MEDC HORN DB3 User manual

© Cooper M

E

DC

2013

Title:

PROCEDURE/

Fax: +44 (0)1773 580282

DOCUMENT NO.

Tel: +44 (0)1773 812249

DB3 TECHNICAL MANUAL

DD036-01-03

Colliery Road,Pinxton, Notts., NG16 6JF U.K.

REV`D

MEDC

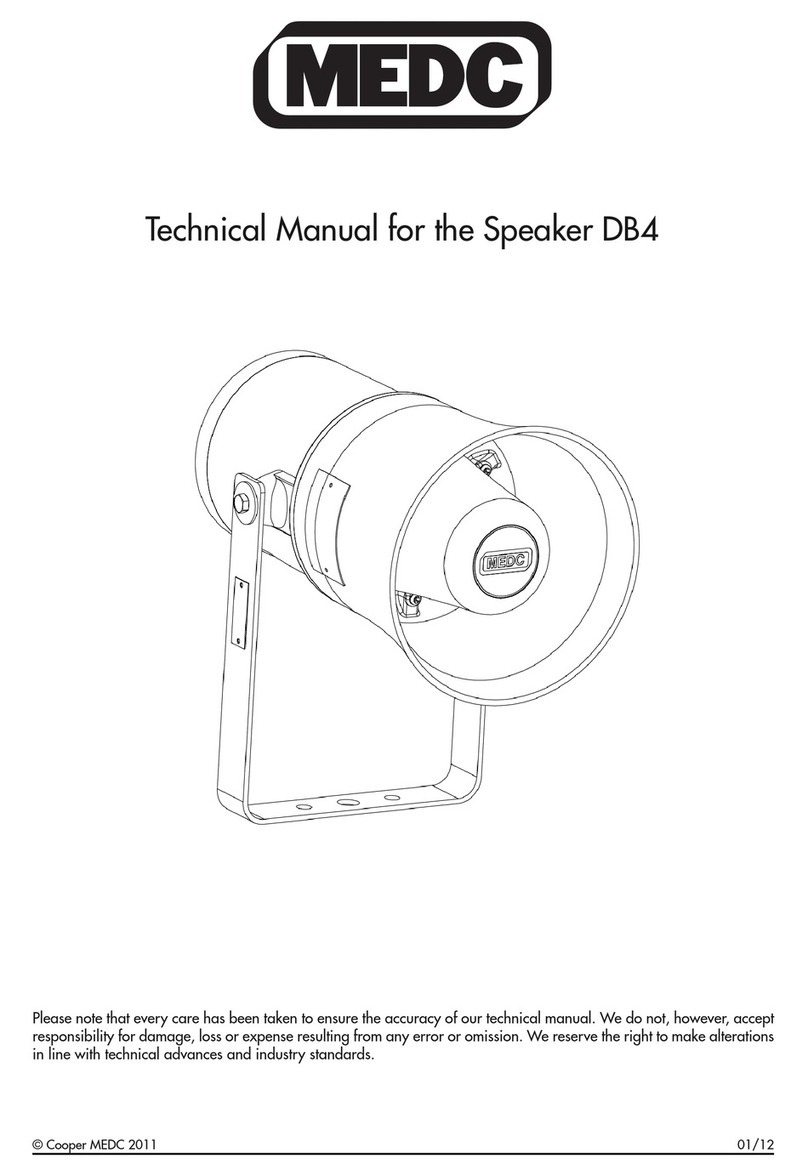

Technical Manual for the Speaker DB3 & DB3L

Please note that every care has been taken to ensure the accuracy of our technical manual. We do not,

however, accept responsibility for damage, loss or expense resulting from any error or omission. We reserve

the right to make alterations in line with technical advances and industry standards.

© Cooper M

E

DC

2013

Title:

PROCEDURE/

Fax: +44 (0)1773 580282

DOCUMENT NO.

Tel: +44 (0)1773 812249

DB3 TECHNICAL MANUAL

DD036-02-03

Colliery Road,Pinxton, Notts., NG16 6JF U.K.

REV`D

MEDC

1.0 INTRODUCTION

This range of light weight all GRP, flameproof sounders is intended for use in potentially explosive gas and

dust atmospheres and has been designed with high ingress protection to cope with the harsh environmental

conditions found offshore and onshore in the oil, gas and petrochemical industries.

The flamepaths, flare and body are manufactured completely from a UV stable glass reinforced polyester.

Stainless steel screws and sinter are incorporated thus ensuring a corrosion free product. A tapered

Flamepath is used to overcome the problems of assembly of parallel spigot flamepaths.

An Optional Exe terminal chamber is available

An uncertified version is available for use in non-explosive atmospheres.

2.0 INSTALLATION

General

When installing and operating explosion-protected equipment, requirements for selection, installation and

operation should be referred to e.g. IEE Wiring Regulations and the ‘National Electrical Code’ in North

America. Additional national and/or local requirements may apply.

Ensure that all nuts, bolts and fixings are secure.

Ensure that only the correct listed or certified stopping plugs are used to blank off unused gland entry points

and that the NEMA/IP rating of the unit is maintained. MEDC recommend the use of a sealing compound

such as HYLOMAR PL32 on the threads of glands and stopping plugs in order to maintain the IP rating of the

unit.

The unit mounts via 2 off 9mm mounting holes in the ‘U’ shaped stirrup / mounting bracket. The holes have

been designed to accept an M8 screw or bolt. If required the unit can be initially placed using the 13mm

central hole in the mounting bracket. The unit can then be rotated into the correct orientation and fixed via the

other two holes.

When the unit is fixed in the required position, its alignment can be adjusted by loosening the two M6 screws

which fasten the mounting bracket to the speaker. The speaker can then be adjusted to the required position

and the screws tightened. The unit should be positioned such that dust/debris or water cannot settle in the re-

entrant horn

MEDC recommend the use of stainless steel screws.

Cable Termination

CAUTION: Before removing the cover assembly, ensure that the power to the unit is isolated.

On Exd versions, the cover is secured with 6 off M5 cover screws (4.0mm A/F hexagon key). Once the cover

fixings are unscrewed, twist the cover assembly gently clockwise and anti-clockwise, whilst pulling it away

from the base. Remove to gain access to the interior.

On Exde versions the removable cover is secured using 2 off M5 cover screws (4.0mm A/F hexagon key).

Once the cover fixings are unscrewed, the cover can be lifted away from the enclosure to gain access to the

interior.

Ensure all non-captive fixings are kept in a safe accessible location during cable termination.

Cable termination should be in accordance with specifications applying to the required application. MEDC

recommends that all cables and cores should be correctly identified. Please refer to the wiring diagram

provided with the product.

Ensure that only the correct listed or certified cable glands are used and that the assembly is shrouded and

correctly earthed.

All cable glands should be of an equivalent NEMA/IP rating to that of the speaker and integrated with the unit

such that this rating is maintained.

The internal earth terminal, where fitted, must be used for the equipment grounding connection and the

© Cooper M

E

DC

2013

Title:

PROCEDURE/

Fax: +44 (0)1773 580282

DOCUMENT NO.

Tel: +44 (0)1773 812249

DB3 TECHNICAL MANUAL

DD036-03-03

Colliery Road,Pinxton, Notts., NG16 6JF U.K.

REV`D

MEDC

external terminal is for a supplementary bonding connection where local codes or authorities permit or require

such a connection.

Once termination is complete, carefully replace the cover assembly back onto the body, avoiding damage to

the mating surfaces. Replace the cover screws into the holes in the cover assembly and tighten evenly.

Ensure the O-ring is seated correctly on the cover during re-assembly. On Exd certified versions, ensure the

required maximum gap of 0.15mm is maintained between the cover and the base once assembled.

Wiring options

The unit is available in six basic configurations:

1. Exd - DC Input, single tone

2. Exde - DC input, single tone

3. Exd - DC input, dual tone

4. Exde - DC input, dual tone

5. Exd - AC input, single tone

6. Exde - AC input, single tone

Types 1 & 2 have 6 terminals labelled as T1 to T6. The supply should be connected to T1 (+ve), T3 (-ve),

loop out on T4 & T6 respectively

Types 3 & 4 have 6 terminals labelled as T1 to T6:

For a 2 wire system, the supply should be connected to T1 (+ve), T2 (-ve), loop out on T4 & T5 respectively

to produce tone 1. Tone2 is produced when the polarity of the supply is reversed T1 (-ve), T2 (+ve), loop out

on T4 & T5 respectively. Optionally an EOL resistor may be connected to T4, T5.

For a 3 wire system, the supply should be connected to T1 (common +ve), T2 (-ve 1) & T3 (-ve 2), loop out

on T4, T5 & T6 respectively. Tone 1 is produced when the supply is connected to T1 (Common +ve) & T2 (-

ve 1). Tone 2 us produced when the supply is connected to T1 (common +ve) & T3 (-ve 2). Optionally an EOL

resistor can be connected to T4, T5 or T4, T6.

Type 5 has 4 terminals labelled as L, L, N, N. The supply should be connected to one L,N pair of terminals,

loop out on the second L,N pair of terminals

Type 6 has 6 terminals labelled as T1 to T6. The supply should be connected to T1 (L), T2 (N), loop out on

T4 & T5 respectively.

3.0 OPERATION

The sounder is available in various AC input voltage versions and a single DC voltage input version.

For AC versions, the nominal operating voltage is stated on the unit label and the supply voltage tolerance is

±10%

For DC versions, the absolute input voltage range is 11.0Vdc to 58.0Vdc

The DC version can be operated as a dual-tone unit (if specified when ordering). The unit can be switched

between the two tones by either:-

a. Reversing the polarity of the supply (2 wire versions)

b. Connecting as a 3 wire common +ve system and switching between the two -ve lines.

Note: - with T1 (+ve), T2 (-ve) tone 1 is produced (as set by DIL switch ‘TONE 1’)

- with T1 (+ve) T3 (-ve) or T1 (-ve), T2 (+ve) tone 2 is produced (as set by DIL switch ‘TONE 2’)

The unit is fitted with a volume control which is positioned adjacent to the DIL switches on dc units and is

mounted on the transformer on ac units. Maximum volume is obtained when this control is turned fully

clockwise.Minimum volume is obtained when this control is turned fully anticlockwise. Please note that on

the EN54-3 compliant version the minimum sound output is 65dB

WARNING: Do not attempt to turn the volume control past its limits of movement as this may cause damage

to the unit.

© Cooper M

E

DC

2013

Title:

PROCEDURE/

Fax: +44 (0)1773 580282

DOCUMENT NO.

Tel: +44 (0)1773 812249

DB3 TECHNICAL MANUAL

DD036-04-03

Colliery Road,Pinxton, Notts., NG16 6JF U.K.

REV`D

MEDC

Tones

For all versions, a 5-way DIL switch selects the tone required. The settings for the standard tones are shown

in table 1 below:

Table 1

TONE

No.

TONE FREQ/DESCRIPTION

SWITCH

SETTING

12345

TONE

DESCRIPTION

Nominal SPL

(dB(A) @ 1M)

1

Alt Tones 800/970 Hz at 1/4 sec

11111

114

2

Sweeping 800/970 Hz at 7 Hz

11110

Fast Sweep (LF)

114

3*

Sweeping 800/970 Hz at 1 Hz

11101

Medium Sweep (LF)

114

4

Continuous at 2850 Hz

11100

109

5

Sweeping 2400-2850 Hz at 7 Hz

11011

Fast Sweep

114

6

Sweeping 2400-2850 Hz at 1 Hz

11010

114

7*

Slow Whoop

11001

Slow Whoop

115

8*

Sweep 1200-500 Hz at 1 Hz

11000

Din Tone

115

9

Alt Tones 2400/2850 Hz at 2 Hz

10111

111

10

Int Tone of 970 Hz at 1 Hz

10110

Back-up Alarm (LF)

114

11

Alt Tones 800/970 Hz at 7/8 Hz

10101

114

12

Int Tone at 2850 Hz at 1Hz

10100

Back-up Alarm (HF)

109

13

970 Hz at 1/4 sec on 1 sec off

10011

114

14

Continuous at 970 Hz

10010

114

15*

554 Hz for 0.1S/440 Hz for 0.4S

10001

French Fire Sound

101

16

Int 660 Hz 150 mS on 150 mS off

10000

Swedish Fire Alarm

106

17

Int 660 Hz 1.8 sec on 1.8 sec off

01111

Swedish Fire Alarm

106

18

Int 660 Hz 6.5 sec on 13 sec off

01110

Swedish Fire Alarm

104

19*

Continuous 660 Hz

01101

Swedish Fire Alarm

106

20*

Alt 554/440 Hz at 1 Hz

01100

Swedish Fire Alarm

100

21

Int 660 Hz at 7/8 Hz

01011

Swedish Fire Alarm

106

22

Int 2850 Hz 150 mS on 100 mS off

01010

Pelican Crossing

109

23

Sweep 800-970 Hz at 50 Hz

01001

Low Freq. Buzz

113

24

Sweep 2400 -2850 Hz at 50 Hz

01000

High Freq. Buzz

112

25

3x970 Hz pulses 0.5 off, 1.5 off

00111

113

26

3x2850 Hz pulses 0.5on/0.5off, 1.5 off

00110

109

27

Int 3100 Hz 0.32s on/0.68s off

00101

110

28

Spare / Customer special tone

00100

29

Spare / Customer special tone

00011

30

Spare / Customer special tone

00010

31

Spare / Customer special tone

00001

32

Spare / Customer special tone

00000

NOTE: If special tones were requested at the time of ordering, please see the separate tones list supplied

with the unit for details of these special tones and their respective switch settings.

* = EN54-3 Compliant Tones

© Cooper M

E

DC

2013

Title:

PROCEDURE/

Fax: +44 (0)1773 580282

DOCUMENT NO.

Tel: +44 (0)1773 812249

DB3 TECHNICAL MANUAL

DD036-05-03

Colliery Road,Pinxton, Notts., NG16 6JF U.K.

REV`D

MEDC

4.0 MAINTENANCE

During the working life of the unit, it should require little or no maintenance. GRP will resist attack by most

acids, alkalis and chemicals and is as resistant to concentrated acids and alkalis as most metal products.

However, if abnormal or unusual environmental conditions occur due to plant damage or accident etc., then

visual inspection is recommended.

If the unit requires cleaning, then only clean exterior with a damp cloth to avoid electro-static charge build up.

Repairs should be undertaken by returning the unit to MEDC or by an authorised repairer of Ex equipment. All

parts of the unit are replaceable.

If you acquired a significant quantity of units, then it is recommended that spares are also made available.

Please discuss your requirements with the Technical Sales Engineers at MEDC.

© Cooper M

E

DC

2013

Title:

PROCEDURE/

Fax: +44 (0)1773 580282

DOCUMENT NO.

Tel: +44 (0)1773 812249

DB3 TECHNICAL MANUAL

DD036-06-03

Colliery Road,Pinxton, Notts., NG16 6JF U.K.

REV`D

MEDC

5.0 CERTIFICATION/APPROVALS

IECEx units

Certified to IEC 60079-0, IEC 60079-1 and IEC 60079-7

Ex d IIC unit (IEC certification No. IECEx BAS 11.0083X)

Ex d IIC TG(Tamb.) Gb

Ex tb IIIC TD(Tamb.) Db IP66

Ex de IIC unit (IEC certification No. IECEx BAS 11.0084X)

Ex de IIC TG(Tamb.) Gb

Ex tb IIIC TD(Tamb.) Db IP66

The IECEx certificate and product label carry the IECEx equipment protection level marking

Gb

Db

Where Gb signifies suitability for use in a Zone 1 surface industries area in the presence of gas.

Where Db signifies suitability for use in a Zone 1 surface industries area in the presence of dust.

ATEX units

Certified to EN50014:1997, EN50018:1994, EN50019:1994 & EN50281-1-1:1998

EExd IIC Atex Certifictaion Number BAS 00ATEX2097X

EExde IIC Atex Certification Number BAS 00ATEX2098X

See special conditions for safe use for ambient temperature ranges and T-ratings

The ATEX certificate and product label carry the ATEX group and category marking:

II 2 GD

Where:

Signifies compliance with ATEX

II Signifies suitability for use in surface industries

2 Signifies suitability for use in a zone 1 area

G Signifies suitability for use in the presence of gases

D Signifies suitability for use in the presence of dust

The ATEX certificate and product label also carry the following mark:

This signifies unit compliance to the relevant European directives, in this case 94/9/EC, along with the number

of the notified body issuing the EC type examination certificate.

© Cooper M

E

DC

2013

Title:

PROCEDURE/

Fax: +44 (0)1773 580282

DOCUMENT NO.

Tel: +44 (0)1773 812249

DB3 TECHNICAL MANUAL

DD036-07-03

Colliery Road,Pinxton, Notts., NG16 6JF U.K.

REV`D

MEDC

EN54-3 Fire Alarm Device –Sounder (11-58V DC ABSOLUTE).

Environment Type B Outdoor applications

IP code (IP33C) to BS EN 60529:1992

This signifies unit compliance to the relevant European regulations, in this case 305/2011, along with the

name and number of the notified body issuing the certificate of conformity.

These units also have the following approvals

Electromagnetic compatibility to BS EN 50081-1:1992

BS EN 50081-2:1995

6.0 SPECIAL CONDITIONS FOR SAFE USE

a) Type DB3/DB3L - IECEx BAS 11.0083X & BAS00ATEX2097X (Exd)

1. This apparatus is not suitable for use in atmospheres containing carbon disulphide

2. This apparatus is suitable for use only in ambient temperatures as follows:

Type

Max. Power

rating

Tamb.

TG

TD

DB3

15W

-20°C to +55°C

T5

T100C

15W

-20°C to +70°C

T4

T135C

DB3L

15W

-55°C to +55°C

T5

T100C

15W

-55°C to +70°C

T4

T135C

3. Painting and surface finishes, other than those applied by the manufacturer, are not permitted

4. When used in dust atmospheres the flameproof cable entry devices or stopping plugs shall be

selected and installed to maintain the dust tight (IP6X) integrity of the enclosure

b) Type DB3E/DB3LE - IECEx BAS 11.0084X & BAS00ATEX2098X (Exe)

1. This apparatus is not suitable for use in atmospheres containing carbon disulphide.

2. Not more than one single or multiple strand wiring lead shall be connected into either side of any

terminal, unless multiple conductors have been joined in a suitable manner, e.g. two conductors into

a single insulated boot lace ferrule.

3. Leads connected to the terminals shall be insulated for at least 275V and this insulation shall extend

to within 1mm of the metal of the terminal throat.

4. All terminal screws, used and unused, shall be fully tightened down.

5. This apparatus is suitable for use only in ambient temperatures as follows:

Type

Max. Power

rating

Tamb.

TG

TD

DB3E

15W

-20°C to +55°C

T5

T100C

15W

-20°C to +70°C

T4

T135C

DB3LE

15W

-50°C to +55°C

T5

T100C

15W

-50°C to +70°C

T4

T135C

6. Minimum creepage and clearance distances between the terminals and adjacent conductive parts

(including cable entry devices) must be at least 5mm.

7. Painting and surface finishes, other than those applied by the manufacturer, are not permitted.

8. When used in dust atmospheres the flameproof cable entry devices or stopping plugs shall be

selected and installed to maintain the dust tight (IP6X) integrity of the enclosure.

© Cooper M

E

DC

2013

Title:

PROCEDURE/

Fax: +44 (0)1773 580282

DOCUMENT NO.

Tel: +44 (0)1773 812249

DB3 TECHNICAL MANUAL

DD036-08-03

Colliery Road,Pinxton, Notts., NG16 6JF U.K.

REV`D

MEDC

7.0 FUNCTIONAL SAFETY

Introduction

The DB3 sounder has been designed for use in potentially explosive atmospheres and harsh environmental

conditions. The glass reinforced polyester enclosures are suitable for use offshore or onshore, where light

weight combined with corrosion resistance is required.

The DB3 sounder can be configured with or without an Exe Chamber on the rear. The FMEDA has

considered the worst case scenario which includes the Exe Chamber on the rear.

The safety function of the sounder is to provide a pre-determined audible warning sound when required if the

correct voltage is applied to the unit. The DC version of the sounder is designed to operate on a supply

voltage between 12 and 48vDC; the AC versions of the sounder are designed to operate on a supply voltage

tolerance of +/- 10%.

Under No fault (Normal) Operating conditions the DB3 sounder will provide an audible warning sound when

required by the system.

Under fault conditions the failure mode of the sounder is a failure to provide an audible warning sound. For

the failure rate associated with this failure mode please refer to the table below.

Assessment of Functional Safety

This sounder is intended for use in a safety system conforming to the requirements of IEC61508.

Sira Test & certification Ltd has conducted a Failure Modes Effect and Diagnostic Analysis (FMEDA) of the

DC version of DB3 sounder against the requirements of IEC 61508-2 using a Proof Test Interval of 8760hrs.

The DC version of the sounder was considered to be the worst case. The results are shown below and are

based on Route 1H

The sounder is classed as a Type B device.

DB3 SOUNDER

Safety Function of DB3 Sounder:

‘To provide a pre-described audible warning sound when required’

Architectural constraints:

Type B

HFT=0

SFF =

74.00%

Proof Test

Interval

=8760Hrs[4]

MTTR = 8 Hrs[4]

SIL 1

Random hardware failures:

λDD = 3.25E-06

λDU = 2.15E-06

λSD = 2.20E-08

λSU = 2.81E-06

Probability of failure on demand:

PFDAVG=9.44E-03

(Low Demand Mode)

SIL 2

Probability of Dangerous failure on safety

function:

PFH = 2.15E-06

(High Demand Mode)

SIL 1

Hardware safety integrity compliance

Route 1H

Systematic safety integrity compliance

Route 1S

Systematic Capability

SC 2 (Ref to 56A24816B)

Overall SIL-capability achieved

SIL 1 (Low Demand)

SIL 1 (High Demand)

© Cooper M

E

DC

2013

Title:

PROCEDURE/

Fax: +44 (0)1773 580282

DOCUMENT NO.

Tel: +44 (0)1773 812249

DB3 TECHNICAL MANUAL

DD036-09-03

Colliery Road,Pinxton, Notts., NG16 6JF U.K.

REV`D

MEDC

Conditions of Safe use

The following conditions apply to the installation, operation and maintenance of the assessed equipment.

Failure to observe these may compromise the safety integrity of the assessed equipment:

1. The user shall comply with the requirements given in the manufacturer’s user documentation (This Safety

Manual and Technical manual) in regard to all relevant functional safety aspects such as application of

use, installation, operation, maintenance, proof tests, maximum ratings, environmental conditions, repair,

etc;

2. Selection of this equipment for use in safety functions and the installation, configuration, overall

validation, maintenance and repair shall only be carried out by competent personnel, observing all the

manufacturer’s conditions and recommendations in the user documentation.

3. All information associated with any field failures of this product should be collected under a

dependability management process (e.g., IEC 60300-3-2) and reported to the manufacturer.

4. The unit should be tested at regular intervals to identify any malfunctions; in accordance with this safety

manual.

0

0.002

0.004

0.006

0.008

0.01

0.012

0.014

0.016

0.018

0.02

0 5 10 15 20 25 30

PFDavg

Time (months)

DB3 Sounder

Selection of Proof Time Interval versus SIL % Contribution

Limited to SIL1 Due to Type B and SFF

© Cooper M

E

DC

2013

Title:

PROCEDURE/

Fax: +44 (0)1773 580282

DOCUMENT NO.

Tel: +44 (0)1773 812249

DB3 TECHNICAL MANUAL

DD036-010-03

Colliery Road,Pinxton, Notts., NG16 6JF U.K.

REV`D

MEDC

EN54-3 Compliant Tones Data

Minimum Volume dB(A)

Horizontal Plane

Vertical Plane

Angle

Max 58V

Min 11V

Max 58V

Min 11V

TONE 3

15°

97.4 dB(A)

95.8 dB(A)

99.1 dB(A)

97.6 dB(A)

45°

101.9 dB(A)

101.2 dB(A)

102.6 dB(A)

102.7 dB(A)

75°

106.2 dB(A)

104.9 dB(A)

106.7 dB(A)

105.6 dB(A)

105°

106.1 dB(A)

104.8 dB(A)

105.5 dB(A)

104.2 dB(A)

135°

103.4 dB(A)

102.9 dB(A)

102.7 dB(A)

101.5 dB(A)

165°

98.7 dB(A)

98.5 dB(A)

98.1 dB(A)

97.1 dB(A)

TONE 7

15°

97 dB(A)

96.5 dB(A)

98.7 dB(A)

98.5 dB(A)

45°

104.7 dB(A)

101.8 dB(A)

102.4 dB(A)

103 dB(A)

75°

105.6 dB(A)

104.5 dB(A)

106.3 dB(A)

105.3 dB(A)

105°

105.5 dB(A)

104.4 dB(A)

105.2 dB(A)

104.1 dB(A)

135°

104.8 dB(A)

103.6 dB(A)

103.8 dB(A)

103.5 dB(A)

165°

100.6 dB(A)

99.7 dB(A)

98.1 dB(A)

98.9 dB(A)

TONE 8

15°

97 dB(A)

95.9 dB(A)

95.9 dB(A)

95.1 dB(A)

45°

103.3 dB(A)

102.8 dB(A)

102.6 dB(A)

100.6 dB(A)

75°

104.6 dB(A)

103.3 dB(A)

104.1 dB(A)

103.2 dB(A)

105°

104.6 dB(A)

103 dB(A)

104.8 dB(A)

104.1 dB(A)

135°

104.4 dB(A)

105 dB(A)

106.4 dB(A)

105.9 dB(A)

165°

99.3 dB(A)

100.3 dB(A)

102.6 dB(A)

101 dB(A)

TONE 15

15°

89.7 dB(A)

88.4 dB(A)

90.4 dB(A)

89.1 dB(A)

45°

93.5 dB(A)

92.2 dB(A)

94 dB(A)

92.7 dB(A)

75°

98.5 dB(A)

97.3 dB(A)

99.1 dB(A)

97.8 dB(A)

105°

98.5 dB(A)

97.3 dB(A)

97.3 dB(A)

96.1 dB(A)

135°

93.1 dB(A)

91.6 dB(A)

92.7 dB(A)

91.1 dB(A)

165°

89 dB(A)

87.9 dB(A)

87.8 dB(A)

86.4 dB(A)

TONE 19

15°

88.6 dB(A)

86.8 dB(A)

89 dB(A)

87.8 dB(A)

45°

94.2 dB(A)

92.7 dB(A)

94.5 dB(A)

93.3 dB(A)

75°

93.1 dB(A)

91.2 dB(A)

94.4 dB(A)

93.3 dB(A)

105°

93.4 dB(A)

92.2 dB(A)

91.1 dB(A)

90.5 dB(A)

135°

94.4 dB(A)

93 dB(A)

94.3 dB(A)

93.1 dB(A)

165°

90 dB(A)

88.5 dB(A)

88.5 dB(A)

87.2 dB(A)

TONE 20

15°

89.5 dB(A)

88.4 dB(A)

90.6 dB(A)

89.3 dB(A)

45°

93.5 dB(A)

92.3 dB(A)

94 dB(A)

92.9 dB(A)

75°

98.6 dB(A)

97.3 dB(A)

99.1 dB(A)

97.9 dB(A)

105°

98.5 dB(A)

97.3 dB(A)

97.3 dB(A)

96 dB(A)

135°

93.3 dB(A)

91.9 dB(A)

92.6 dB(A)

91.5 dB(A)

165°

89 dB(A)

87.8 dB(A)

87.7 dB(A)

86.5 dB(A)

© Cooper M

E

DC

2013

Title:

PROCEDURE/

Fax: +44 (0)1773 580282

DOCUMENT NO.

Tel: +44 (0)1773 812249

DB3 TECHNICAL MANUAL

DD036-011-03

Colliery Road,Pinxton, Notts., NG16 6JF U.K.

REV`D

MEDC

Cooper MEDC Ltd, Unit B, Sutton Parkway, Oddicroft Lane, Sutton –In-Ashfield NG17 5FB, United Kingdom

Tel: +44 (0)1623 444400

E-Mail [email protected]

Web: www.coopermedc.com

MEDC Stock No. TM141-ISS.L

Other manuals for HORN DB3

5

This manual suits for next models

1

Table of contents

Other MEDC Speakers manuals