MBS THERMO VULKAN User manual

MANUAL INSTRUCTION

Solid fuel stove for central heating –

THERMO VULKAN

DEAR CUSTOMER,

We appreciate your trust dedicated to us and your determination to buy our product.

You made a good choice, since this oven has technical characteristics which place it

into top class, and you will be assured of it during exploitation.

Please, carefully read this manual before you start to use his oven, since you will find

tips and tricks for proper handling.

We believe that you will be one of the millions of satisfied customers of our products.

A.D „Milan Blagojević“Smederevo

CONTENTS

Warning before use ...............................................................................1

Description ............................................................................................2

Installation .............................................................................................4

Installation to the water heating system ................................................6

Managing operation of the stove...……..........…………………..............10

Firing up and ignition ….........................................................................11

Cleaning and maintenance ...................................................................12

General notes …....................................................................................13

Advices for environmental protection.....................................................13

WARNING BEFORE USE

To obtain proper operation of your stove, it is important to read this manual and

strictly observe directions for use and handling.

For combustion, use solid fuels like woods, briquettes and low-caloric coal. It is

forbidden to put explosive devices and materials into the firebox or on the plate. It is

forbidden to keep combustible materials in direct vicinity of the stove.

For proper combustion, in normal operating mode, draft in the chimney should be 10-

12 Pa. In case if draft is higher then 15Pa, flap should be installed into the chimney.

It is necessary on regular basis to ventilate room in which stove is located due to

inflow of fresh air necessary for combustion.

Stove parts get heated to high temperatures during operation and appropriate

attention is necessary during handling. Do no allow children to handle and play in

vicinity of the stove.

Only spare parts approved by the manufacturer may be installed on the stove. Do

not make any changes to the stove.

At the first firing up, slight smoking may occur, especially from the surface of the

plate. It is common appearance which originates due to combustion of deposits on

the plate surface (anti-corrosive protection, color, dust....). Room in which stove is

located should be ventilated during first firing up.

Do not allow parts of the stove to become extremely hot.

It is not recommended to install the stove onto collective chimney since it will cause

weak draft.

Do not connect gas device on the same chimney.

During burning, use protective gloves since door handles and vessels are hot.

DO NOT USE STOVE:

•If stove is not connected to the installation

•If there is not water in installation

•If installation is defected

During installation, please follow national and local regulations for installation.

In case of non-observance of instructions, manufacturer does not bear any

responsibility for damages.

STOVE DESCRIPTION

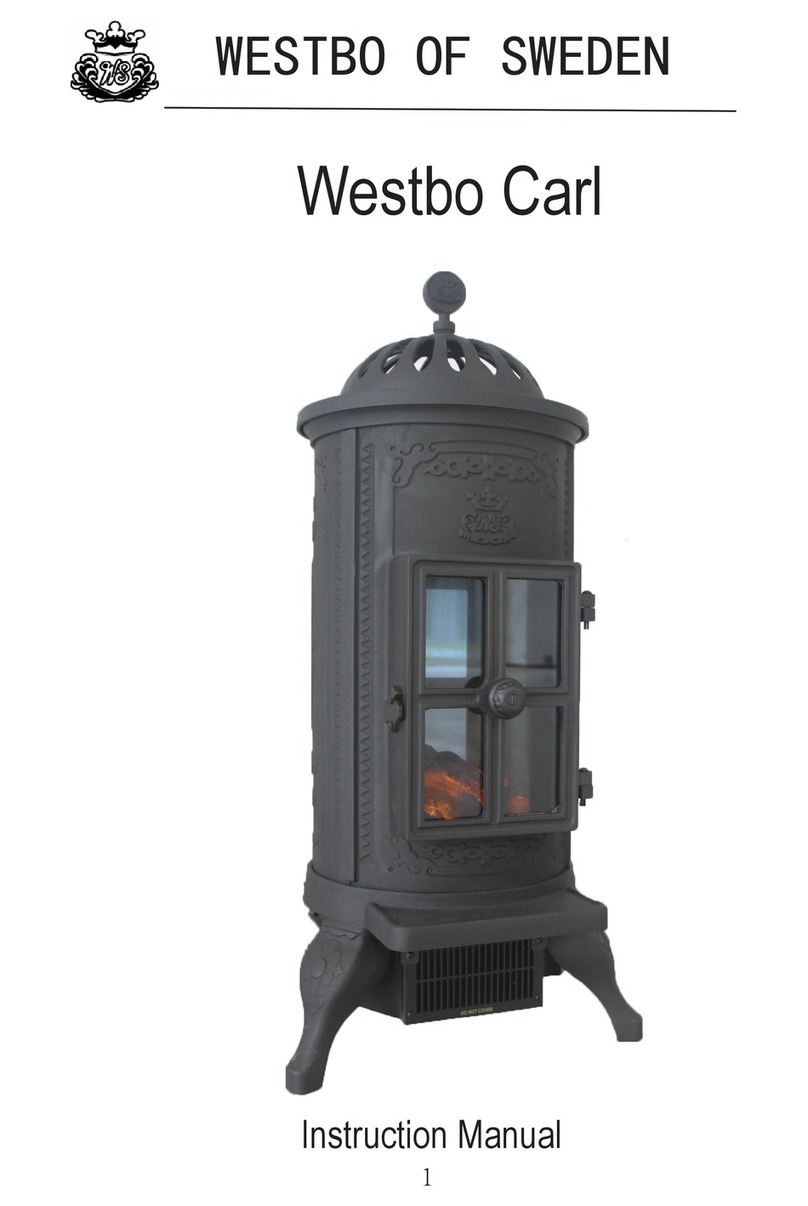

Solid fuel stove for central heating THERMO VULKAN is produced and tested

according to the European standard EN 13240. On figure no. 1 given in the

introduction page, layout of the stove with integral parts important for handling is

displayed. Floor oven Thermo Vulkan has boiler of 24 liters capacity which is made

of boiler sheets with standard thickness. With production like this, life span of the

boiler increases. Water connections are 1“.Working area is consisted of cast plate

(fig. 1, pos. 5) with smoke exhaust connection (fig. 1, pos. 7) which is mounted on

the plate with two screws. Firebox area is built with bricks made of vermiculite.

Firebox door (fig.1, pos.8) are made of cast iron and has transparent glass. Ashtray

door (fig.1, pos.11) are made of cast iron and has manual air flow regulator.

Fig. 1. Integral parts of Thermo Vulkan

1 – natural stone

2 – secondary air flow regulator

3 – boiler

4 – cast iron grid

5 – thermo-regulator button

6 – ashtray

7 – smoke exhaust

8 – firebox door

9 – firebox door handle

10 – auxiliary air regulator

11 – ashtray door

12 – ashtray door handle

Central heating stoves are intended for heating of residential facilities. Integral part of

installation is thermal valve which serves as safety thermal valve against eventual

overheating. Recommended safety thermal valve is Caleffi 544 ½, displayed in fig.2.

Comment: Thermal valve is not a part of the product and will not be delivered with it.

Guarantee for central heating stove is valid excusively with thermal valve installed.

Fig. 2

TECHNICAL DATA

Technical characteristics

Product name THERMO VULKAN

Product purpose Solid fuel stove for central heating

Nominal power (wood/ coal) 19,7 / 24.8 kW

Power given to water (wood/ coal) 14 / 14.5 kW

Power given to room (wood/ coal) 5,7 / 10,3 kW

Efficiency

- wood 86%

- coal 85%

Dimensions of stove (HxWxD) 780 x 650 x 500 mm

Dimensions of firebox (HxWxD) 310 x 400 x 400 mm

Weight (wihtout water/ with water) 156 / 177 kg

Minimal distance from combustible

materials

- back 50 cm

- side 50 cm

- front 80 cm

Emission of CO (reduced to 13% O2)

- wood 0,07 % 0,966 g/m³

- coal 0,08 % 1,003 g/m³

Emission of dust

- wood 0,037 g/m³

- coal 0,039 g/m³

Chimney connection Ø120 mm

Position of chimney connection central top

Average temperature of smoke gases

(wood/ coal) 227,5 / 199 °C

Air regulation primary, secondary

Draft 10-14 Pa

Amount of water in boiler 24 l

Water connection diameter 1"

Max. temerature of the water in boiler 90 °C

Max. working pressure 2 bar

INSTALLATION

Do not put the stove in direct vicinity of wooden elements, cooling devices, plastic

parts of the furniture and other combustible materials, since it creates high working

temperature which is distributed at the exterior of the stove. The least distance

between oven and surrounding elements is 50 cm, and from combustible materials

80 cm.

If the base on which stove will be positioned is made of easily combustible material

(wood, warm floor, laminate...) it is necessary to put larger dimension protection -

laterally 10 cm, and in front 50 cm.

Stove is to be connected with chimney through flue pipes and via connection of the

stove, in order to provide adequate sealing and smoke draft from stove to the

chimney. Smoke exhaust pipe may not be inserted too deeply into the chimney not

to reduce surface of its cross-section thus reducing draft.

Ventilators which work in the same room in which stove is mounted may create

disturbances with the stove operation. Also, all devices or air conditioning which

make sub-pressure in the room in which stove is installed must be adjusted not to

make decompression which disables normal operation of the stove.

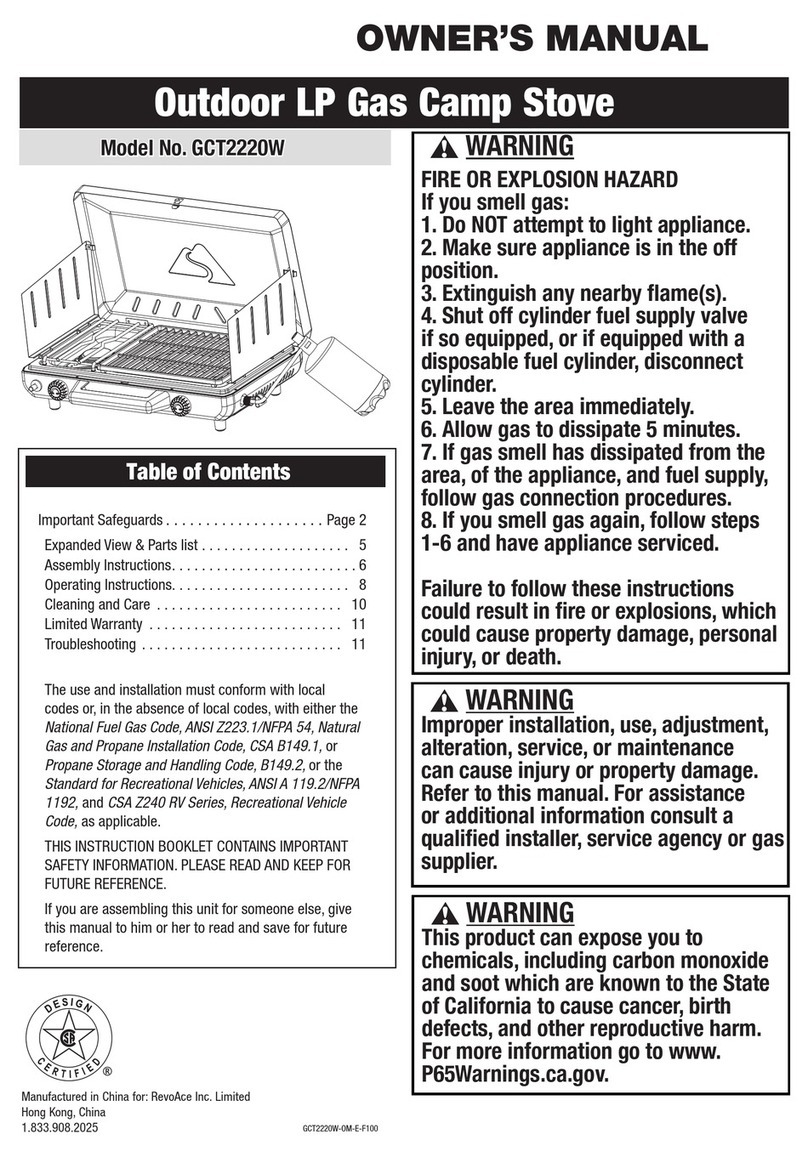

Prior to installation of the stove, check draft in the chimney since it is one of the key

factors of proper operation. Draft depends on accuracy of the chimney and

meteorological conditions. One of the simplest aspects for checking of the draft in

the chimney is using candle flame, as illustrated in the figure 2a and 2b.

Candle flame is to be offered to connection opening of the chimney and, if it sways

towards opening, draft is satisfactory. Weak swaying of the flame is indicator of weak

draft. In that case, check draft in the chimney.

Fig. 2a. Fig. 2b.

If draft in the chimney is weak (fig. 2a), check accuracy of the chimney. Chimney

should be located within interior of an object, and if it’s on external walls of an object,

it is recommended to insulate the chimney.

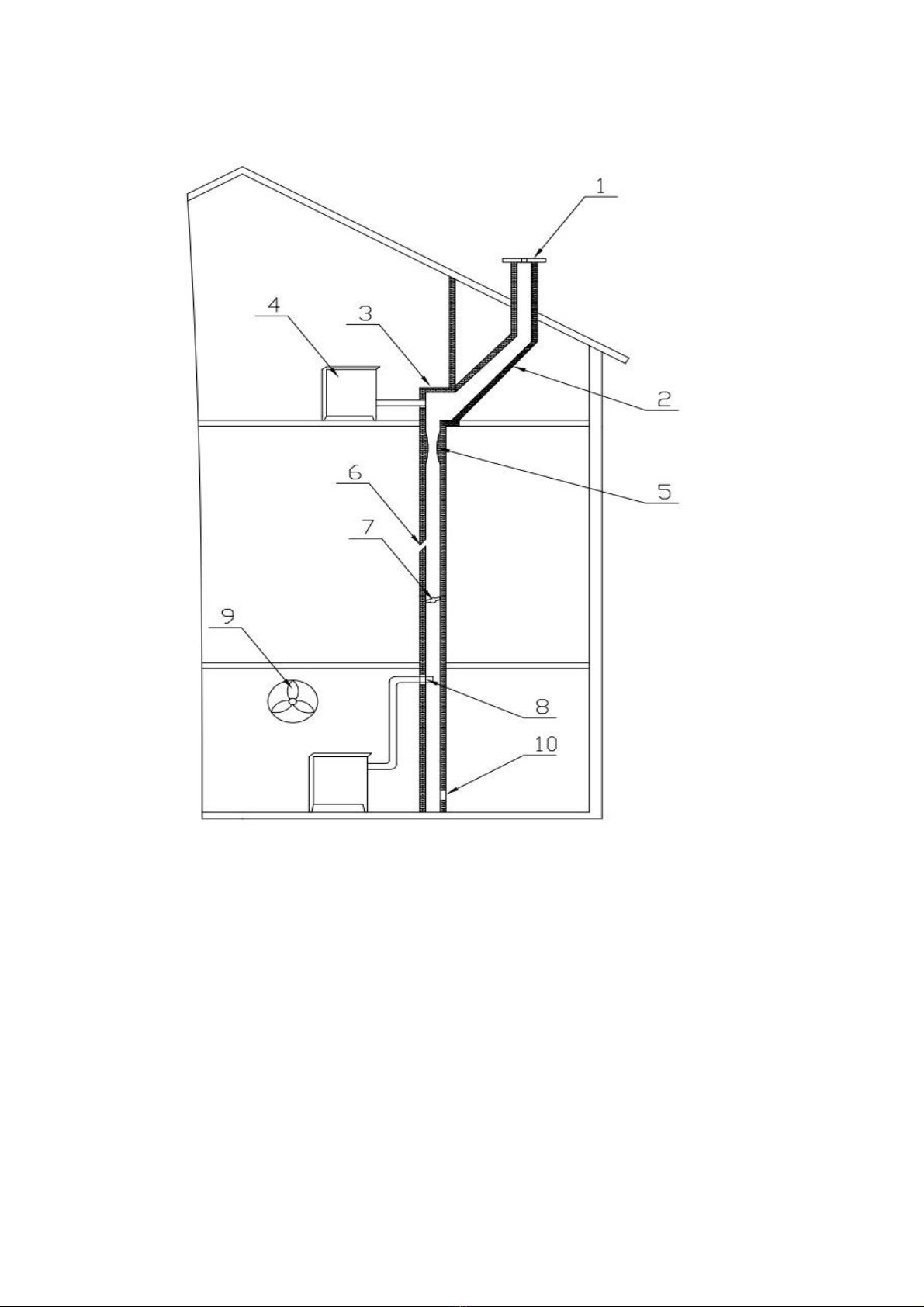

Fig. 3

Defaults of the chimney may be: (fig. 3):

1. Chimney is lower then top of the roof, small cross section of the exit

2. Too large slope

3. Abrupt alteration of the direction of smoke channel,

4. Oven or other device connected to the same smoke channel,

5. Bulges in the smoke channel,

6. Cranks,

7. Foreign body or deposited smut,

8. Too deep installed pipe,

9. Ventilator or other device which creates sub-pressure in the room

10. Leaky or open aperture for cleaning

Installation into the water heating system

For intake and and drainage of water into the system of floor (central) heating, 1"

boiler connector are provided.

Stove may be mounted on closed or open central heating system.

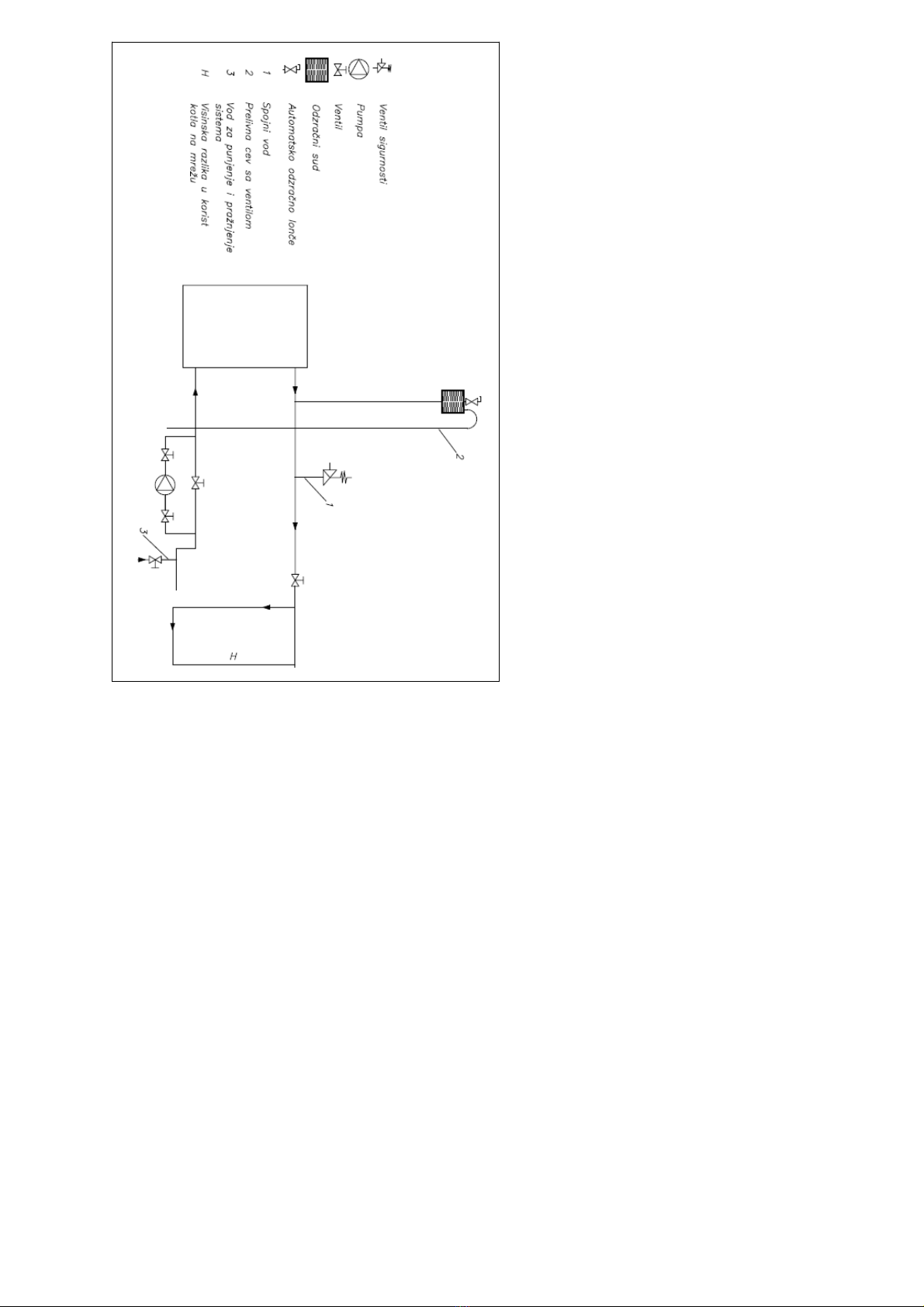

Mounting on closed central heating system

One of the installations is depicted on the fig. 5.

- Safety valve must be installed in the vicinity of boiler and must be set to the

pressure of max. 3 bar (boiler is tested for 4 bars). Connection guide of safe valve

must be as shorter as possible and may not have capability of closing. In this guide,

also, may not be any valve beither any other armature.

- closed expansion vessel is to be installed close to the boiler and his safety valve is

short. Capacity of this vessel is determined based on the capacity of the boiler with

the proportion 1kW:1l.

- Installation of safety thermal valve of the boiler is mandatory on prescribed

position. We recommend safety thermal valve Caleffi 544.

Thermo

Vulkan

Fig. 5

Scheme of closed heating system

Mounting on open heating system

One of the aspects of carrying out installations is shown on fig. 6.

At this system, on initial guide: safety distribution guide of expansion vessel and

valve of the boiler are to be installed in order, and on initial guide of the system boiler

valve, pump and valve are to be installed. Directly below open expansion vessel

short connection between safety distribution guide and safety return guide is to be

installed, which on winter provides freezing of water in expansion vessel.

On safety distribution and safety return guide there may not be any armature.

Expansion vessel itself must have overflow pipe as on fig. 7. Capacity of expansion

vessel is determined as follows:

V = 0,07 x Vwater, (l), where V water is capacity of water in entire system.

Open expansion vessel is to be installed vertically above the highest heating body.

At the open heating system, gravitational heating system is possible.

Note:

Installation and putting into operation of the entire system must be carried out

exclusively by professional who guarantees proper operation of entire heating

system. In case of weak design of the system and eventual defaults during

installation carried out by mentioned professional, which again may cause improper

operation, complete material responsibility is transferred to such professional,not

manufacturer, representative or vendor.

Important

All connections must be well sealed and tightened. Prior to operation, complete

installation should be tested with water under pressure of 2,5bar.

At the mounting of safety valve, pay attention on direct connection with water and

sewage, and if valves (taps) are always open.

If armored hose is used for connection to sewage, it must be away of back side of

the stove due to high temperatures from the stove.

At the first firing up, it is necessary to test accuracy of thermal exhaust valves by

short-term overheating up to 100°C, as well as accuracy of draft regulator, hot water

distribution to radiator.

Thermo

Vulkan

Fig. 6

Scheme of open central heating system

FIRING UP AND IGNITION

Prior to the first ignition, wipe all enameled surfaces of the stove with dry mop to

avoid combustion of dirt on the stove and creation of unpleasant scents.

Firing up in the firebox should be carried out as follows:

• open firebox and ashtray door,

• put into the firebox some firing materials (chopped wood on non-greasy and

crumpled paper),

• fire up,

• ashtray door should be left open until stable flame occurs, and after closing,

intensity of the burning should be regulated on the air flow regulator, (fig. 1, pos. 3)

• close burner and ashtray door,

• after creation of basic cinder, put into the firebox some bigger pieces of woods or

coal and close firebox door. If briquettes are used, you must wait all quantity of fuel

to get ignited then to reduce air flow to half.

• at adding fuel, open firebox door (fig. 1, pos. 1) for only few degrees,

wait for 4-5 seconds, then open it wide very slowly. Do not open it abruptly, because

when flame in the firebox is too strong, it may effuse into the room.

By regulation of draft in the stove, you set temperature, power and pace of fuel

combustion, and it is to be carried out by turning air flow regulator on the ashtray

door (fig. 1, pos. 3). Stove has secondary air flow regulation due to improvement of

combustion and maintaining firebox glass clean. By combining primary air through

regulator on the ashtray door and secondary air via buttons above firebox door (fig.1,

pos. 12) desired combustion is achieved.

Stove has auxiliary tools which serve to facilitate maintenance of the stove. Use

these tools for shaking of the grid, it is to be inserted into the aperture of the shaker

which is located below ashtray door, then use slow motions forward and backward

during operation of the stove to enable passage of primary air.

Woods and briquettes are recommended for burning.

Do not use fuel oil, gasoline or similar as fuel for the stove, since usage of

liquid fuels creates conditions for damaging of stove and possible explosion.

Attention!

•Do not use organic residues, food residues, plastic objects, combustible and

explosive materials as fuel, since their combustion disturbs proper operation

of the stove and may cause damages and pollution of environment.

•Increased external temperatures may cause weak draft in the chimney, thus it

is recommended more frequent burning in smaller quantities.

•Usage of the stove in cases when meteorological conditions are bad and in

case of strong wind, it is to be maintained on proper sub-pressure in the

chimney. In indicated cases, smoke may return into the room in which stove is

located. Firing up is protracted in such cases.

We recommend burning on each one hour with the height of the fuel in the firebox up

to 15 cm with crosswise positioning of the woods due to higher draft.

Upon each filling, it is recommended to let stove to burn at least 30 minutes with

maximal power, in order to burn all evaporable ingredients which are the reason of

creation of condensate in the stove in this stage of combustion.

For proper operation of the stove, it is necessary to:

• regularly clean stove and chimney,

• regularly ventilate rooms due to good combustion,

• regularly remove ash from ashtray,

• regularly remove deposited gravel and unburned materials from the grid, using

cleaning accessories.

MANAGING OPERATION OF THE STOVE

Start firing up with moderate fire in terms of avoiding thermal shocks.

Following quantity of woods is to be inserted only when previous quantity gets

burned.

Do not allow clogging of the grid with ashes and unburned fuel. Clean the grid.

Open the door slowly and carefully, not abruptly, enabling equalization of pressures

in the firebox and room, otherwise, it may cause occurrence of smoke in the room.

Stove is designed and provided for operation with constantly closed firebox door,

except during filling with fuel. Do not open door unnecessarily.

Wood must be with maximal 20% humidity for maximal burning performance.

Otherwise, tar and gases occurs which create creosote with water vapor. If creosote

occurs in larger quantity, fire may occur in the chimney.

Fire in the chimney will be easily recognized as follows: characteristic sound which

comes from the chimney like loud hoot, visible flame which comes from chimney,

high temperature of surrounding walls and characteristic smell of flare.

If fire occurs, take following steps:

•Immediately call fire department

•Suppress oxygen inflow into the chimney and turn off the stove

•Do not put anything in chimney and look after fire not to extend to the wooden

construction or some other combustible material in vicinity.

•NEVER extinguish the chimney with water or to pour water in the stove

•Fire in the chimney may be extinguished only with the device with dry powder

•Water may be used only for surrounding materials

•Do not cool surrounding walls with water

Comment:

If fire in the stove in any reason becomes dangerously strong, do as follows:

close air flaps which provide air for combustion. If necessary, put some

specially prepared sand into the burner or special fireproof extinguishing

blanket. It would be good to have fire-extinguishing device.

Prior to second filling, clean roast grid with auxiliary tools to avoid clogging of fresh

air intake.

Regularly clean ashtray, taking care top leave enough space for the ash.

Combustion agility, thus amount of heat obtained by the stove, depends on

combustion primary air amount which is brought in the area below the grid.

Regulation of primary air amount is provided automatically using air flow regulator

Rathgeber (fig. 7).

Fig. 7

During burning, turn regulator button into position of maximally opened flap in

direction shown on fig. 8. During operation, depending on temperature, regulator flap

will open and close automatically. If we want lower temperature then set, turn

regulator button in desired position of minimally open flap, and it closes. Button is to

be turned using auxiliary tools by putting longer side of the tool into the bed of the

button and turning, as necessary.

Fig. 8

If there are disturbances during heating (weak fuel, unsolved irregularities) by using

auxiliary regulator which is located on the front side of the ashtray door (fig. 1 pos.

11), we can bring additional primary air, for improved combustion.

CLEANING AND MAINTENANCE

Regular and proper cleaning enable proper operation and longer life span of the

stove.

Cleaning of external surfaces – with soft cloth which will not damage stove

surfaces. Chemical cleaning agents may be used and don’t damage surfaces of the

stove. Do not clean colored and enameled surfaces with abrasive agents.

Cleaning of internal surfaces –when clean, use protective gloves.

Clean internal walls of the burner against deposited smut, collect small and

unburned particles from the grid, clean ashtray and deposited ash within the stove.

Cleaning of glass surfaces – firebox glass gets dirty during operation. For cleaning,

use soft detergents. Do not use abrasive agents since glass surface may get

damaged. Clean glass when it’s cold.

Cleaning and maintenance of the chimney- cleaning and control of the chimney is

recommended at least once a year as well as after longer inactivity. Regular

maintenance and control of the chimney will prevent origination of fire and weak

operation.

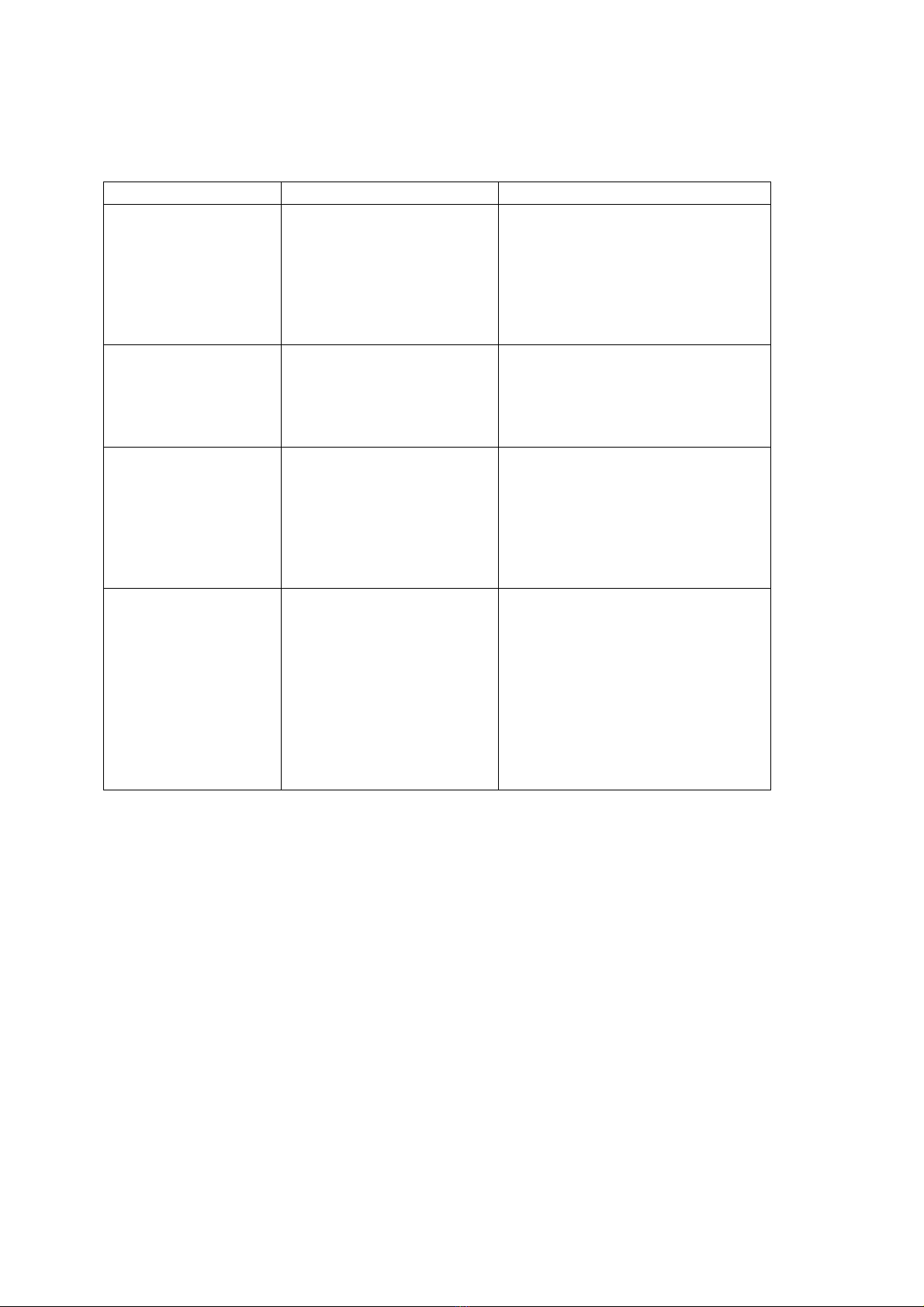

IRREGULARITIES IN OPERATION AND TROUBLESHOOTING

In the following table, there are most frequent operating irregularities and

troubleshooting.

Table: Display of the most frequent irregularities, possible causes and

troubleshooting.

GENERAL NOTES

If all installation recommendations, operating and cleaning regulation given in this

manual are met, stove represents proven and safe household device.

Prior to installation, remove the package. Take care of possible injuries since

wooden battens on packaging have nails. Dispose of plastic bag in the proper place

according to the local regulations. Old stove which will not be used in the future

should be disposed of according to the local regulations.

All claims, evaluated as defects or weak functioning of the stove should be reported

to manufacturer or authorized service via phone or in written form with fiscal bill

attached. All contact information is given at the end of this manual.

All defects on the stove are to be repaired exclusively by the manufacturer.

If unauthorized personnel make any servicing or repairs or changes, owner of the

stove will lose the right to service guaranteed by the manufacturer.

Procurement of spare parts is to be done exclusively through manufacturer, based

on positions and figures or their names in this manual.

Manufacturer shall not bear any liability if purchaser does not observe instructions

and installation manual.

Problem Possible cause Remedy

Stove weakly heats

and cooks

•Irregular handling

•Bad chimney

•Carefully read and

observe manual

•In case if all conditions

from the manual are

fulfilled and problem still

persists, call service

Problems with firing

up

•closed air intake

regulator

•wet woods

•lack of oxygen

•open air intake regulator

and provide primary air intake

•use dry woods

•ventilate the room to

provide fresh air

Smoke is coming

below the plate

•closed air intake

regulator

•lack of air flow

•unclean ash from

the grid

•open air intake regulator

and provide primary air

intake

•carefully read manual and

apply tips for providing air

flow

•clean the grid

Firebox door glass

has tar after a short

period of operation

•wet woods

•too much fuel

•lack of draft

•closed secondary

air intake

•use dry woods

•see recommended

amount of fuel for

combustion given in the

manual

•check connection with the

chimney

•carefully read manual and

apply tips for providing

secondary air

ADVICES FOR ENVIRONMENTAL PROTECTION

Packaging

- Packaging material may be 100 % recycled.

- At disposing of the waste, observe local regulations.

- Packaging material (plastic bags, parts of polystyrene-styropor etc.) should be

kept out of reach of children, since it is potential source of danger.

- Pay attention to safety during removal and disposing of wooden battens since

they are nailed.

Product

- Device is made of materials which may be recycled. At the disposal of waste,

Observe local environmental laws.

- Use only recommended fuels.

- It is forbidden to burn inorganic and organic waste (plastic, cardboard,

textile, oiled wood etc.), since within combustion it discharges cancerous and

other harmful materials.

A.D. “Milan Blagojević” Smederevo

Đure Strugara 20

11300 Smederevo

tel: 026 633 600

026 633 601

fax: 026 226 926

e-mail: [email protected]

www.mbs.rs

Table of contents

Other MBS Stove manuals

Popular Stove manuals by other brands

Morso

Morso 8100 series instruction manual

St. Croix

St. Croix 45Lbs. Hopper Operation & maintenance manual

US Stove Company

US Stove Company 5501S owner's manual

Lofty

Lofty SJ15SFB owner's manual

Harrie Leenders

Harrie Leenders Cylon Instructions for installation, use and maintenance

AGA

AGA Ellesmere EC5W Installation and operating instructions