McConnel V3 Proportional User manual

V3 Proportional

Armrest Controls

USE THIS MANUAL IN CONJUNCTION WITH

MACHINE’S SPECIFIC OPERATOR MANUAL

OperatorManual

Publication 647

March 2010

Part No. 22674.47

For Safety and Performance …

ALWAYS READ THIS BOOK FIRST

McCONNELLIMITED

Temeside Works

Ludlow

Shropshire

England

Telephone: 01584 873131

www.mcconnel.com

SAFETY SECTION

This machine has the potential to be extremely dangerous - in the wrong hands it can kill

or maim; It is therefore imperative that both owner and operator of the machine reads and

understands the following section to ensure they are fully aware of the dangers that do, or

may exist, and their responsibilities surrounding the use and operation of the machine.

The operator of this machine is responsible not only for their own safety but equally for the

safety of others who may come into the close proximity of the machine, as the owner you

are responsible for both.

When the machine is not in use the cutting head should be lowered to rest on the ground.

In the event of any fault being detected with the machine’s operation it must be stopped

immediately and not used again until the fault has been corrected by a qualified technician.

POTENTIAL SIGNIFICANT DANGERS ASSOCIATED WITH THE USE OF THIS MACHINE:

▲Being hit by debris thrown by rotating components.

▲Being hit by machine parts ejected through damage during use.

▲Being caught on a rotating power take-off (PTO) shaft.

▲Being caught in other moving parts i.e.: belts, pulleys and cutting heads.

▲Electrocution from Overhead Power Lines (by contact with or ‘flashover’ from).

▲Being hit by cutting heads or machine arms as they move.

▲Becoming trapped between tractor and machine when hitching or unhitching.

▲Tractor overbalancing when machine arm is extended.

▲Injection of high-pressure oil from hydraulic hoses or couplings.

▲Machine overbalancing when freestanding (out of use).

▲Road traffic accidents due to collision or debris on the road.

BEFORE USING THIS MACHINE YOU MUST:

▲Ensure you read all sections of the operator handbook.

▲Ensure the operator is, or has been, properly trained to use the machine.

▲Ensure the operator has been issued with and reads the operator handbook.

▲Ensure the operator understands and follows the instructions in operator handbook.

▲Ensure the tractor front, rear and sides are fitted with metal mesh or polycarbonate

guards of suitable size and strength to protect the operator against thrown debris or

parts.

▲Ensure tractor guards are fitted correctly, are undamaged and kept properly

maintained.

▲Ensure that all machine guards are in position, are undamaged, and are kept

maintained in accordance with the manufacturer’s recommendations.

▲Ensure flails and their fixings are of a type recommended by the manufacturer, are

securely attached and that none are missing or damaged.

▲Ensure hydraulic pipes are carefully and correctly routed to avoid damage by chaffing,

stretching or pinching and that they are held in place with the correct fittings.

▲Always follow the manufacturer’s instructions for attachment and removal of the

machine from the tractor.

▲Check that the machine fittings and couplings are in good condition.

▲Ensure the tractor meets the minimum weight recommendations of the machine’s

manufacturer and that ballast is used as necessary.

▲Always inspect the work area thoroughly before starting to note obstacles and remove

wire, bottles, cans and other debris.

▲Use clear suitably sized warning signs to alert others to the nature of the machine

working within that area. Signs should be placed at both ends of the work site. (It is

recommended that signs used are of a size and type specified by the Department of

Transport and positioned in accordance with their, and the Local Highways Authority,

guidelines).

▲Ensure the operator is protected from noise. Ear defenders should be worn and tractor

cab doors and windows must be kept closed. Machine controls should be routed

through proprietary openings in the cab to enable all windows to be shut fully.

▲Always work at a safe speed taking account of the conditions i.e.: terrain, highway

proximity and obstacles around and above the machine. Extra special attention should

be applied to Overhead Power Lines. Some of our machines are capable of reach in

excess of 8 metres (26 feet) this means they have the potential to well exceed, by

possibly 3 metres (9’ 9”), the lowest legal minimum height of 5.2 metres from the

ground for 11,000 and 33,000 volt power lines. It cannot be stressed enough the

dangers that surround this capability, it is therefore vital that the operator is fully aware

of the maximum height and reach of the machine, and that they are fully conversant

with all aspects regarding the safe minimum distances that apply when working with

machines in close proximity to Power Lines. (Further information on this subject can be

obtained from the Health & Safety Executive or your Local Power Company).

▲Always disengage the machine, kill the tractor engine, remove and pocket the key

before dismounting for any reason.

▲Always clear up all debris left at the work area, it may cause hazard to others.

▲Always ensure when you remove your machine from the tractor that it is left in a safe

and stable position using the stands and props provided and secured if necessary.

WHEN NOT TO USE THIS MACHINE:

▲Never attempt to use this machine if you have not been trained to do so.

▲Never use a machine until you have read and understood the operator handbook, are

familiar with it, and practiced the controls.

▲Never use a machine that is poorly maintained.

▲Never use a machine if guards are missing or damaged.

▲Never use a machine on which the hydraulic system shows signs of wear or damage.

▲Never fit, or use, a machine on a tractor that does not meet the manufacturer’s

minimum specification level.

▲Never use a machine fitted to a tractor that does not have suitable front, rear and

side(s) cab guarding made of metal mesh or polycarbonate.

▲Never use the machine if the tractor cab guarding is damaged, deteriorating or badly

fitted.

▲Never turn a machine cutting head to an angle that causes debris to be ejected

towards the cab.

▲Never start or continue to work a machine if people are nearby or approaching - Stop

and wait until they are at a safe distance before continuing. WARNING: Some cutting

heads may continue to ‘freewheel’ for up to 40 seconds after being stopped.

▲Never attempt to use a machine on materials in excess of its capability.

▲Never use a machine to perform a task it has not been designed to do.

▲Never operate the tractor or machine controls from any position other than from the

driving seat, especially whilst hitching or unhitching the machine.

▲Never carry out maintenance of a machine or a tractor whilst the engine is running –

the engine should be switched off, the key removed and pocketed.

▲Never leave a machine unattended in a raised position – it should be lowered to the

ground in a safe position on a level firm site.

▲Never leave a tractor with the key in or the engine running.

▲Never carry out maintenance on any part or component of a machine that is raised

unless that part or component has been properly substantially braced or supported.

▲Never attempt to detect a hydraulic leak with your hand – use a piece of cardboard.

▲Never allow children near to, or play on, a tractor or machine under any circumstances.

ADDITIONAL SAFETY ADVICE

Training

Operators need to be competent and fully capable of operating this machine in a safe and

efficient way prior to attempting to use it in any public place. We advise therefore that the

prospective operator make use of relevant training courses available such as those run by

the Agricultural Training Board, Agricultural Colleges, Dealers and McConnel.

Working in Public Places

When working in public places such as roadsides, consideration should be paid to others

in the vicinity. Stop the machine immediately when pedestrians, cyclists and horse riders

etc. pass. Restart only when they are at a distance that causes no risk to their safety.

Warning Signs

It is advisable that any working area be covered by suitable warning signs and statutory in

public places. Signs should be highly visible and well placed in order to give clear

advanced warning of the hazard. Contact the Department of Transport or your Local

Highways Authority to obtain detailed information on this subject. The latter should be

contacted prior to working on the public highway advising them of the time and location of

the intended work asking what is required by way of signs and procedure. – ‘Non-

authorised placement of road signs may create offences under the Highways Act’.

Suggested Warning Signs Required

‘Road works ahead’ warning sign with a supplementary ‘Hedge cutting’ plate. ‘For 1

mile’ or appropriate shorter distance may be added to the plate.

‘Road narrows’ warning signs with supplementary ‘Single file traffic’ plate.

White on blue ‘Keep right’ (*) arrow sign on rear of machine.

* Note – this applies to UK Market machines where traffic passes to the right of a machine working in

the same direction as the traffic flow. The direction, use and colour of the arrow sign will depend on

the country of use and the Local Highway Authorities regulations in the locality.

Use of Warning Signs

▲On two-way roads one set of signs is needed facing traffic in each direction.

▲Work should be within 1 mile of the signs.

▲Work only when visibility is good and at times of low risk e.g.: NOT during ‘rush-hour’.

▲Vehicles should have an amber-flashing beacon.

▲Ideally, vehicles should be conspicuously coloured.

▲Debris should be removed from the road and path as soon as practicable, and at

regular intervals, wearing high visibility clothing and before removing the hazard

warning signs.

▲Collect all road signs promptly when the job is completed.

Although the information stated here covers a wide range of safety subjects it is impossible to

predict every eventuality that can occur under differing circumstances whilst operating this

machine. No advice given here can replace ‘good common sense’ and ‘total awareness’ at all times,

but will go a long way towards the safe use of your McConnel machine.

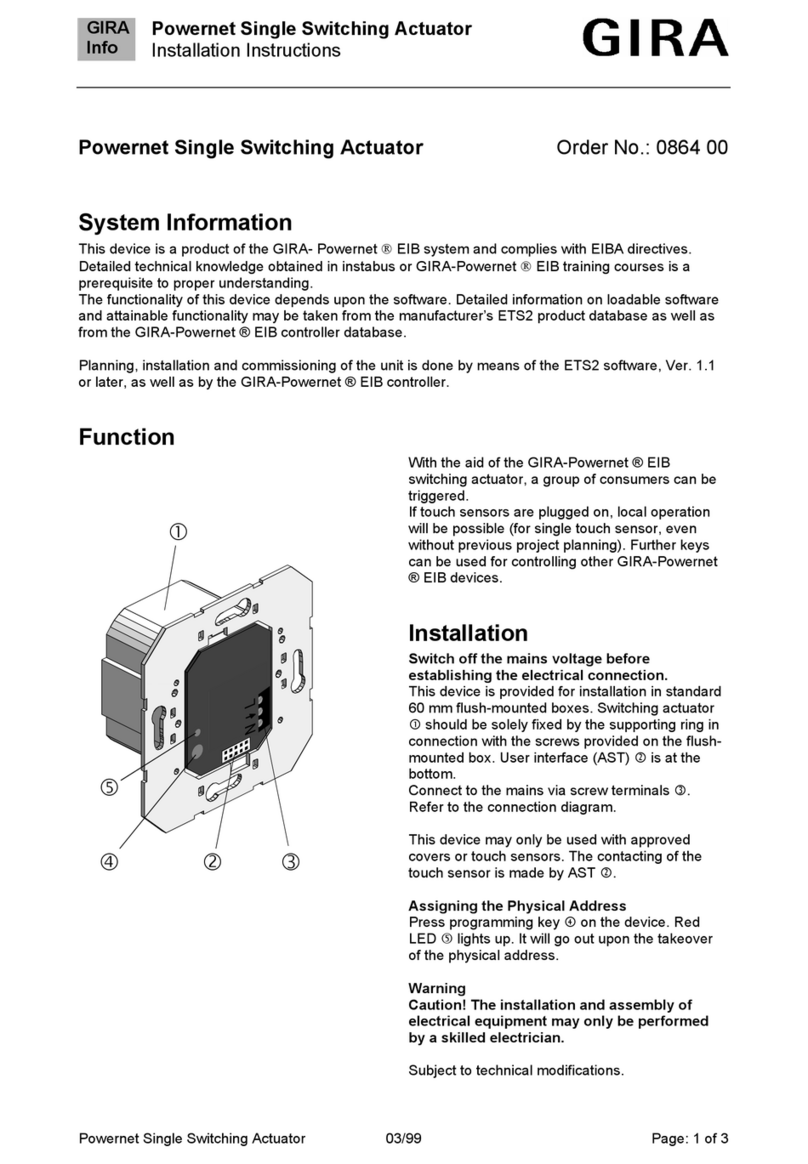

PROPORTIONAL ARMREST CONTROLS - v.3

Left Hand

Right Hand

Left Hand

Right Hand

2

1

4 or 6

3

6or 4 5

ARMHEAD FUNCTIONS – Electric Proportional Control Machines

D

d

C

c

B

b

H

h

D

d

C

c

F

f

G

gA

E

I

J

SWITCH LOCATIONS - v.3 Proportional Armrest Controls

SWITCH FUNCTION L.E.D.

A Power ON/OFF - Turn clockwise for ON, Push for OFF -

B Auto Reset b

C Lift Float c

D Head Angle Float d

E Rotor Off e

F Rotor On - Upward Cutting f

G Rotor On - Downward Cutting g

H Tele/Slew Swap - determines operating mode of: I & J h

I Slew Operation - H deactivated

J Tele Operation - H deactivated h OFF

I Tele Operation - H activated

J Slew Operation - H activated h ON

Note: The mode selection of H is retained in the circuit memory when powering off

and on, it does not deselect when the unit is switched off.

SWITCH FUNCTION/OPERATION

SWITCH ‘A’ POWER ON/OFF

Turn clockwise for ‘ON

’

and push down for ‘OFF

’

SWITCH ‘B’ AUTO RESET

(L.E.D. light ‘b’) Press down to select ‘auto reset

’

(i.e. normal working).

Pressing either 'Slew' buttons will de-select 'Auto Reset'

and allow 'Slew' operation. 'Auto Reset' will have to be

reselected if required.

SWITCHES ‘C’ LIFT FLOAT

(L.E.D. light ‘c’) Press either switch to select or deselect the 'lift float'

function.

When ‘ lift float ‘ is selected operating the lift service will

override the float operation. On completion of the arm

adjustment ‘lift float’ will automatically be reinstated.

SWITCHES 'D' HEAD ANGLE FLOAT

(L.E.D. light 'd') Press either switch to select or deselect the 'head

angle float' function.

When 'angle float' is selected operating the angle

service will override the float operation. On completion

of the head adjustment 'angle float' will be automatically

reinstated.

SWITCHES 'E', 'F' & 'G' OPERATIONAL ON MACHINES WITH ELECTRIC

ROTOR ON/OFF CONTROL ONLY

SWITCH 'E' ROTOR OFF

SWITCH 'F' ROTOR ON - UPWARD CUTTING

(L.E.D. light 'f') Press to select

SWITCH 'G' ROTOR ON - DOWNWARD CUTTING

(L.E.D. light 'g') Press to select

REVERSING ROTATION: TURN ROTOR OFF

WAIT until Rotor has STOPPED

Select opposite rotation

SWITCH 'H' Press switch 'H

'

to swap the operation controls of the

(L.E.D. light 'h') Slew' and 'Tele' (red light appears). The Control box

will remember this mode when the controls are turned off

and will remain in the same mode when next switched on.

SWITCHES 'I' & 'J' SLEW & TELE or TELE & SLEW

dependent on mode of Switch 'H'

SWITCH FUNCTIONS - v.3 Proportional Armrest Controls

All auxiliary switch controls are accompanied by an L.E.D. light, these indicate to the

operator that a function is selected and working correctly.

SCREEN DISPLAY AND FUNCTIONS

Twist E/stop on armrest controls to power on and the screen will light up. Note: 12Volts at

the battery are required for correct function.

1. The screen will initially display the McConnel

logo, software version and the PTO maximum

speed.

2. Pressing scroll forward once will display the

running screen. The TOT displays the total time

the rotor has been switched on. The JOB also

displays the rotor on time but may be reset to

zero by pressing the Xbutton for 3 seconds.

3. Pressing either of the Rotor ON buttons will

activate the ‘egg timer’ and rotor image.

4. Pressing the EDS Lift float button will turn on the

EDS (EDS Lift Float machines only). Then

SOFT, MED or HARD will be added to the

running screen.

5. Pressing 9while the EDS is turned on will scroll

through the SOFT, MED and HARD working

settings.

6. Pressing scroll forward displays the actual

Tractor PTO running speed

7. Scrolling forward again displays the Power

Monitor screen.

Scrolling backwards will display the screens in the opposite order.

McConnel Limited, Temeside Works, Ludlow, Shropshire SY8 1JL. England.

Telephone: 01584 873131. Facsimile: 01584 876463. www.mcconnel.com

Table of contents

Other McConnel Controllers manuals

Popular Controllers manuals by other brands

AMALGAMATED INSTRUMENT

AMALGAMATED INSTRUMENT PM4-RT8 Operation and instruction manual

Elko

Elko iNels BPS3-01M quick start guide

Siemens

Siemens SIMOTION C operating instructions

SCORPION

SCORPION Commander 26V SBEC series user guide

Pentair

Pentair SPEEDEO CONNECT Installation and user manual

Toshiba

Toshiba JK-UC1 Installation and operation manual