McConnel Twose Series User manual

Twose Series

FR3 & BR3 SERIES ROLLERS

Models: FR3-64 / FR3-73 / FR3-82

BR3-64 / BR3-73 / BR3-82

OPERATOR MANUAL

Publication 770 / Part No. 22675.70 May 2016

IMPORTANT

VERIFICATION OF WARRANTY REGISTRATION

DEALER WARRANTY INFORMATION & REGISTRATION VERIFICATION

It is imperative that the selling dealer registers this machine with McConnel Limited before

delivery to the end user – failure to do so may affect the validity of the machine warranty.

To register machines go to the McConnel Limited web site at www.mcconnel.com, log

onto ‘Dealer Inside’ and select the ‘Machine Registration button’which can be found in

the Service Section of the site. Confirm to the customer that the machine has been

registered in the section below.

Should you experience any problems registering a machine in this manner please contact

the McConnel Service Department on 01584 875848.

Registration Verification

Dealer Name:

……………………..…………………………………………………………….

Dealer Address:

…….………………………………………………………………………….

Customer Name:

……………………..…………………………………………………………

Date of Warranty Registration:

……/……/...…… Dealer Signature: ………………..……

NOTE TO CUSTOMER / OWNER

Please ensure that the above section above has been completed and signed by the selling

dealer to verify that your machine has been registered with McConnel Limited.

IMPORTANT: During the initial ‘bedding in’ period of a new machine it is the customer’s responsibility

to regularly inspect all nuts, bolts and hose connections for tightness and re-tighten if required. New

hydraulic connections occasionally weep small amounts of oil as the seals and joints settle in – where

this occurs it can be cured by re-tightening the connection – refer to torque settings chart below.The

tasks stated above should be performed on an hourly basis during the first day of work and at least

daily thereafter as part of the machines generalmaintenance procedure.

CAUTION: DO NOT OVER TORQUE HYDRAULIC FITTINGS AND HOSES

TORQUE SETTINGS FOR HYDRAULIC FITTINGS

HYDRAULIC HOSE ENDS PORT ADAPTORS WITH BONDED SEALS

BSP

Setting

Metric

BSP

Setting

Metric

1/4” 18 Nm 19 mm 1/4” 34 Nm

19 mm

3/8” 31 Nm 22 mm 3/8” 47 Nm

22 mm

1/2” 49 Nm 27 mm 1/2” 102 Nm

27 mm

5/8” 60 Nm 30 mm 5/8” 122 Nm

30 mm

3/4” 80 Nm 32 mm 3/4” 149 Nm

32 mm

1” 125 Nm 41 mm 1” 203 Nm

41 mm

1.1/4”

190 Nm

50 mm

1.1/4”

305 Nm

50 mm

1.1/2” 250 Nm 55 mm 1.1/2” 305 Nm

55 mm

2” 420 Nm 70 mm 2” 400 Nm

70 mm

WARRANTY POLICY

WARRANTY REGISTRATION

All machines must be registered, by the selling dealer with McConnel Ltd, before delivery to the

end user. On receipt of the goods it is the buyer’s responsibility to check that the Verification of

Warranty Registration in the Operator’s Manual has been completed by the selling dealer.

1. LIMITED WARRANTIES

1.01. All machines supplied by McConnel Ltd are warranted to be free from defects in material and

workmanship from the date of sale to the original purchaser for a period of 12 months, unless

a different period is specified.

1.02. All spare parts supplied by McConnel Ltd and purchased by the end user are warranted to be

free from defects in material and workmanship from the date of sale to the original purchaser

for a period of 6 months. All parts warranty claims must be supported by a copy of the failed

part invoice to the end user. We cannot consider claims for which sales invoices are not

available.

1.03. The warranty offered by McConnel Ltd is limited to the making good by repair or replacement

for the purchaser any part or parts found, upon examination at its factory, to be defective

under normal use and service due to defects in material or workmanship. Returned parts

must be complete and unexamined. Pack the component(s) carefully so that any transit

damage is avoided. All ports on hydraulic items should be drained of oil and securely plugged

to prevent seepage and foreign body ingress. Certain other components, electrical items for

example, may require particular care when packing to avoid damage in transit.

1.04. This warranty does not extend to any product from which McConnel Ltd’s serial number plate

has been removed or altered.

1.05. This warranty does not apply to any part of the goods, which has been subjected to improper

or abnormal use, negligence, alteration, modification, fitment of non-genuine parts, accident

damage, or damage resulting from contact with overhead power lines, damage caused by

foreign objects (e.g. stones, iron, material other than vegetation), failure due to lack of

maintenance, use of incorrect oil or lubricants, contamination of the oil, or which has served

its normal life. This warranty does not apply to any expendable items such as blades, belts,

clutch linings, filter elements, flails, flap kits, skids, soil engaging parts, shields, guards, wear

pads, pneumatic tyres or tracks.

1.06. Temporary repairs and consequential loss - i.e. oil, downtime and associated parts are

specifically excluded from the warranty.

1.07. Warranty on hoses is limited to 12 months and does not include hoses which have suffered

external damage. Only complete hoses may be returned under warranty, any which have

been cut or repaired will be rejected.

1.08. Machines must be repaired immediately a problem arises. Continued use of the machine

after a problem has occurred can result in further component failures, for which McConnel Ltd

cannot be held liable, and may have safety implications.

1.09. If in exceptional circumstances a non McConnel Ltd part is used to effect a repair, warranty

reimbursement will be at no more than McConnel Ltd’s standard dealer cost for the genuine

part.

1.10. Except as provided herein, no employee, agent, dealer or other person is authorised to give

any warranties of any nature on behalf of McConnel Ltd.

1.11. For machine warranty periods in excess of 12 months the following additional exclusions

shall apply:

1.11.1.Hoses, exposed pipes and hydraulic tank breathers.

1.11.2. Filters.

1.11.3. Rubber mountings.

1.11.4. External electric wiring.

1.11.5. Bearings and seals.

1.12. All service work, particularly filter changes, must be carried out in accordance with the

manufacturer’s service schedule. Failure to comply will invalidate the warranty. In the event of

a claim, proof of the service work being carried out may be required.

1.13. Repeat or additional repairs resulting from incorrect diagnosis or poor quality previous repair

work are excluded from warranty.

NB Warranty cover will be invalid if any non-genuine parts have been fitted or used. Use of non-

genuine parts may seriously affect the machine’s performance and safety. McConnel Ltd cannot be

held responsible for any failures or safety implications that arise due to the use of non-genuine parts.

2. REMEDIES AND PROCEDURES

2.01. The warranty is not effective unless the Selling Dealer registers the machine, via the

McConnel Ltd web site and confirms the registration to the purchaser by completing the

confirmation form in the operator’s manual.

2.02. Any fault must be reported to an authorised McConnel Ltd dealer as soon as it occurs.

Continued use of a machine, after a fault has occurred, can result in further component

failure for which McConnel Ltd cannot be held liable.

2.03. Repairs should be undertaken within two days of the failure. Claims submitted for repairs

undertaken more than 2 weeks after a failure has occurred, or 2 days after the parts were

supplied will be rejected, unless the delay has been authorised by McConnel Ltd. Please

note that failure by the customer to release the machine for repair will not be accepted as a

reason for delay in repair or submitting warranty claims.

2.04. All claims must be submitted, by an authorised McConnel Ltd Service Dealer, within 30 days

of the date of repair.

2.05. Following examination of the claim and parts, McConnel Ltd will pay, at their discretion, for

any valid claim the invoiced cost of any parts supplied by McConnel Ltd and appropriate

labour and mileage allowances if applicable.

2.06. The submission of a claim is not a guarantee of payment.

2.07. Any decision reached by McConnel Ltd is final.

3. LIMITATION OF LIABILITY

3.01. McConnel Ltd disclaims any express (except as set forth herein) and implied warranties with

respect to the goods including, but not limited to, merchantability and fitness for a particular

purpose.

3.02. McConnel Ltd makes no warranty as to the design, capability, capacity or suitability for use of

the goods.

3.03. Except as provided herein, McConnel Ltd shall have no liability or responsibility to the

purchaser or any other person or entity with respect to any liability, loss, or damage caused

or alleged to be caused directly or indirectly by the goods including, but not limited to, any

indirect, special, consequential, or incidental damages resulting from the use or operation of

the goods or any breach of this warranty. Notwithstanding the above limitations and

warranties, the manufacturer’s liability hereunder for damages incurred by the purchaser or

others shall not exceed the price of the goods.

3.04. No action arising out of any claimed breach of this warranty or transactions under this

warranty may be brought more than one (1) year after the cause of the action has occurred.

4. MISCELLANEOUS

4.01. McConnel Ltd may waive compliance with any of the terms of this limited warranty, but no

waiver of any terms shall be deemed to be a waiver of any other term.

4.02. If any provision of this limited warranty shall violate any applicable law and is held to be

unenforceable, then the invalidity of such provision shall not invalidate any other provisions

herein.

4.03. Applicable law may provide rights and benefits to the purchaser in addition to those provided

herein.

DECLARATION OF CONFORMITY

Conforming to EU Machinery Directive 2006/42/EC

We,

McCONNEL LIMITED, Temeside Works, Ludlow, Shropshire SY8 1JL, UK

Hereby declare that:

The Product; Tractor Trailed Horizontal Folding Rollers

Product Code; TWBR, TWFR , THFR

Serial No. & Date ………………………………… Type …………………………

Manufactured in; United Kingdom

Complies with the required provisions of the Machinery Directive 2006/42/EC

The machinery directive is supported by the following harmonized standards;

■BS EN ISO 12100 (2010) Safety of machinery –General principles for design –Risk

assessment and risk reduction.

■BS EN 349 (1993) + A1 (2008) Safety of machinery - Minimum distances to avoid the

entrapment with human body parts.

■BS EN ISO 14120 (2015) Safety of machinery - Guards general requirements for the

design and construction of fixed and movable guards.

■BS EN 4413 (2010) Hydraulic fluid power. Safety requirements for systems and their

components.

McCONNEL LIMITED operates an ISO 9001:2008 quality management system,

certificate number: FM25970.

This system is continually assessed by the;

British Standards Institution (BSI), Beech House, Milton Keynes, MK14 6ES, UK

BSI is accredited by UK Accreditation Service, accreditation number: UKAS 003.

The EC declaration only applies if the machine stated above is used in

accordance with the operating instructions.

Signed …………………................ Responsible Person

CHRISTIAN DAVIES on behalf of McCONNEL LIMITED

Status: General Manager Date: January 2018

THIS MANUAL IS TO BE HANDED TO THE CUSTOMER BEFORE THE

MACHINE IS TO BE USED FOR THE FIRST TIME

McCONNEL LIMITED

TEMESIDE WORKS

LUDLOW

SHROPSHIRE

SY8 1JL

TEL: (01584) 873131

Email: sales@mcconnel.com

All dimensions and capacities mentioned in this book are approximate. In pursuance of the

Companies policy of constant development, the right is reserved to depart, without notice,

from any detail illustrated or specified in this book, without incurring the obligation to

provide such modifications on machines previously delivered.

No responsibility will be accepted by McConnel Limited for any injury, damage or loss

arising from the improper use or lack of maintenance of any machinery supplied by them

or from any failure of the user to comply with all instructions published by Tractor or

Loader manufacturers, particularly with regard to maximum load capacities, tyre pressures

and stability, or with instructions and regulations pertaining to Tractor Cabs.

INDEX

General Information

1

Introduction

2

Health And Safety

4

General Instructions

7

Operating Instructions

8

Safety When Rolling

10

Routine Maintenance And Laying-Up

11

1

GENERAL INFORMATION

NOTE: This handbook has been designed to help the operator and service/mechanic

to use and understand the machine fully, safely and efficiently.

NOTE: It is vital that the manual has been read thoroughly and is fully understood

before attempting to attach or use the machine in any way.

The operator should also read and fully understand the manuals supplied by

the tractor manufacturer and also any relevant information available from the

Health and Safety Executive.

CAUTION: When ordering spares, please state clearly:

(a) Machine type and model number.

(b) Part No. of component.

(c) Description of component.

(d) Quantity required.

(e) Full address to which spares are to be sent.

(f) Method of delivery required.

CAUTION: Always insist on genuine and correct spare parts.

NOTE: Further copies of this handbook/manual can be obtained from:

McCONNEL LIMITED

TEMESIDE WORKS

LUDLOW

SHROPSHIRE

SY8 1ND

TELEPHONE:

01584 873131

4

2

INTRODUCTION

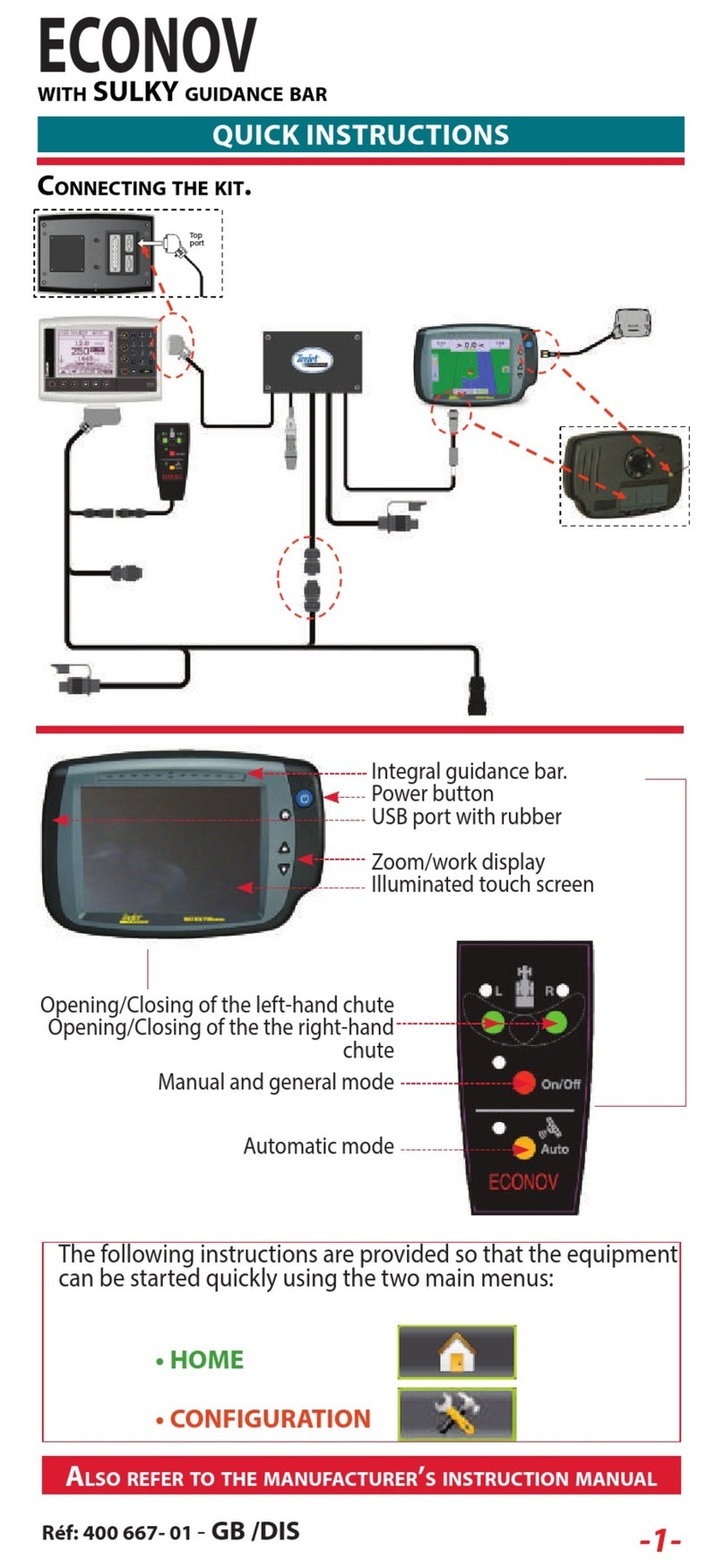

This manual describes a range of 3 gang folding rollers available in 6.4m, 7.3m or 8.2m

working widths. Roller options offer a choice of either Cambridge or Cambridge/Breaker

Rings of 55cm (22”) diameter or Ballast Drums of 76cm (30”) diameter.

A set of wheels with pneumatic tyres permits transportation of the machine.

The machines have fabricated steel frames and the roller shafts rotate in sealed roller

bearings

The wings are folded and the axle and wheels are raised and lowered from the transport to

work positions hydraulically by double acting rams. Hydraulic power is provided from the

tractors double acting spool valve. The hydraulic hoses are provided with quick release

couplings complete with dust covers.

Optional levelling board kits are available which feature a hydraulic control for placing

them in either the work position or the ‘out of work’ position.

A lighting kit is also available for use when transporting the machine on the public

highway.

It is designed for attachment to an agricultural vehicle by means of the ‘Draw-bar-hitch’

couple-up system.

The purpose for its production and its sole intention is to roll cultivated land. Never attempt

to use this machine for anything other than the task for which it was designed.

IMPORTANT

To permit even rolling and allow the roller sections to follow ground contours, the services

controlling the rams should be placed in the float mode. This allows hydraulic oil to enter

and exit the hydraulic system on the roller and the tractor un-pressurised.

Levelling boards (when fitted) should be fully lowered into the work position or folded up

when not required. The tine angle cannot be adjusted using the hydraulic rams.

3

FR3 Series –Cambridge Roller

BR3 Series –Ballast Roller

4

HEALTH AND SAFETY

Throughout the handbook the following sub headings are used to draw attention to various

points of importance.

This is to draw attention to very important instructions that MUST be followed precisely to

avoid injury or death.

CAUTION This is used to draw attention to instructions that MUST be followed to avoid

damage to operator, machine, process or the environment.

NOTE This is used to highlight points used for supplementary information.

5

HEALTH AND SAFETY

Never attempt to assemble, couple up, or

operate machinery until you understand fully

the functions, controls and safety precautions

required, as shown in the operator’s manual.

Always follow tractor safety operations and

instructions VERY carefully.

NEVER TAKE RISKS

CAUTION

Be aware of warning and instruction decals on machine as care must be taken and

instructions obeyed.

Transport the machinery only at safe speeds.

Never drive machinery at speeds that could

cause danger to other persons or properties,

or in a manner that may cause accidents.

Never attempt to Service/adjust or work on any

machinery in an unsupported state.

Always ensure that machinery is safely

supported and propped in position to prevent

sudden or inadvertent falling that could cause

serious injury or even death.

Ensure helpers and bystanders are well clear

of the machine when unfolding or folding the

rolls. There is a danger of crushing, trapping,

impact or other serious injury

CAUTION

Always ‘SWITCH OFF’ the tractor’s engine before attempting to carry out inspection,

adjustments or service repairs on the machine.

6

HEALTH AND SAFETY

Always be aware of your surroundings - and

operate machinery accordingly. Beware of

confined or tight areas, low height restrictions,

buildings and overhangs etc. Also drive and

operate bearing in mind weather conditions

such as sun, rain, ice, snow, wind etc. Make

allowances in all situations.

CAUTION

Never carry passengers on the machinery or on the tractor. Falling off can result in serious

injury or even death. Ensure bystanders/onlookers are kept well away from the operational

area of apparatus.

CAUTION

When machine is being removed from tractor’s linkage and being 'parked up' it is essential

that a good firm base and level site is used. Always chock and prop machine to prevent

moving.

CAUTION

Never allow children to play on, or around, parked machinery.

CAUTION

Never wear loose fitting or ragged clothing that could get caught in machinery or controls.

CAUTION

Always dispose of discarded or worn out parts thoughtfully - by disposing of them in an

approved and specified legal scrap site, bin or skip.

Do not mount or exit the Tractor while the

tractor is moving. Mount or leave the Tractor

only when the Tractor and all moving parts have

completely stopped.

Do not operate this Equipment with hydraulic oil

leaking. The presence could present a hazard.

Do not check for leaks with your hand! Use a

piece of heavy paper or cardboard. High-

pressure oil streams from breaks in the line

could penetrate the skin and cause tissue

damage including gangrene. If oil does

penetrate the skin get medical attention

immediately.

7

GENERAL INSTRUCTIONS

1. Before attaching any machine to a tractor make sure that implement is still standing

firmly on a good solid level site - as it will be, providing unit was previously parked

correctly. Check that any wheels are 'chocked' correctly, and where applicable

supports/props are in position where necessary to prevent booms etc. dropping.

2. Before and during the manoeuvring of the tractor or vehicle in order to attach

machinery/implements, - make sure that No other persons are in the vicinity. Keep

other persons well clear and make known your intentions, all the while keeping a sharp

lookout whilst reversing and aligning machines for coupling up.

3. Always secure tractor into selected position by ensuring that brakes are applied

correctly in order to prevent vehicle moving off on its own to cause injury and damage.

4. Check that the hitch on the tractor is in good condition and that the hitch pin used is of

the correct size and type to suit the draw bar of the roller, and is properly secured when

fitted.

5. Never attempt to work on, adjust or service repair machinery of any kind whilst it is still

running or working. Always stop the machine and STOP THE TRACTOR ENGINE

before any service/repairs begin.

SWITCH OFF THE TRACTOR ENGINE BEFORE LEAVING THE TRACTOR SEAT

6. In transit always use transport stays or locking devices where provided. If, as in the

case of some longer machines, the unit is transported lengthways - make sure that the

front of the tractor is suitably ballasted to maintain stability. A method of achieving this

would be to add suitable weights to a correctly specified and fitted front weight frame.

7. Always use machines in a sensible and reasonable manner and do not attempt to use

them in work for which they are not intended. Avoid overloading and abusing them as

this can cause damage to machine and tractor and can be very dangerous.

8. When detaching a machine from a tractor ensure that any stands or legs are securely

positioned and that the machine is parked where it will not be a safety hazard or cause

annoyance to others. Make sure that chosen 'parking site' is firm and level.

9. Carry out regular periodic maintenance. - Always with safety in mind.

10.For transportation on the public highway ensure that a legally approved lighting board

is fitted and connected.

8

OPERATING INSTRUCTIONS

Machine must only be folded out or in whilst it is securely attached to a suitably

sized tractor and located on a firm level site.

WARNING! Never attempt to fold or unfold the machine on sloping ground.

Attaching Roller to the Tractor

1. Position tractor and align tractors pick up hitch with draw bar of roller.

2. Attach roller draw bar to the hitch, fit draw bar pin and lock in position.

3. Couple the hydraulic ‘quick release’ fittings to the tractor.

Note: One single acting service with float function is required for the main lift/draw

bar ram. One double acting spool with float is required for the wing rams.

If levelling boards are fitted a third double acting spool valve is required; this

does not require the float function.

CAUTION: To fold or unfold the roller a flat and even site must be selected.

To Change the Roller from Transport to In Work Position

1. Extend the main ram to the fully open position.

2. Retract the wing ram so that the wing sections pivot open fully.

3. Retract the main ram so that the transport wheels lift clear of the ground and the

machine is supported on the centre roller. Leave the spool valve in the float

position.

Note: Depending on surface conditions it may be necessary to move the tractor

forward very slowly to assist this operation.

4. Extend the wing ram to lower the wing sections to the ground. Place the spool valve

in the float position.

If levelling boards are fitted they can be set in the fully raised or lowered position. The

rams must not be allowed to float and the tine angle cannot be adjusted hydraulically.

To Change the Roller from In Work to Transport Position

1. Place all spool valves in the neutral position and out of float.

Note: If levelling boards are fitted they should be fully folded ‘out of work’.

2. Operate the wing ram to fully charge the cylinders.

3. Operate the main ram and fully extend it; this will lift the centre roller off the ground

and the machine will rest on its transport wheels.

4. Extend the wing ram and slowly fold in the wings.

5. Operate the main ram to lower the wing sections into their carriers.

6. Place all spool valves in the NEUTRAL position.

9

Parking the Machine

1. Find a good firm level site preferably under cover for long term storage

2. Park roller in the desired position and apply tractor handbrake.

3. Chock the roller wheels to prevent movement.

4. Ensure hoses are not pressurised and remove hydraulic connections from tractor –

fit dust caps to tractor and hoses, and disconnect road lighting plug (if fitted).

5. Stow hoses neatly.

6. Lower tractors hitch and. remove towing pin from draw bar

7. Carefully drive tractor forward.

Note: Rollers can be stored in either the work position or the transport position.

Levelling Boards (Option)

◄Levelling Board Tine Wear

As the tine feet wear it will be necessary to adjust the position

between the body and foot; there are two positions available.

Ballast Rollers

The outer ends of the ballast rollers are equipped with access

plugs to allow the drums to be filled with the chosen liquid ballast.

If water is used for ballast it must be either drained for winter

periods or antifreeze added to protect it from risk of freezing.

Whatever the ballast used when draining the drums the

procedure must be performed with care and the ballast liquid

disposed of in an environmentally safe manner.

Scraper Adjustment (Ballast Rollers)

Adjustment of the scrapers is performed by loosening the

attachment fixings which will then allow the scraper bar to

be slid to the desired distance from the roller, re-tighten the

fixings to secure the position.

10

SAFETY WHEN ROLLING

Before starting work with any roller ensure

that the bearings are properly greased and

that all bolts and nuts are tight.

Remember that a heavy roller will add to

your momentum and will require a longer

distance for stopping. Particular care will

be needed on hilly or sidling ground.

Avoid turning so acutely that the tractor’s

rear wheels foul the rollers draw bar.

Do not attempt to use rollers when the

ground conditions are unsuitable i.e.

When ground is excessively wet or greasy.

When ground is frozen or thawing after a

frost.

Do not attempt to use the rollers on very

steep sloping ground.

11

ROUTINE MAINTENANCE AND LAYING-UP

Daily

Grease shaft bearings thoroughly.

Check nuts and bolts for tightness.

Check wheel nuts for tightness; 185lbs.ft.(250 Nm).

Weekly

Grease pivot points thoroughly.

Check all bolts and nuts for tightness.

Check all hoses for splits or damage.

Check all rams for leaks or damage.

Check tyres for any signs of damage and ensure they are inflated to the correct

pressure; 70 psi (5.2 bar).

Annually & Laying Up

Periodically (once a year should suffice) check the bearings, wheel bearings, pivot

pins, bushes, spacers and axles for wear; dismantling if necessary. Replace any parts

that are appreciably worn.

Apply grease to all exposed ram rods and plated parts.

Lubricate and use anti-corrosion measures when storing the roller.

McConnel Limited, Temeside Works, Ludlow, Shropshire SY8 1JL. England.

Telephone: 01584 873131. Facsimile: 01584 876463. www.mcconnel.com

Other manuals for Twose Series

3

This manual suits for next models

8

Table of contents

Other McConnel Tractor Accessories manuals

McConnel

McConnel ECON Application guide

McConnel

McConnel ROBO-FLAILHEAD 1300 User manual

McConnel

McConnel PA50 Mk3 User manual

McConnel

McConnel EZI-EDGER Programming manual

McConnel

McConnel TA320 User manual

McConnel

McConnel ROBO-FLAILHEAD 1300 User manual

McConnel

McConnel 77 Series User manual

McConnel

McConnel ROTA-ROLL Twose Series Programming manual

McConnel

McConnel PA7070T User manual