►

www.tmgindustrial.com P3 / 12 Toll Free: 1-877-761-2819

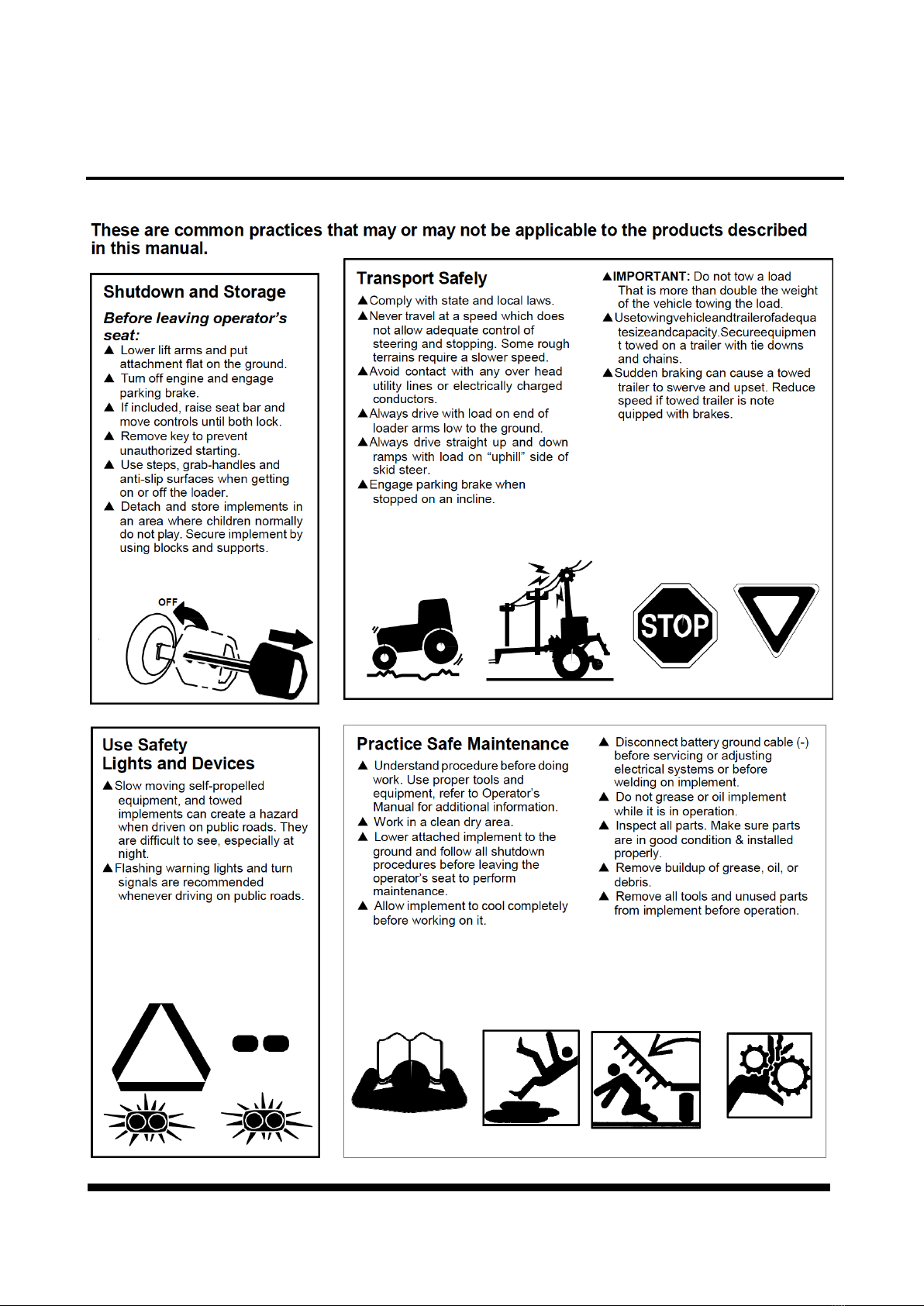

SAFETY PRECAUTIONS

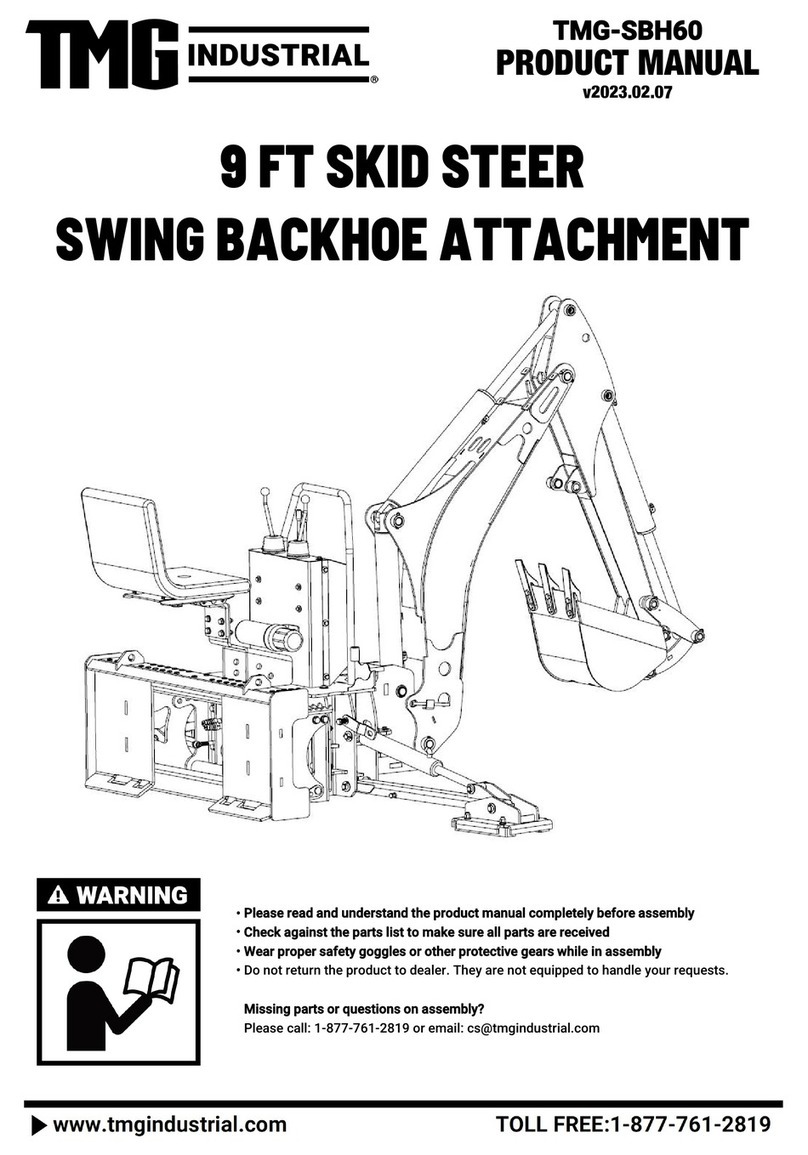

BEFORE OPERATION

1.The operator must read the operation manual carefully before installation,

operation or maintenance. Improper operation will cause the machine damage or harm to the

operator.

2.Read all the safe signs and safe declarations. Follow all the safeyrules, local laws or the

professional directions.

3.Familiarize yourself with the skid steer backhoe attachment functions, specs and operation.

Replace the worn parts immediatly. Make sure all the hydraulic installations and couplings

connect firmly, andall the safe signs stick on the suitable positions clearly.

TO THE OPERATOR

WARNING! PROTECT AGAINST FLYING DEBRIS

1. Always wear proper safety glasses, goggles, or a face shield when driving pins in or out,

or when any operation causes dust, flying debris, or any other hazardous material.

2. Don’t modify the skid steer backhoe attachment casually.

3. Should keep the machine on the flat ground when repair, far away from transportation

and other dangerous places.

4.Must not leave the machine when the machine is running. Must stop the engine at first

and then remove the key if want to leave.