Overspeed Governor

OL20

Operating instructions

Subject to change without notice! © Copyright WITTUR 2016

Content Page

Sheet PM.7.005825.EN.02

Version -

Date 27.05.2021

Approved WAT/KKR

1. General information prior to installation

1.1 Description and functions........................................................................................................ 4

1.2 Liability and guarantee ............................................................................................................ 5

1.3 Safety precautions .................................................................................................................. 5

1.4 Preparation ............................................................................................................................. 6

1.5 Advices for the work on safety components.............................................................................. 6

1.6 Scope of supply ...................................................................................................................... 7

2. Name plate, designation, identification

3. Mechanical installation and adjustment

3.1 General................................................................................................................................... 9

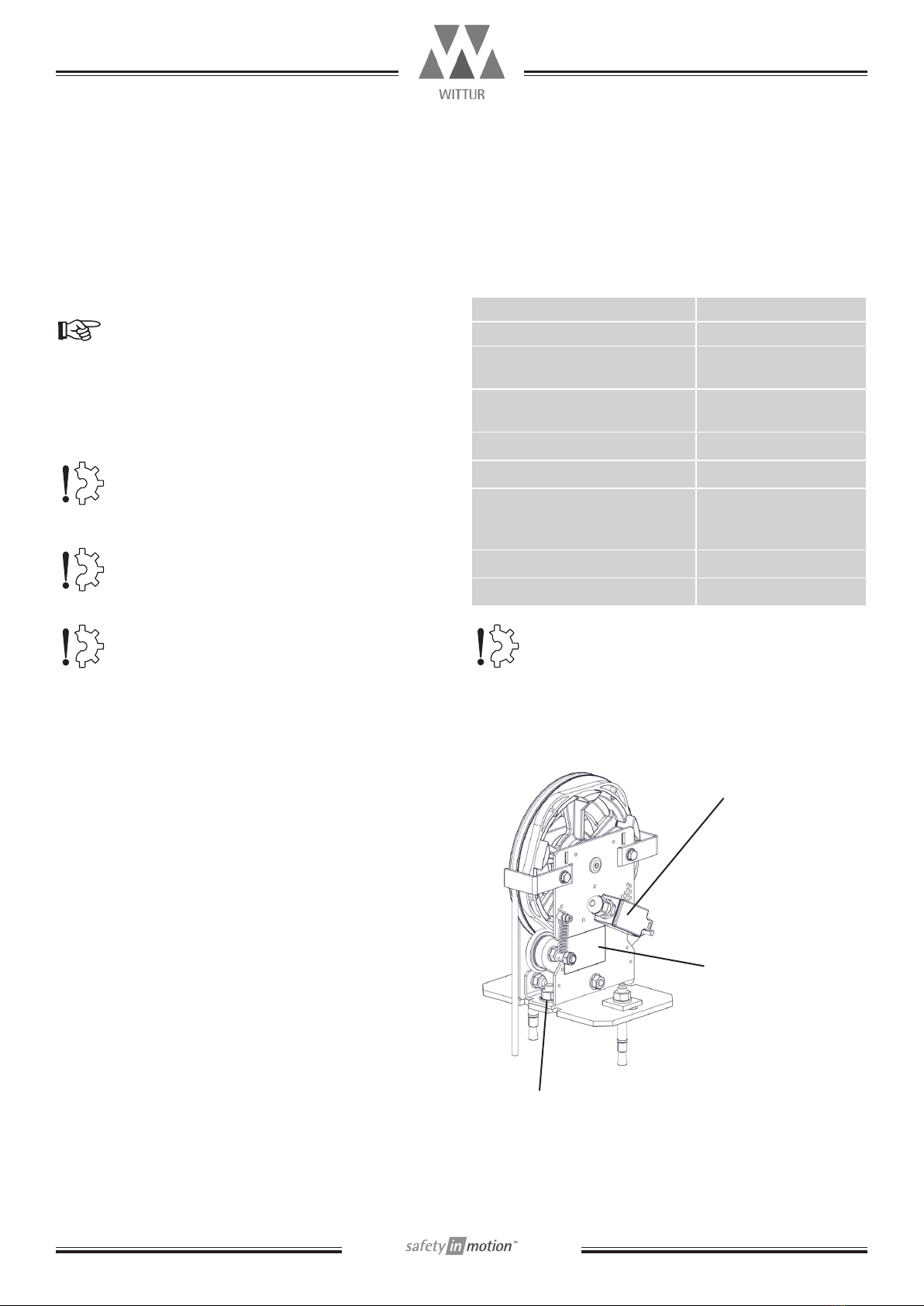

3.1.1 Handling of the OL20............................................................................................................... 9

3.1.2 Permissible Forces.................................................................................................................. 9

3.1.3 Fixing possibilities ................................................................................................................ 10

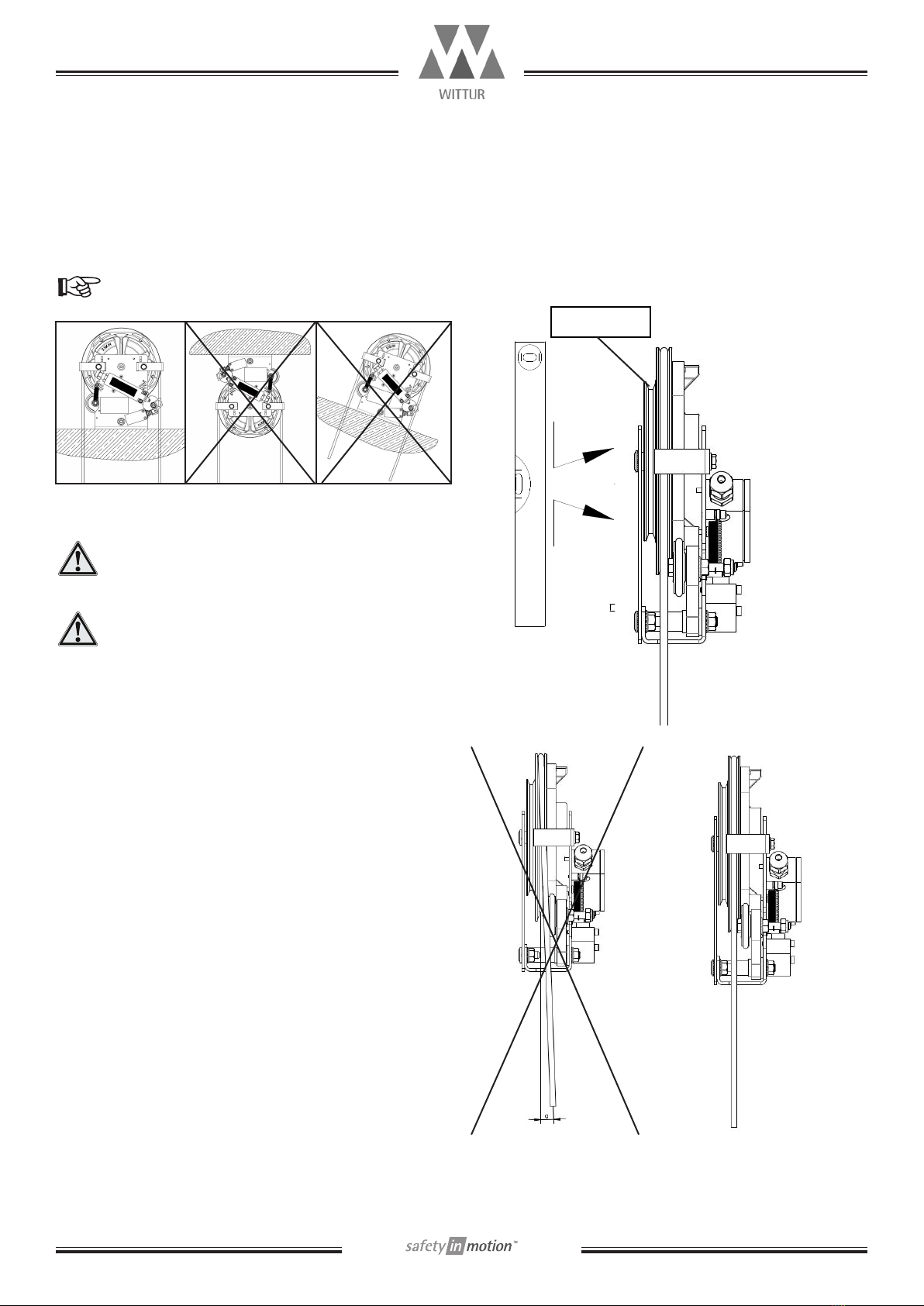

3.1.4 Installation tolerances ........................................................................................................... 10

3.1.5 Installation ........................................................................................................................... 10

3.2 Installing the overspeed governor........................................................................................... 11

3.2.1 Prior to installation................................................................................................................ 11

3.2.2 Installing in the machine room .............................................................................................. 12

3.2.3 Shaft head installation........................................................................................................... 13

3.3 Roping of the overspeed governor .......................................................................................... 14

3.4 Variants of OL20 overspeed governor arrangements ............................................................... 14

3.5 Electrical installation and adjustment..................................................................................... 15

3.5.1 Overspeed contact ................................................................................................................ 15

3.5.2 remote control ...................................................................................................................... 16

3.6 Attaching the safety cover ..................................................................................................... 16

4. Function testing

4.1 Static function test:............................................................................................................... 18

4.1.1 Overspeed governor with manual tripping: .............................................................................. 18

4.1.2 Overspeed governor with remote control:................................................................................ 18

4.2 Dynamic function test............................................................................................................ 19

4.2.1 Check of the electrical tripping:.............................................................................................. 19

4.2.2 Check of mechanical tripping................................................................................................. 19

4.2.3 Check of tripping speed (CS / TS):.......................................................................................... 19

4.3 Tripping speed adjustment..................................................................................................... 20

5. Maintenance, inspection and repair

5.1 Maintenance and inspection .................................................................................................. 21

5.2 Mandatory checks/tests and periods...................................................................................... 21

5.3 Inspection checks ................................................................................................................. 22