HMI with PLC: TPAC1008 02 Mect srl

ME7030_15 06/22

INDEX

1. Introduction ............................................................................................................... 1

1.1. Staff skill.............................................................................................................. 1

1.2. Symbols ............................................................................................................... 1

1.3. Terms................................................................................................................... 1

1.4. Security................................................................................................................ 2

1.5. REFERENCE MANUAL.................................................................................... 2

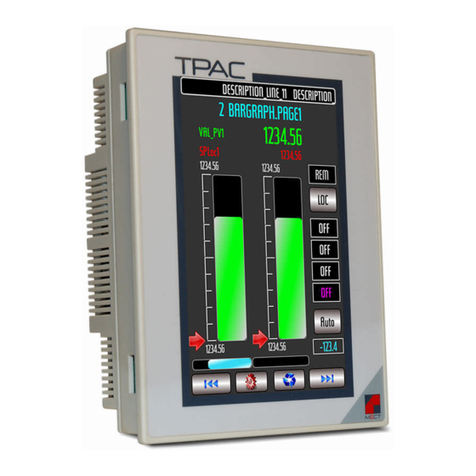

2. System description .................................................................................................... 3

2.1. Specification........................................................................................................ 4

3. Hardware installation ................................................................................................ 6

3.1. Mechanical dimensions ....................................................................................... 6

3.2. Panel mount......................................................................................................... 8

3.2.1. Distance ......................................................................................................... 8

4. TPAC1008 02 wiring ................................................................................................ 9

4.1. Connections......................................................................................................... 9

4.2. Power supply ..................................................................................................... 11

4.2.1. Isolation ....................................................................................................... 11

4.2.2. System power supply................................................................................... 11

4.2.3. Digital output power supply........................................................................ 11

4.2.4. Fuse.............................................................................................................. 11

4.3. Digital input/output wiring...............................................................................12

4.4. Analogue input wiring....................................................................................... 12

4.5. Analogue output wiring..................................................................................... 14

4.6. CanOpen (TPAC1008 02 AA model)...............................................................15

4.7. ModBus wiring (TPAC1008 02 AB model)..................................................... 17

4.8. Analogue outputs wiring (TPAC1008 02 AD/AE/AF models)........................17

4.9. ModBus wiring (on all models)......................................................................... 17

5. Peripherals...............................................................................................................18

5.1. USB....................................................................................................................18

5.2. Ethernet..............................................................................................................19

6. PLC and HMI.......................................................................................................... 19

6.1. System variables................................................................................................ 20

7. How to order............................................................................................................25