The following symbols and labels are used throughout this

manualtoindicateimmediateorpotentialsafetyhazards. Itis

the owner’s and installer’s responsibility to read and comply

withallsafetyinformationand instructionsaccompanyingthese

symbols. Failuretoheedsafetyinformationincreasestherisk

ofpersonalinjury,propertydamage,and/orproductdamage.

HIGH VOLTAGE!

Failure to do so may cause property

damage, personal injury or death.

Disconnect ALL power before servicing or

installing this unit. Multiple power sources

may be present.

Only personnel that have been trained to install,

adjust, service or repair (hereinafter, “service”) the

equipment specified in this manual should service

the equipment. The manufacturer will not be

responsible for any injury or property damage arising

from improper service or service procedures. If you

service this unit, you assume responsibility for any

injury or property damage which may result. In

addition, in jurisdictions that require one or more

licenses to service the equipment specified in this

manual, only licensed personnel should service the

equipment. Improper installation, adjustment,

servicing or repair of the equipment specified in this

manual, or attempting to install, adjust, service or

repair the equipment specified in this manual without

proper training may result in product damage,

property damage, personal injury or death.

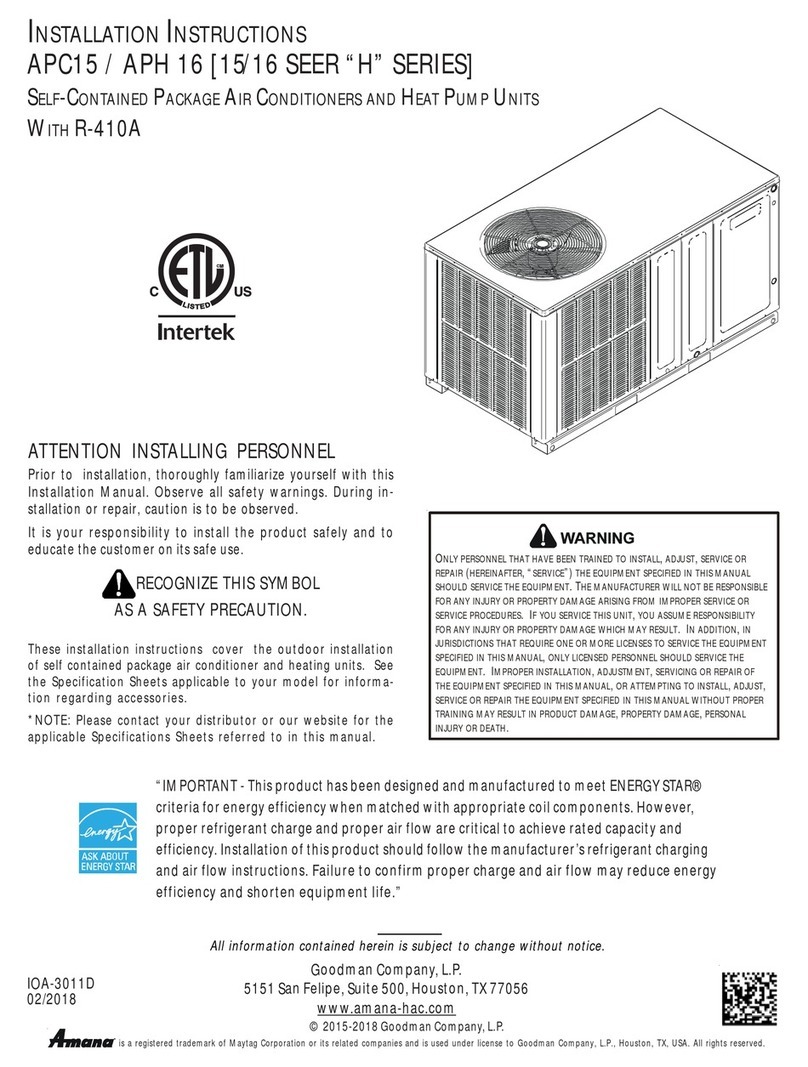

Shipping Inspection

Upon receiving the product, inspect it for damage from ship-

ment. Shipping damage, and subsequent investigation is the

responsibilityofthe carrier. Verify the model number, specifi-

cations, electrical characteristics, and accessories are cor-

rectpriortoinstallation. The distributorormanufacturerwillnot

accept claims from dealers for transportation damage or in-

stallation of incorrectly shipped units.

HORIZONTALCOILS

INSTALLATION INSTRUCTIONS

Codes & Regulations

This product is designed and manufactured to comply with

nationalcodes.Installationinaccordancewith suchcodesand/

orprevailinglocalcodes/regulationsistheresponsibilityof the

installer. Themanufacturerassumesnoresponsibilityforequip-

mentinstalled in violation of anycodes or regulations.

TheUnited States EnvironmentalProtection Agency (EPA)

has issued various regulations regarding the introduc-

tion and disposal of refrigerants. Failure to follow these

regulations may harm the environment and can lead to

the imposition of substantial fines. Theseregulationsmay

vary by jurisdiction. A certified technician must perform the

installation and service of this product. Should you have any

questions please contact the local office of the EPA.

Replacement Parts

Whenreporting shortagesordamages,ororderingrepairparts,

givethecompleteproductmodelandserialnumbersasstamped

onthe product. Replacement parts for this product areavail-

able through your contractor or local distributor. For the loca-

tion of your nearest distributor consult the white business

pages,the yellow pagesection of the local telephone book or

contact: HOMEOWNERSUPPORT

GOODMANMANUFACTURINGCOMPANY,L.P.

19001KERMIERROAD

WALLER, TX 77484

877-254-4729

Pre-Installation Instructions

Carefullyreadallinstructionsfortheinstallation prior to install-

ingproduct. Make sure each stepor procedure is understood

and any special considerations are taken into account before

starting installation. Assemble all tools, hardware and sup-

plies needed to complete the installation. Some items may

needtobepurchased locally. Make sureeverythingneededto

install the product is on hand before starting.

IO-283J

02/2018