Sambo SB series bevel gear operator

2.3

Storage

Procedure

NOTE:

The following

is

the recommended storage procedure

to

retain maximum product integrity during storage. Failure

to

comply

with

recommended procedure

will

void the

warranty.

Storage (less than one

year)

Store the gearboxes on wooden skids

to

protect the machined mounting flange. Placethe wooden skids containing the gearboxes

in

aclean,

dry,

protected warehouse.

If

the gearboxes must be stored outside, they must be covered in polyethylene protection with silica gel crystals

toabsorb

moisture.

If

an electric actuator

is

attached

to

the V gearbox, refer

to

the storage procedures in

its

respective manual

for

appropriate storage

proce-

dures. Rotate input shafts every three months

to

mix the

lubricant.

2.4 Safety

Precautions

c

WARNING:

Read this Installation, Operation and Maintenance manual carefully and completely before attempting

to

install, operate or

trouble-

shoot the SAMBO

gearbox.

c

WARNING:

Potential HIGH-PRESSURE vessel

—

be aware

of

high-pressure hazards associated with the attached valve

or

other actuated

de-

vice when installing or performing maintenance on the gearbox. Do not remove the gearbox mounting bolts from the valve or actuated

device

unless the valve or device stem

is

securedor there

is

no pressure in the

line.

c

WARNING:

For maintenance and/or disassembly

of

the gearbox while installed on the valve, ensure that the gearbox

is

not under thrust

or

torque load.

If

the valve must be left in service, the valve stem must be locked in such away as

to

prevent any movement

of

the valve

stem.

c

WARNING:

Do not manually operate the gearbox with devices other than the installed handwheel. Using force beyond the ratings

of

the gearbox

and/or using additive force devices such as cheater bars, wheel wrenches, pipe wrenches, or other devices on the gearbox handwheel

may

cause serious personal injury and/or damage

to

the gearbox and

valve.

c

WARNING:

Do not exceed any design limitations

or

make modifications

to

this equipment without first consulting

Mechanical Advantage

c

WARNING:

Use

of

this product must besuspendedanytime

it

fails

to

operate

properly.

a

CAUTION:

If

a motor actuator

is

driving the gearbox, do not operate the valve under motor operation without first checking and setting

the limit

switch and checking for correct motor rotation.

a

CAUTION:

Do not use replacement parts that are not genuine SAMBO parts, as serious personal injury and/or damage

tothe

gearbox and valve may

result.

2.5

Safety

Practices

Thefollowing checkpoints should be performed

to

maintain safe operation

of

the SAMBO

gearbox:

•

Set up a periodic operating schedule on infrequently used

valves.

•

Ensure that the limit and/or torque switches on any electric actuator fitted

to

the V gearbox are correctly and appropriately

adjusted.

2.6

General Mounting

Instructions

The mounting instructions

for

the SB bevel gearboxes are outlined

below.

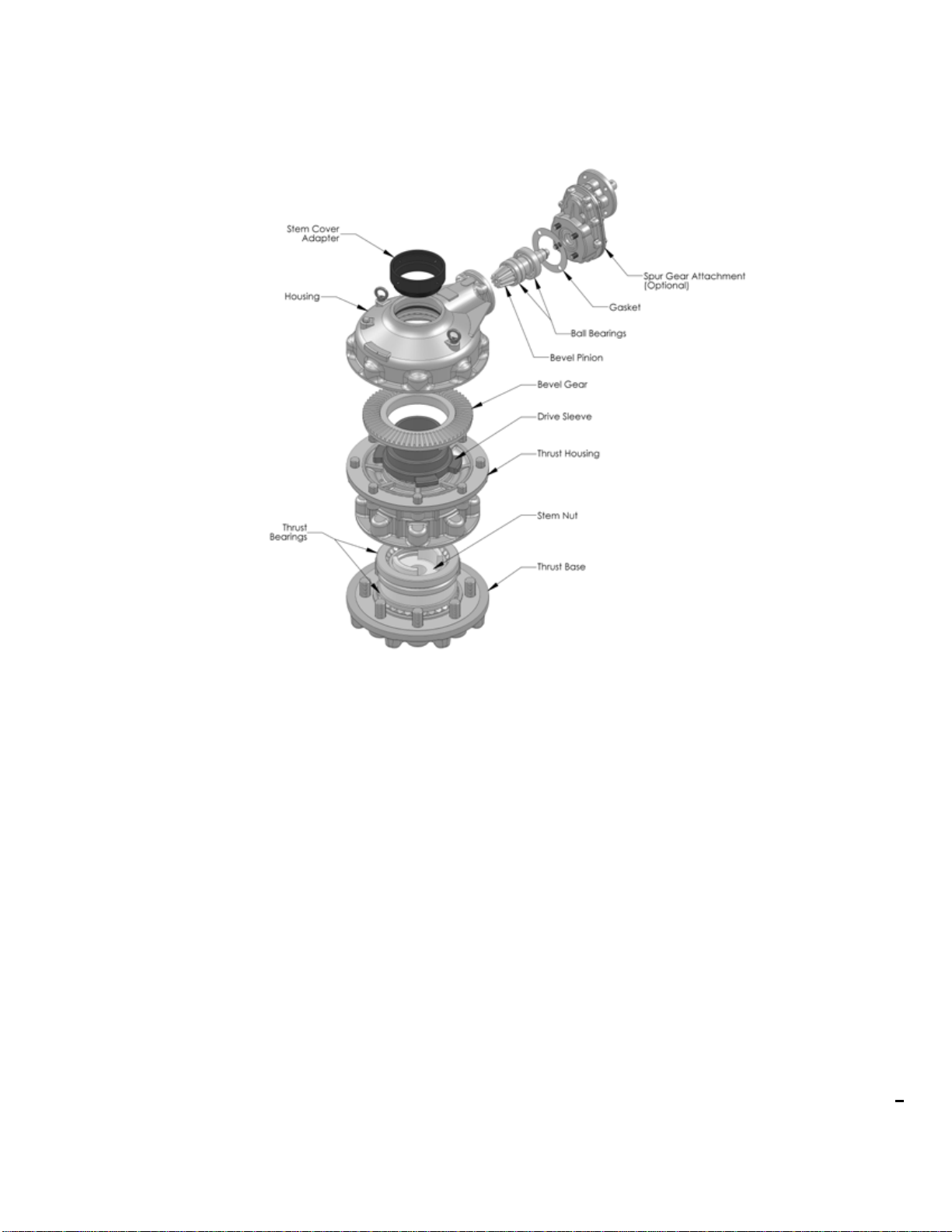

The V0 through V9 gearboxes are designed with a splined top-entry

Stem

Nut which

is

retained in the Drive Sleeve by two Lock

Nuts.

6

The V35H through V9H gearboxes are designed with a Stem Nut which

is

retainedby two Thrust Roller Bearingswithin the Thrust Housing

and

Thrust Base. Partial disassembly

of

the Thrust Base

is

required

for

Stem Nut removal and/or

installation.