Meanwell PHP-3500-HV User manual

PHP-3500-HV

User's Manual

0. Safety Guidelines

1. Introduction

2. Mechanical Specification and Input/Output Terminals

1.1 Introduction

1.3 Order Information

1.4 Main Specification

1.2 Features

..........................................................................................................

...................................................................................................................

...............................................

...................................................................................................................

.................................................................................................................

.......................................................................................................................

.......................................................................................................

..........................................................................................................

..................................................................................................

.........................................................................................................

.................................................................................................................

........................................................................................

.................................................................................

........................................................................

.................................................................................................

...........................................................................

................................................................................................................

...........................................................................................................

...........................................................................................................

.......................................................................................................................

....................................................................................................

................................................................................................................

......................................................................................................................

...................................................................................

..............................................................................

........................................................................................................

........................................................................................................................

1

1

1

1

1

2

3

3

4

4

12

4

12

13

13

14

4

4

5

6

6

6

6

6

6

7

11

3.Functions

4.Notes on Operation

2.1 Mechanism

3.1 Input Voltage Range

3.2 Inrush Current Limiting

4.1 Derating

3.3 Rated Power

3.4 Power Factor Correction (PFC)

3.5 Output Voltage/Current Adjustment

3.6 Short-Circuit and Over-Current Protection

3.7 Over-Voltage Protection

3.8 Over-Temperature Protection and Alarm

3.9 DC OK Signal

3.10 Remote Control

3.11 Auxiliary Power

3.12 PMBus Communication Interface

3.13 CANBus Communication Interface

4. 3 Water Cooling System

4. 2 External filter

4.4 Warranty

Nov. 2021 Version 0

0.Safety Guidelines

1.Introduction

PHP- 3500-HV User's Manual

◎ Risk of electrical shock and hazard, all failure should be examined by a qualified technician. Please do not remove the case from

the supply by yourself.

1.1 Introduction

1.2 Feature Description

1.3 Order Information

◎ Please do not change any component on the unit or make any kind of modification on it.

◎ Please do not install the unit in places with high ambient temperature or under direct sunlight.

◎ The input voltage range is 100-240Vac(50/60Hz), please do not feed in voltage that is over or less than 10% of that range.

PHP series is a water-cooled power supply designed to provide energy for s, industrial control system battery charging systems

and laser processing equipment.

◎ Universal AC input/Full range.

◎ . Built-in active PFC function, PF>0.95

◎ . Protection: Short circuit/ Overload/ Over voltage/ Over temperature

◎ . Built-in remote ON-OFF control and DC-OK active signal

◎ . Output voltage programming

◎ . Output current programming

◎ . 12V/0.5A auxiliary output

◎ . PMBus serial data transmission function

◎ .Please refer to the safety label sticker on the top of the unit before use (Figure 1-1)

Figure 1-1 PHP-3500 Safety label sticker

◎ 5 years warranty.

1.3.1 Explanation for Encoding

1.3.2 Marking

1

PHP-3500- 115

Output Voltage

Bauar

Sicherh eit

egel gema

t gepru ft

od

be

www .

ID 2000000000

tuv.com

wac g

o s

Bauar

Sicherh eit

egel gema

t gepru ft

od

be

www .

ID 2000000000

tuv.com

wac g

o s

Bauar

Sicherh eit

egel gema

t gepru ft

od

be

www .

ID 2000000000

tuv.com

wac g

o s

2

1.4 Main Specification

105 ~ 115% rated output power

VOLTAGE RANGE Note.4

FREQUENCY RANGE

POWER FACTOR (Typ.)

EFFICIENCY (Peak) Note 10

INPUT

INRUSH CURRENT (Typ.)

LEAKAGE CURRENT

OVER TEMPERATURE

WORKING TEMP.

WORKING HUMIDITY

STORAGE TEMP., HUMIDITY

TEMP. COEFFICIENT

VIBRATION

DIMENSION

OTHERS

NOTE

OVERLOAD

OVER VOLTAGE

AC CURRENT (Typ.)

90 ~ 264VAC 127 ~ 370VDC

Cold start 80A/230VAC 40A/115VAC

2mA / 240VAC

-30 ~ +70℃(Refer to “Derating Curve")

20 ~ 90% RH non-condensing

-40 ~ +85℃, 10 ~ 95% RH non-condensing

±0.03%/℃ (0 ~ 50℃)

10 ~ 500Hz, 2G 10min./1cycle, 60min. each along X, Y, Z axes

192.1K hrs min. 63.9Khrs MIL-HDBK-217F (25℃)

PF 0.95/230VAC at full load PF 0.95/115VAC at 60% load≥ ≥

℃

.

℃ ℃

※ : , https://www.meanwell.com/serviceDisclaimer.aspx

ENVIRONMENT

PROTECTION

380*141.4*60mm (L*W*H)

Protection type :Shut down O/P voltage,re-power on to recover

Protection type :Shut down O/P voltage, recovers automatically after temperature goes down

Adjustment of output voltage is allowable to 50~120% of nominal output voltage.

Please refer to the function manual

20A/230VAC 21A/115VAC

4.5Kg;4pcs/19Kg/2.46CUFT

47 ~ 63Hz

Protection type : unit will shut down after 5 sec, re-power on to recover.Constant current limiting,

FUNCTION

REMOTE ON/OFF CONTROL

AUXILIARY POWER

DC-OK SIGNAL

Power ON : Short circuit Power OFF : Open circuit

12V@0.5A tolerance±10%, ripple 150mVp-p

The TTL signal out, PSU turn on = -0.5 ~ 0.5V ; PSU turn off = 3.5 ~ 5.5V. Please refer to the Function Manual.

SAFETY STANDARDS

SAFETY &

EMC

(Note.7,8)

WITHSTAND VOLTAGE

ISOLATION RESISTANCE

I/P-O/P:6KVDC I/P-FG:4KVDC O/P-FG:4KVDC

I/P-O/P, I/P-FG,O/P-FG:100M Ohms/500VDC/25℃/ 70%RH

UL62368-1,TUV BS EN/EN62368-1, approved ; design refers to BS EN/EN61558-1, BS EN/EN60335-1EAC TP TC 004

MTBF

PACKING

Adjustment of constant current level is allowable to 20 ~ 100% of rated current.

Please refer to the Function Manual.

OUTPUT VOLTAGE

PROGRAMMABLE(PV) Note 5,6

OUTPUT CURRENT

PROGRAMMABLE(PC) Note 6

95% 95.5% 96%

168 ~ 200V 273 ~ 320V 413 ~ 460V

EMC IMMUNITY

EMC EMISSION

Parameter

Parameter

ESD

Radiated

EFT / Burst

Surge

Conducted

Magnetic Field

Voltage Dips and Interruptions

Conducted

Radiated

Harmonic Current

Voltage Flicker

Standard

Standard

EN55032 (CISPR32)

EN55032 (CISPR32)

EN61000-3-12

EN61000-3-3

EN61000-4-2

EN61000-4-3

EN61000-4-4

EN61000-6-2

EN61000-4-6

EN61000-4-8

EN61000-4-11

Test Level / Note

Test Level / Note

Level 3, 8KV air ; Level 2, 4KV contact

Level 3

Level 3

2KV/Line-Line 4KV/Line-Earth

Level 3

Level 4

>95% dip 0.5 periods, 30% dip 25 periods,

>95% interruptions 250 periods

Class B

Class A

-----

-----

OVER VOLTAGE CATEGORY Ⅲ; According to EN61558 ; altitude up to 2000 meters.

VOLTAGE ADJ. RANGE

MODEL

DC VOLTAGE (Factory default)

RATED CURRENT(Max.)

OUTPUT

LINE REGULATION

LOAD REGULATION

SETUP, RISE TIME

HOLD UP TIME (Typ.)

2000ms, 60ms/230VAC at full load 2500ms, 60ms/115VAC at 60% load

16ms/230VAC at 75% load 10ms/230VAC at full load 10ms/115VAC at 60% load

RIPPLE & NOISE (Max.) Note.2

VOLTAGE TOLERANCE Note.3

RATED POWER(Max.) Note.11

1.15Vp-p 2.3Vp-p 3.8Vp-p

±0.5% ±0.5% ±0.5%

±0.5% ±0.5% ±0.5%

±1.0% ±1.0% ±1.0%

PHP-3500-115 PHP-3500-230 PHP-3500-380

3500W 3500W 3500W

115V 230V 380V

26.3A 16.1A 10.5A

110~160V 170~260V 260~400V

By built-in potentiometer, SVR

CURRENT (Factory default)

POWER (Factory default) 2898W

25.2A

SHORT CIRCUIT Protection type : Constant current limiting, unit will shut down after 5 sec, re-power on to recover.

15.2A

3500W

9.2A

3500W

3

2.Mechanical Specification and Input/Output Terminals

2.1 Mechanism

Figure 2-2 PHP-3500 terminal illustration

LED Status Indicator

Figure

※ LED Status Indicators

LED

Green

Red

The power supply functions normally

Description

Abnormal status (Over temperature protection, Overload protection, Fan fail.)

Red (Flashing)

The LED will flash with red light when internal temperature reaches

85℃; under this condition, the unit still operates normally without entering

OTP. (In the meantime, an alarm signal will be sent out through the PMBus

/CANBus interface.)

60 1±

TB1

1

2

3

710

380 0.5±

369 0.5±5.5 0.2±

125 0.3±

141.4 0.3±

-V

+V

SVR

6-ψ5.2 L=12

154 0.3±

8.2 0.2±

183 0.3±

LED

T case

T case

tc

tc

‧ : Max. Case Temperature

tc

CN55

CN47

10 9

2 1

12

2

11

1

Pin No.

1

3

2

Assignment

AC/L

AC/N

AC Input Terminal(TB1) Pin NO. Assignment

Terminal

DECA

T25-EM10-03

Max mounting torque

18Kgf-cm

※DC Output Terminal Pin No. Assignment

Assignment Diagram Maximum mounting torque

10Kgf-cm

+V, -V

4

3.Functions

3.1 Input Voltage Range

3.2 Inrush Current Limiting

3.3 Output Power

◎ . The input voltage range is or AC90~264V DC127~370V

◎ To insure proper operation, AC input should be within the pre-specified range. A wrong input will cause the supply unit operating

improperly, losing PFC function or even damaging the unit in a worst case scenario.

with a lower input voltage. Please refer to 4.1 Derating for more information.

inrush current of the unit.

specified value if the input thermistor is not allowed sufficient time to cool down. After turning off the supply, a 10 second cool down

period is recommended before turning them on again.

◎ The efficiency will be lower and the output current will be automatically limited to a predetermined safe value if the unit is applied

◎ . Built-in inrush current limiting circuit

PHP-3500-115 : 2898W (115V / 25.2A)

PHP-3500-230 : 3500W (230V / 15.2A)

◎ If adding an external switch (a relay/ a circuit breaker) at the input side is required, choose switches that are able to withstand

◎ Since the inrush current limiting circuit mainly consists of a NTC thermistor and a relay, inrush current will be much higher than the

3.4 Power Factor Correction (PFC)

◎ Built-in active power factor correction (PFC) function, power factor (PF) will be 0.95 or better when input voltage is in a range of

90-230Vac and operated at full load condition. PF will be less than 0.95 if the output is not at full load or the input voltage is higher

than 230Vac.

※Control Pin No. Assignment( ) : CN55

Pin No. Function Description

Connection for constant current level programming. (Note.1)

1,3

PC

-V (Signal) Negative output voltage signal.

Connection for output voltage programming. (Note.1)

2,4

PV

7,8,9,10,11,12

Note1: Non-isolated signal, referenced to [-V(signal)].

12

2

11

1

NC

5,6

Pin No. Function Description

※Control Pin No. Assignment( ) : CN47

3The unit can turn the output ON/OFF by electrical signal or dry contact between Remote ON/OFF and +12V-AUX. (Note.1)

Short (10.8 ~ 13.2V) : Power ON ; Open (-0.5 ~ 0.5V) : Power OFF ; The maximum input voltage is 13.2V.

Remote

ON-OFF

5Low (-0.5 ~ 0.5V) : When Vout ≧80%±5%.

The maximum sourcing current is 10mA and only for output. (Note.1)

DC-OK

1Auxiliary voltage output, 10.8~13.2V, referenced to GND-AUX (pin 2).

The maximum load current is 0.5A. This output has the built-in "Oring diodes" and is not controlled by the Remote ON/OFF control.

+12V-AUX

Auxiliary voltage output GND. The signal return is isolated from the output terminals (+V & -V).

2GND-AUX

4GND-AUX(S)

6

High (3.5 ~ 5.5V) : When the internal temperature exceeds the limit of temperature alarm.

Low (-0.5 ~ 0.5V) : When the internal temperature is normal.

T-ALARM

High (3.5 ~ 5.5V) : When the Vout ≦80%±5%.

The maximum sourcing current is 10mA and only for output(Note.1)

The signal return is isolated from the output terminals (+V & -V).

10 9

2 1

9,10

For PMBus model: Serial Data used in the PMBus interface. (Note.1)

For CANBus model: Data line used in CANBus interface. (Note.1)

SDA

CANH

7,8

For PMBus model: Serial Clock used in the PMBus interface. (Note.1)

For CANBus model: Data line used in CANBus interface. (Note.1)

SCL

CANL

Note1: Isolated signal, referenced to GND-AUX(S).

PHP-3500-380 : 3500W (380V / 9.2A)

50

OUTPUT VOLTAGE(%)

100

120

Vout

0.401

4.7

V

4.8

Non-Linear

67 108 167V

115V(default)

230V/380V(default)

160 260 400V

◎The 100% output voltage is 133V/217V/333V.

5

3.6

EXTERNAL VOLTAGE (DC)

5

3.5 Output Voltage/Current Adjustmen

3.5.1 General adjustment

Output voltage can be trimmed by adjusting SVR ( ), please utilize an insulated cross-head screwdriver toon the terminal end

make an adjustment.

3.5.2 Adjustment with an external 0 - 5Vdc source (Output Voltage Programming)

(1) Connect output of the external DC source to PV (PIN1 or PIN3) and -V(signal) (PIN5 or PIN6) on CN55, shown in Figure 3-1.

(2) Relationship between output voltage and external DC source is shown in Figure 3-2.

(3) While increasing the output to a higher voltage level, please reduce the load current accordingly. Output wattage of the

unit should not exceed the rated value under any circumstances.

Figure 3-1 Connection of external DC voltage source

PV

1,3

5,6

0~5V

-V

Figure 3-2

3.5 3.Output current adjustment (Output Current Programming)

※Constant current level can be adjusted within a range of 20 -100% of the rated current via an external DC source, wiring

is shown as below.

Relationship between output current and external DC source is shown as below.

+V

-V

PHP-3500

LOAD

PC

CN55 -V Signal

EXTERNAL

VOLTAGE

3,4

1

◎The rated current should change with the output voltage

programming accordingly.

OUTPUT VOLTAGE (%)

115V 127V 133V 160V

40

20

108V

167V

206V 217V 260V

316V 333V 400V

115V

230V

380V

V

o

OUTPUT CURRENT (%)

67V

60

100

83.3

100% load output

model

model

model

70

95.5

113V

184V

283V

5,6

2,4

20

OUTPUT CURRENT(%)

100

110

Iout

0

EXTERNAL VOLTAGE (DC)

0.4 1

4.7

V

4.8

Non-Linear

5.0

◎The 100% output current is rated current.

◎operation current 100% is recommended.

Maximum <

-V(signal)

-V(signal)

0~5V

Note:The PHP-3500 will trigger OLP to shut down itself if the output stays at constant current level condition for more than

5 seconds.

3.6 Short Circuit Protection & Over Current Protection

3.7 Over Voltage Protection (OVP)

3.8 Over Temperature Protection (OTP) and Alarm

◎ The protection activates when the output is short-circuited or the output current exceeds 110%±5 of the rated output current.

◎ . Built-in over voltage protection circuit

◎ Built-in thermal detection circuit, once the internal temperature exceeds a threshold value, the unit will shut down automatically.

◎ When the internal temperature is within a normal value, there will be a LOW signal (-0.5-0.5V) sent out through T-ALARM on " "

◎ Maximum output current: 10mA

◎ When internal temperature reaches 85℃, trigger point of a thermal alarm, the red LED on the output will flash and there will be an

alarm signal sent out through the PMBus/CANBus (by request) interface, please refer to 3.12.2. Even so, the unit is still operating

normally.

◎ . OVP triggering points vary in different output models. Please refer to the specification sheet for detailed information

◎ Once OVP is triggered, leave the unit off for 20 seconds before recycling AC again.

Re-power on to recover when short-circuit/overload condition is removed.

Please switch off the AC input, remove all possible causes and then leave the unit cooling down to a normal working temperature

(approximate 10 minutes - 1 hour) before repower on again.

CN47; There will be a HIGH signal (3.5-5.5V) sent out through T-ALARM on CN47 when internal temperature exceeds a " "

certain value. (referenced to GND-AUX).

6

3.10 Remote Control

◎ Built-in remote ON/OFF control circuit, refer to Figure 3-3 for the control method.

◎ Please be aware that ON/OFF and +12V-AUX on CN47 should be linked together to allow the unit operate normally; If they " " " "

are kept open, there will be no output voltage.

◎ Maximum input voltage: 13.2V

Figure 3-3 Connection of Remote Control

Remote ON/OFF and +12V-AUX

SW Open

SW Short

Output

OFF

ON

◎ When DC output voltage is out of normal range, there is a HIGH signal (3.5-5.5V) sent out through DC-OK on CN47. " "

◎ Maximum output current: 10mA

◎ When DC output voltage is within a normal value, there is a LOW signal (-0.5-0.5V)sent out through DC-OK on CN47. " "

(referenced to GND-AUX).

(referenced to GND-AUX).

◎ . Built-in DC output voltage detection circuit

3.9 DC OK Signal

+12V-AUX

CN47

Remote ON/OFF

PHP-3500

3

1

3.1 1 Auxiliary Output

◎ Built-in 12V/0.5A auxiliary output.

Switch

7

123

ON

OFF

Module

No.

Module

No.

1 1

A0 A0

0

1

2

3

4

5

6

7

2 2

A1 A1

3 3

A2 A2

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON ON

ON ON

OFF OFF

OFF OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

Device address Device address

DIP switch position DIP switch position

Table 3-1

3.1 2.1 PMBus Addressing

◎ Each PHP-3500 unit should have their unique and own device address to communicate over the PMbus. 7-bit address

setting pins are used to assign a device address for a PHP-3500 unit, as shown in the description below.

A0- A2 allow users to designate an address for PHP-3500 units; these three bits are defined through a 3-pole DIP switch

on the terminal end of the unit. There are up to 8 different addresses are available to be assigned. When DIP switch in the

"ON" position means logic "0"; when it is in the "OFF" position, meaning logic "1", for example, position 3 in "OFF", the

corresponding bit, A2, is set to logic "1". Please refer to Table 3-1 for the detailed setup advice.

3.1 2 PMBus Communication Interface

◎ PHP-3500 is compliant with PMBus Rev.1.1, the maximum communication speed is 100KHz and it has the capability of

identifying up to 8 addressed units.

◎ PMBus communication interface is able to provide the current operating status and information as followings:

. Output voltage, current and internal temperature

Alarm and status.

Manufacture and model data.

1

MSB

0 0 0 A2 A1 A0

LSB

3.1 . 2 2 PMBus Control Setting

3.12.3 Factory Resetting

3.12.4 Initial Operational Behavior Setting

◎ There are two means to control the power supply, analog signals and digital communication. Analog is the default setting

◎ Users can follow the steps below to restore factory settings for commands: , , and 01h 22h 46h BEh.

◎ Initial behavior of the power supply can be changed by setting SYSTEM_CONFIG(BEh), for OPERATION_INIT of

for the supply, signals including PV, PC and SVR can be used immediately once receiving the supply . The digital communication

1. Set DIP switch all in the "ON" position.

example: power on without output. For detailed information, please refer to 3.12.5 PMBus Command List.

2. Turn on the AC without remote on, there should be no voltage at the output.

3. Within 15 seconds, set DIP switch all in the "OFF" position and all back in the "ON" again.

4. The green LED flashing 3 times means the process is successfully done.

5. Restart the supply to load factory settings.

of PMBus is initially uncontrollable but readable. To activate the adjustment Commands of OPEREATION(01h, regarding

remote ON-OFF function), VOUT_TRIM(22h, regarding output voltage programming function) and IOUT_OC_FAULT_

LIMIT(46h, regarding output current programming function), set PM_CTRL of SYSTEM_CONFIG(BEh) at "1" and then

reboot the supply. Once the digital communication dominates the supply, the analog signals become invalid.

NOTE: 1. At default setting of analog, the following commands are invalid but can be written while other PMBus commands

are effective: OPEREATION(01h), VOUT_TRIM(22h) and IOUT_OC_FAULT_LIMIT(46h).

is activated.

2. All written parameters of commands: 01h, 22h and 46h are saved into EEPROM and take effect after the digital

8

3.1 . 2 5 PMBus Command List

◎ The command list of the PHP-3500 is shown in Table3-2. It is compliant with the standard protocol of PMBus Rev 1.1.

For more detailed information, please refer to PMBus official website http://pmbus.org/specs.html)(

Command

Code

01h

02h

19h

20h

21h

# of data

Bytes

1

1

1

1

2

Description

Remote ON/OFF control

ON/OFF function configuration

Capabilities of a PMBus device

Define data format for output voltage

(format: Linear, N= -7)

Output voltage setting value

(format: Linear, N= -7)

Command

Name

OPERATION

ON_OFF_CONFIG

CAPABILITY

VOUT_MODE

VOUT_COMMAND

Transaction

Type

R/W Byte

Read Byte

Read Byte

R Byte

R Word

22h 2 Output voltage trimmed value

(format: Linear, N= -7)

VOUT_TRIM R/W Word

47h

79h

7Ah

7Bh

7Ch

7Dh

1

2

1

1

1

1

Define protection and response when an

output overcurrent fault occurred

Summary status reporting

Output voltage status reporting

Output current status reporting

AC input voltage status reporting

Temperature status reporting

IOUT_OC_FAULT_RESPONSE

STATUS_WORD

STATUS_VOUT

STATUS_IOUT

STATUS_INPUT

STATUS_TEMPERATURE

R Byte

R Word

R Byte

R Byte

R Byte

R Byte

80h

88h

7Eh

8Bh

8Ch

1

2

1

2

2

Manufacture specific status reporting

AC input voltage reading value

(format: Linear, N=-1)

Communication, logic,

Memory status reporting

Output voltage reading value

(format: Linear, N= -7)

Output current reading value

(format: Linear, N= -4)

STATUS_MFR_SPECIFIC

READ_VIN

STATUS_CML

READ_VOUT

READ_IOUT

R Byte

R Word

R Byte

R Word

R Word

46h 2Output overcurrent setting value

(format: Linear, N= -4)

IOUT_OC_FAULT_LIMIT R/W Word

8Dh 2 Temperature 1 reading value

(format: Linear, N= -3)

READ_TEMPERATURE_1 R Word

98h 1 The compliant revision of the PMBus

(default: 11h for Rev. 1.1)

PMBUS_REVISION R Byte

99h 12 Manufacturer's nameMFR_ID Block Read

9Ah

9Bh

9Ch

9Dh

9Eh

BEh

BFh

12

24

3

6

12

2

2

Manufacturer's model name

Firmware revision

Manufacturer's factory location

Manufacture date. (format: YYMMDD)

Product serial number

System setting

System status

MFR_MODEL

MFR_REVISION

MFR_LOCATION

MFR_DATE

MFR_SERIAL

SYSTEM_CONFIG

SYSTEM_STATUS

Block Read

Block Read

Block R/W

Block R/W

Block R/W

R/W Word

Read Word

Command

Code

# of data

Bytes Description

Command

Name

Transaction

Type

Table

Bit 1: 2 OPERATION_INIT: Initial Operational Behavior

Bit 1: DC_OK: The DC Output Status

Bit 2 PFC_OK:The PFC Status

Bit 4 ADL_ON:Active Dummy Load Status

Bit 5 INITIAL_STATE: Initial State Indication

0b00=Power on with 0x00: OFF

0=DC output too low

0=The PFC NOT activate or abnormal

0=Active dummy load NOT activate

0=The unit NOT in an initial state

0b01=Power on with 0x80: ON (default)

1=DC output at a normal range

1=The PFC activate

1=Active dummy load activate

1=The unit in an initial state

Note: Unsupported settings display with "0"

0b10=Power on with the last setting

0b11=Not used

Note: Unsupported settings display with "0"

◎ Definition of Command BEh SYSTEM_CONFIG

◎ Definition of : Command BFh SYSTEM_STATUS

Note:

Bit7

Bit7

Bit6

Bit6

Bit5

Bit5

Bit4

Bit4

Bit3

Bit3

Bit2

Bit2

Bit1

Bit1

Bit0

Bit0

High byte

High byte

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Low byte

Low byte

-

-

- - -

-

PM_CTRL

M/SDC_OKPFC_OKADL_ON

INITIAL_

STATE

OPERATION_INIT

Low byte

Low byte

Bit 0 PM_CTRL: PMBus Control Selecting

Bit 0 M/S: Master/Slave Indication

0= .Output voltage and current controlled by SVR/PV/PC(default)

0=The unit is a slave

1=Output voltage, current and remote ON/OFF controlled by PMBus (VOUT_TRIM、IOUT_FAULT_LIMIT、OPERATION).

1=The unit is the master

Note:

9

EEPROM

-

EEPER: When EEPROM Access Error occurs, the supply stops working and the LED indicator turns red. The supply needs to re-power on to

recover after the error condition is removed.

Bit 6 EEPER EEPROM Access Error:

0=EEPROM accessing normally

1=EEPROM access error

PMBus command Range ToleranceModel

Table 3-3

3.1 . 2 6 PMBus Data Range and Tolerance

◎ Display parameters

PMBus command Range Tolerance DefaultModel

Table 3-4

◎ Control parameter

Adjustable voltage range

Minimum readable current

Model

Model

Table

Table

Note:

2.When using PMBus to adjust output voltage, VOUT_COMMAND only can be used to display the rated voltage of the unit and

3.Insert a at least 35msec delay between commands.

1.READ_IOUT will display ZERO amp when output current is less than the values in the table below.

cannot be written. It is VOUT_ TRIM that provides voltage trimming function. Take PHP-3500-115 as an examples, to get a

67V output, please set value of VOUT_TRIM to -48V. Adjustable voltage range for each model is shown as below.

10

READ_VIN

READ_TEMPERATURE_1

READ_VOUT

READ_IOUT

(Note. 1)

80 ~ 264V

-40 ~ 100℃

0 ~ 160V

0 ~ 32.6A

0 ~ 260V

0 ~ 28.8A

ALL88h

ALL8Dh

115V

230V8Bh

8Ch

±10V

±5℃

±1.15V

±1.26A

±2.3V

±0.68A

0 ~ 400V380V ±3.8V

0 ~ 11.4A ±0.41A

115V

230V

380V

SYSTEM_CONFIG N/A

01h

ALLBEh

21h

22h

46h

OPERATION

IOUT_OC_FAULT_LIMIT

VOUT_COMMAND

(Note. 2)

VOUT_TRIM

(Note. 2)

00h(OFF) / 80h(ON)

-48 ~ +45V

-122 ~ +30V

N/A

N/A

N/A

80h(ON)

±1.15V

±2.3V

0V

0V

ALL

115V

230V

N/A

5.2 ~ 28.93A

3.22 ~ 17.71A

±1.18A

±0.72A

28.93A

17.71A

02h

N/A380V

-213 ~ +20V ±3.8V 0V

2.1 ~ 11.55A ±0.47A 11.55A

115V

230V

380V

115V

230V

380V

115V

230V

380V

115V

230V

380V

115V

230V

1.18A±1A

0.72A±1A

380V 0.47A±1A

67 ~ 160V

108 ~ 260V

115V

230V

380V 167 ~ 400V

11

5.Data format of VOUT_MODE, VOUT_COMMAND, VOUT_TRIM, READ_VIN, READ_VOUT, READ_IOUT, READ_TEMPERATURE

_1 is as below:(Please refer to PMBus_Specification_Part_II_Rev_1-1 for detailed information)

(1)DIRECT Data Format

a.Interpreting Received Values

b.Sending A Value

DIRECT format data is a two byte, two’s complement binary integer. IRECT format data may be used with any command

that sends or reads a arametric value. If a PMBus device uses DIRECT form data, this shall be clearly described in the

product literature.

The host system uses the following equation to convert the value received from the PMBus device into a reading of

volts, amperes, degrees Celsius or other units as appropriate:

◎ .Please refer to the specification about PV/PC or SVR function

3.1 3 CANBus Communication Interface

◎ . For further CAN bus information, please contact MEAN WELL

4.Data format of IOUT_OC_FAULT_LIMIT(46h) is as below: (Please refer to PMBus_Specification_Part_II_Rev_1-1 for detailed

information).

4.Note on Operation

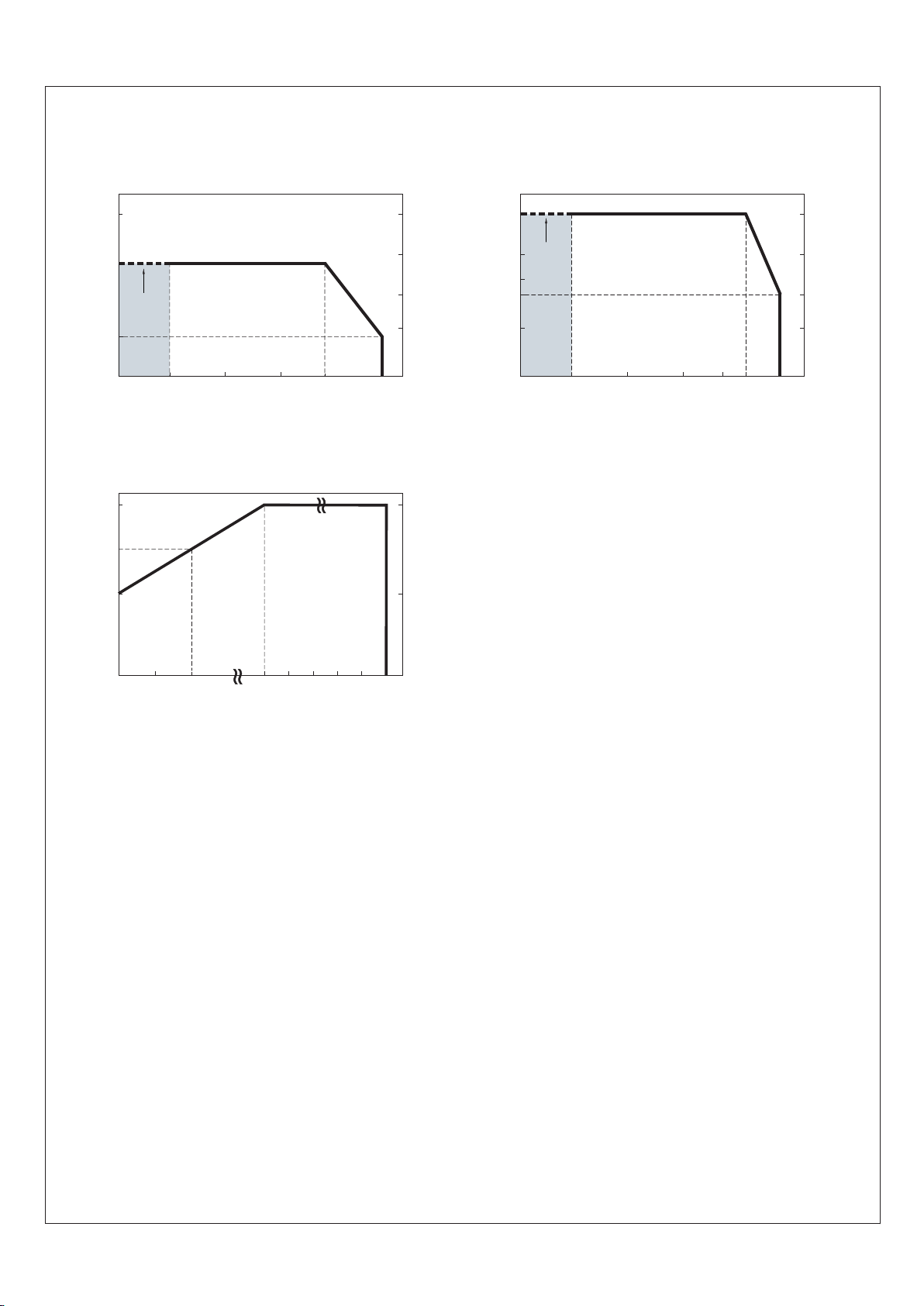

4.1 Derating

◎ When PHP-3500 is operating at a lower AC input voltage, the unit will derate its output current automatically to protect itself.

12

LOAD (%)

INPUT VOLTAGE (VAC) 60Hz

90 100 115 180 264

100

50

(HORIZONTAL)

70

AMBIENT TEMPERATURE WITH 128 CFM FAN*2 OR WATER

COOLING SYSTEM (℃)

5025 450-25-30

LOAD (%)

30

60

75

50

100

230VAC

Input only

(HORIZONTAL)

60

AMBIENT TEMPERATURE WITH ADDITIONAL ALUMINUM PLATE(℃)

(450x450x3mm)

o

Note. Tcase max.≦70 C and ambient temp must be within above

de-rating curve.

o

Note. Tcase max.≦45 C and ambient temp must be within above

de-rating curve.

25 400

230VAC

Input only

-25-30

LOAD (%)

20

60

100

60

4.2 External filter

4.3 Water Cooling System

4.3.1 water cold plate Quality requirement for surfaces

4.3.2 water cooling loop Operational requirement for

4.3.3 water cold plate Note on design

4.3.4 Condensation prevention and control

◎ . There should be no any shrinkage cavity, corrosion or cracks on the surfaces

◎ Using good quality water is recommended, resistance < ℃, 2.5KΩ and having a pH of 6-9; Inlet temperature of 25 flow rate

of 1 liter per .minute

◎ Please make sure there is no fluid leaks, blocks or condensation under operation.

◎ Material (purity, thickness, machining precision, etc) and manufacturing craft (whether there are cracks, fractures, etc

It is important to minimize or prevent condensation because condensate could drip onto electronics or collect in the bottom

of the system and cause corrosion. To avoid condensation, please follow below:

◎ Flatness between mating parts plays a critical role in thermal contact conductance.

◎ Please make sure cooling capacity of the chiller is greater than 175W so as to dissipate heat from the power supply efficiently.

◎ Temperature difference between the water and ambient temperature should be lower than ℃ in hot and humid places.5

◎ . Turn off the water cooling system during a power outage

caused by extrusion) have an profound impact on thermal conductivity of a cold plate.

13

LINE

1 3

Cx Cx

Cy

Cy

RL L

2 4

5

LOAD

4.2.2 Schematic

EMI

FILTER

AC Utility

LOAD

PHP-3500

AC

I/P

DC

O/P

4.2.1 Configration

FREQ. MHz

L Cx Cy

0.6mH 1.0uF 10000pF

0.01

2

4

0.05

5

15

0.10

8

18

0.15

10

18

0.50

30

45

1.0

35

50

5.0

55

40

10

45

40

30

30

40

COM. MODE dB

DIF. MODE dB

4.2.3 Minimum insertion loss (In dB at 50Ω system): Filter model 30DPGS5C or equivalent

Note : Need additional EMI filter to meet regulations of EMC conducted and radiated emission. Characteristics of EMI filter please refer to the table,

Minimum Insertion Loss.

Optional MEAN WELL cold plate is ready for order, Ordering No.: HS-656

4. 4 Warranty

◎ A five year global warranty is provided under normal operation. Please do not change any component or modify the unit by

yourself or MEANWELL may reserve the right not to provide the complete warranty service.

14

M5*6

N o . 28 , W u q ua n 3 rd R d . , Wu gu D i st . , N ew Tai p ei C i ty 24 8 , Ta iwa n

This manual suits for next models

3

Table of contents

Other Meanwell Industrial Equipment manuals