Opening Procedures (continued)

©McDonald’s Corporation · Planned Maintenance Manual · Revised January, 2021 Page 3 of 4

Taylor Company milkshake and soft

-serve machine model C602

SS 3 D1

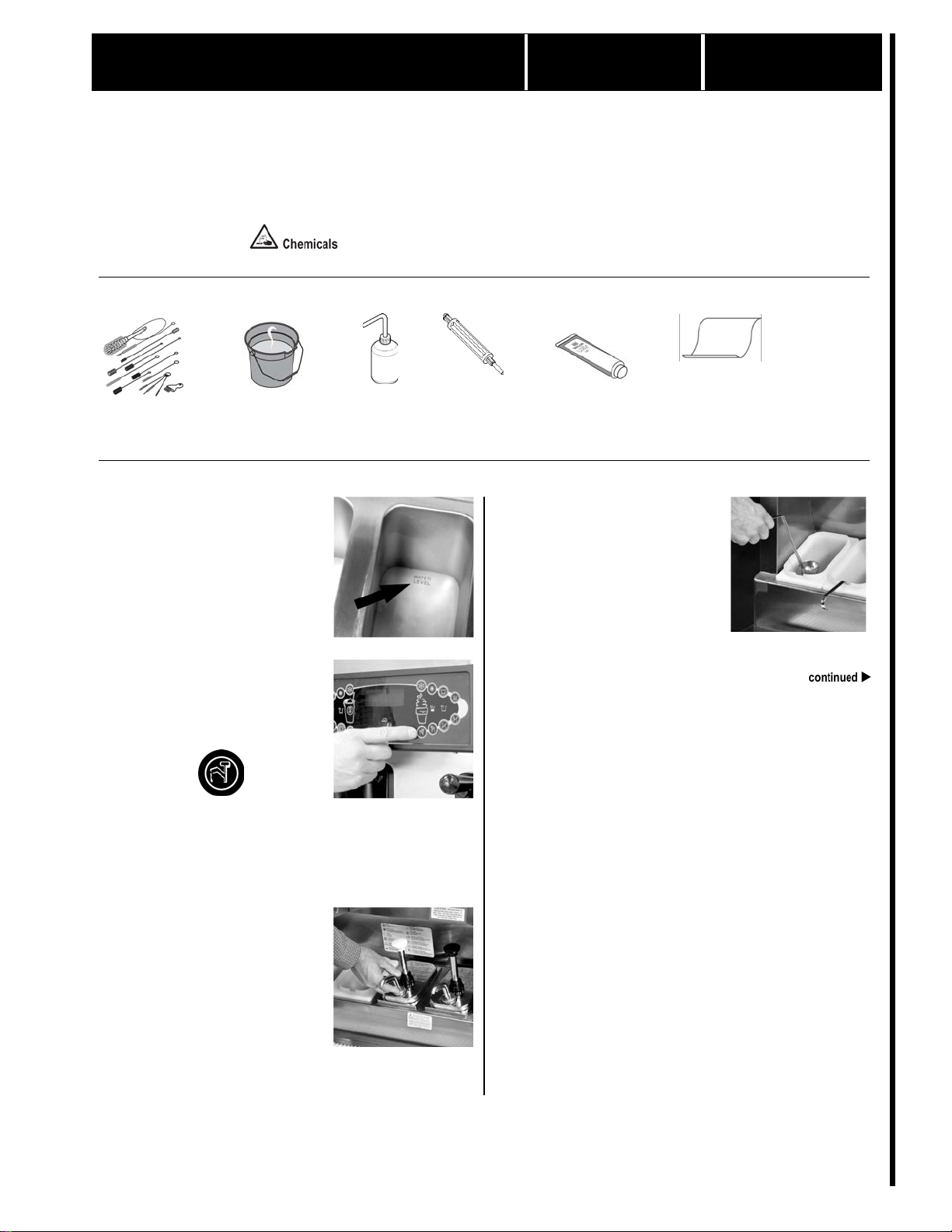

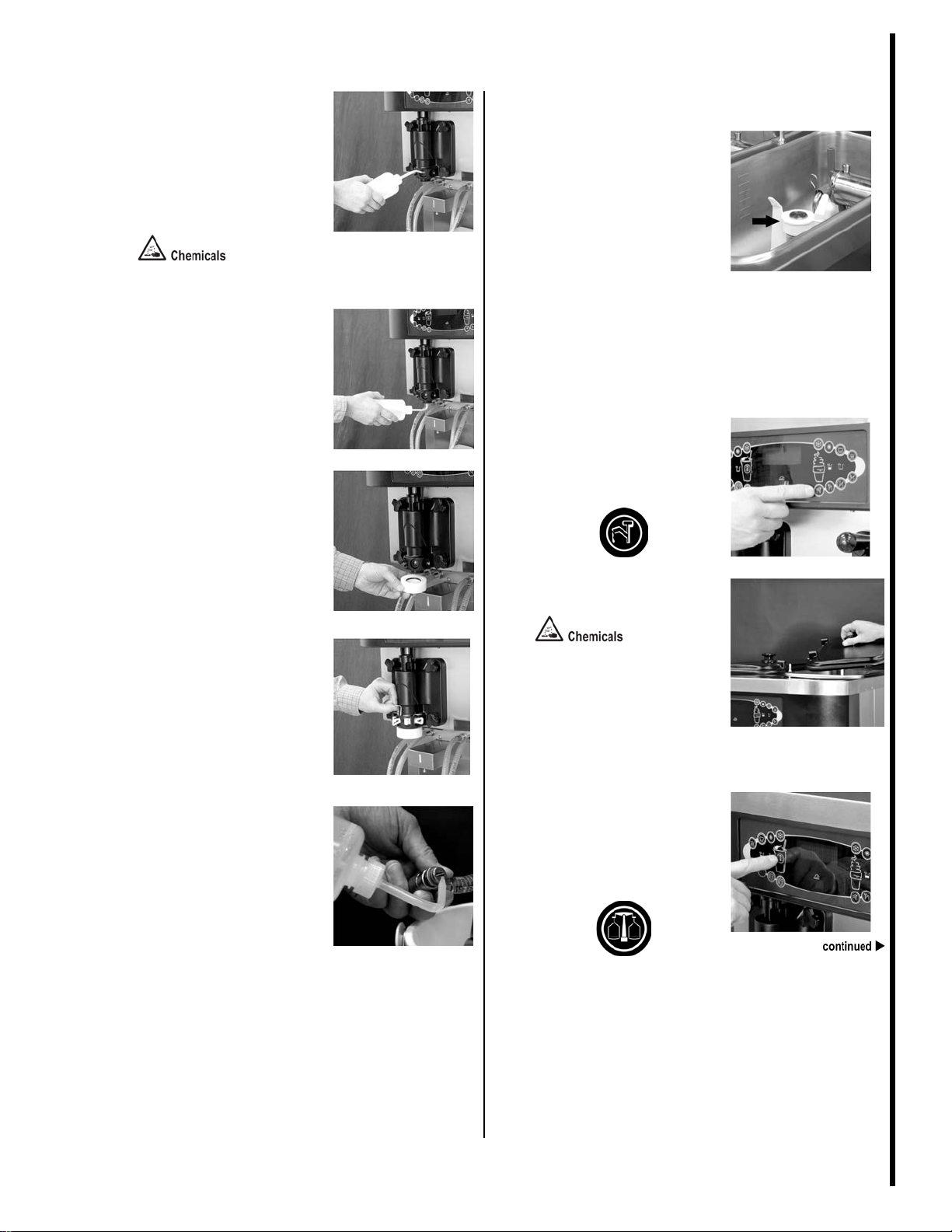

Remove the duckbill valve

and the o-ring from each

syrup nose fitting, by using

the seal removal tool.

Clean syrup nose fitting.

Using a brush and the

sanitizing solution, brush

clean the inside of each syrup

nose fitting until there is no

remaining syrup or mix inside

the fitting.

Sanitize syrup nose fittings

and duckbill valve.

Using a clean, sanitized

towel, gently wipe any syrup

and mix from each duckbill

valve.

Use a milkshake cup filled

with sanitizing solution to

thoroughly rinse the nose

fittings and duckbill valve.

Install duckbill valve into syrup

nose fitting and install syrup

nose fitting onto syrup line

fitting.

Install the duckbill valve into

the syrup nose fitting with the

flat end aligned with the open

slot in the fitting.

Install the syrup nose fitting

onto the syrup line fitting.

Tighten by hand (clockwise)

until snug.

Install and lubricate the o-ring

on the syrup nose fitting.

Raise the syrup valve retainer

and install the syrup valve.

Push the retainer down to

hold the valve in place.

Repeat for each syrup valve.

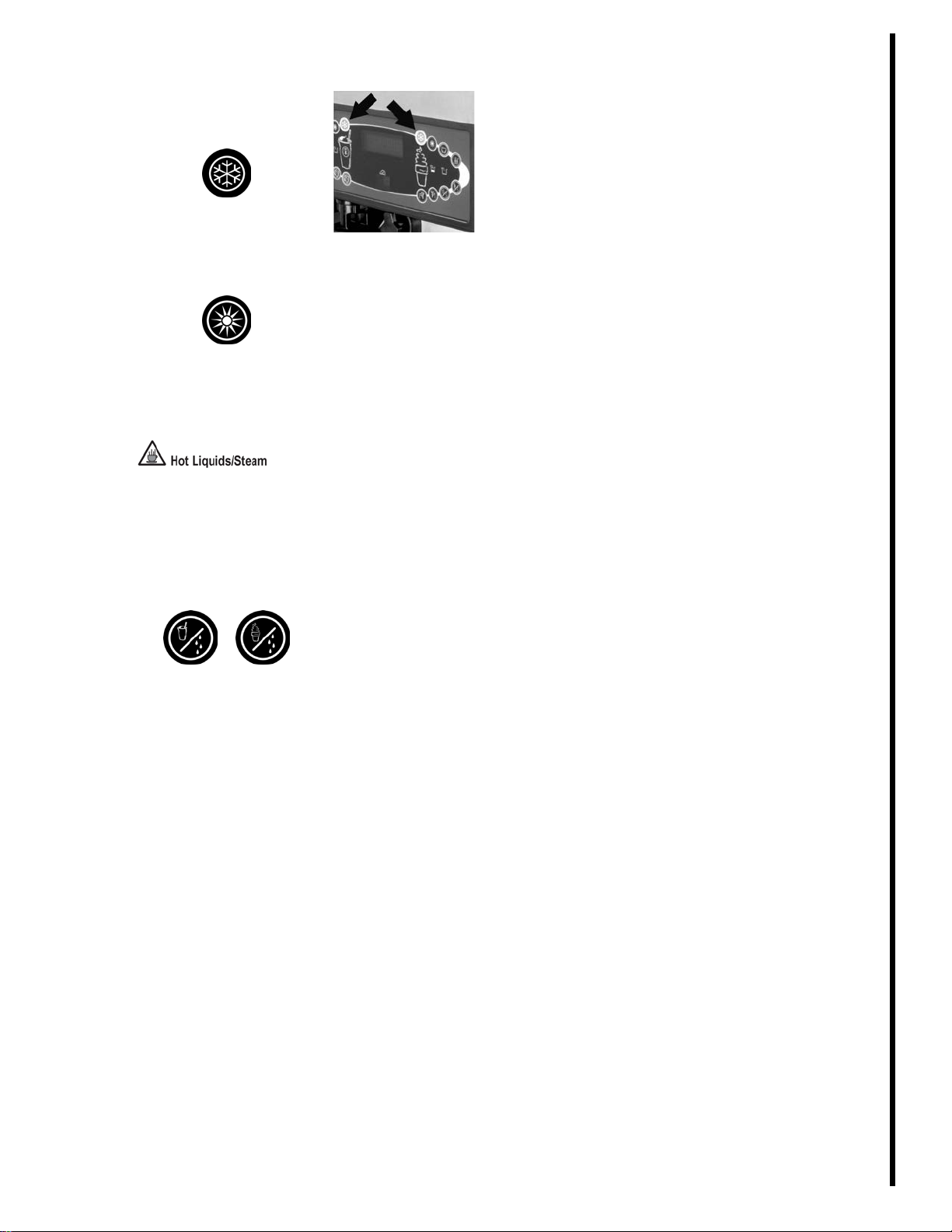

Check syrup lines for air

pockets in the line.

If air pockets are present,

prime the syrup lines. (See

Operator Manual for priming

syrup lines.)

Install syrup plugs for unused

syrup lines.

Install a syrup hole plug into

the syrup port in the door

whenever a syrup line is not

in use. (Example: When the

optional flavor shake is not

being served.)

Do not install an empty syrup

line into the syrup port of an

unused syrup line.

Note: The syrup system

must be flushed and

sanitized weekly.

Wipe exterior of machine.

Using a clean, sanitized

towel, wipe down the freezer

door, front panel, and other

areas that have a build up of

moisture or food substance.