Vacuum Generator Series

Vacuum Generator VG

VH · VS

115

VU

VB

VM · VC

VG

VY

VUM

VRL

VACUUM

GENERATOR

Detailed Safety Instructions

Before using PISCO products, be sure to read “Safety Instructions” and “Safety Instruction

Manual” on page 35-39, “Common Safety Instructions for Vacuum Series” on page 47-49

and “Common Safety Instructions for Vacuum Generator VG & VK” on page 105.

Warning

1.

Attentions should be paid when pipe resistance is large or a large amount of blow-off air rate is required.

Insufficient blow-off air may cause troubles. Make sure to evaluate PISCO products by actual system.

2.

The coil in a pilot valve generates heat under the following ①-③conditions. Heating may be a cause of

dropping life cycle, malfunctions and burn or may affect negatively on peripheral machines due to the heat.

Contact us when the power is applied to the vacuum generator under the following conditions:

①The power is continuously ON for over 2 hours.

②High-cycle operation.

③Even when intermittent running of the generator is carried out, the total operation time per day is

longer than non-operation time.

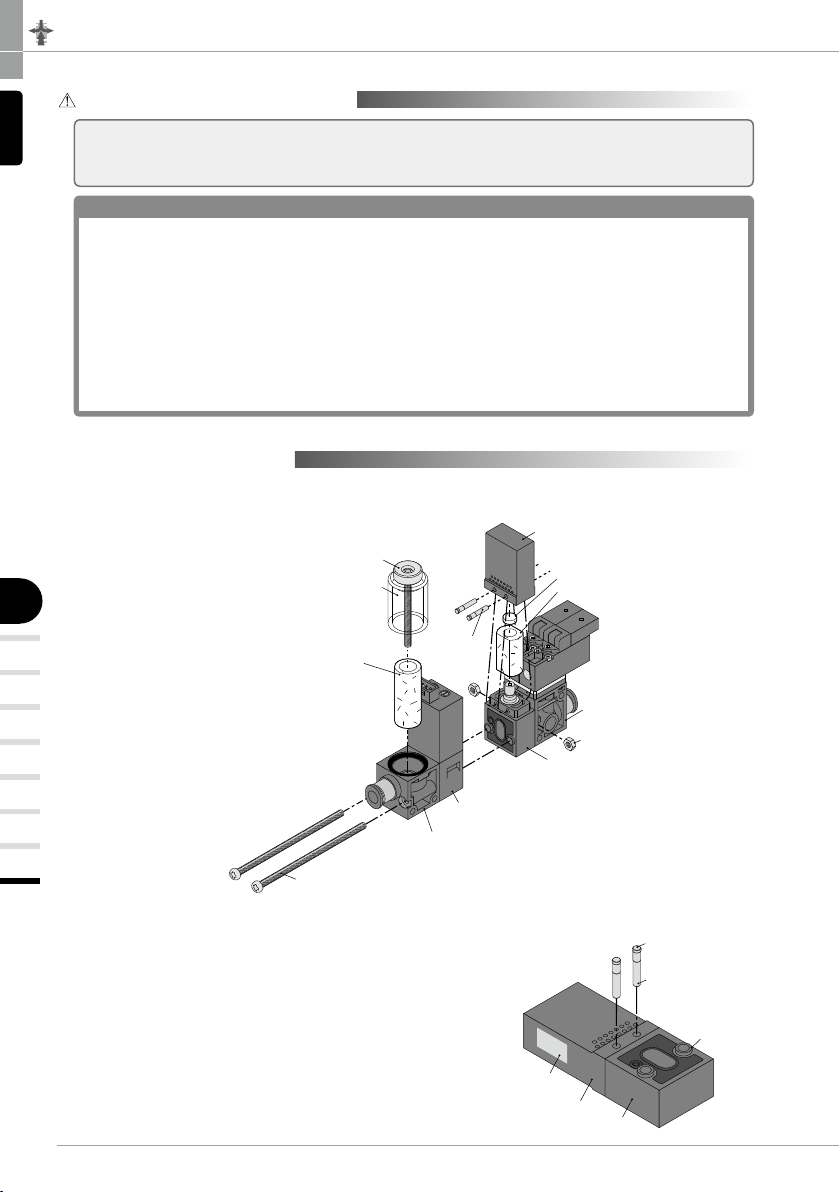

■ Replacement Element

■Remove the fixing screws to replace filter elements. Make sure not to lose the filter seal ring after the

replacement and tighten the screws with tightening torque 0.18-0.22Nm.

Silencer cover

Filter cover

Filter element

Model code:VGFE10

Filter unit

Vacuum sensor

Valve unit assembly

Ejector body

Hexagonal nut

Round head screw

Fixing Pin

Silencer element

Model code:SEE0602

Model code:VGED-G

■Replacement of Silencer Elements

Replace elements after removing 2 round head screws and 2 fixing pins.

※Make sure not to lose 2 hexagonal nuts.

■Procedures After Replacing Silencer Element

As the right figure shows, attach the silencer cover to the

ejector body and insert thinner end of 2 fixing pins into the

holes from the side with protrusion of the ejector body. Make

sure all seal materials of each unit are fit before assembling

the units. Use a screwdriver to appropriately tighten the

round head screw and the hexagonal nut with 0.35-0.4Nm

of the tightening torque.

Protrusion

Thinner end

Fixing Pin

Marking side

Fixing screw

Silencer cover

Ejector body