Medin medinSINDI 1080 Configuration guide

Operating, cleaning and maintenance instructions

medinSINDI®Universal Gas Supply Unit

with Pressure Monitor

2von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

Contact and ordering information

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

Sales and customer service:

by authorised partners

a detailed list can be found on the website

www.medingmbh.com

Copyright

This document is the exclusive property of medin Medical Innovations GmbH. No part of this document may be

copied or otherwise reproduced or stored in any form on electronic media without prior written consent of the

company, except in the case of express authorisation from the company. Contact the manufacturer for further

information.

Information on the validity and retention time of documents

This document is valid until it is changed or revoked by the manufacturer and it must be kept until the end of

the lifespan of the product.

Disposal

Classification

II B according to guideline 93/42 EEC

0483

Warranty

With this warranty, the manufacturer guarantees, for a period of 12 months, that this product has no material

and processing defects at the time of initial purchase. If the product should have any defects during the period

of the warranty (at the time of the initial purchase) based on material or workmanship, the manufacturer or his

authorised sales and service partner will repair the product at no charge for labour or material costs under the

following conditions, or (at the manufacturer's discretion) will replace the product itself or its defective parts.

The manufacturer and his authorised sales and service partners may replace defective products or parts with

new or reconditioned products or parts. All replaced products and parts become the property of the

manufacturer.

Conditions:

1. Warranty claims can only be made if the model name or the serial number on the product has not

been changed, effaced, removed, or made illegible and the safety seal must not be removed or

damaged.

2. This warranty does not cover the costs for transporting the product to the manufacturer or its

authorised sales and service partners, or any risks associated with the transport.

Separate collection of electrical and electronic devices according to guideline

2002/96/EEC: The product may not be disposed of together with household

waste. It must be collected separately from household waste and disposed of

in an environmentally safe manner in accordance with local regulations.

3von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

3. This warranty does not cover:

- regular maintenance and repair or replacement of parts due to normal wear and tear

- consumables (components which could be expected to need regular replacement

over the course of the life of the product)

- damage or defects caused by use, operation or handling of the product not in

accordance with the intended use specified in the instructions for use

- damage or changes to the product caused by:

a) improper use

b) improper installation

c) improper cleaning

d) failure to follow the manufacturer's instructions for use and

installation

e) failure to follow the manufacturer's care and maintenance

instructions

f) connecting or using the product in a manner that is contrary to the

applicable technical or safety regulations or to the standards of the

country in which the product is used

g) use of the product in systems or under conditions which are not

intended for use with the product

h) use of the product with accessories, accessory devices and other

products which differ in nature, condition or standard from those

authorised by the manufacturer

i) repairs or attempts at repair made by persons not authorised by the

manufacturer

j) adaptations or changes without prior written agreement of the

manufacturer

k) product upgrades beyond the specifications or features described in

the instructions for use

l) modifications to the product to adapt it to national or local technical

or safety standards in countries other than those for which the

product was specially manufactured

m) neglect

n) accidents, fire, liquids, chemicals, other substances, flooding,

vibrations, excessive heat, insufficient ventilation, sudden power

spikes, overly high or inverse voltage or input voltage, radiation,

electrostatic discharges (including lightning strikes, other external

forces and impacts).

Warranty Exclusions and Limitations

With the exception of the points mentioned above, the manufacturer does not provide any express, tacit, legal

or other guarantees regarding the quality, performance, accuracy, reliability, suitability for a particular purpose

or other properties of the product. If this exclusion is not admissible according to applicable law or has only

limited admissibility, the manufacturer excludes its guarantees as permitted by applicable law or limits them to

the minimum allowed by law. Each guarantee which cannot be fully excluded is limited to the duration of this

warranty, if permitted by applicable law.

The service life of the device is defined as 8 years.

4von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

Table of Contents

Warranty 2

Table of Contents 4

List of Figures 5

List of Tables 5

Electromagnetic Compatibility 6

Intended Use 6

1.1. Pneumatic Blender 7

1.2. Electronic Monitoring Unit 7

2. Product Specifications 8

2.1. Modes 8

2.2. Controls and Displays 8

2.3. Monitoring 8

2.4. Pneumatic Properties 8

2.5. Power Supply 9

2.6. Atmosphere and Environment 9

2.7. Dimensions and Weight 10

2.8. Overview of the General Technical Description 10

2.9. Accessories for medin medinSINDI®REF 1080 10

3. Unpacking and Set-Up 10

3.1. Mounting and Setting Up the Parts 10

3.2. Connection to Gas Supply 11

3.3. Gas Supply Connection (see Figure 3) 11

3.4. Power Supply Connection 12

3.4.1. Initial start-up and long-term storage: 12

3.4.2. Connection 12

3.4.3. Operating and Idle Times 12

3.4.4. Interruption of the External Power Supply 12

3.4.5. Background Illumination Display 12

3.4.6. Power supply connection: 12

3.5. Connection to Medijet14

3.6. Connection to nasal cannula 14

4. Operation 15

4.1. Operating Controls 15

4.2. Display Elements 16

4.3. Starting Up and Adjusting Settings 16

4.3.1. Starting Up 17

4.3.2. Adjusting the Oxygen Concentration 17

4.3.3. Adjusting the Driving Flow 17

4.3.4. Alarms 17

4.3.5. Spontaneous Respiratory Rate 18

4.3.6. Oxygen Concentration Adjustment Trend 18

4.4. Special Functions 19

4.4.1. Software Failure 19

4.4.2. Acoustic Alarm Off 19

4.4.3. Service Menu 19

4.4.3.1. Oxygen Calibration 20

4.4.3.2. Pressure Calibration 21

4.4.3.3. (De-)activation of "Acoustic alarm off" Function 21

4.4.3.4. Internal Data 22

4.4.3.5. Restarting after Calibration 22

4.4.4. External Alarm 22

4.4.5. Illumination of the Flowmeter 23

5. Alarm 23

5.1. Gas Mixer 23

5.2. Monitoring Alarms in the medinSINDI®CPU Monitor: 23

5.3. Error messages during operation 24

5.4. Signals 25

5von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

6. Cleaning and Maintenance 25

6.1. Cleaning 25

6.2. Exchange of the Internal Batteries 25

6.3. Repairs 25

6.4. Device Modifications 25

6.5. Power Supply Unit (Cleaning, Maintenance, Repairs and Modifications) 25

6.6. Maintenance 26

6.6.1. Every 2 months - oxygen calibration: 26

6.6.2. Maintenance intervals: 26

6.7. medinSINDI®- Basic Construction of the Monitor and the Mixer 27

7. Explanation of the Symbols 28

7.1. Device Symbols 28

7.2. Symbols Used on Buttons 29

8. Glossary 29

9. Elektromagentic compatibility 32

9.1 electromagnetic transmission 33

9.2 electromagnetic immunity 33

10. Appendix –Device Passport 34

List of Figures

Figure 1: Screws for attachment to the rolling cart rail 11

Figure 2: Symbol to indicate the charging process 12

Figure 3: Connection to Medijet®14

Figure 4: medinSINDI®front 15

Figure 5: medinSINDI®Monitor 16

Figure 6: Oxygen concentration trend 18

Figure 7: Special function buttons 19

Figure 8: Service Menu 20

Figure 9: Oxygen calibration 20

Figure 10: Pressure calibration 21

Figure 11: Manometer for pressure calibration 21

Figure 12: Acoustic Alarm 21

Figure 13: Internal Data 22

Figure 14: Construction of the monitor and mixer and pneumatic diagram of the mixer 27

Figure 15: medinSINDI®CPU and open housing with mixer and CPU 27

Figure 16: Disassembly of the knobs on the front panel and mixer with oxygen cell 28

List of Tables

Table 1: Accessories for medinSINDI®10

Table 2: Errors and causes 24

Table 3: Device Symbols 29

Table 4: medinSINDI®Display Symbols 29

Table 5: Glossary 29

Note - Instructions for Use and Serial Number

Please read these instructions carefully before using the device. Please keep the original packaging in the event

the device needs to be returned. Please make a note of the serial number on the identification plate on the

back of the device for your records.

6von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

Warning - Handling

-Do not operate the device in the vicinity of highly flammable gases

-Do not use any oil or lubricant on or near the oxygen equipment

-Do not place any containers with liquids on the device

-Oxygen may only be supplied via the connection provided

-The oxygen supply must be monitored

-This equipment may be changed without prior notice

-The medinSINDI®may not come into contact with flammable anaesthesia gases or other flammable

materials while in use.

Electromagnetic Compatibility

It is confirmed that the device meets the EMC guidelines 89/336/EEC, 93/68/EEC and 93/42/EEC.

Intended Use

Therapeutic use for enriching the breathing gas mixture with oxygen for premature and newborn infants as

well as in connection with the nCPAP generator Medijetto support respiration with continuous positive

airway pressure with monitoring and alarm parameters.

FOR HOSPITAL USE ONLY

Important Note - Haemodynamic Monitoring

The device may only be used with simultaneous haemodynamic monitoring of the patient.

Only trained hospital staff are authorised to use the device on patients.

7von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

1. Product Description

medinSINDI®universal gas supply unit with pressure monitor is an electronic unit with microprocessor-

controlled monitoring and is used to display the set parameters. The unit is battery-operated and is charged by

an external power supply plug. The screen is backlit. The operating time without mains power is approximately

5 hours. The oxygen concentration is determined in the gas flow delivered. The O2cell is delivered ready to use

by a known manufacturer. This cell generates an analogous DC voltage proportional to the oxygen

concentration. The cell itself does not need any supply voltage. It should be treated like a battery. The cell is a

consumable and must be calibrated in the device from time to time and replaced every 12 months. The

calibration is performed using internal software as a two-point calibration (21% and 100% O2).

The CPAP generated is determined by an electronic pressure transducer. This has a supply voltage of 9 V. The

CPAP pressure value to be recorded is between 0 and 20 cmH2O. The clinically relevant value is 5 - 8 cmH2O.

The design of the displays ensures easy operation by the user. All necessary calibration steps run automatically

and are accessed via a service menu. This is provided with a security code.

The system consists of two main components:

1.1. Pneumatic Blender

The pneumatic blender is an air and oxygen mixer with an integrated flowmeter. It has an acoustic alarm unit

and a safety warning system in the event of low gas pressure. Normal operating pressure of the mixer is 350

kPa (3.5 - 6.0 bar). In the event of reduced inlet pressure of one of the gases, the mixer automatically reduces

the pressure of the other gas, as long as the difference between the two gases is not greater than 100 kPa (1

bar). The flowmeter with a needle valve can be adjusted from 0 to 16 L per minute.

1.2. Electronic Monitoring Unit

The oxygen content is read into a memory by pressing the "Confirm FiO2Alarm“ button and it is compared with

deviations of ± 10% from the current concentration and monitored. If the FiO2is changed on the device, this

must be confirmed by once again pressing the "Confirm FiO2" button, otherwise the device alarm will sound.

The oxygen concentration is shown in digital and analogue form on the display. In the event of an alarm, the

display blinks and an acoustic alarm is triggered. The alarm can be silenced for 2 minutes by pressing the

"Reset" button. The visual alarm remains active until any problems are corrected.

The channel for the CPAP (continuous positive airway pressure) is fully independent from the FiO2. It is likewise

displayed in analogue and digital form. The analogue value is shown in coordinate axes whose size is shown by

the abscissa (perpendicular plane). The low scan speed for the ordinate was deliberately selected.

Warning –Gas Supply Pressure

If the difference between the gas pressures of the two gases is more than 1 bar, an internal valve opens in

order to compensate for the lower gas supply. This will trigger an acoustic alarm. As of this point in time, the

mixer loses its function and the oxygen content of the gas mixture becomes uncontrollable.

Important Note –Supply Gas

-To ensure high respiratory flows, the mixer must be properly connected to full gas cylinders (O2

and air) or a central gas supply.

-The gas supply must be controlled and monitored.

-When gas bottles are used: set initial pressure regulator to a pressure between 3.5 and 6.0 bar.

-When connected to a central gas supply system: use pressure reducers at the gas supply tubes to

compensate for pressure differences (see list of accessories on page 29)

8von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

2. Product Specifications

2.1. Modes

- Automatic shutoff of the pressure monitor if no CPAP use is taking place

- 21–100% continuous adjustment of the oxygen concentration

- Reset for alarms –2-minute alarm silencing (make silent or end):

Warning –Alarm Silencing

Silencing the alarm requires additional monitoring of vital signs!

- Confirmation of the nCPAP alarm setting for automatic monitoring

- Confirmation of the FiO2concentration setting for automatic monitoring (± 10% of the O2)

- Disconnection or leakage alarm (if the patient pressure falls below 1.5 cm H2O) - Alarm after 3

seconds

- Battery monitoring with charge status display and alarm

- Overpressure alarm in 3 seconds (if the patient pressure exceeds 10 cm H2O)

- Microprocessor-controlled input of programmes on FLASH (= technical upgrade)

2.2. Controls and Displays

- Flow adjustment control knob

- FiO2adjustment control knob

- Soft-touch membrane keypad

- Monitor with integrated 96 x 61 mm LCD display and illumination resolution 240 x 128 dots b/w

2.3. Monitoring

- Oxygen supply pressure, air supply pressure

- Spontaneous respiratory rate

- Alarm functions:

CPAP

FiO2

Battery charge indicator

Mute setting

Automatic alarm system for loss of oxygen or air pressure:

acoustic and pneumatic

2.4. Pneumatic Properties

- Patient gas outlet: Connection with 22 M and 15 F converter

- Patient flow: 0 –16 L/min, working area 4-10 l/min

- Gas supply: Oxygen and air

- Range: 3.5 –6.0 bar

- Adjustment range: 21% to 100% oxygen (tolerance ±3%)

- Gas connections: for DISS supply (alternative to NIST)

- Oxygen sensor for FiO2measurement - sensor type MLF16 (unleaded)

- Overpressure valve 80 mbar

9von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

2.5. Power Supply

The electronic system is fully battery-operated and can be recharged with an external power supply plug.

Uninterruptible operation for an intensive care unit, with an external power supply plug (automatic 100 to 230

V AC) - Input voltage, external power supply plug, mains adapter: 100 - 230 V AC

- Input frequency mains adapter 50 –60 Hz

- Power input: 400 mA

- Output voltage 24 V DC/625 mA

- Internal battery: rechargeable–NiMh 9.6 volts/1100 mA

- Internal battery life: approx. 5 hours (when fully charged)

- Battery charging time –max. 5 hours

2.6. Atmosphere and Environment

- Temperature Range

Operation: 10 –40° C

Storage: 10 –40° C

- Relative humidity

Operation: 0 –95% non-condensing

Storage: 0 –95% non-condensing

Environmental conditions for the medinSINDI®during operation:

Ambient pressure: 700hPa to 1100hPa

Altitude: ≤ 2000m above sea level

Environmental conditions of the power supply unit during operation:

Temperature:

- between 0°C and 40°C

- do not use power supply unit in locations exposed to significant temperature

fluctuations.

Moisture:

- use only in dry locations

- do not use in locations exposed to significant amounts of moisture or condensate

- do not use in locations exposed to significant environmental stress

- do not use outdoors

Vibrations:

- do not use in locations exposed to constant vibration

Environmental conditions of the power supply unit during transport and storage:

Temperature:

- not in locations exposed to significant temperature fluctuations.

Moisture:

- only in dry locations

- not in locations exposed to significant amounts of moisture or condensate

- not in locations exposed to significant environmental stress

- not outdoors

Vibrations: - not in locations exposed to constant vibration

10 von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

2.7. Dimensions and Weight

- Dimensions (height x width x depth):

180 x 240 x 145 mm (without connections and holder)

- Weight: 2.6 kg (without holder)

2.8. Overview of the General Technical Description

Information on these points can be found in the chapters indicated:

Conditions for use, transport and storage: see chapter 3.7

Characteristics and accuracies of the device: see chapter 2

Information on the installation of the device: see chapter 3

Description of the supply gases required: see chapter 3.3

Description of the power supply: see chapter 3.4

The device is disconnected from the mains by pulling the power supply unit cable of the

medinSINDI®out of the electrical outlet. Thus when installing the medinSINDI®, it should be

ensured that this plug is always freely accessible and can be disconnected from the mains without

difficulty. The medinSINDI®does not contain any switch which disconnects it from the mains.

Changes and modifications to the medinSINDI®are not permitted without the permission of the

manufacturer: see chapter 6.4

Repairs and an exchange of parts may only be made by trained, professional service personnel and

only in accordance with the instructions in the Maintenance Manual, observing warnings in the

manual and in these instructions for use: see chapter 6.3

The medinSINDI®and its power supply unit are not suitable for use in the direct vicinity of the

patient. Only the patient tubes, the Medijet®and the masks and prongs used are used in the direct

vicinity of the patient.

2.9. Accessories for medin medinSINDI®REF 1080

REF

Description

Optional

NIST connection

2020/2030

Air and oxygen supply tubes DISS

2020/2030_NIST (alternative to DISS)

Connection gas supply air and oxygen NIST

2120/2130

Connection gas supply air and oxygen, DIN DISS

2120/2130_NIST (alternative to DISS)

Connection gas supply air and oxygen, DIN NIST

2220/2230

Connection gas supply air and oxygen AGA DISS

2220/2230_NIST (alternative to DISS)

Connection gas supply air and oxygen AGA NIST

2320/2330

Connection gas supply air and oxygen Parcodex DISS

2320/2330_NIST (alternative to DISS)

Connection gas supply air and oxygen Parcodex NIST

5002

Mounting rail for rolling cart

5001

Rolling cart

MFL16

O2cell (unleaded)

FW7555/24

Power supply unit

51091

Flow outlet converter (ID F15mm, OD M22mm)

1244-3DW

Tapered outlet adapter (from 4 to 8 mm tube ID)

11810

Conversion kit for central control/ nurse alarm

SMPV

Push-Bag for manual ventilation

Table 1: Accessories for medinSINDI®

3. Unpacking and Set-Up

3.1. Mounting and Setting Up the Parts

- Remove device and equipment from the packaging

11 von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

- Attach device to wall/rolling cart rail mounting and secure in place:

- Loosen the knurled head screws of the rail clamps on the back of the device

- Hang device on wall rail or rolling cart rail

- Tighten the knurled head screws.

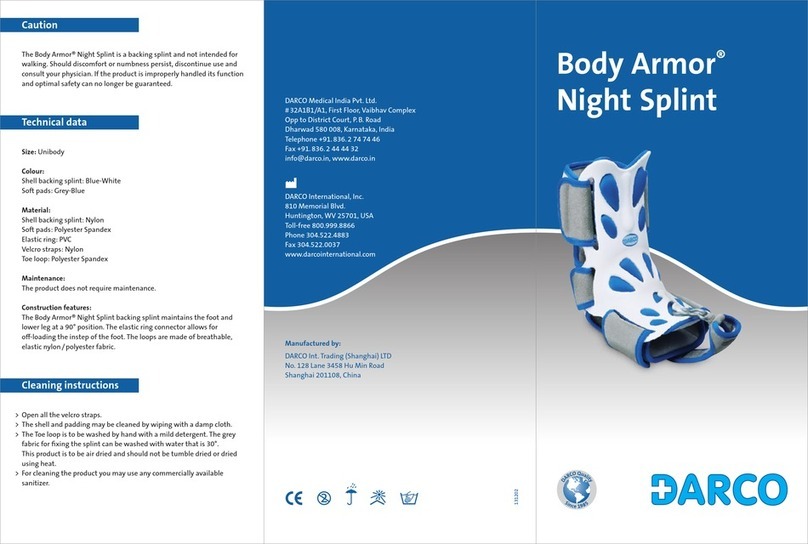

Figure 1: Screws for attachment to the rolling cart rail

The medinSINDI®can be transported when it is not in use; however, when it is in use, it must be securely

mounted. However, if the medinSINDI®becomes damaged during this transport or due to rough handling, its

function must be checked by a service technician. It is not allowed to be used until then.

3.2. Connection to Gas Supply

medinSINDI®requires clean, oil-free and dry air as well as medical oxygen; both gases need to be at an

operating pressure of 3.5 to 6.0 bar respectively.

The central gas supply or gas bottles with a connected pressure-regulating unit can be used as sources of air

and oxygen.

Air and oxygen must have the same pressure stage (maximum difference ± 1 bar). medinSINDI®monitors the

pressure of both gases to ensure this correct gas mixture.

medinSINDI®requires both gases simultaneously for the connection, otherwise an acoustic alarm will

immediately sound. (Loss of gas)

Important Note –Gas Supply

-The oxygen content of the gas mixture can no longer be controlled if the difference in the supply

gas pressures is greater than 1 bar. In this case, an internal valve opens and connects the air and

oxygen supply channels to compensate for the lower gas supply. As of this point, the mixer loses

its function and an acoustic-pneumatic alarm is triggered.

-Connect medinSINDI®properly to the central gas supply or full gas bottles (oxygen and air). This

will ensure high gas flows.

-When using gas bottles, set the initial pressure regulator to a pressure between 3.5 and 5.0 bar

and check the alarm function.

-Ensure that the pressure reducers of the gas supply tubes –if available (see list of accessories,

page 29) –are set to 3.5 bar.

-Supply gases only via the connections provided.

3.3. Gas Supply Connection (see Figure 3)

- Screw air gas supply tube (b/w) onto medinSINDI®

- Screw oxygen gas supply tube (white) onto medinSINDI®

- Attach air gas supply tube (b/w) to central gas supply or full gas cylinder (3.5 –6 bar)

- Attach oxygen gas supply tube (white) to central gas supply or full gas cylinder (3.5 –6 bar)

Knurled head screws

12 von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

- Disconnect the power supply unit from the mains during thunderstorms or if the device is not used

for a longer period of time.

3.4. Power Supply Connection

medinSINDI®is immediately ready for use if the battery is charged. If the battery is depleted, the power supply

unit must be connected.

3.4.1. Initial start-up and long-term storage:

For the initial start-up and after a longer period of storage, the external power adapter provided must be

connected in order to charge the battery. The charging time is approx. 5 hours. An oxygen and pressure

calibration must be performed before the initial start-up (see 4.4.3. Service Menu Page 19).

3.4.2. Connection

Plug external power adapter into the connector provided (see Figure 3)

3.4.3. Operating and Idle Times

- Without external power supply:

Operation for 5 hours is possible with a fully charged battery for brief operating or transport times.

- With external power supply: Continuous operation possible (ICU)

Important Note –Battery

When the battery is nearly depleted, an alarm sounds once per minute for 1 second.

The charging process is shown on the medinSINDI®monitor when the device is switched off.

Figure 2: Symbol to indicate the charging process

3.4.4. Interruption of the External Power Supply

The power supply can be disconnected or connected during operation without any effect on functionality or

loss of data.

3.4.5. Background Illumination Display

- brightly lit when external power supply is used

- dimmed when internal battery is used (energy-saving mode)

- off when battery is nearly depleted

3.4.6. Power supply connection:

To disconnect the medinSINDI®from the mains, the plug of the power supply unit of the medinSINDI®must be

pulled out of the electrical outlet. Otherwise the medinSINDI®is still connected to the mains, even when it is

turned off.

Therefore, when setting up the medinSINDI®, it should be ensured that the plug of the power supply unit is still

accessible even when set up and the medinSINDI®can thus be easily disconnected from the mains.

Disconnect the power supply unit from the mains during thunderstorms or if the device is not used for a longer

period of time.

13 von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

Warning:

The plug of the power supply unit of the medinSINDI®must also always be freely accessible even when set up,

in order to allow the medinSINDI®to be quickly disconnected from the mains in the event of a hazardous

situation.

Do not insert the power supply plug of the medinSINDI®into ceiling outlets since, due to its weight, it can be

pulled out of the outlet in this case.

14 von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

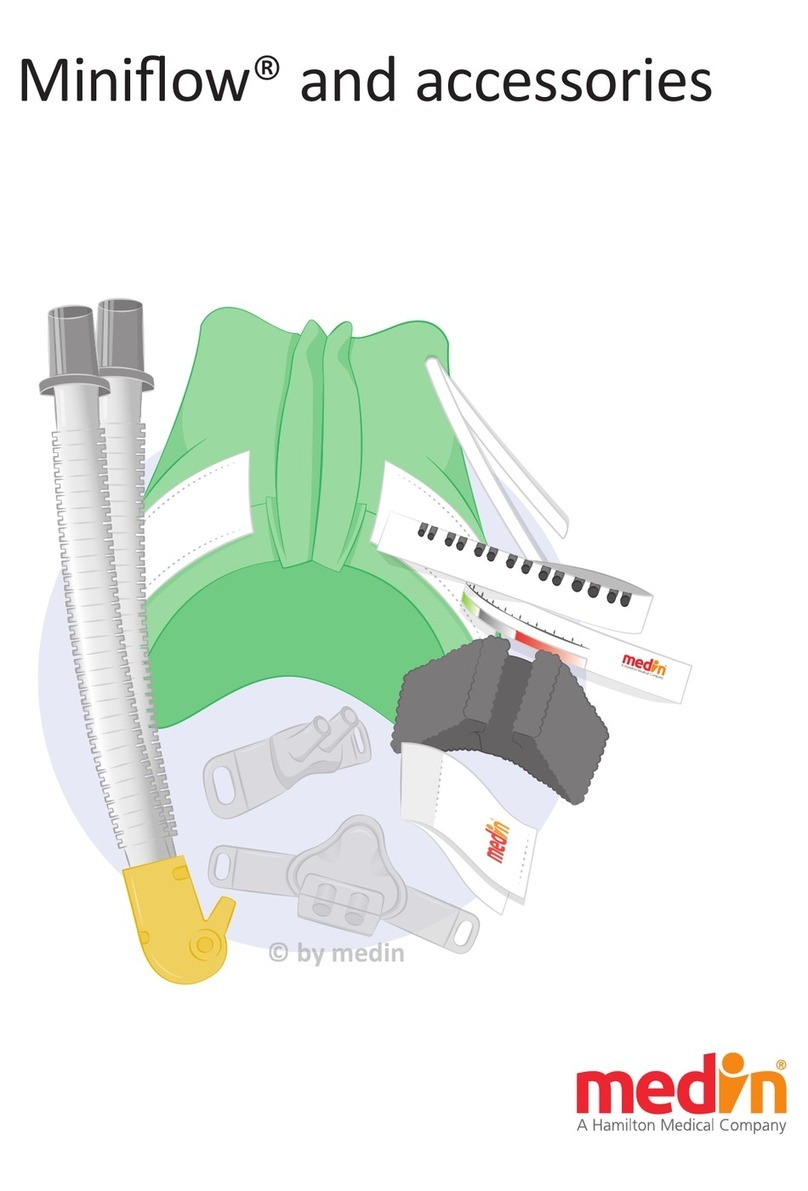

3.5. Connection to Medijet

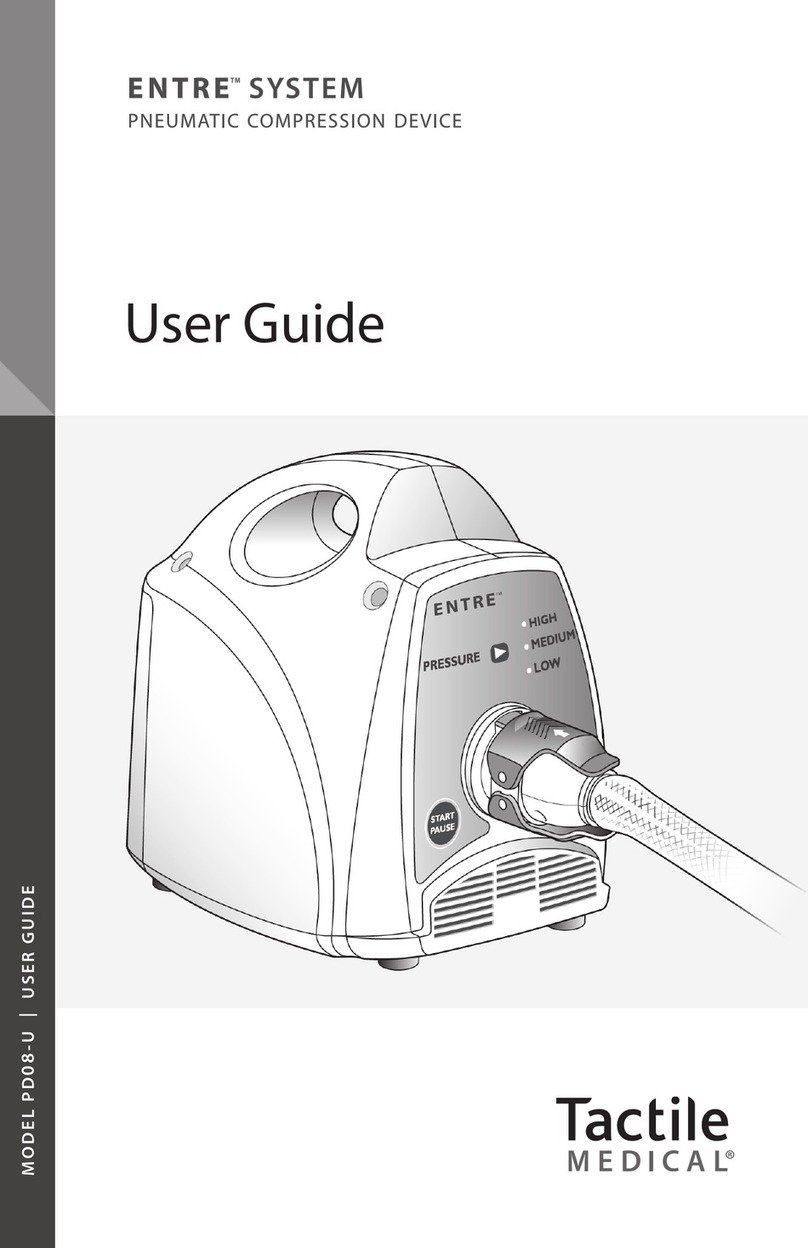

Figure 3: Connection to Medijet®

A. Screw air gas supply tube (b/w) and oxygen gas supply tube (white) onto medinSINDI®.

B. Connect air gas supply tube (b/w) and oxygen gas supply tube (white) to the central gas supply or a full

gas cylinder.

C. Insert external power adapter plug into connector provided and screw in place.

D. Connect short tube from the patient tube set on the outlet converter (REF 51091) and connect to

humidifier chamber - any type of humidifier chamber is suitable.

E. Using the long tube from the patient tube set, connect the humidifier outlet to the inlet of the Medijet®

nCPAP generator. Connect temperature probe and power cable.

F. Connect the nCPAP pressure line on the Medijetand guide back to the medinSINDI®. It will be

connected there at the "PATIENT" connection in order to measure nasal pressure and display on the

screen. The nCPAP connection to medinSINDI®is a female Luer-type. The pressure line can be found in

each patient tube set.

G. Optimal manual push ventilation (SMPV)

3.6. Connection to nasal cannula

The system is set up as described in chapter 3.5, A to D. The difference is in step E: the nasal cannulas are

connected instead of the Medijet®. Steps F and G are omitted.

Important note when using nasal cannula

-During device start-up, nothing should be connected to the medinSINDI®® and also no flow should

be emitted.

-After the device start, activate "alarm silent". Then "CPAP alarm off" appears in the upper right-

hand part of the display.

-Now the therapy can be started and the flow as well as the concentration can be adjusted

accordingly.

E

A

C

D

F

F

G

15 von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

Warning

The nasal cannulas to be used may not exceed a stagnation pressure of 80 mbar during use!

4. Operation

The device should not be connected to a patient during set-up and system start. In addition, during set-up,

system start and operation, the user should not simultaneously touch the patient and the device. This applies

above all to the power supply, the alarm or RS232 Interface and the accessible metal parts of the pneumatic

unit (gas connections).

The adapter should not be used if it has visible damage to the housing or cord.

4.1. Operating Controls

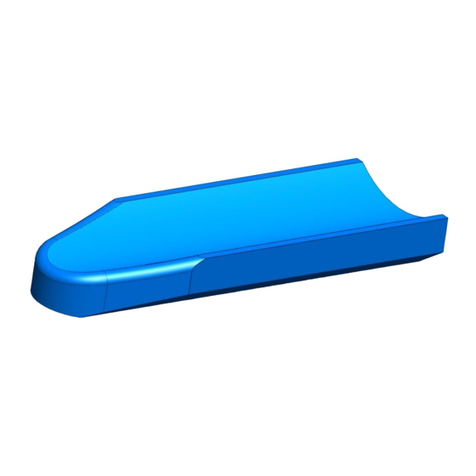

Figure 4: medinSINDI®front

Operating Controls

A. "ON" soft-press button

B. "OFF" soft-press button

C. Adjustment knob for FiO2

D. Adjustment knob for amount of outgoing flow

E. Soft-press buttons for alarm adjustment (see chapter 4.3.4 and chapter 5)

F. Monitor with integrated 96 x 61 mm LCD display, resolution 240 x 128 dots b/w, including

illumination

G. Display for amount of driving flow

16 von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

4.2. Display Elements

Figure 5: medinSINDI®Monitor

Features of the display:

A. nCPAP pressure display: analogous graph in cmH2O

B. nCPAP pressure display in cmH2O (Fair value)

C. Oxygen concentration display: as bar chart

D. Oxygen concentration display in %

E. Triggering of spontaneous respiration: blinking

F. Spontaneous respiratory rate display: Breaths per minute

G. Upper (a) and lower (b) pressure alarm limits

H. Loudspeaker symbol: to indicate alarm mute setting

I. Battery charge monitoring display

Up to software version 1.016 only a pressure of a maximum of 10 cmH2O can be measured and displayed in

pressure curve (A) and at pressure value (B).

Starting with software version 1.017 values up to 10 cmH2O are displayed in pressure curve (A) and a pressure

up to 35 cmH2O is displayed at pressure value (B).

Starting with software version 1.021 the mute setting must be activated

Starting with software version 1.022 current CPAP low and CPAP high values change in conjunction

Starting with software version 1.023 larger visual alarm displays, automatic trending stop in the event of an

alarm

Starting with software version 1.024 Update via RS232 Interface

4.3. Starting Up and Adjusting Settings

Important Note –Start-Up

Training after installation by authorized sales and service partners!

For use by trained professionals only!

After long idle times, oxygen calibration must be performed - see service menu oxygen calibration (page 20).

Ga

A

B

C

D

E

F

Gb

I

H

17 von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

4.3.1. Starting Up

Turn medinSINDI®on using the “ON” button on the front panel of the device. medinSINDI®starts a SYSTEM

CHECK which takes approximately 15 seconds. A bar on the monitor shows the test time.

Starting with software version 1.017 the installed software version is shown in the lower part of the display

during the start.

After this procedure is completed, medinSINDI®is ready for use.

4.3.2. Adjusting the Oxygen Concentration

Turn the FiO2knob of the mixer to the right or left to adjust the FiO2concentration. Adjustment range from 21

to 100% oxygen.

If the control knob of the mixer is turned to the right, the FiO2increases.

4.3.3. Adjusting the Driving Flow

The ball in the flowmeter indicates the flow rate. If the control knob of the flowmeter is turned to the right, the

flow rate decreases. The value is read at the lower end of the ball.

Important Note –Flow Adjustment

Do not turn the adjustment knob for the amount of outgoing flow forcefully (the needle valve may otherwise

become damaged).

4.3.4. Alarms

Important Note –Medijet Connection

If Medijet®is not connected and if no propellant is flowing, the medinSINDI®monitor displays “LOW CPAP” and

an acoustic alarm signal is triggered. Press the “RESET” button to turn the alarm off. "CPAP ALARM OFF“ is

displayed in the upper right-hand part of the monitor.

If no nCPAP pressure is registered in the next 30 seconds, medinSINDI®automatically turns off the blinking

alarm symbol "LOW CPAP“ in the middle of the monitor.

If medinSINDI®measures an nCPAP pressure greater than 1.5 cmH2O after the pressure line has been attached,

medinSINDI®automatically turns on the measurement function of the nCPAP and displays it. The text "CPAP

ALARM OFF" is once again dimmed and all alarm systems are active.

medinSINDI®contains an overpressure alarm with fixed settings which is activated in the case of pressures of

10 cmH2O or higher, and a disconnection alarm in the case of a CPAP pressure of less than 1.5 cmH2O. Both of

these alarms have fixed settings and cannot be changed.

In addition, there is an over- and underpressure alarm which can be adjusted by the user. There is also a built-

in mechanical overpressure valve which opens at 80 mbar or higher. These alarm limits (CPAP-LOW ALARM and

CPAP-HIGH ALARM) are automatically set after the first time the device is turned on. For this purpose,

medinSINDI®measures the nCPAP level and calculates a margin of ± 3 cmH2O for the alarm limits.

By using the respective arrow buttons (CPAP-LOW/-HIGH ALARM and ), the alarms can be manually

adjusted to the desired values.

Important Note –CPAP Alarms

Up to software version 1.014 each change in the alarm limits or the nCPAP pressure level must be confirmed by

pressing the “CONFIRM CPAP” button. If the change is not confirmed, no acoustic and visual alarm will be

triggered.

Starting with software version 1.015 the CPAP alarm limits are automatically activated. The change can be

confirmed using the "CONFIRM CPAP" button but this is no longer necessary.

Starting with software version 1.022 the current CPAP low and CPAP high values change in conjunction.

Starting with software version 1.0124 Alarms are prioritized with melody

18 von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

After setting the desired oxygen concentration with the control knob on the mixer, the alarm can be activated

to monitor the concentration by pressing the "CONFIRM FiO2" button. The alarm sounds in the case of

deviations of ± 10%.

Important Note –O2 Alarm

Any change in the alarm limits of the oxygen concentration must be made by pressing the “CONFIRM FiO2"

button, otherwise an alarm will be triggered. (± 10% of the concentration)

4.3.5. Spontaneous Respiratory Rate

A sensitive nCPAP pressure measurement is necessary to determine the respiratory rate. The pressure

difference must be approx. ± 1 cmH2O during inhalation and exhalation.

The rate is determined, calculated and displayed in each case for 30-second intervals.

If no spontaneous respiration is detected, 2 lines are seen instead of the spontaneous respiratory rate display.

4.3.6. Oxygen Concentration Adjustment Trend

Figure 6: Oxygen concentration trend

Starting with software version 1.019, the adjusted oxygen concentration of the past 8 hours can be displayed.

To do this, hold down the "CONFIRM FiO2" button for 5 seconds. After 20 seconds, medinSINDI®automatically

switches back to the regular CPAP monitor. If medinSINDI®is switched off, the saved FiO2values are deleted.

Starting with software version 1.023, trending is automatically discontinued in the event of an alarm.

19 von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

4.4. Special Functions

Figure 7: Special function buttons

4.4.1. Software Failure

In the event of a software failure, a “soft reset” function is available.

Simultaneously press “CONFIRM CPAP” and “CONFIRM FiO2 and the CPU will be reactivated. (Case 1 in Figure

7)

4.4.2. Acoustic Alarm Off

Starting with software version 1.021e, the "Acoustic alarm off" function is deactivated when the medinSINDI®

is delivered. If necessary, it can be activated for individual devices in the service menu. (See individual chapter)

The function is then operated as described below.

To turn off the "ACOUSTIC ALARM", press “ALARM RESET” (Figure 7 -3) for 5 seconds until you hear three brief

beeps. A loudspeaker with a line running through it will then appear on the display.

The acoustic signal is now turned off in the event of an alarm. In the event of an alarm, only a visual signal

appears on the monitor and incorrect data are indicated by blinking.

To reactivate the acoustic alarm, the "ALARM RESET" button must be pressed for 5 seconds until a beep can be

heard.

Warning –Alarm Silencing

Alarm silencing should not be activated without additional monitoring of vital signs and only by qualified staff!

4.4.3. Service Menu

To open the service menu, medinSINDI®must be switched off.

Up to software version 1.018, the 24V cable must not be connected to medinSINDI®, however it must already

be in the electrical outlet. Press the “CPAP-HIGH-ALARM ” and “CPAP-HIGH-ALARM ” buttons (Figure

7 -2) simultaneously, hold down the buttons and connect the 24V cable to medinSINDI®.

Starting with software version 1.019 the cable can remain on the device. It is sufficient to hold down the

“CPAP-HIGH-ALARM ” and “CPAP-HIGH-ALARM ” (Figure 7 -2) buttons and press the ON button. Both

CPAP buttons must be held down for another 3 seconds.

The CPU will then start the “SYSTEM TEST” and open the service menu after this test. The display then appears.

20 von 36

medin Medical Innovations GmbH

Adam-Geisler-Str. 1

D-82140 Olching

OP_medinSINDI EN

Rev 14 Stand 30.10.2017

Figure 8: Service Menu

The desired procedure can be set by using the function keys on the keypad. Follow the directions on the

display. The display is controlled by the CPU programme.

To exit the service menu, select "Exit" and confirm with the "Confirm CPAP" button

Warning –Service Menu

The service menu may only be opened by technically trained staff who have the necessary knowledge and

equipment. If calibrations are performed improperly, medinSINDI®will no longer work correctly and the patient

will be at risk.

4.4.3.1. Oxygen Calibration

Connect a calibrated oxygen measuring device to the patient gas outlet.

Open the flow of the medinSINDI®and adjust the FiO2knob to 21%. Then check whether the external oxygen

measuring device shows 21% ± 3 vol%. If this is not the case, technical services must be called.

Open the flow of the medinSINDI®and adjust the FiO2knob to 100%. Then check whether the external oxygen

measuring device shows 100% ± 3 vol%. If this is not the case, technical services must be called.

Select the Oxygen –Calibration item and follow the instructions of the CPU.

Figure 9: Oxygen calibration

Important Note –Oxygen Calibration

Wait until the ADC VALUE is STABLE! Then confirm.

After the calibration is completed, the service menu reappears.

Table of contents

Other Medin Medical Equipment manuals