Meeting Pod 2 Person Pod User manual

Installation Guide

2 Meeting Pod Installation Guide sales@themeetingpod.co.uk

Table of contents

-Fixings Guide, Tools & Accessories 3

-Floor Plans 4

-Installation Instructions 6

-Pod Accessories 10

-Pod Electrics: Lighting & Power 18

-Warranty: Pod & Accessories 20

-Pod Cleaning 22

-Working Together 23

Installation Guide

3 Meeting Pod Installation Guide sales@themeetingpod.co.uk

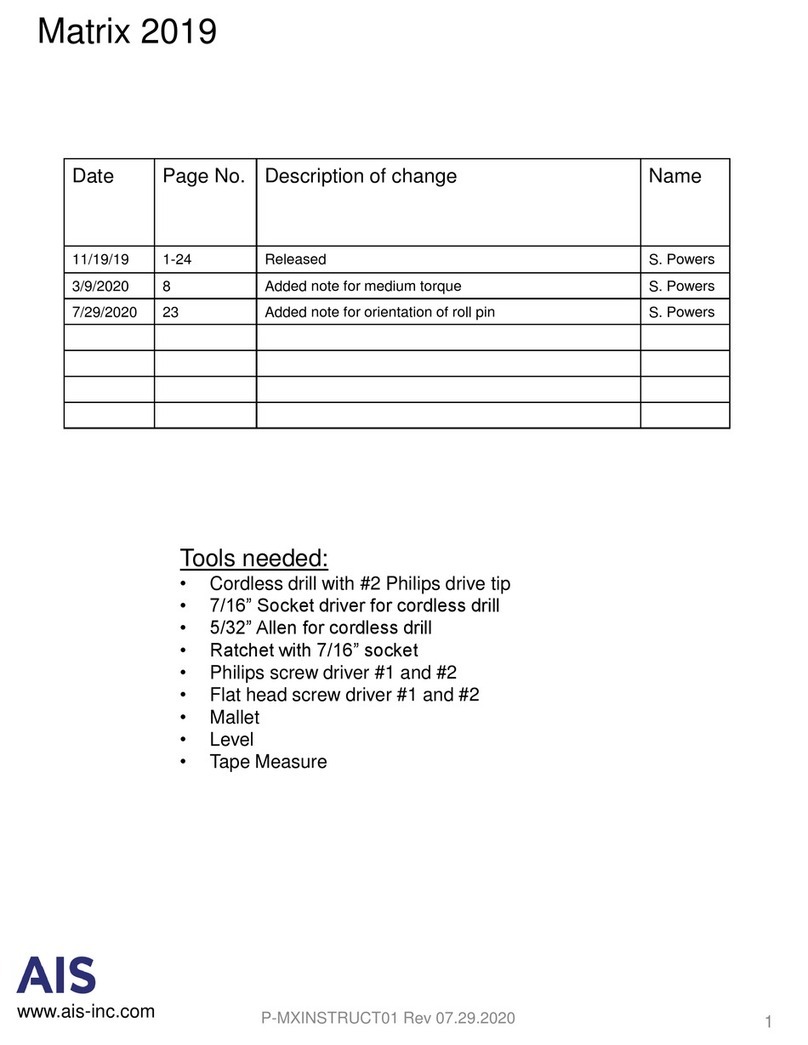

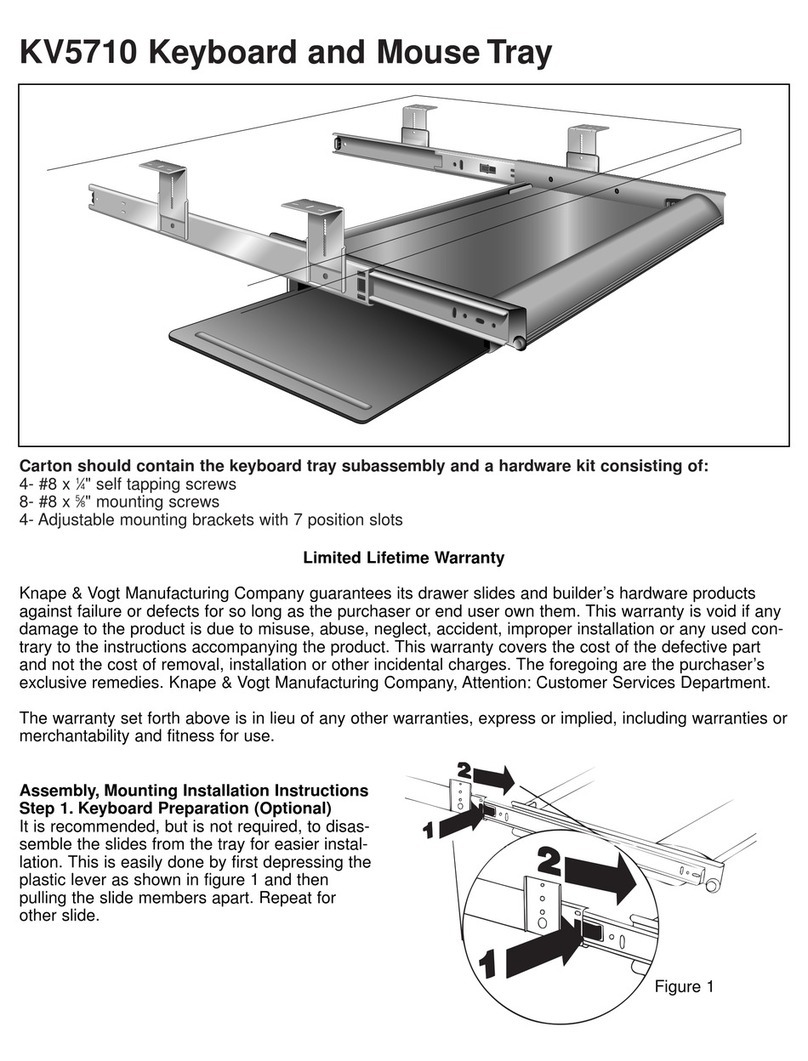

Fixings Guide

Fixing box contents

-2 x m6 x 25mm zinc plated bolts

-4 x zinc plated m6 penny washers

-8 x m6 x 20mm self tapping screws

-Pod cloth

-Pod cleaner

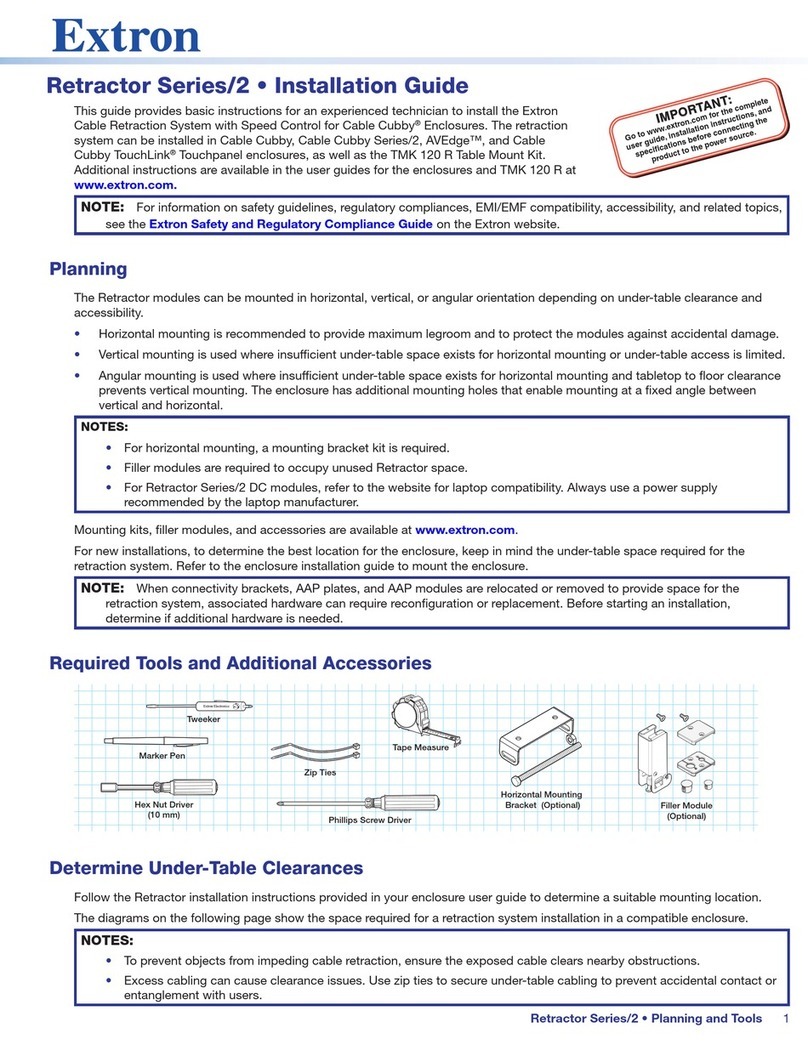

Tools & Accessories

-M10 ratchet socket set with spacer bar

-M10 spanner angled or flat

-Tape Measure

-Step ladder

-G Clamps x 2

-Bin liner

Installation Guide

4 Meeting Pod Installation Guide sales@themeetingpod.co.uk

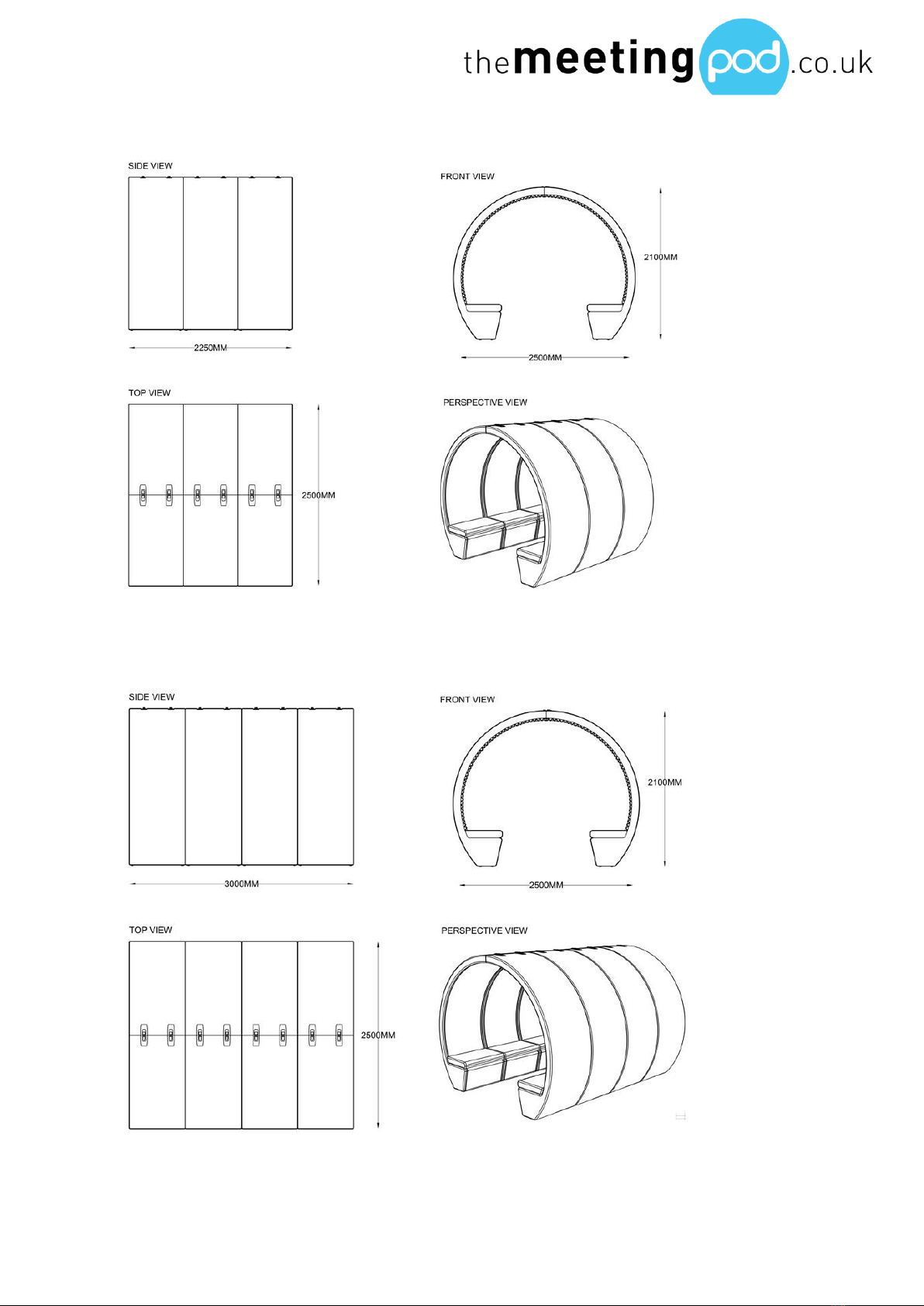

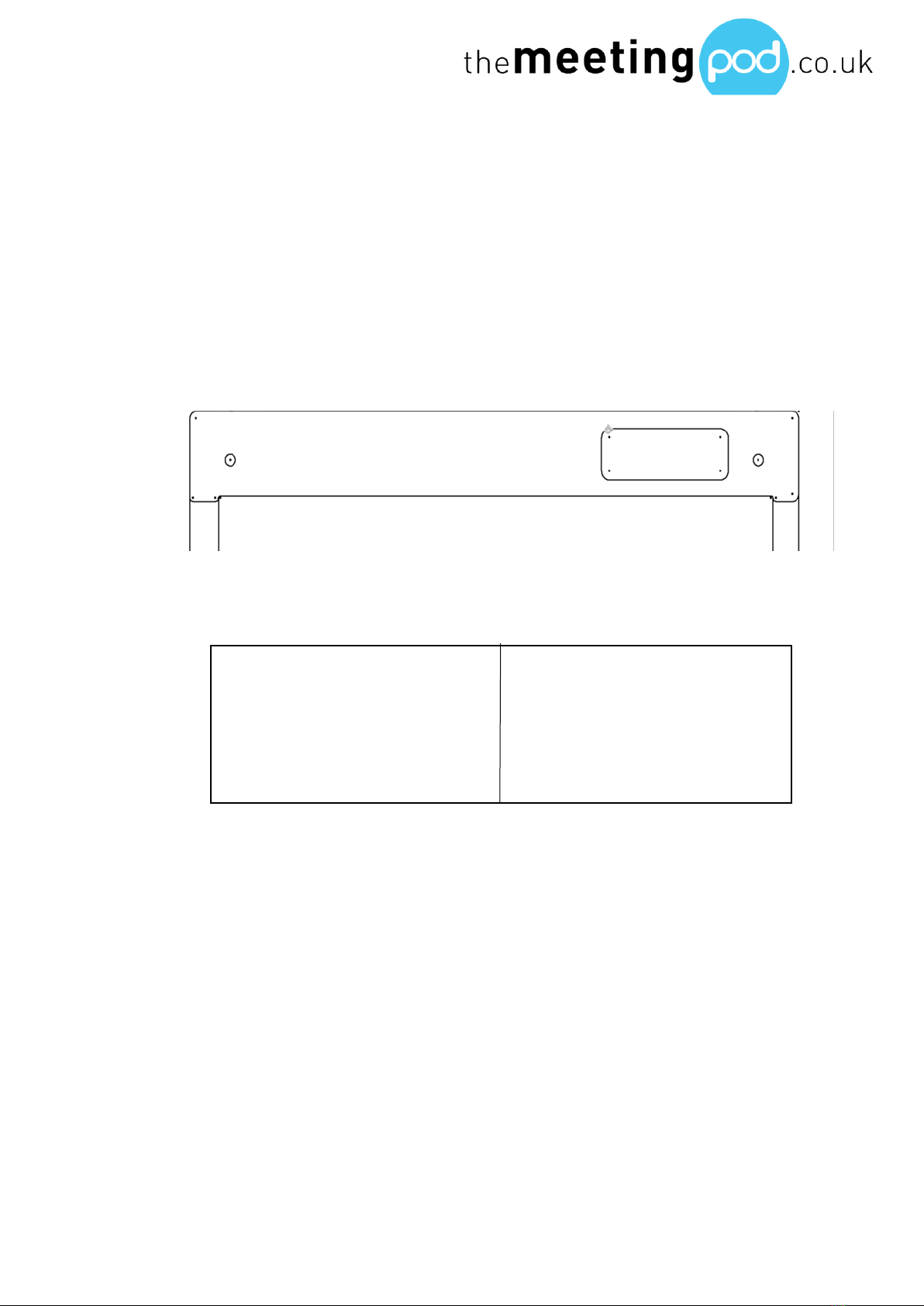

Floor Plans

2 Person Meeting Pod

4 Person Meeting Pod

Installation Guide

5 Meeting Pod Installation Guide sales@themeetingpod.co.uk

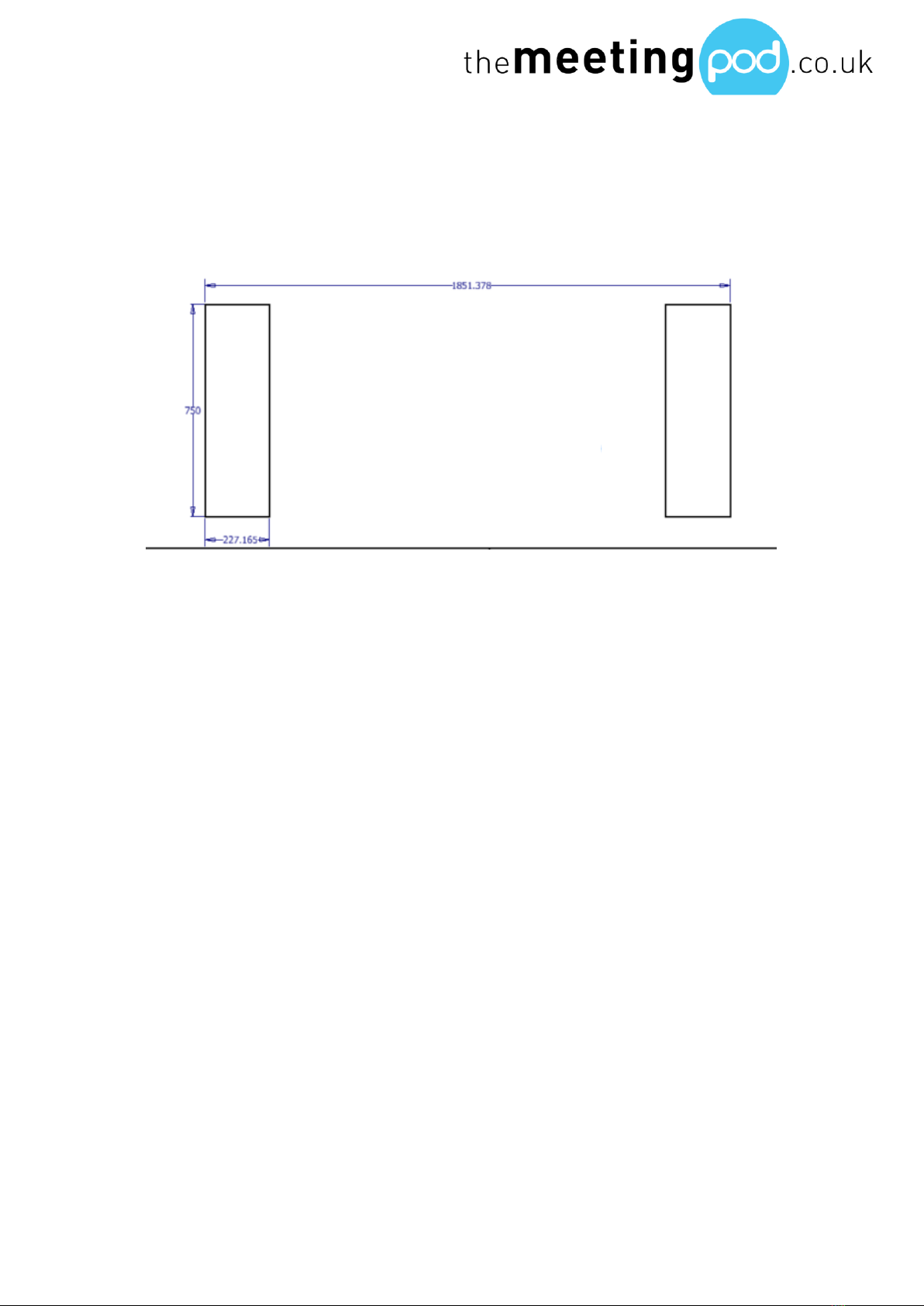

6 Person Meeting Pod

8 Person Meeting Pod

Installation Guide

6 Meeting Pod Installation Guide sales@themeetingpod.co.uk

Installation Instructions

Placement

-Lay all items flat to ensure limited damage occurs. Keep desire location

of the pods clean

-Remove all packaging. Take care when removing packaging as this

can cause damage easily

-Product code on top of the joining faces will help to locate pods

(example below)

-Segments should be placed according to floor plan

Joining

-Collect 2 x m6 25mm bolts along with 2 x m6 penny washers

-Carefully peel back the top 300mm of acoustic foam- note the foam

can rip if care is not taken

-Repeat process on all segments

Front Left

Front Right

Front Entrance

Front Right

Installation Guide

7 Meeting Pod Installation Guide sales@themeetingpod.co.uk

-The pods are designed to stay up right when left idle. To remove any

danger of segments falling clamp the products together as indicated

above, this helps the final alignment when bolting together.

-When pulling back the acoustic foam you will find two access holes in

the meeting pod lining.

-Place m6 bolts and washers through the access hole into the bolting

hole

Installation Guide

8 Meeting Pod Installation Guide sales@themeetingpod.co.uk

-Bolt through the right-hand pod

-Nut and washer through the left-hand pod

-Tighten loosely with hands and repeat this process on both holes

-Once hand tight, tighten further using a M10 socket. Hold the second

spanner on the nut end and together firmly

-Bolting alignment is now complete

Fixing down

-Tools required: 4 x 25mm coach bolts and 4 x m6 penny washers. M10

socket drive and power drill

-Remove cushions. Cushions are secured with Velcro on the underside

and the upper side of the seat moulding

-Four pre-drilled bolting hold will be visible in composite seat base

Bolting holes

Installation Guide

9 Meeting Pod Installation Guide sales@themeetingpod.co.uk

-Use 4 x m6 penny washers and 4 x m6 self-tapping screws to fix down-

using a M10 spanner

-Once one side is fixed, align the other segments accordingly. See

below for dimensions

-Repeat fixing down process once segments in correct location

-Use a straight edge to ensure there is no twist within the front facing

planes of the pods. If a straight edge is not avaiable, please use the

method of measuing to the nearest wall

Final process

-Once all the steps have been followed, place cushions back down by

pushing back of cushions into the pod acoustic foam, and align

accordingly to front and back of composite seat base

Pod bases

Installation Guide

10 Meeting Pod Installation Guide sales@themeetingpod.co.uk

Pod Accessories

Rear Glass Enclosure

Tools required: 2 x 6mm glass wings, 10 x glass adapters and glass adapter

key (supplied)

-Locate rear left and right pods. Pods can be located via labelling

system on the front face of the pod (fix each wing onto pods before

they are assembled)

-Wipe clean bolting surface of glass and pod

-Ensure floor is clean and free of debris

-Bolt glass wings onto pod using glass adapters. Start from the bottom

and work way up (this removes any discrepancies in alignment that

may occur)

Installation Guide

11 Meeting Pod Installation Guide sales@themeetingpod.co.uk

-Tighten all glass adapter hand tight. Final tension is gained using glass

adapter key. Work 1 to 5 (1 being bottom, 5 being top), tighten glass

adapters clockwise

-Repeat process on other wing

-Once complete, bring pods together leaving 60mm face to face at

the top

-Push pods carefully into desired location. Leave 30mm gap to insert

back panel

-Wipe clean glass faces

Central Core Back Panel

Tools required: 4 x m6 washers, 2 x m6 bolts, 2 x m6 nuts, 2 x 10mm socket

spanners and spray adhesive

-Slide central core Y section over the edge of the glass wing

-Pull opposite pod into place

-Ensure both wings are positioned correctly in Y section grove

-Carefully pull down top 300mm of acoustic foam

Installation Guide

12 Meeting Pod Installation Guide sales@themeetingpod.co.uk

-Place 2 x 25mm x 6mm bolts over 2 x m6 penny washers. Place bolts

through the opening holes on the right hand pod (when facing the

product)

-Place 2 x m6 penny washers and 2 x m6 onto the male end of the bolts.

Hand tighten

-Ensure top join of pods are in correct alignment

-Left hand nut will require open ended m10 spanner

-Right hand bolt will require a m10 spanner with extension bar to gain

access to turn tight.

-Tighten bolts in clockwise motion

Front Glass Enclosure

Tools required: 2 x 10mm glass wings, 2 x 8mm glass doors, 10 x glass adapters,

4 x glass to glass hinges, 2 x glass handles, 2 x silicone stopper, glass adapter

key (supplied), m6 Alan key, pozi screwdriver and packers

-Locate front left and right pods, putting them near the desired end

location. Pods can be located via labelling system on the front face of

the pod

-Wipe clean bolting surface of glass and pod

-Ensure floor is clean and free of debris

Installation Guide

13 Meeting Pod Installation Guide sales@themeetingpod.co.uk

-Bolt glass wings onto pod using glass adapters. Start from the bottom

and work way up (this removes any discrepancies in alignment that

may occur)

-Tighten all glass adapter hand tight. Final tension is gained using glass

adapter key. Work 1 to 5 (1 being bottom, 5 being top), tighten glass

adapters clockwise

-Repeat process on other wing

-Ensure all glass adapters are tightened correctly

-Make sure all pod alignment is correct in both planes and eliminate

any twists within the pods

Hanging glass doors

-Collect 4 x glass to glass hinges

-Remove the machine screws using the Alan key supplied within the

pack

-Collect right hand glass door- ensure glass door is correct. Magnet can

be found on the left-hand side on the outwards face. The door will

automatically pull into the hidden reverse magnet within the pod

-Pack the door until hinge holes on glass door and wing are horizontally

level

Installation Guide

14 Meeting Pod Installation Guide sales@themeetingpod.co.uk

-Place hinge through machines holes in glass

-Ensure hinge fixing holes are facing inwards towards the pod, leaving a

seamless machine hinges finish on the exterior of the glass. The hinge

leaf containing two knuckles should always be on the glazed wing

-Ensure rubber leafs and gaskets are in place before tightening

machine screws

-Tighten all four screws clockwise using the m6 Alan key

-Ensure glass is packed up and taking weight directly into the ground

before fitting second hinge

-Repeat process on other door

-Remove all packers

-Ensure doors hang freely

-To eliminate damage push left-hand door shut into concealed

magnet, making sure the door stays shut

-Repeat process on right-hand door

Installation Guide

15 Meeting Pod Installation Guide sales@themeetingpod.co.uk

-Ensure all hinge machine screws are tightened correctly

-Ensure glass alignment is parallel between the door and the glass wing.

6mm gap

-Ensure glass to door joining alignment is parallel. 4mm gap is necessary

for acoustics

(to achieve parallel lines, move pods either in or out to shut or open

glass gaps)

-Ensure top arcs of pod segments are in true radius

Fitting Handles

-Unpack 2 x glass handles

-Loosen grub screw on the top and bottom of the handle using Alan

key supplied. Ensure not to drop or lose screws when dismantling

-Remove machine screw from back side of the front handle

-Place screws through the located holes on the glass, found on the

inner leading edges

-Place handles through holes

-Join back handle onto front hand on the other side of the glass

-Ensure grub screw is in correct position, then retighten screw with Alan

key

-Test pull the handle to chick rigidity in fixing

-Repeat process on other handle

Installation Guide

16 Meeting Pod Installation Guide sales@themeetingpod.co.uk

Silicone stoppers

-Peel off silicone stoppers from backing film

-Stick on the inside of the glass door, behind the centre of the magnet

Additional Pod Segments

Tools required: 8 x m6 washers per additional segment, 4 x m6 bolts per

additional segment, 4 x m6 nuts per additional segment and 2 x 10mm socket

spanners

Installation Guide

17 Meeting Pod Installation Guide sales@themeetingpod.co.uk

-Remove top 300mm acoustic foam to gain access to fixing holes

-Place m6 bolt and m6 washer through the hole into the other pod

segment

-Place m6 washer and m6 nut on the male side of the bolt

-Hand tighten

-Ensure alignment is correct. If yes, then tighten further using spanners

-Collect 3 x m6 nuts and 3 x m6 washers, place through the locating

holes under the seat

-Match remaining 3 x m6 nuts and 3 x m6 washers through the other

pod segment and hand tighten

-Tighten further using spanners

-Repeat process on opposite side and for any additional segments

Installation Guide

18 Meeting Pod Installation Guide sales@themeetingpod.co.uk

Pod Electrics: Lighting & Power

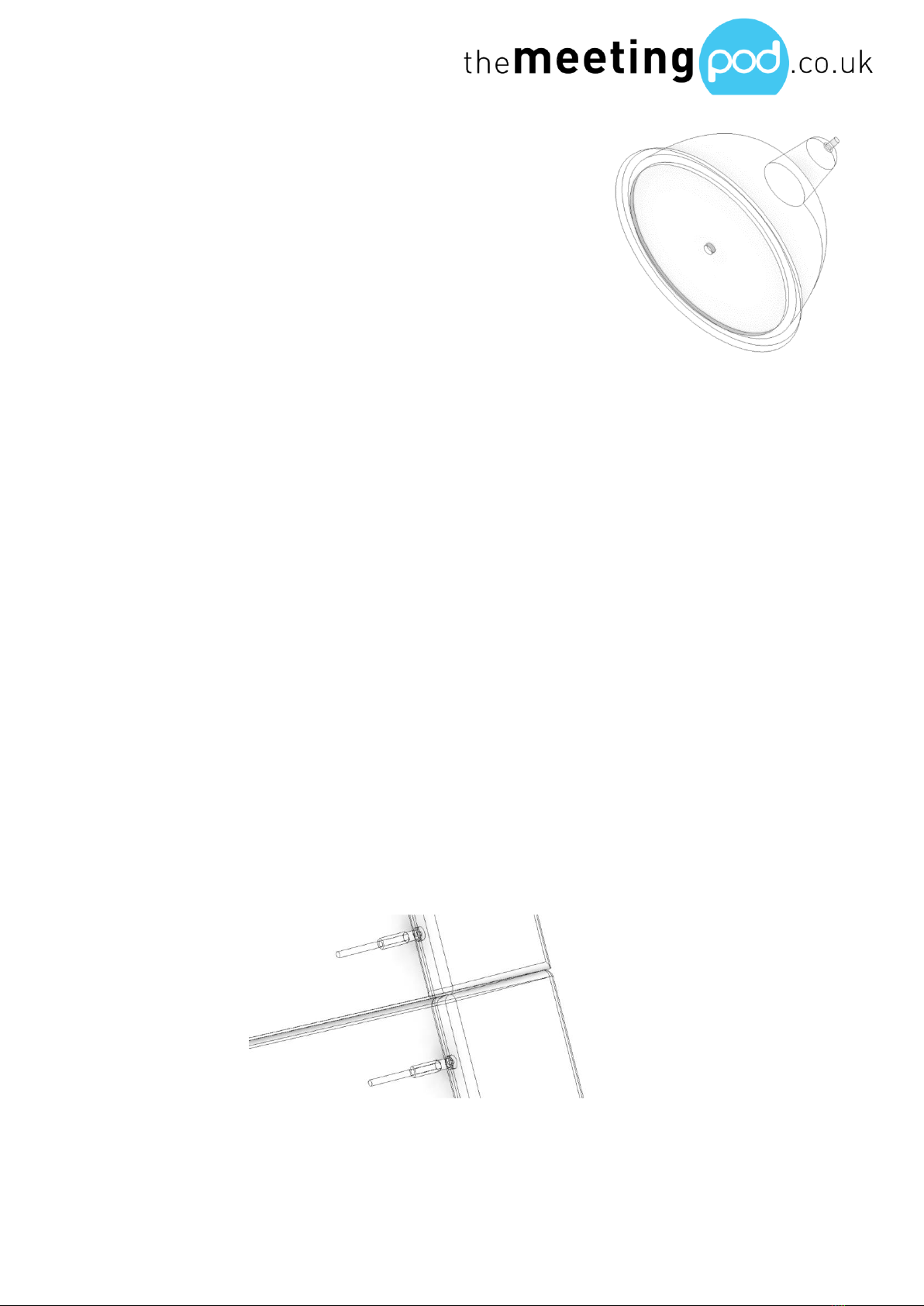

Lighting

Note: Light fitting can only be completed once the

pods have been secured together

Fitting

-Locate lighting track from packaging

-De-tangle any lines from the track

-Place snap hooks on D-rings found at back of pod

-Ensure light bulbs are facing down

-Pull tight cable tracks until tension buckles reach D-rings at the

entrance of the pod

-Tighten tension buckles in a clockwise motion until track is taught.

Removing any sag from line

-Ensure bulbs are vertically level

Pod with Back Panel

-Ensure snap hooks are connected securely to D-rings at entrance of

the pod

-Check the tension is correct

-De-tangle any lines from the track

-Place male connectors into the two female connection ports located

at the top of the back panel

-Ensure connection is pushed in correctly

Installation Guide

19 Meeting Pod Installation Guide sales@themeetingpod.co.uk

Open ring pod

-Ensure snap hooks are connected securely to D-rings at entrance of

the pod

-Check the tension is correct

-De-tangle any lines from the track

-Place male connectors into the two female connection ports located

at the top of the composite rib

-Ensure connection is pushed in correctly

Installation Guide

20 Meeting Pod Installation Guide sales@themeetingpod.co.uk

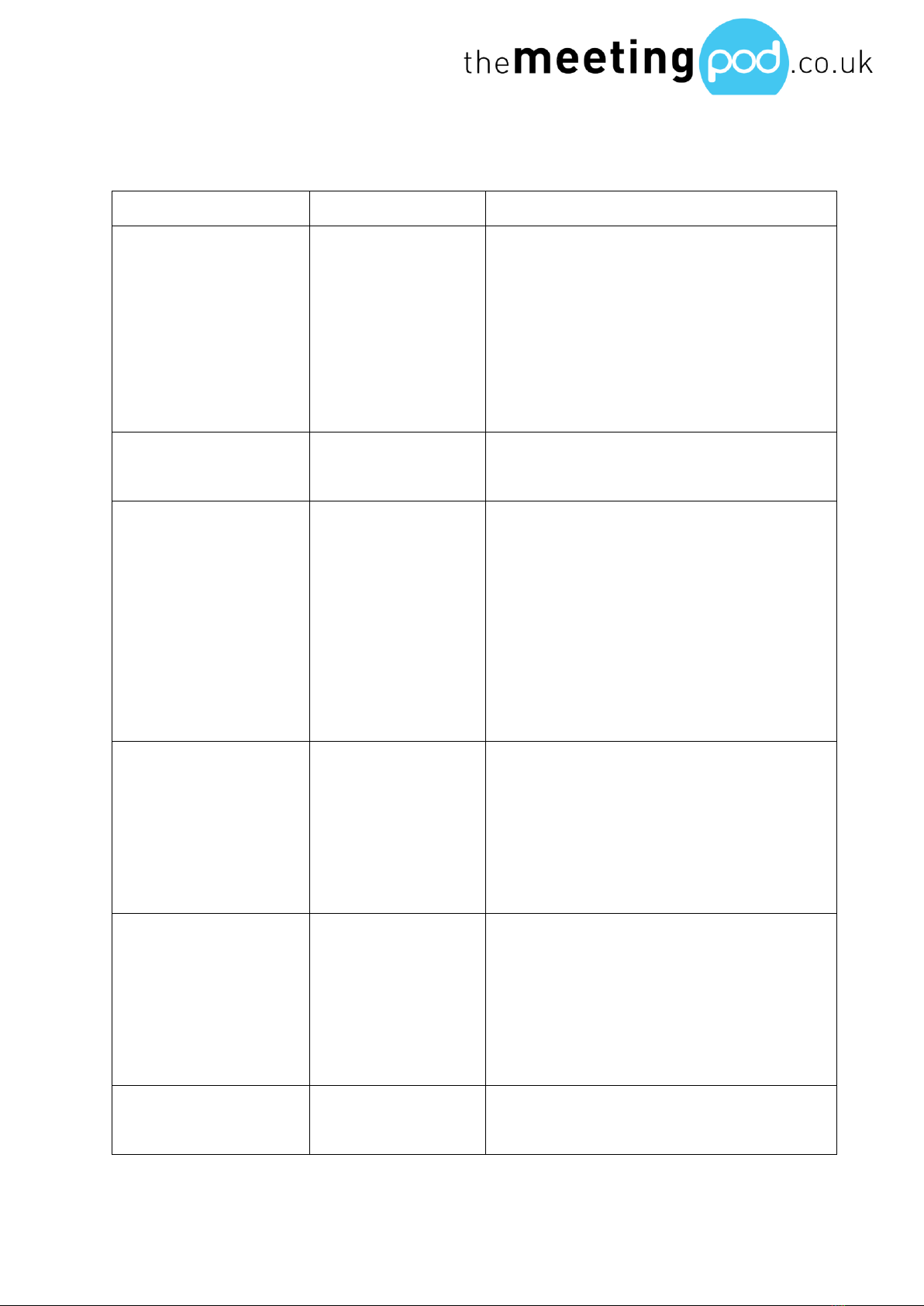

Warranty: Pod & Accessories

Pod components

Warranty length

Covered when installed correctly

Shell

12 months

-All pod shells should be wiped

clean with no smears

-All bolts present in joining holes

-Pods screwed down correctly

-Accurate silicone beading

applied

Acoustic foam

12 months

-Ensure all edges are secured

-Test pull each foam edge

Cushions

12 months

-Ensure Velcro has been

applied to pod seat base and

underside of cushion correctly

-Place cushions directly onto

Velcro

-Test pull cushions to assure no

lifting

Back panel central

core

12 months

-Ensure back panel is bolted

into wings correctly

-Ensure back panel is level

-Table is secure and correctly

fixed

Lighting

12 months

-Confirm lighting track is taut

-Bulbs are tightened and caps

clicked into place

-Electric modules fitted in back

panel correctly

Table: 2 person

12 months

-Table fitted correctly to back

panel

This manual suits for next models

3

Table of contents