UP MEVACS M90 - D4O-0085-2-0 / 13.1.2009

T-QN-04/05-01-1

13 / 15

immediately exchanged the filter and used up filter to disposal. It prevents spread of infection. The vessel

content is decontaminated in a way utilised on site and the vessels including hoses are submerged into

the disinfection solution. Keep the following rules during maintenance of the polycarbonate secretion

reservoir and silicone hoses:

•Do not use abrasives

•Check the compatibility of polycarbonate and detergents used in the hospital. Polycarbonate

enters into reaction with aldehyde residues, which are always present after use of disinfection

solutions containing formaldehyde, glyoxale, glutaraldehyde

•Since we cannot know the whole range of cleaning and sterilization agents used in hospitals, we

recommend to contact your suppliers and consult the compatibility of their agents and

polycarbonate. Disinfection agents proved to be successful in practice are sekusept and

chloramine (Formalin and organic solvents are prohibited)

•Before putting into autoclave wash the bottle thoroughly and dry in order to remove all residues of

disinfection agents and water

•Put the bottle into autoclave always upside down without contact with other components

•Autoclave the bottle and the cover always separately

•Do not put heavy subjects on the bottle in the autoclave to prevent its deformation

•Autoclave the polycarbonate and silicone hoses at temperatures not exceeding 121°C max. for

the period of 20 min.), autoclave mode „RUBBER“.

The microbiologic filter is disposable. The filter replacement when it has blocked with liquid or dirty over

time. The microbiologic filter protected in the main patient or operating personnel into the face of infection

and protect together suction unit for overflow secretion.

The plastic case, holders, truck and other equipment can be cleaned with soft, wet cloth moistened by

cleaning agent, which does not react with the plastic and its surface finish,(SEKUSEPT). Agents with

organic solvents are prohibited.

Also cleaning agents based on synthetic spirit (OKENA) are suitable, but also disinfection agents on the

basis of sprays can be used.

Important! It is necessary to disconnect the mains cord before cleaning the unit. During cleaning the

electric connectors, switch and the mains socket must be protected against water or cleaning agents, do

not submerge the unit into water.

Note: No lubrication is necessary.

8.2. Small faults correction, unit trouble shooting

As each unit of our company, also MEVACS suction unit was tested and found trouble-free. Despite

that fact some faults can occur, which follow either from blocking protection systems or from incorrect

use.

For better orientation the faults, you can correct yourselves, are shown in the following table.

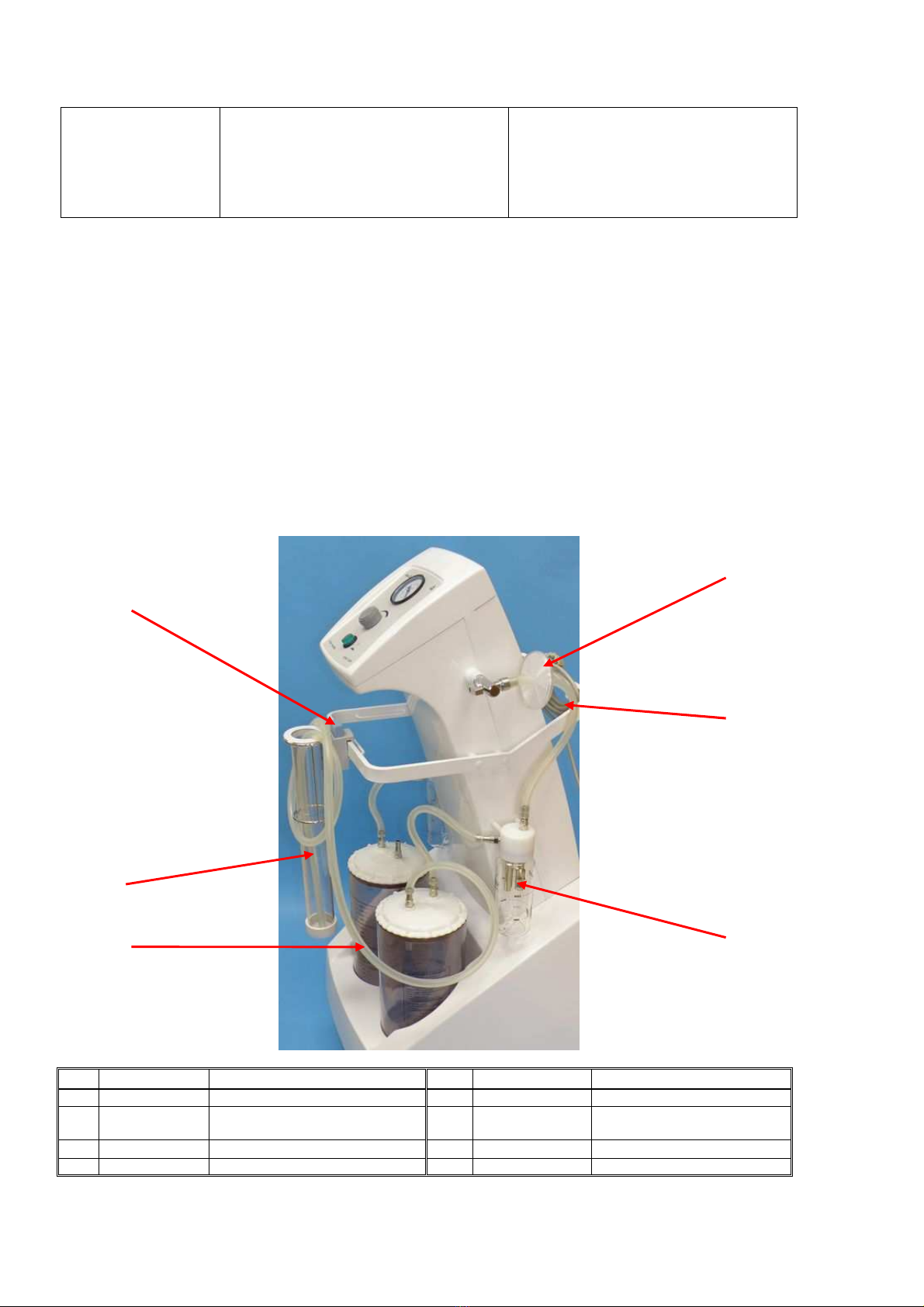

Damage symptom Possible reason Repairing action

Vacuum pump engine

does not operate

•Switch is not on

⇒Power supply

•Instrument is not connected

⇒Fuses

•Air pump engine is damaged

•Turn the switch into the position “I“

⇒Repair electric socket into the room

•Connect a power cord into the instrument

⇒Replace fuses into the instrument socket

•Call service technician

Inadequate sucking

⇒Leakage into the vacuum pump or inner

suction perimeter

•Hoses are damaged or set up incorrectly

⇒Glazed filter

•Damaged filter body

⇒Damaged connectors or “O” rings on the

vessel lid

⇒Damaged gasket into the vessel lid

•Damaged vessel, ripped or torn boundaries

⇒Determine failure source according to point

6.4.1. Call service technician.

•Control and push hoses

⇒Replace the filter

•Replace the filter

⇒Replace a vessel lid, call service technician

⇒Replace a vessel lid, call service technician

•Replace the vessel