Operating Instructions (Cont.)

7. Allow the 1 minute self-test to end (or press the test switch

again to cancel self-test cycle).

8. Press the test switch again. Verify that the "Lamp Fail" LED

and the "Service Alert" LED are not illuminated.

Operation

SPECTRON electronics operation is fully automatic.

Accidental discharge of the unit battery prior to energization

is prevented by an AC lockout circuit. The unit's green

"Operating Status" LED, located on the Spectron display

panel, illuminates to indicate the presence of AC power. The

unit's red "Service Alert" LED will blink after application of

AC power if the battery connection is not completed. During

normal operation, the unit's charging circuit maintains the

battery at full capacity and the Spectron Controller constantly

monitors charger performance. Should the terminal voltage

vary from design parameter values, the unit's red "Service

Alert" LED will blink , indicating a malfunction of the battery or

charger. Upon interruption of normal AC power, or brownout

condition, the Spectron Controller automatically switches the

emergency lighting load to the battery. Emergency power will

be provided for a minimum of 90 minutes. During emergency

operation, the battery is protected from deep discharge by a

low voltage battery disconnect circuit. Upon return of normal

AC power, a 15 minute retransfer delay holds the unit in

emergency operation mode allowing utility voltage to stabilize

prior to reconnection. The charger will then begin a recharge

cycle. A temperature compensated oat type charger is

provided in LZ models utilizing Pure-Lead or Lead-Calcium

batteries. This charger is designed to adjust charging

voltage with changes in ambient temperature to maximize the

life and performance of the unit's batteries. LZ Series models

utilizing Nickel-Cadmium batteries require no temperature

compensation as they utilize a constant current type charger

design to maintain the unit's batteries. The charger will

bring the battery to full capacity within acceptable U.L. time

standards. The Spectron Controller automatically initiates a

one minute discharge/diagnostic test every 28 days ± 3.5

hours and a 30-minute discharge/diagnostic test every 6

months ± 1 day. These tests exercise the unit’s battery to

optimize its capacity and allows the SPECTRON Controller to

analyze emergency operation performance. Any malfunction

of the unit’s transfer circuit or emergency lamps will cause

the red "Service Alert" LED on the unit's display panel to

blink. During normal operation, all red "Service Alert" LED

blinking indications of unit malfunction remain latched until

corrected and retested. A manual test switch allows a user

programmable 1, 5, 30 or 60-minute diagnostic/discharge test

at any time. During all automatic and user initiated self-tests,

the unit's green "Operating Status" LED will blink to indicate a

diagnostic cycle in process.

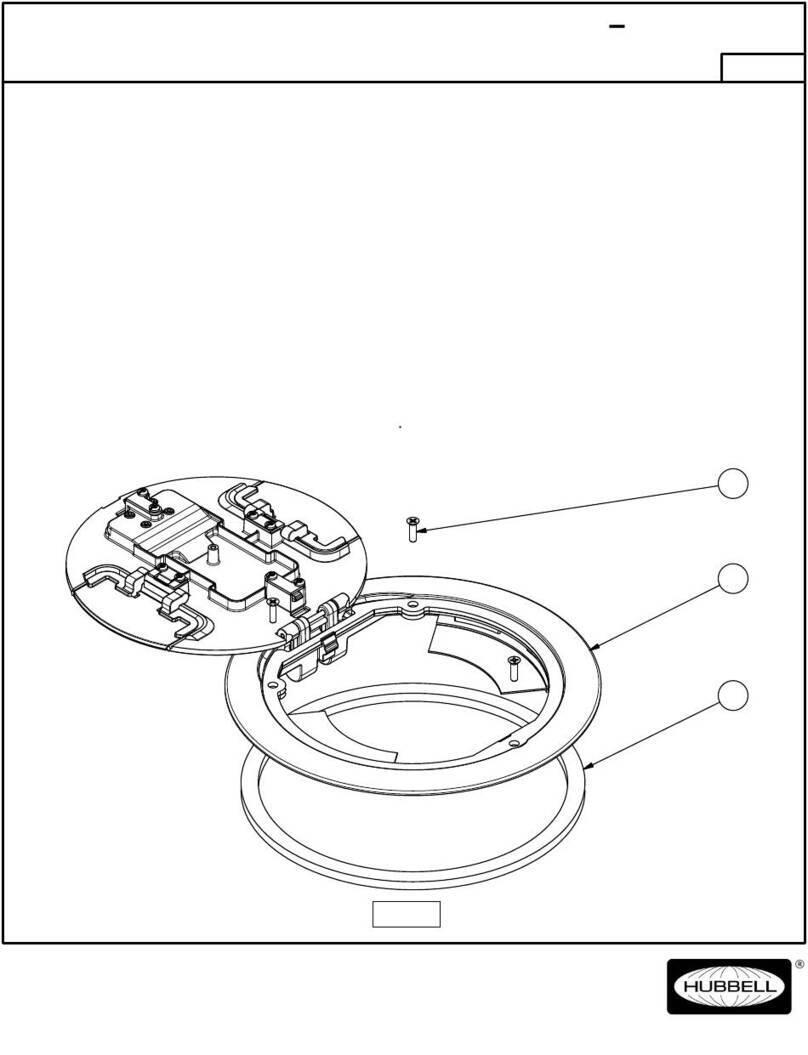

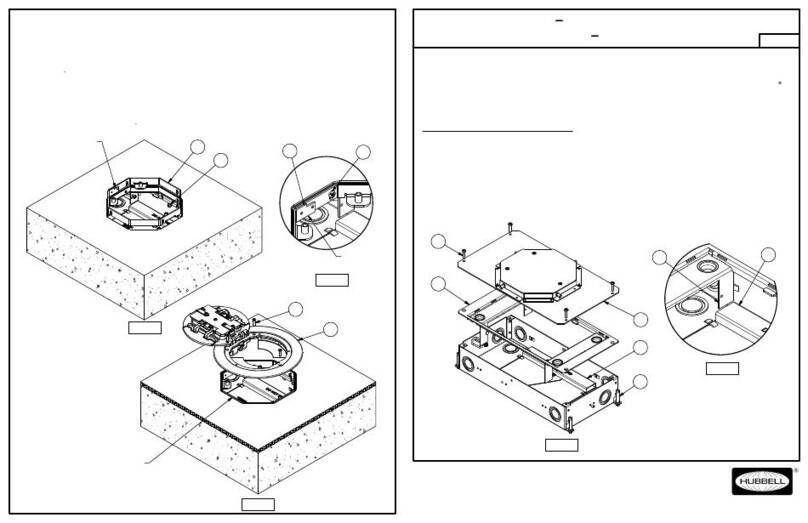

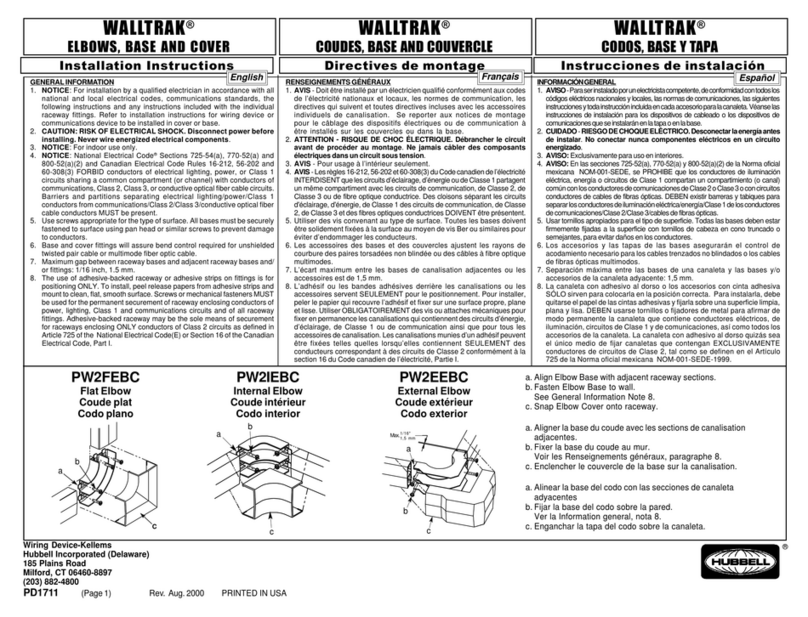

2. Using a pen or a small screwdriver, select the proper load

range by pressing the appropriate rocker switch to the left

as shown in the Fig. 1 example above.

CAUTION: Only one rocker must be selected.

3. With a small screwdriver, turn the Lamp Sense Adjust

potentiometer fully clockwise.

4. Press the unit test switch once. The emergency lamps will

illuminate and a 1 minute self-test will begin. The green

"Operating Status" LED on the unit's Spectron control panel

will also begin to ash. The "Lamp Fail" LED located on

the charger/distribution board (see Fig.1) should not be

illuminated at this time. If "Lamp Fail" LED is illuminated,

select the next lower load range. Example: If load range "4"

was selected, select load range "3".

5. Slowly turn the "Lamp Sense Adjust" potentiometer

counterclockwise until the "Lamp Fail" LED on the

charger/distribution board illuminates. Then turn the

adjustment pot back clockwise just slightly beyond the

point where the "Lamp Fail" LED turns off to avoid false

failure indications. At this point, the red "Service Alert" LED

on the unit's Spectron control panel will begin a repetitive

cycle of ashing 5 times followed by a pause ("lamp fault"

service alert).

6. While the self-test is still in progress, disconnect one of the

emergency lamp wires from the charger/distribution board.

The "Lamp Fail" LED on the charger/distribution board

should turn on. Reconnect the lamp wire and observe that

the "Lamp Fail" LED goes out. If "Lamp Fail" LED remains

illuminated, turn the "Lamp Sense Adjust" potentiometer

fully clockwise and repeat step 5.

1234

OPEN

Lamp Fail LED

Lamp Sense Adjust

Potentiometer

Example:

Press here to select load

"RANGE" switch setting "1".

*

Fig. 1 Charger Distribution Board

Spectron®

Self-Diagnostic Electronics Option

Hubbell Lighting, Inc. Life Safety Products • www.dual-lite.com

Copyright© Hubbell Lighting, Inc., All Rights Reserved • Specications subject to change without notice. • Printed in U.S.A. 0601570 E 9/08