Meanwell DDR-240 Series User manual

www.procontechnology.com.au

1

Phone: (0

3

)

98306288

MEAN WELL DC-DC CONVERTER USER MANUAL

1. INPUT

1.1 INPUT VOLTAGE

DC to DC converters are widely used all over the world. Many types of products are available for both high and low DC voltage

input. Before using any DC-DC converter, ensure that the output voltage and current is suitable for the intended load. Verify the

correct input connections, particularly the polarity, and any other conditions that might affect the unit's operation.

If an input voltage is applied which is different from the converter's rating, the unit may be damaged. Also remember that if the

input voltage is not pure DC, the device may not operate normally. Only the Meanwell SD-100D and SD-150D, type D input

converters allow an AC input (85~132VAC).

For all Mean Well Models refer to the label on the converter for the input voltage range.

1.2 INPUT CURRENT

The essential difference between an AC to DC power supply and a DC to DC converter is not just that the DC-DC converter

generally uses lower input voltages but that it does not require rectification of AC to DC nor does it require AC power factor

correction circuitry. Standard DC to DC converters simply filter the Direct Current (DC) input which then charges a smoothing

or filtering capacitor. The input current required is determined by the output power, input voltage and efficiency. The simplest

input stage with reverse polarity fuse protection is shown below:

Fig. 2

Not all Meanwell DC-DC converters have reverse polarity input protection. The simplest form of protection is a fuse and a

diode; if necessary the user may provide these components externally. The latest Meanwell high-wattage DC-DC converters

(RSD and DDR series) use a MOSFET circuit that tolerates accidental polarity reversal without damaging the unit.

Also not all DC-DC converters have sufficient EMI (Electromagnetic Interference) filtering and may require external filtering

of the input to meet regulatory requirements. Please refer to the data sheet.

1.3 INRUSH CURRENT

When power is applied, a large current flows to charge the input smoothing or filter capacitor. This current is called the "inrush

current". The value of the inrush current varies according to the size of the smoothing capacitor and the presence or absence of

the inrush current protection devices. The inrush current is many times larger than the normal input current. The more DC-DC

converters used in the same system, the larger the inrush current. Please ensure that fuses, switches, and other parts connected to

the input supply side are appropriately selected. Also, when powering DC-DC converters from other DC sources you will need

to allow for this inrush current and make allowance for the switch-on sequence of multiple converters.

If the converter's fuse is blown, do not replace the fuse and operate the unit before rectifying the problem that caused it to fail –

otherwise further damage may occur! Always replace the fuse with the same rated type. Always remove power to the unit and

discharge the input smoothing capacitor before attempting to replace the fuse.

www.procontechnology.com.au

2

Phone: (0

3

)

98306288

2. OUTPUT

2.1 MAXIMUM OUTPUT POWER

Maximum power output (Pout) is defined as: Pout = Vout x Iout

Where Vout is the output voltage and Iout is the output current. Some DC-DC converters allow Vout to be adjusted. However,

Pout must remain constant. Therefore, if Vout is increased, the maximum Iout must be decreased.

E.g. The DDR-120B-12 converter has an output voltage of 12 volts and an output current of 10 amps. The maximum continuous

power output is 120 watts. The adjustable voltage range is 9 volts to 14 volts. If the output voltage is adjusted to 13.8 volts, the

maximum continuous output current can be calculated by:

Iout = Pout / Vout

i.e. Iout = 120 watts / 13.8 volts = 8.7 amps.

The output voltage can also be adjusted lower than 12 volts. However, due to the design of the output circuit, exceeding the 10

amp maximum output is not recommended as over current protection may activate.

2.2 OVERCURRENT PROTECTION (OCP) / OVERLOAD PROTECTION (OLP)

Most Mean Well DC-DC converters are equipped with protection circuits that automatically operate when the output current or

output power exceeds a minimum of 105-110% of the rating. Some Meanwell module types do not provide continuous overload

or short-circuit protection, in this case the maximum current output should not be exceeded or damage to the device can result.

Types of Protection:

a. Foldback Current Limiting:

The Foldback Current Limiting circuit is designed to linearly decrease both the voltage and current to a level that will prevent

the unit from being damaged during overcurrent/overload conditions. See curve "a" in Fig. 4.

b. Constant Current Limiting:

Constant Current Limiting allows the output current to remain stable, but reduces the output voltage to a level that permits the

safe operation of the unit. Constant Current Limiting is preferred when charging batteries and when driving devices such as

motors, incandescent lamps and highly capacitive loads which have a high initial current. See curve "b" in Fig. 4.

c. Constant Power Limiting:

Constant Power Limiting linearly reduces the output voltage and simultaneously allows the output current to increase. See curve

"c" in Fig. 4.

d. Hiccup Current Limiting:

When overloaded, the output voltage and current will be shut down for a short period of time and then automatically attempt to

periodically recover again (hi-cup) until the fault condition is removed. In some DC-DC converters the output voltage is shut

down permanently*, reducing the output voltage and current to zero. A manual recovery is then necessary. In some cases a DC-

DC converter will operate in constant current mode and then shut down after a time delay of 5 seconds. *It is possible, with

some SD Series units, to modify the DC-DC converter to provide a continuous constant current output rather than shutting

down the unit. Please ask Procon Technology for information.

Fig. 4

www.procontechnology.com.au

3

Phone: (0

3

)

98306288

Recovery Circuits

a. Automatic Recovery

Automatic Recovery senses the removal of the fault condition and returns the unit to normal operation.

b. Manual Recovery

Before proceeding with Manual Recovery, make sure that the fault condition is removed. Manual Recovery requires cycling the

input power off and on.

Overcurrent /Overload Precautions

Protection and Recovery circuits are designed to prevent damage to the device during an Overcurrent or Overload condition.

However, leaving a device overloaded (or shorted) for extensive periods of time is NOT recommended and may result in

reduced life and/or damage to the DC-DC converter.

2.3 OVER TEMPERATURE PROTECTION (OTP)

Some DC-DC converters have an excessive temperature shut down circuit. When the unit's operating temperature is too high,

the protection circuit will shut down the output. Some common causes of excessive temperature are Overcurrent/Overload, high

ambient temperature or restricted ventilation (e.g. faulty cooling fan). Automatic or manual recovery can occur once the cause

of the over temperature condition is removed (high ambient temperature and/or high load).

2.4 OVER VOLTAGE PROTECTION (OVP)

When the output voltage exceeds the rated value by approximately 130%, the unit will be protected by the following three

possible methods to prevent damage to the components at the load terminals:

a. Shut down the output voltage. Reset the DC-DC converter by turning it OFF for several seconds and then back ON again.

b. Hiccup mode. The output will shut down for a few seconds and then attempt to restart automatically.

Over Voltage Protection may be triggered by a fault within the converter, most commonly by setting the output voltage trim pot

too high (especially when switching inductive loads) or it can occur when an external voltage is applied to the output. Using an

external voltage applied to the output terminals, provides a simple means of testing the over voltage threshold of a DC-DC

converter. Note, excessive voltage or reverse polarity voltages applied to the output can damage a DC-DC converter!

There are three kinds of Over Voltage Protection:

a. Disabling the control circuit controlling the feedback loop shutting down the unit.

b. Shorting the output by using a "Crowbar" activating the unit's overcurrent/overload protection.

c. Clamping the output voltage by using a zener diode.

Fig. 5

www.procontechnology.com.au

4

Phone: (0

3

)

98306288

3. INSTALLATION, WIRING AND OPERATION

Even the most efficient switched mode DC-DC converter will not function properly if the installation, wiring or connections are

incorrect. Follow the installation, wiring and connection instructions specified in the data sheet or manual before switching on

any unit. Also see the document 'Power Supply Cables and Connectors' (Meanwell_Connect_Safety.pdf).

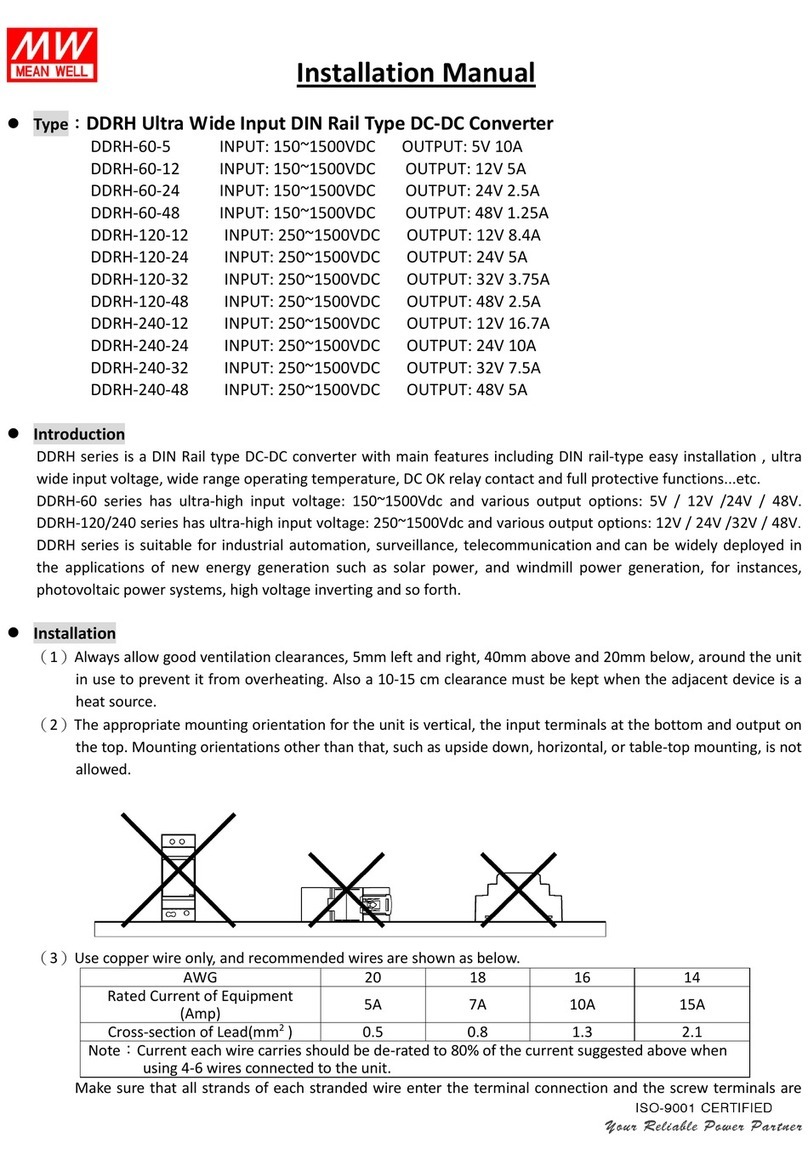

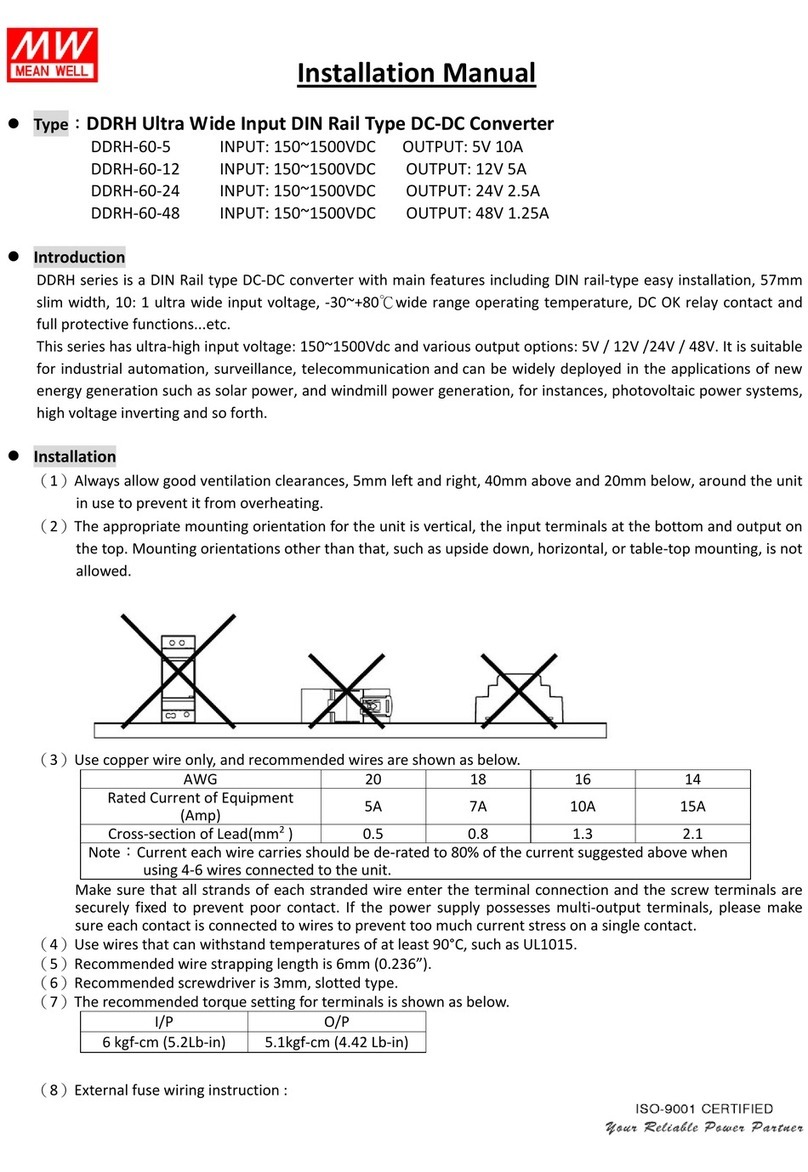

3.1 INSTALLATION

Heat Dissipation

a. Ensure the unit is properly ventilated.

b. Install the unit in the correct position. Remember 'hot air rises' and ensure correct orientation.

c. Ensure the unit has proper heat conduction and is not mounted near other heat sources.

d. When you install two or more units, leave additional space between them for cooling.

e. Forcing air over the unit will improve heat dissipation.

Fig. 6

When mounting any device please refer to any notes and temperature derating curves in the specifications. For example with

DIN rail converters, the minimum installation clearances are: 40mm on top, 20mm on the bottom, 5mm on the left and right

sides unless the adjacent device is also a heat source then 10-15mm clearances are recommended.

Output Derating

Output power depends on operating temperature. Derate the output of the DC-DC converter according to the temperature

derating curve shown in the specifications. The Railway DC-DC converter series (RSD) when mounted on an iron plate of

sufficient size allows for the elimination of any derating up to its' maximum operating temperature of 70°C. Note the output

power may also need to be derated with low input voltages. Specifications cannot be guaranteed when under-voltage. Some

units will shut down on under-voltage.

Fig. 7

Securing Screws

Always check the specified screw length and tightening torque when attaching to your equipment enclosure.

Fig. 8

See the mechanical

specifications in the data

sheet. Length L=? is in

millimetres.

www.procontechnology.com.au

5

Phone: (0

3

)

98306288

3.2 WIRING AND OPERATION

Input and output wiring

a. Separate the input and output wires so that any external surge voltage and/or ripple on the input lines does not interfere with

the output side. This will also insure that the output ripple and noise does not increase.

b. Use short, thick wires on the output. Wire thickness will also depend on the current capacity required.

c. When connecting wires to the unit, use the appropriate terminal screws, solder-less terminals and tools.

d. Be careful to prevent wire off-cuts or other objects entering the unit. It is recommended that the converter not be mounted

until all work has been completed or the vents are covered until the converter is ready to be operated.

Fig. 9

Ground connection

Connect the ground terminal of the DC-DC converter to the frame of the equipment with regulation size and colour wire to

ensure safety and to minimize noise and interference.

Fig. 10

Inrush Current Control

Mean Well DC-DC converters have large capacitors incorporated in the input supply circuit. Consequently, there is a high

inrush current when input power is applied (see the unit's data sheet). When using several units in a single system, do NOT

apply power to all of them simultaneously. Note: ten SD-100D units could theoretically draw a peak inrush current of 180A at

96VDC. A preferred power application would be a "delayed power circuit" as in Fig. 11.

Fig. 11

www.procontechnology.com.au

6

Phone: (0

3

)

98306288

Remote Control and Remote Voltage Sensing

a. Remote Control of the Output

The output of some DC-DC converters can be controlled by supplying an appropriate signal to the RC terminal. Normally an

open-circuit (>4 volts) will turn the output on and a short (< 0.8 volts) will turn the output off. With the SD-500 and SD-1000

units an externally applied voltage is required to turn off the output. The SD-1000 provides a 12V auxiliary output for this

purpose. You should always refer to the data sheet for all Remote ON/OFF controlled converters. See Fig 12.

b. Remote Voltage Sensing

DC-DC Converters equipped with a Remote Voltage Sense capability (SD-500 and SD-1000) can detect a voltage drop at the

load. This feature is especially useful when the unit and the load are connected by long cables. With Remote Sensing capability,

+S (or +RS) and –S (or –RS) terminals are provided (as shown in Fig. 12). When the +S and –S terminals are connected to the

load side of the output, the unit will be able to detect any voltage drop at the load. The unit will raise the output until the correct

voltage is provided at the load terminals. Remote sensing compensates for voltage drops of up to 0.5V.

Fig. 12

Operation in Parallel

Power supplies are commonly used in parallel to increase the output current. Mean Well's DDR-240 and DDR-480 series are

designed for parallel use. These power supplies have "P+" and "P–" terminals that sense other power supplies connected in

parallel. This circuit controls the output voltage and allows a more efficient operation of each supply – sharing the load current

equally.

Fig. 13

Notes on parallel operation:

a. Always use the same model type and voltage in any parallel configuration.

b. The output voltage of each unit should be the same (within 0.2V).

c. Each converter's output should be wired together with short and thick wiring first and then connected to the load.

d. The total output current should not exceed 90% of the total current for all power supplies.

e. Always check the specifications for the required connections, restrictions on the number of parallel units that can be used,

minimum load requirements and connecting the sense terminals (+S and –S) or other features (e.g. remote control).

www.procontechnology.com.au

7

Phone: (0

3

)

98306288

Fig. 14

Figure 14 illustrates a method of paralleling DC-DC converters for redundant use - increasing the reliability of a system. Diodes

are connected to the positive side of each unit's output. This connection is only for use in redundant systems, where the

maximum current requirement can be handled by one unit alone, and allows the system to continue to operate even when one

unit fails. Also see the Meanwell DRDN20 for 20A and the DRDN40 for 40A applications. These modules provide a DC OK

indication and alarm relay contacts.

Operation in Series

DC-DC converters are often connected in series to produce higher voltages. Two types of series connections are described

below. For series operation all DC-DC converters require 'floating' or isolated outputs!

a. Fig. 15 describes a sample setup for separate distinctive loads. Protective diodes (D1 and D2 below) may be necessary with

this type of application to protect the units if connection X is lost.

Fig. 15

b. Fig. 16 illustrates a sample setup for series connected DC-DC converters. The diode, connected directly across the output

terminals, is also recommended in any application where a reverse voltage may be applied to the unit's output. As a general

guide, the diodes should be Schottsky Barrier with a reverse voltage more than twice the output voltage and rated output current

more than twice the rated output current or short-circuit current whichever is greater.

Fig. 16

www.procontechnology.com.au

8

Phone: (0

3

)

98306288

Additional Output Ripple and Noise Control

Fig. 17 is a diagram of a sample circuit that will improve the output ripple, noise, and Electromagnetic Interference (EMI) or

Common Mode Noise. Fig. 17 is an example circuit only. Further design considerations are essential for specific applications.

Fig. 17

Note: C1 & C3 are electrolytic capacitors and control the output ripple. Their values should be between 47uf and 100uf. C2, C4

& C5, C6 are high frequency ceramic capacitors and reduce the output noise. Their values range from 0.01uf and 0.1uf. The

value of inductance L1 is 0.5uH to 5uH.

Surge Voltage Control

Fig.18 shows a circuit used to control voltage surges that may be caused by power fluctuations or stray surges due to lightning.

The circuit has varistors connected between +Vin & –Vin, +Vin & FG, and –Vin & FG. This type of circuit is the minimum

recommended in areas where there are frequent lightning strikes.

Fig. 18

www.procontechnology.com.au

9

Phone: (0

3

)

98306288

4. SAFETY

Generally speaking, Meanwell DC-DC converters are manufactured to produce an isolated stabilized DC supply. Converters

with high voltages (greater than 60VDC) must not be used until incorporated into a suitable enclosure as required by local laws

and regulations. Please consult the relevant authority.

Electric Shock

High voltages may be present inside the converter. Do NOT attempt to repair the unit or remove the cover. If the unit needs

service or repair return it to Mean Well or an authorized Mean Well repair centre. When the unit is installed in a system, be sure

that the case is properly grounded. Some units are 'Open Frame' and supplied without a case. Use extreme caution when

touching or removing these units for repair. Appropriate safety equipment and procedures must be used when touching or

removing the units where high voltages are present.

High Operating Temperatures

When the unit is operating at high output or is faulty, internal component temperatures may exceed 100ºC. Do NOT touch any

components inside the case. The external case temperature may also be at a point where it is unsafe to touch.

Keep all flammable, explosive, and volatile materials away from any DC-DC converter.

Rated Input Voltage

The input voltage of the DC-DC converter, by design, is limited. It can be dangerous to apply voltage which is outside of the

specified range, damage may occur to the unit. Always operate it within its specified input voltage range. Always check the

polarity of the input voltage before applying power.

Leakage Current

The internal noise filter capacitors generate a leakage current within the range specified by international safety standards.

However, if two or more units are used, the leakage current increases and electrical shock may occur. Take measures such as

securely grounding the unit, to prevent electric shock.

Wiring Materials

To prevent wiring materials from heating up or igniting, use the correct gauge of wire which can withstand the output current

capacity of the unit. Also, check the rated voltage of any wire used.

Shared Usage

It is particularly important to be careful when the current is diverted for use by a low current load. If a thin wire is used as a

branch line, the overcurrent/overload protection circuit may not work if the load is short-circuit. To ensure safety, attach a

suitably rated fuse, circuit-breaker or other protection device (resettable fuse or polyswitch) to the low-current wire as shown in

Fig. 19. Remember, overloading of circuits beyond their capacity causes overheating of cables and conductors, and can result in

direct fire hazards or, more often, in damage to insulation with the development of arcing or sparking.

Fig. 19

www.procontechnology.com.au

10

Phone: (0

3

)

98306288

Connection Cable Material

The tables below contain a selection of UL approved connection wire. These tables should be reviewed when selecting cable for

the input and output sides of the DC-DC converter.

Ground Wire

Connect the grounding terminal of the unit to the frame of the equipment with a short, thick wire.

Note: For DC-DC converters integrated into other equipment, safety standards differ from country to country. Check the

standards (specifications) listed in documents provided by your supplier or relevant government agency when you use a

converter inside your own equipment.

www.procontechnology.com.au

11

Phone: (0

3

)

98306288

5. EMI

DC-DC converters are manufactured to comply with electro-magnetic interference (EMI) standards (refer to relevant

specification). Depending on the wiring of the unit, load and grounding, the unit may not function correctly. To ensure optimal

use of the DC-DC converter, consider the following steps:

a. Separate Input and Output Wires

If the input and output wires are too close to each other, induced noise on the output terminal increases. Typically, if the noise

terminal voltage of the input line increases, noise radiation (noise field intensity) from the equipment increases. Also, if the

input line and the internal circuits (digital circuits, in particular) of the equipment are too close to each other, the noise terminal

voltage increases and the equipment may not operate properly. Make sure that the input cables are separated from any low

voltage internal circuits of the equipment.

b. Short, Thick Wires

Input and output wires on the equipment should be short and thick. Each set of two wires should either be attached or bundled

in parallel or twisted together. If wires are looped, the noise and interference from the DC-DC converter will be affected.

6. RELIABILITY

6.1 LIFE CYCLE AND BREAKDOWN

DC-DC converters have proven to be highly reliable when used in household appliances and industrial products and are highly

rated throughout industry.

The following figure shows the failure rate curve (bathtub curve) during a typical product life cycle.

The Early Failure Period - to prevent early failure, each manufacturer screens out parts or performs aging tests on the finished

product. When Mean Well DC-DC converters are delivered to customers, the power supplies have already entered the random

failure period.

Random Failure Period - the stability of each DC-DC converters depends on its own reliability (Mean Time Between Failure:

MTBF).

Basically, the failure rate is very low. However, the failure rate in the random failure period differs depending on installation

and operating conditions (ambient temperature, installation method, derating, ventilation, vibration and shock) which are

determined by the user.

Fatigue Failure Period - At some time, the DC-DC converters will enter the fatigue failure period.

Fig. 20

6.2 AMBIENT TEMPERATURE AND SERVICE LIFE

High efficiency switching at a high frequency, improvement in parts and integrated technology has greatly reduced the size of

DC-DC converters. Integration density has allowed the internal parts to be packed closer together.

Each part of a DC-DC converters distinctly differs in its service life depending on the ambient temperature.

www.procontechnology.com.au

12

Phone: (0

3

)

98306288

An electrolytic capacitor, used as a smoothing filter, is more sensitive to variations in the ambient temperature because of the

chemical reactions which occur within it.

Typically, the service life of electrolytic capacitors halves for every ambient temperature increase of 10ºC. This characteristic

determines the service life of most DC-DC converters.

Fig. 21 shows the relationship between the service life of the DC-DC converter and ambient temperature. If the DC-DC

converter is used at high temperatures, the electrolytic capacitor may enter the fatigue failure period while the other parts are

still in the random failure period. To increase the service life of the DC-DC converter, it may be necessary to replace some

electrolytic capacitors.

Fig. 21

6.3 OVERHAUL

As technology improves, the number of continuous operating systems increases. And though the service life of DC-DC

converters is also increasing, they cannot be relied upon forever.

Therefore, periodic overhauls are required to ensure the reliability of any equipment. How often an overhaul needs to be

performed on a unit depends on the operating conditions and temperature. Service life is most seriously affected when a unit is

operated continuously. In this case, the frequency of overhauls to the DC-DC converter should be as follows:

Ta is between 40ºC and 45ºC - once every three years

Ta is between 35ºC and 40ºC - once every four years

Ta is between 30ºC and 35ºC - once every five years

Where: Ta indicates the ambient temperature of the DC-DC converter.

The above temperature values may differ depending on the type of DC-DC converter used. For more details on overhauls and

service life, contact the manufacturer.

6.4 LOAD CAPACITY AND AMBIENT TEMPERATURE

A DC-DC converter's operating temperature depends on input voltage, output load, ambient temperature, and cooling. The most

ideal way to increase the service life of a converter is to NOT continuously operate it at full capacity. This becomes even more

critical in warmer climates or conditions.

Example: Two identical DC-DC converters (subjected to the same environmental conditions) were operated using different

loads. One had a 40% load condition and the other had an 80% load condition. The test showed that the unit with the 40% load

lasted four times longer that the unit with the 80% load condition.

Every new model of the Mean Well DC-DC converter range is subjected to an environmental test during the prototype phase.

Fig. 22 on the next page shows how temperature probes are connected to the unit. Figures 23 and 24 show the typical rise in

temperature for each of the temperature probes with increasing load for two different models.

www.procontechnology.com.au

13

Phone: (0

3

)

98306288

Fig. 22

Fig. 23 Fig. 24

Where: TA: Temperature inside chamber

TA1: Temperature inside unit

TPC: Temperature of unit case

TCAP: Temperature of output capacitor

IMPORTANT NOTE

This summary of information is provided by Procon Technology and is largely from the Mean Well Switching

Power Supply Technical Manual (September, 2003). Any circuit diagrams or assembly diagrams provided herein

are for reference purposes only. It is provided in good faith but without any warranty or guarantee as to fitness to

purpose. It is solely left to the discretion of the user as to the suitability of this information for their application.

We strongly advise all customers to contact us for advice on the most suitable

DC-DC converter

for their needs. It is

especially important that the correct

DC-DC converter

is used, and protective circuits are installed, when driving

heavily inductive or capacitive loads including motors, DC to DC converters and other loads with high inrush

current such as lamps. Please follow all instructions regarding units in parallel or series or used for charging

batteries.

Please contact Procon Technology for a CD-ROM copy of the complete 110 page Switching Power Supply

Technical Manual and for all your industrial, LED lighting power supply, charger, DC-DC converter and DC-AC

inverter needs. Procon Technology can also supply desk-top power supplies suitable for test and research purposes.

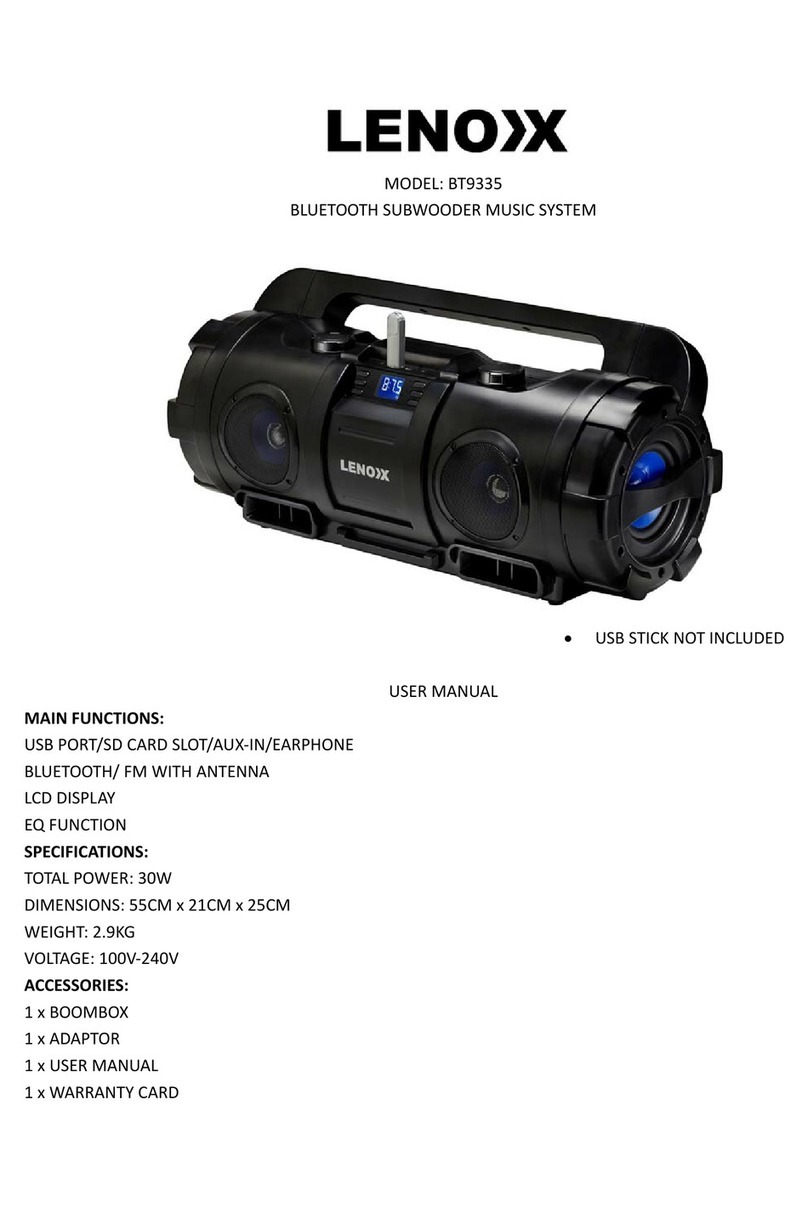

This manual suits for next models

2

Table of contents

Other Meanwell Media Converter manuals

Popular Media Converter manuals by other brands

HDCVT TECHNOLOGY

HDCVT TECHNOLOGY HDV-331 user manual

RDS

RDS P132 Quick installation guide

Linnenberg

Linnenberg SATIE owner's manual

ELGO Electronic

ELGO Electronic EMAX-RO Series Operation manual

Patton electronics

Patton electronics 2300M user manual

Lynn Electronics

Lynn Electronics TEC MC-1500 Quick installation guide