12345

Matrix 2019

www.ais-inc.comwww.ais-inc.com 6

P-MXINSTRUCT01 Rev 07.29.2020

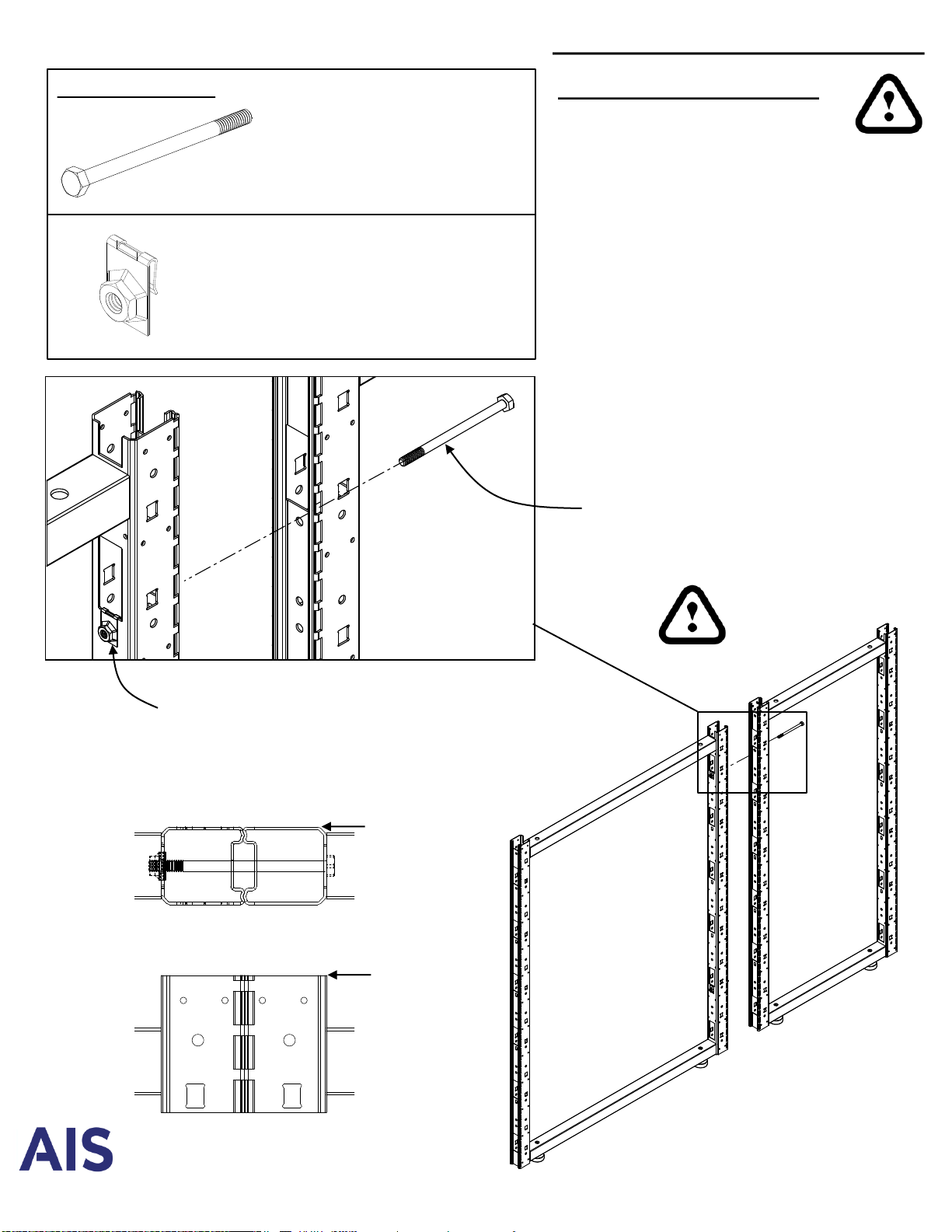

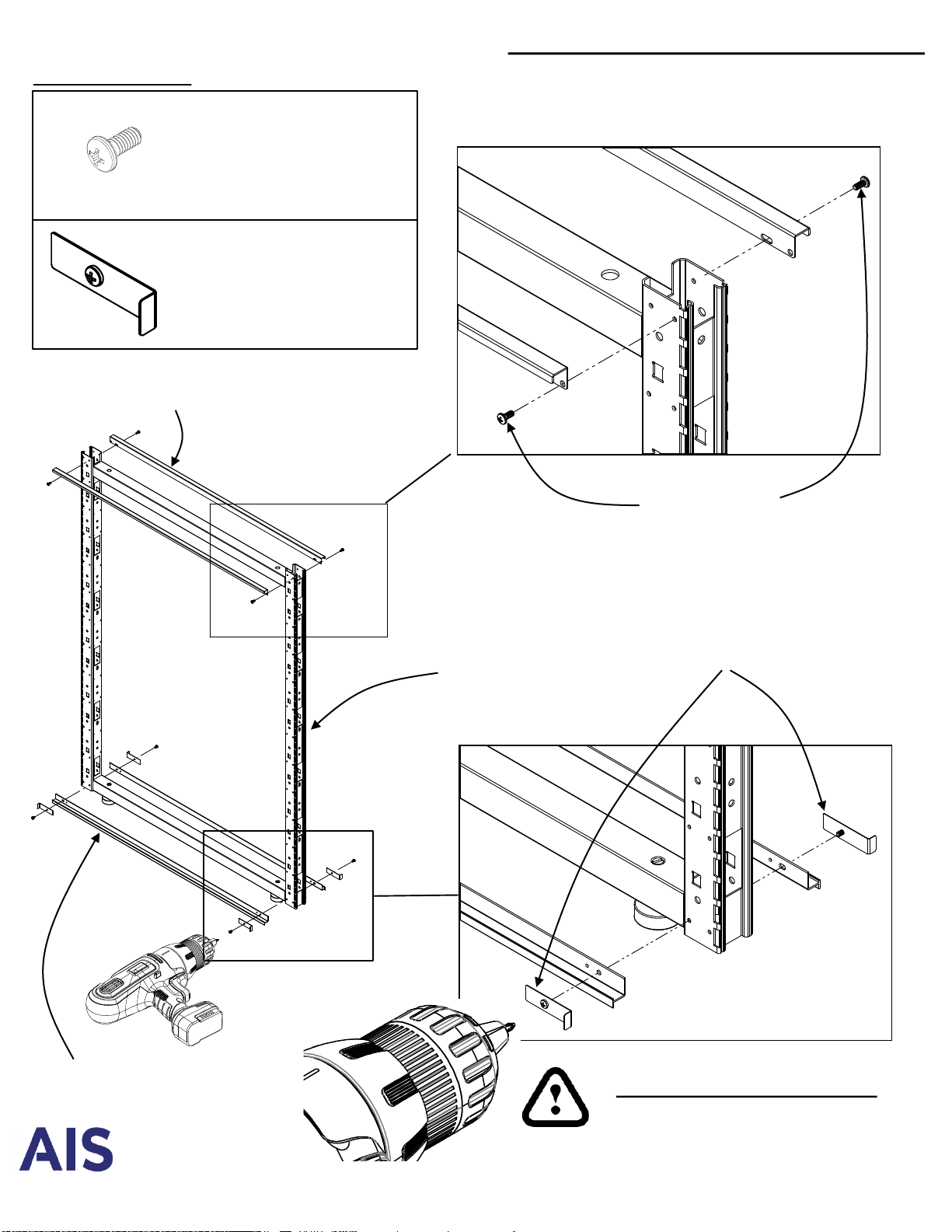

Stack-On Connectors

#10-32 Hex Nut

Remove Base Connector Vertical Cover:

1. Remove and save #10-32 Hex Nuts and

Bolts at top of Connector (2 places)

2. Slide Vertical Cover up approximately ¾”

to release it from the bottom tabs.

Up

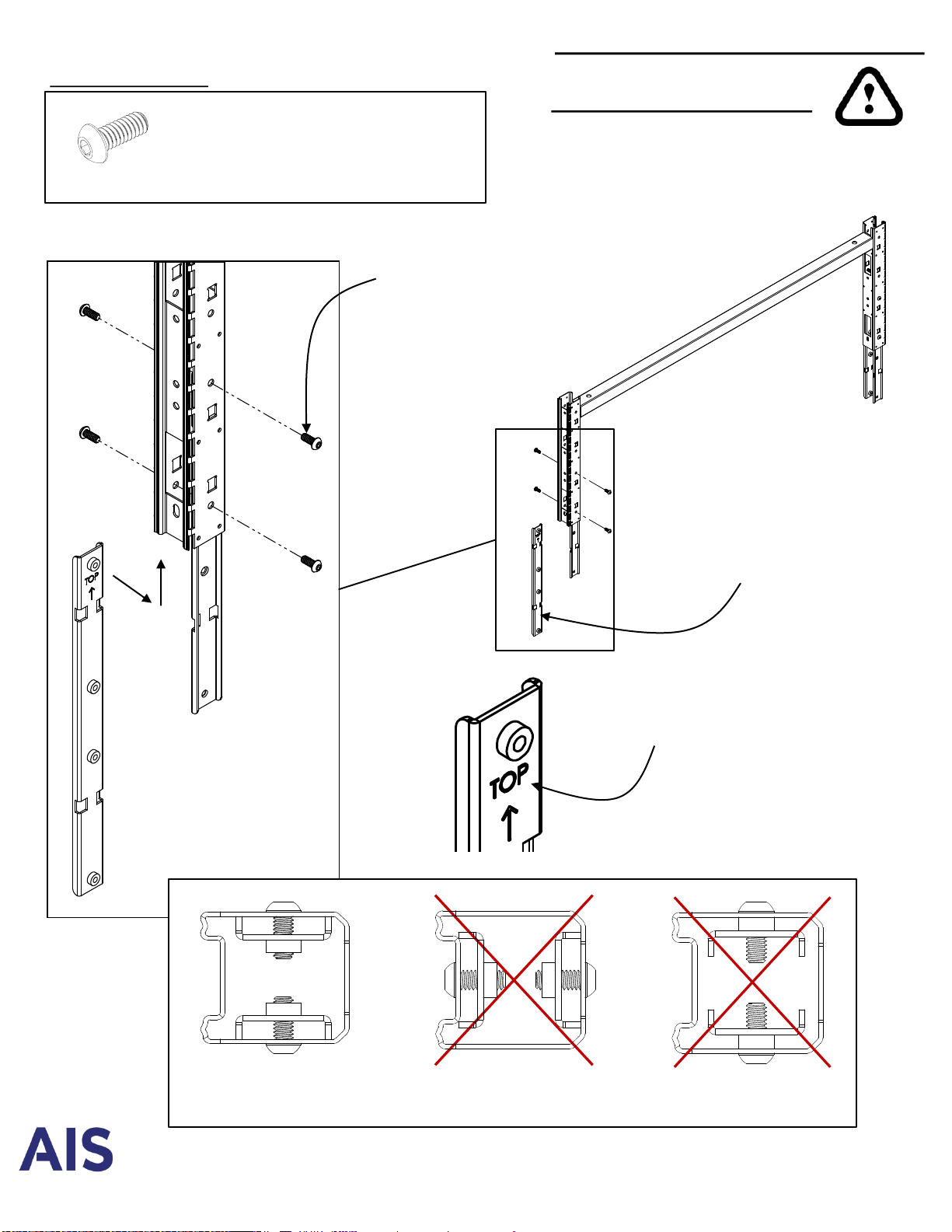

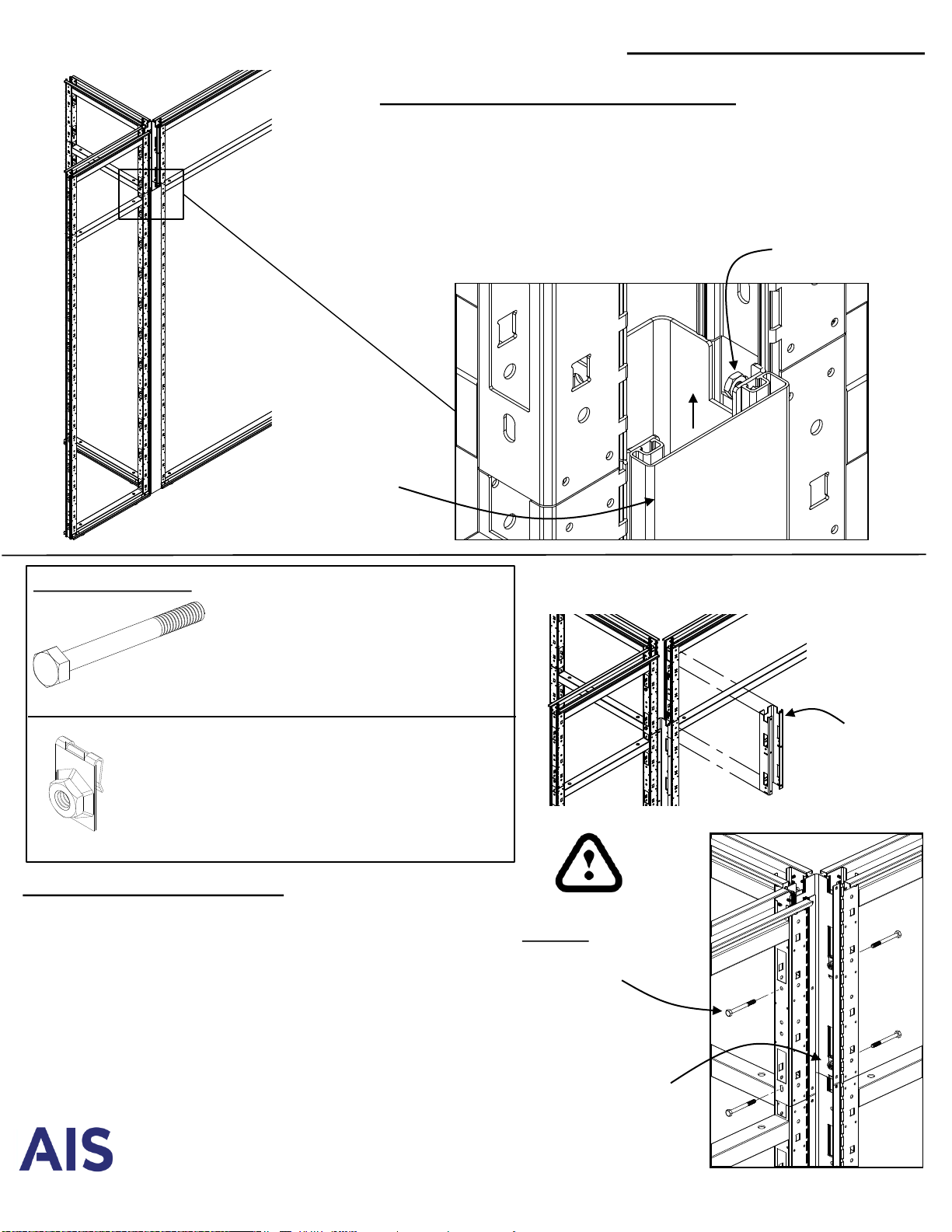

Required hardware: ¼-20 x 2 ¼” Hex Bolt

#RP-M2BOLT1

Use 7/16” magnetic hex drive

2-way Connection = 4 bolts

3-way Connection = 6 bolts

4-way Connection = 8 bolts

¼-20 Tinnerman Nut

#RS-HNC33892

(Factory installed, on one side of

frame. Installers may be required to

remove from frames if connecting to

2-way, 3-way or 4-way connector)

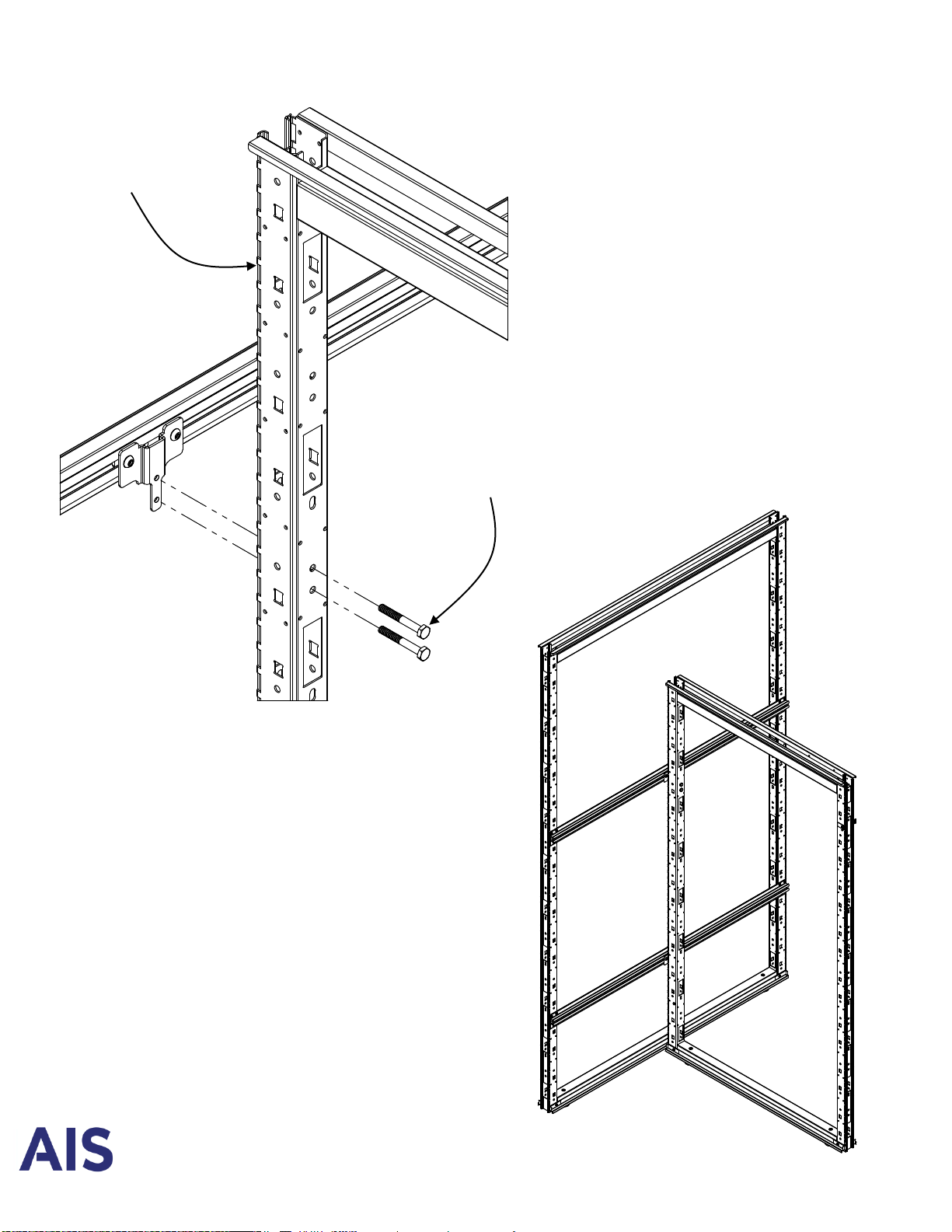

Stack-On

Connector

¼-20 Tinnerman Nut

May have moved during shipping.

To re-center, briefly insert

#2 philips screw driver through

connector hole into the

tinnerman nut.

¼-20 x 2 ¼” Hex Bolt

First bolt must be installed at

top of frame to ensure proper

vertical alignment

IMPORTANT INSTRUCTIONS:

•Place first bolt at top of frame, below

first electrical chase hole. This hole is

round and will align frames vertically. All

other bolt locations are slots.

•Thread all bolts loosely, making sure

bolts are properly threaded to prevent

cross-stripping. Tighten top bolt first,

then tighten all remaining bolts to

approx. 100 inch lbs torque, or using a

12 volt drill on medium torque.

Lift off

Vertical Cover