5

85372

The operator must be aware of the conditions around

the machine. Be careful to observe other people and

machines in the area.

Beware of slippery conditions. Wet turf can be

encountered on slopes, when turning or stopping, or

at higher speeds.

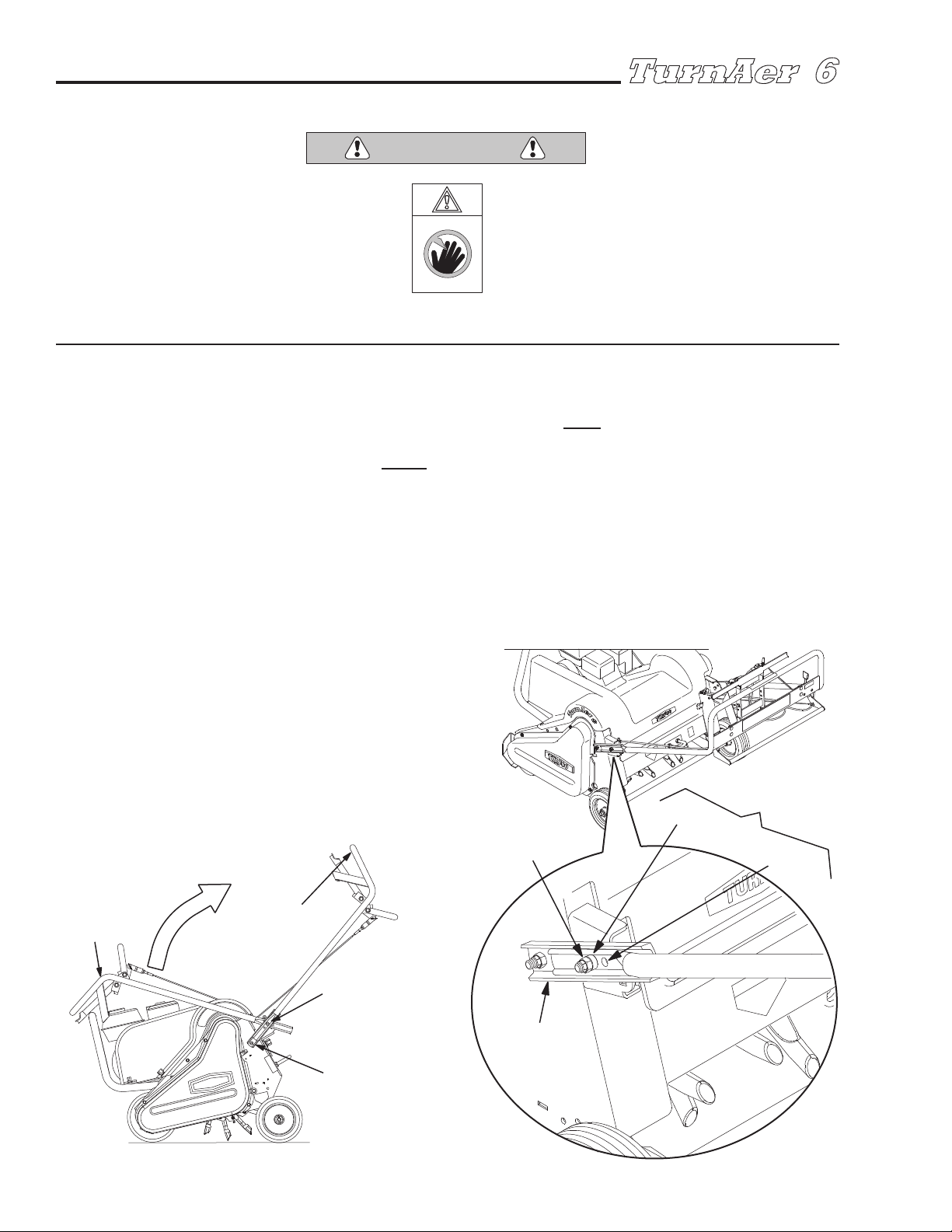

Keep hands and feet away from cutting devices and

drive components. Shut off the engine and remove the

key or spark plug wire when servicing cutting devices

or drive components.

Care should always be taken when mounting and

dismounting a riding machine. Prevent injuries and

falls by making sure the operator does not slip. Unless

it is an emergency, do not jump off a machine. Injury

may result when an operator’s foot slips trying to jump

from a machine.

If required to lift, an operator should ask for help if the

object is too heavy. The operator should lift with the

legs instead of the back. Care should be taken to avoid

twisting the back while lifting a heavy load.

Never allow children to operate the machine.

THE MACHINE:

Do not modify the machine in any manner. Always

check the machine to make sure it is in good working

order.

Do not place hands or feet near moving or rotating

parts. Check that all guards are functional and properly

installed. Do not operate a machine without all guards

installed.

Do not use your fingers or hands to check for leaks.

High pressure leaks can puncture the skin and force oil

into the body. This can cause severe injury or death.

Check to assure that all controls are in good operating

condition.

Do not overload machinery. The components

are designed for certain weights and capacities.

Overloading machine will cause unsafe conditions

Shut off the engine before servicing the machine.

Check machines on a level area. Machines on a slope

may roll when the engine is off.

Refer unfamiliar repairs and adjustments to mechanics

that have been trained to do them properly.

Replace decals that are damaged or illegible.

THE ENGINE:

Do not run the engine in an enclosed area. The

exhaust gases contain carbon monoxide, an odorless

and deadly poison. The engine exhaust from this

product contains chemicals known to the State of

California to cause cancer, birth defects or other

reproductive harm.

Do not refuel machines indoors or in an unventilated

area. Do not over fill. Do not add fuel while the machine

is hot because spilled fuel may cause a fire. Use

fresh gasoline. Stale fuel can gum the carburetor and

can cause leakage. Check the fuel lines and fittings

frequently for cracks and leaks.

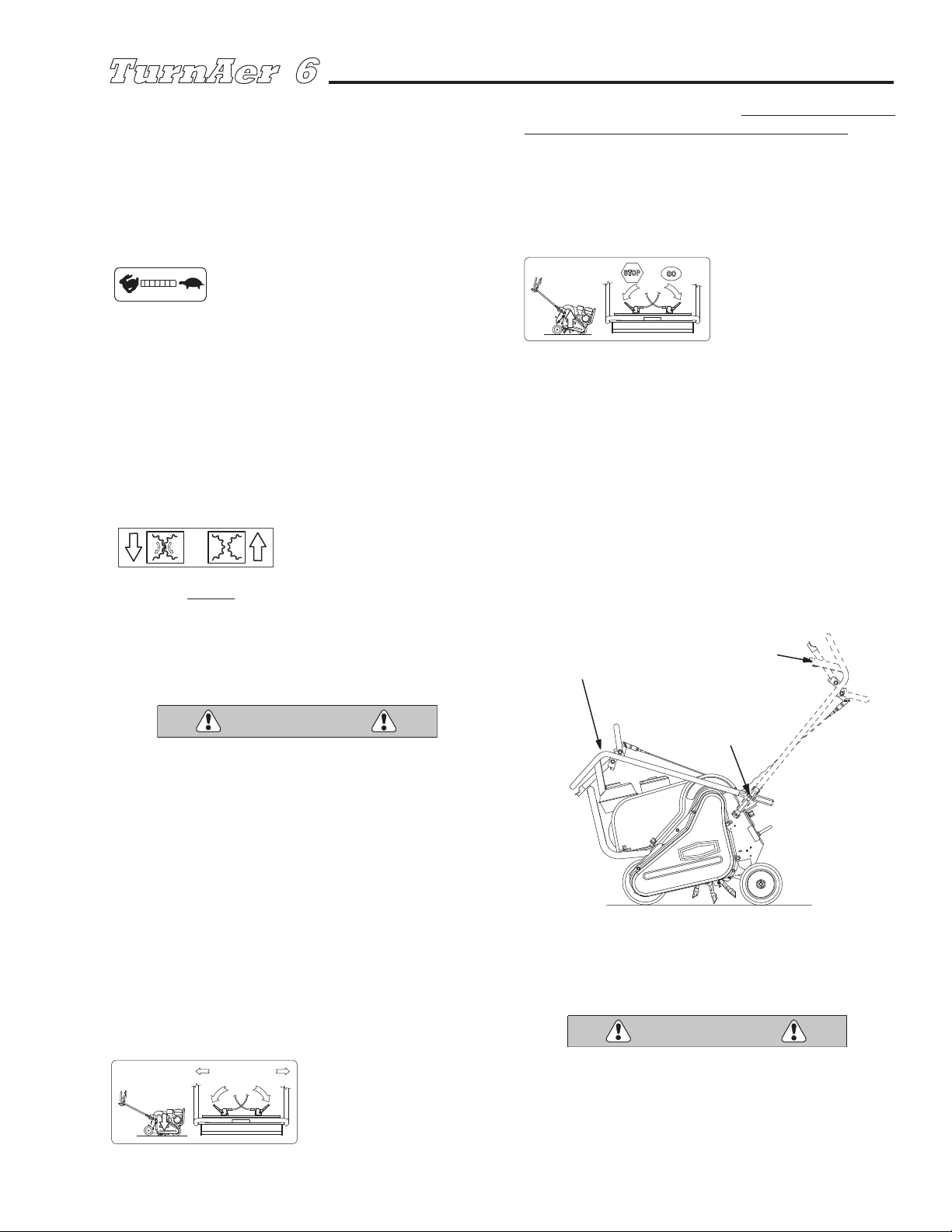

Pull the starter cord slowly until resistance is felt. Then

pull the cord rapidly to avoid kickback and to prevent

hand or arm injury.

Do not remove the fuel tank cap or fill fuel tank while

the engine is hot or running. Allow the engine to cool

before refueling.

Do not operate the engine if gasoline is spilled. Do

not operate the engine when the smell of gasoline

is present or if any other explosive conditions exist.

Move the equipment away from the spill and avoid any

ignition until the gasoline has evaporated.

Do not store, spill, or use gasoline near an open

flame. Do not store, spill, or use gasoline near a stove,

furnace, water heater, or appliance that uses a pilot

light or can create sparks.

Do not choke the carburetor to stop the engine.

Whenever possible, gradually reduce the engine

speed before stopping.

Do not tamper with the governor springs, links or other

parts to increase the engine speed. Run the engine at

the speed set by the equipment manufacturer.

Keep the cylinder fins and the governor parts free of

dirt, grass, and debris which can affect engine speed.

Do not transport the engine with fuel in the tank.

Prevent accidental starting by removing the spark plug

wire(s) when servicing the engine or the equipment.

Disconnect the negative wire from the battery terminal

if the engine is equipped with an electric starting

system.

Do not strike the flywheel with a hammer or any

hard object. This may cause the flywheel to shatter

during operation. Use the correct tools to service the

machine.

Do not check for a ignition spark with the spark plug

removed. Use an approved tester.

Do not crank the engine with the spark plug removed.

If the engine is flooded, place the throttle in fast and

crank until the engine starts.

Do not start the engine with the air cleaner and/or the

air cleaner cover removed. Do not operate the engine

without a muffler. Replace the muffler if it is leaking or

worn. Replace only with correct muffler. Do not touch a

hot muffler, cylinder, or fin. It will cause burns.

Do not operate the engine with an accumulation of

grass, leaves, or other combustible material in the

muffler area.

Do not use the engine on any forest covered, brush

covered, or grass covered unimproved land unless

a spark arrester is installed in the muffler. The spark

arrester must be maintained in good working order.

In the State of California, the above is required by

law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal

laws apply on federal lands.

SAFETY