Megmeet MTC-04-NTR User manual

1

MTC-04-NTR Thermostat User Manual

Thank you for using Megmeet MTC-04-NTR module. Before using the

PLC product, please carefully read this booklet so as to better

understand it, fully use it, and ensure safety.This user manual is to offer

you a quick guide to the design, installation, connection and

maintenance of MTC-04-NTR module, convenient for on-site reference.

Briefly introduced in this booklet are the hardware specs, features, and

usage of MTC-04-NTR module, plus the optional parts and FAQ for

your reference.

This manual MTC-04-NTR module for the following members:

MTC-04-NTR Thermostat User Manual

Version 1.0

Revision date July 16, 2012

BOM

1.Introduction

Model description as 1-1.

TR: transistor and relay

temperature control, 8 relay

alarm, 4 I/O input mode.

Input method

N: No CT (Current test)

Input

The same input and

output channels of

channel number and

module number

Thermostat

Megmeet

TR

M

TC

04

-

-

N

Table 1-1 Module Description

2.Wiring Instructions

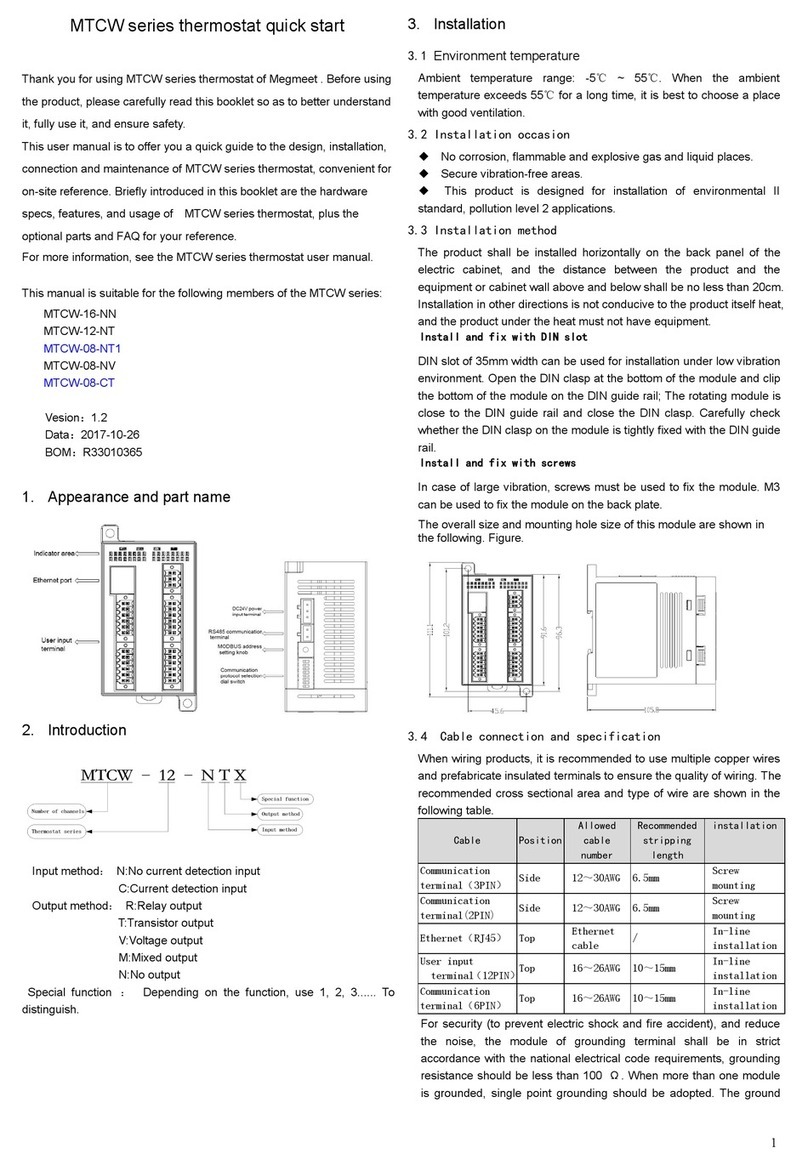

User input wiring terminals shown in figure 2-1.

Table 2-1 MTC-04-NTR enter the user terminal wiring diagram

Figure ①~⑦wiring must be noted that seven aspects:

①The thermocouple (thermal resistance) signal is recommended to be

accessed via a shielded cable (connection cable). Cables should be

kept away from power lines or other wires that may cause

electromagnetic interference. It is recommended to use cables less

than 100 meters in length (connecting cables). There is impedance in

the cable (connecting cable), which will introduce measurement error.

Characteristic adjustment can solve this problem. For specific operation,

please refer to "MTC-04-NTR thermostat user manual".

②Thermal resistance (type Pt100, JPt100, Cu100, Cu50)

required the three-wire connection.

③If there is too much electrical interference, the shield wire

(thermocouple compensationcable shielding terminal, thermal

resistance of the connecting cable shielding terminal 485 linescreen)

should be connected to ground terminal PG.

④The thermostat grounding PG should be good grounding.

⑤24V power supply can use the main output of 24Vdc auxiliary power

supply module, you can also use the other to meet the

requirements of power.

⑥3.2 user basis having the output performance indicators to select

the appropriate power supply and solid state relays

⑦Relay output control, power supply ≤DC30V or ≤AC250V, current

≤2A.

⑧4 external input support source input and sink input, input voltage

range DC18V ~ DC28V.

Note: please do not connect the 220VAC to OUT1 ~ OUT4 output

by mistake to avoid burning out the module!

3.Instructions

3.1 Power indicator

The power indicator of MTC-04-NTR is shown in figure 3-1.

Table 3-1 Power indicator

Project

Instruction

Power

24Vdc (-15% ~20%), the maximum allowable ripple

voltage 5%, maximum power consumption 160mA.

3.2 Performance indicators

Table 3-2 Performance indicators

Project

Indicators

Input signal

Thermocouple

type

K、J、E、N、T、R、S、B(Applicable

to each channel)

Thermal

resistant type

Pt100、Cu100、JPt100、Cu50、Ni120

(Applicable to each channel)

Output

method

The output

gate open

transistor

Power supply voltage circuit:5V~24V;

The biggest power supply voltage

circuit:30V;Loop current:0.3A/24Vdc;

leakage current when open:<

0.1mA/30Vdc;Minimum load:5mA

(5Vdc~24Vdc)

Delay output

≤DC30V or ≤AC250V; Current≤2A

Input port

Input method

Support source input and sink input

Voltage range

DC18V~DC28V

Sampling period

100 milliseconds or 1 second (optional)

Control cycle

0.1~2seconds or 1~100 seconds,The

default value for 0.2s or 2s

Control method

ON/OFF control,Hand control,PID

control.Heating and cooling PID

control①

Nominal

Temperat

ure Rang

e

Type K

-100℃~1200℃(-148℉~2192℉)

Type J

-100℃~600℃(-148℉~1112℉)

Type E

-100℃~850℃(-148℉~1562℉)

Type N

-100℃~1200℃(-148℉~2192℉)

Type T

-200℃~300℃(-328℉~572℉)

Type R

0℃~1600℃(32℉~2912℉)

Type S

0℃~1600℃(32℉~2912℉)

Type B

400℃~1800℃(752℉~3272℉)

Pt100

-150℃~600℃(-238℉~1112℉)

JPt100

-150℃~500℃(-238℉~932℉)

Cu100

-30℃~120℃(-22℉~248℉)

Cu50

-30℃~120℃(-22℉~248℉)

Ni120

-80.0℃~280.0℃(-112.0℉~536.0℉)

2

Project

Indicators

Precision

Thermocouple

± 0.3% input range.Ambient

temperature compensation error ≤2℃

Thermal

resistant

± 0.5% input range

Isolation

The sampling channel is isolated from

the power supply, the sampling channel

is isolated from the output, and the

channels are isolated from each other

Note①: when the input type of channel 2 and channel 4 is 0, the

temperature control output OUT2 and OUT4 will be automatically

assigned to the refrigeration control output of channel 1 and channel 3;

If the input type of channel 1 to channel 4 is not selected as 0, and are

set to the heating and cooling control function, then the refrigeration

control of each channel can choose OUT5 ~ OUT12 to output, or

through the PLC read MTC #733 (refrigeration output state) register to

use the PLC I/O port output refrigeration control.

3. 3 Buffer Zone(BFM)

MTC-04 Modbus or MCbus through the BFM and the main module

temperature data and other information exchange. Reading and writing

attributes of buffer can use MODBUS or MCBUS instructions for

reading and writing. If you read the reserve unit, will get zero value.

Save mark Y representative with the parameter save function, can be

flash memory, marked N said cannot be flash memory. Using MODBUS

agreement, most once writeable only 50 BFM unit. BFM unit part

content as follows:

1. The channel operation monitoring;

2. Channel characteristics set;

3. Control function setting;

4. BFM parameters save Settings;

5. Other.

For more about the PID, set, alarm, MCbus and other related content

and routines, please refer to the MTC-04-NTR thermostat user manual

".

3. 3.1 The channel operation monitoring

MTC-04-NTR buffer (BFM) to monitor the operation of the channel

contents in Table 3-3.

Table 3-3 The channel operation monitoring of MTC-04-NTR buffe(BFM)

BFM

Contents

Remarks

na

tur

e

Sa

ve

CH1

CH2

CH3

CH4

#701

#702

#703

#704

Measured value

(PV)*1

Units: 0.1 ℃

and 0.1 ℉

R

N

#709

#710

#711

#712

Heat side

control output

(MV) * 2

The default

value: 0.0%

(percentage

show)

R

N

#717

#718

#719

#720

More

paragraphs of

the currently

executing

period control *

3

Default value:

0.0%

(expressed as a

percentage)

R

N

#725

#726

#727

#728

Multi-step

control current

execution

segment * 3

Default value:0

Range:0~8

R

N

#733

Output state of

refrigeration

end *4

Default value:0

R

N

#734

Input port

status*5

Default value:0

R

N

#735

Error status

word * 6

Default value:0

R

N

#736

Set value range

error address*7

0:normal

Other values:

setting the

wrong BFM

address

R

N

#737

Cold junction

temperature*8

Default value:0

R

N

#738

#739

#740

#741

Work status

word * 9

Default value:0

R

N

* 1. #701 ~ #704:The measured value of channel 1 to channel 4. The

unit is determined according to the input type (#901 ~ #904). When the

mode is Celsius, the unit is 0.1℃; when the mode is Fahrenheit, the

unit is 0.1℉.

* 2. #709 ~ #712:Heating side control output value MV; #717 ~ #720:

cooling hot side control output value MV; The control output value of the

channel obtained by the control algorithm.

* 3. #725 ~ #728: Each channel multi-step setting executes the current

segment. The segment number being executed when multiple segment

Settings are displayed. 0: indicates that the execution state is not set in

multiple segments or that multiple segments are completed.

* 4. #733: Output status of refrigeration end. Bit0 corresponds to the

output state of the refrigeration end of channel 1, Bit1 corresponds to

the output state of the refrigeration end of channel 2, and so on. When

is 1, the output of the refrigeration end is effective; when is 0, the output

of the refrigeration end is invalid.

* 5. #734: Input port status. Bit0 corresponds to input port 1, Bit1 to

input port 2, and so on. A value of 1 indicates that the input is valid, and

a value of 0 indicates that the input is invalid.

* 6. The failure status information of #735 is shown in table 3-4.

Table3-4 BFM#735 State Information

A state of BFM#735

ON(1)

OFF(0)

b0:Error

When b1 ~ b15 any error occurs,

this flag is 1 (b1 ~ b2 in any

one of 1, stop all channel AD

converter)

Correct

b1:Save

-

-

b2:Hardware fault

AD converter or other hardware

failure

Hardware

normal

b3:Set value

backup error

When the interference and

the MTC due to an internal error

occurs, the flag will change

to 1. Then if you turn the

power off, still not be clear error,

please contact the sales agent or

our

Data

backup

normal

b4:The cold

junction

temperature

compensation error

b5:AD transform

digital range error

AD transform digital output value

is less than -1 or greater than

4096, the flag is 1

Digital

output

value is

normal

b6:Set data

recovery error

When the interference and

the MTC due to an internal error,

if error reading backup data, the

flag is 1

-

b7:Save

-

-

b8~b15 Broken

accidentally

detection (only

support

thermocouple)

1 ~ 4 channel thermocouple

broken accidentally, the flag is 1

No broken

accidentall

y wrong

channel

* 7. #736: error address setting value range. Incorrect BFM area code

is displayed.

* 8. #737: reflects the current cold end temperature.

* 9. #738 ~ #741: status word for each channel. Shows the error state

and control state of each channel, #738 corresponds to channel 1,

#739 corresponds to channel 2, and so on. See table 3-5 for specific

information.

Table 3-5 each channel error status and control of the state

Bite

Definition

ON(1)

OFF(0)

b0~b3

Alarm 1 ~ 4 state

Alarm

No alarn

b4

Sign of

Initialization

complete

Initialization complete

Initialization

unfinished

b5

Auto-tuning state

Self-tuning state

Status of no

self-tuning

b6

Control state

Control state

uncontrolled

state

b7

Control

completion status

The temperature reaches

setting and in a stable

state

Incomplete

control

b8~b15

Save

-

-

3

3. 3.2 channel characteristics set

MTC-04 buffer (BFM) channel characteristics set as table 3-6

Table 3-6 MTC-04-NTR buffer (BFM) channel characteristics set

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1

CH2

CH3

CH4

#200

Restore

factory

setting*1

Default value:0

R/W

N

#201

Change

Settings

allowed*2

Default value:1,

Allows to change

0:Not Allowed

To Change

R/W

N

#801

#802

#803

#804

Digital filter

set of one

step

Default value:0

Range:0~100

(Seconds)

R/W

Y

#809

#810

#811

#812

D0*3

Default value:0

R/W

Y

#817

#818

#819

#8209

D1*3

Default value:

12000(With the

input type

change)

R/W

Y

#825

#826

#827

#828

A0*3

Default value:0

R

N

#833

#834

#835

#836

A1*3

Default value:

12000

(With the input

type change)

R

N

* 1. After #200 is set to 1, all BFM units of the module are reset to their

default values.

* 2. Change Settings allowed for BFM. Setting BFM#201 to 0 will

prevent the user from making inadvertent adjustments to BFM. Once

the disable Settings feature is set, it remains in effect until the allow

command is set (#201 = 1).

* 3. #801 ~ #804: set the data cache D0 for each channel; #809 ~ #812:

each channel feature sets the data cache D1. Use the two-point

method to set channel characteristics, D0, D1 represents the channel

output digital quantity, A0, A1 represents the channel actual input

temperature value, each channel occupies 4 words. Considering the

convenience of the user's setting, and without affecting the realization

of the function, A0 was fixed as 0℃, and A1 was fixed as the maximum

of the measurement range in the current mode. If you change the D0

and D1 values of the channel, you can change the channel

characteristics. D0 and D1 can be adjusted ±1000 on the basis of

factory setting. If the current mode USES Celsius, the adjustment range

is ±100℃; if the current mode USES Fahrenheit, the adjustment

range is ±100℉. If a value is set beyond this range, the MTC will not

accept it and will keep the original valid setting.

3. 3.3 control function setting

MTC-04-NTR buffer (BFM) set the control function of the content to

table 3-7.

Table 3-7 MTC-04 buffer (BFM) the control function of the set

BFM

Content

Remarks

Natu

re

Sa

ve

CH1

CH2

CH3

CH4

#901

#902

#903

#904

Input type *1

Default value:0

R/W

Y

#909

#910

#911

#912

Set value

(SV) * 2

Default value:

0.0

Unit:0.1℃/℉

R/W

Y

#917

#918

#919

#920

Proportional

cycle time* 3

Default value:2

Range:1~100

R/W

Y

#925

#926

#927

#928

Heat side

proportional

band

Default value:

30

Unit:0.1%

Range:0.1%~

1000.0%

R/W

Y

#933

#934

#935

#936

Heat side int

egral time

Default value:

240

Range:1~3600

(Seconds)

R/W

Y

#941

#942

#943

#944

Heat side

Derivative

time

Default value:

60

Range:0~3600

(Seconds)

R/W

Y

BFM

Content

Remarks

Natu

re

Sa

ve

CH1

CH2

CH3

CH4

#957

#958

#959

#960

Cool side

proportional

band

Default value:

30

Unit:0.1%

Range:0.1%~

1000.0%

R/W

Y

#965

#966

#967

#968

Cool side int

egral time

Default value:

240

Range:1~3600

(Seconds)

R/W

Y

#973

#974

#975

#976

Cool side

derivative

time

Default value:

60

Range:0~3600

(Seconds)

R/W

Y

#981

#982

#983

#984

Overlap/dead

band*4

Default value:0

No overlapped

non-inductive

belt

Setting

range:-input

range~+input

range

R/W

Y

#989

#990

#991

#992

Undershoot

suppression

factor*5

Water-cooled

default

Air-cooled

default

Range:0~1000

R/W

Y

#997

Run/stop

transfer of

CH1-CH4 *6

Default value:

B0000

0:Stop 1:Start

R/W

Y

M0

M1

M2

M3

Run/stop

transfer of

CH1-CH4 *6

Default value:

B0000

0:Stop 1:Start

R/W

Y

#999

Auto-tuning

setting of

CH1- CH4 *7

Default value:

B0000

0:Not self-tuning

or auto-tuning h

as been

completed

1:Auto-Tune

R/W

Y

M8

M9

M10

M11

Auto-tuning

setting of

CH1- CH4 *7

Default value:0

0:Not self-tuning

or auto-tuning h

as been

completed

1:Auto-Tune

R/W

Y

#100

0

#100

1

#100

2

#100

3

Run/stop

transfer of

CH1-CH4 *6

Default value:2

0:Hand 1:

ON/OFF 3:PID

R/W

Y

#100

8

#100

9

#101

0

#101

1

Heat/Cool

action*8

Default value:1

0:Cooling

1:Heating

2:Heating and

cooling (air

cooling)

3:Heating and

cooling (water

cooling)

4:Position ratio

PID

R/W

Y

#101

6

#101

7

#101

8

#101

9

Hand output

value

Default value:0

Range:0.0~

100.0(%)

R/W

Y

#102

4

#102

5

#102

6

#102

7

Adjust

sensitivity

(ON/OFF

control

method is

effective)

Default

value:100

Unit:0.1℃/℉

Range:0~999

R/W

Y

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1

CH2

CH3

CH4

#103

2

#103

3

#103

4

#103

5

Auto-tuning

deviation

Default value:0

Unit:0.1℃/℉

Range:±input

range

R/W

Y

#110

#110

#110

#110

Heat side

Default value:

R/W

Y

4

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1

CH2

CH3

CH4

1

2

3

4

proportional

band

adjusting

factor

100%

Setting

range:0~1000%

#110

9

#111

0

#111

1

#111

2

Heat side

integral time

adjusting t

factor

Default value:

100%

Setting

range:0~1000%

R/W

Y

#111

7

#111

8

#111

9

#112

0

Heat side

derivative

time adjusting

t coefficient

Default value:

100%

Setting

range:0~1000%

R/W

Y

#112

5

#112

6

#112

7

#112

8

Cool side

proportional

band

adjusting t

factor

Default value:

100%

Setting

range:0~1000%

R/W

Y

#113

3

#113

4

#113

5

#113

6

Cool side

integral time

adjusting t

factor

Default value:

100%

Setting

range:0~1000%

R/W

Y

#114

1

#114

2

#114

3

#114

4

Cool side

derivative

time adjusting

t factor

Default value:

100%

Setting

range:0~1000%

R/W

Y

#114

9

#115

0

#115

1

#115

2

Set change

rate limit rise

* 10

Default value:0

Range:0~range,

Unit:℃/second

R/W

Y

#115

7

#115

8

#115

9

#116

0

Set change

rate limit drop

* 10

Default value:0

Range:0~range,

Unit:℃/second

R/W

Y

#116

5

#116

6

#116

7

#116

8

Selection of

temperature

control object

characteristic

s * 11

Default value:0

0:Slow heating

object

1:Slow heating

object

R/W

Y

#117

3

#117

4

#117

5

#117

6

PID algorithm

selection

Default value:1

0:Fuzzy PID

algorithm

1:Intelligent PID

algorithm

R/W

Y

#118

1

#118

2

#118

3

#118

4

PID output

upper limit

setting

Default value:

0.0%

Setting

range:0.0%~100.

0%

R/W

Y

#118

9

#119

0

#119

1

#119

2

PID output

lower limit

setting

Default value:

0.0%

Setting

range:0.0%~100.

0%

R/W

Y

#119

7

#119

8

#119

9

#120

0

PID output

dead zone

Default value:

0.0%

Setting

range:0.0%~100.

0%

R/W

Y

#120

5

#120

6

#120

7

#120

8

Hand /

automatic

bumpless

switching

setting * 12

Default value:0

0:Turn off

bumpless

switching

1:Turn on

bumpless

switching

R/W

Y

#121

3

#121

4

#121

5

#121

6

External

manual /

automatic

bumpless

switch setting

* 13

Default value:0

0:Turn off

external manual /

automatic switch

input

1:Turn on

external manual /

automatic switch

input

R/W

Y

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1

CH2

CH3

CH4

#1309

OUT 5 output

connection *

14

Default value :0

connect channel

1

alarm 1 mode

1: Turn off the

output

2: Turn on the

output

3: Channel 1

heating, cooling

and cooling

output

4: Channel 1

heating output

R/W

Y

#1310

OUT 6 output

connection

Default value :0

connect channel

1

alarm 2 mode

1: Turn off the

output

2: Turn on the

output

3: Channel 2

heating, cooling

and cooling

output

4: Channel 2

heating output

R/W

Y

#1311

OUT 7 output

connection

Default value :0

connect channel

2

alarm 1 mode

1: Turn off the

output

2: Turn on the

output

3: Channel 3

heating, cooling

and cooling

output

4: Channel 3

heating output

R/W

Y

#1312

OUT 8 output

connection

Default value :0

connect channel

2

alarm 2 mode

1: Turn off the

output

2: Turn on the

output

3: Channel 4

heating, cooling

and cooling

output

4: Channel 4

heating output

R/W

Y

#1313

OUT 9 output

connection

Default value :0

connect channel

3

alarm 1 mode

1: Turn off the

output

2: Turn on the

output

3: Channel 1

heating, cooling

and cooling

output

4: Channel 1

heating output

R/W

Y

#1314

OUT 10

output

connection

Default value :0

connect channel

3

alarm 2 mode

1: Turn off the

output

2: Turn on the

output

3: Channel 2

heating, cooling

and cooling

output

4: Channel 2

heating output

R/W

Y

5

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1

CH2

CH3

CH4

#1315

OUT 11

output

connection

Default value :0

connect channel

4

alarm 1 mode

1: Turn off the

output

2: Turn on the

output

3: Channel 3

heating, cooling

and cooling

output

4: Channel 3

heating output

R/W

Y

#1316

OUT12

output

connection

Default value :0

connect channel

4

alarm 2 mode

1: Turn off the

output

2: Turn on the

output

3: Channel 2

heating, cooling

and cooling

output

4: Channel 2

heating output

R/W

Y

* 1. #901 ~ #904: input type . Select the input type and temperature

mode for each channel, #901.

For channel 1, #902 for channel 2, and so on. When the channel is set

to 0, the channel.closed, the corresponding channel does not perform

A/D conversion. The meaning of the pattern is shown in table 3-8.

Table 3-8 Model specification

NO.

× value

(decimal)

Significance

1

1

K-type thermocouple .Scope :-100.0~

200.0℃

2

2

K-type thermocouple .Scope :-100.0~

400.0℃

3

3

K-type thermocouple .Scope :-100.0~

1200.0℃

4

4

K-type thermocouple .Scope :-148.0~

800.0℉

5

5

K-type thermocouple .Scope :-148.0~

2192.0℉

6

6

J-type thermocouple .Scope :-100.0~

200.0℃

7

7

J-type thermocouple .Scope :-100.0~

400.0℃

8

8

J-type thermocouple .Scope :-100.0~

600.0℃

9

9

J-type thermocouple .Scope :-148.0~

752.0℉

10

10

J-type thermocouple .Scope :-148.0~

1112.0℉

11

11

E-type thermocouple .Scope :-100.0~

200.0℃

12

12

E-type thermocouple .Scope :0.0~850.0℃

13

13

E-type thermocouple .Scope :-148.0~

1562.0℉

14

14

N-type thermocouple .Scope :-100.0~

1200.0℃

15

15

N-type thermocouple .Scope :-148.0~

2192.0℉

16

16

T-type thermocouple .Scope :-200.0~

200.0℃

17

17

T-type thermocouple .Scope :-200.0~

300.0℃

18

18

T-type thermocouple .Scope :0.0~300.0℃

19

19

T-type thermocouple .Scope :-328.0~

400.0℉

20

20

T-type thermocouple .Scope :-328.0~

572.0℉

21

21

T-type thermocouple .Scope :0.0~572.0 ℉

22

22

R-type thermocouple .Scope :0.0~1600.0℃

NO.

× value

(decimal)

Significance

23

23

R-type thermocouple .Scope :32.0~

2912.0℉

24

24

S-type thermocouple .Scope :0.0~1600.0℃

25

25

S-type thermocouple .Scope:32.0~2912.0℉

26

26

Pt100.Scope :-50.0~150.0℃

27

27

Pt100.Scope :-150.0~600.0℃

28

28

Pt100.Scope :-238.0~300.0℉

29

29

Pt100.Scope :-238.0~1112.0℉

30

30

JPt100.Scope :-50.0~150.0℃

31

31

JPt100.Scope :-150.0~500.0℃

32

32

JPt100.Scope :-238.0~300.0℉

33

33

JPt100.Scope :-238.0~932.0℉

34

34

Cu100.Scope :-30.0~120.0℃

35

35

Cu100.Scope :-22.0~248.0℉

36

36

Cu50.Scope :-30.0~120.0℃

37

37

Cu50.Scope :-22.0~248.0℉

38

38

Ni120.Scope :-80.0℃~280.0℃

39

39

Ni120.Scope :-112.0℉~536.0℉

Explanation:Celsius=5/9×((Fahrenheit)-32)

* 2. #909 ~ #912: temperature setting. Set the target value of each

channel temperature control. The unit is determined according to the

input type (#901 ~ #904). When the mode is Celsius, the unit is 0.1℃;

when the mode is Fahrenheit, the unit is 0.1℉.

* 3. #917 ~ #920: proportional cycle time. The control output cycle of

each channel is set, the setting range is 1 ~ 100, the default value is 2,

the unit is determined according to the temperature control object

characteristic selection of #1165 ~ #1168, when the temperature control

object is selected for slow temperature rise, the unit of temperature

control period is seconds, but when the temperature control object is

selected for fast temperature rise, the unit of temperature control period

is hundreds of milliseconds.

* 4. #981 ~ #984: overlap/deaband..

* 5. #989 ~ #992: Undershoot suppression factor.

* 6. #997:Run/stop transfer. Bit0 corresponds to channel 1, Bit1

corresponds to channel 2, and so on. Is 1 when the channel opens the

heating temperature control, is 0 when the channel closes the heating

temperature control; M0 ~ M3 elements map directly to Bit0 ~ Bit3 of

#997, and the start and stop of each channel can be directly controlled

by setting M0 ~ M3 elements.

* 7. #999: Auto-tuning enable. Bit0 corresponds to channel 1, Bit1 to

channel 2, and so on. When is 0, it means self-tuning is closed or

self-tuning is completed; when is 1, it means self-tuning is opened (at

this time, the channel should be set in the state of temperature control

and heating); M8 ~ M11 elements map directly to Bit0 ~ Bit3 of #999. By

setting M8 ~ M11 elements, you can also directly control the opening

and closing of each channel self-tuning.

* 8. #1008 ~ #1011: heat/cool action. When the "position proportional

PID" mode is selected, the MV value of temperature control output is

the change of PID output value.

* 9. #1016 ~ #1019: hand output Settings. Set the duty cycle of the

constant output of each channel, the setting range is: 0 ~ 1000 (unit is

0.1%), the default value is 0.

* 10. #1149 ~ #1152: set the rate of change to increase. #1157 ~ #1160:

set the rate of change to decrease. Range 0 ~ range, when set to 0, it

means that there is no limit for l/l/cooling, and the unit is ℃/ min.

* 11. #1165 ~ #1168:Control action. When the object of slow

temperature rise is selected, the temperature control output period,

integral time and differential time are measured in seconds. When the

object of rapid temperature rise is selected, the temperature control

output period, integral time and differential time are measured in

hundreds of milliseconds.

* 12. #1205 ~ #1208: manual/automatic no disturbance switch Settings.

When the manual/automatic non-disturbance switch setting is effective,

the module will switch from manual mode to automatic mode or from

automatic mode to manual mode, and the temperature control output

MV value will switch smoothly to the next output state.

* 13. #1213 ~ #1216: external manual/automatic switching of input

Settings. When both external manual/automatic input Settings and

external input are valid, the manual/automatic temperature control

modes switch to each other. The external port inputs IN1 control

channel 1, IN2 control channel 2, and so on.

* 14. #1309: OUT5 enter the connection. OUT5 output Settings, which

can be set to alarm output or forced output high or low level, or

6

temperature controlled heating or cooling output, OUT6, OUT7, OUT8,

OUT9, OUT10, OUT11, OUT12 are similar to OUT5.

3. 3.4 BFM parameters save Settings

MTC-04-NTR buffer (BFM) of the BFM parameter set to save the

contents of Table 3-9.

Table 3-9 MTC-04-NTR buffer (BFM) BFM parameters save Settings

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1

CH2

CH3

CH4

#700

Module

paramet

ers to

save *1

Default value:0

(Does not

save parameters)

1:Save the

startup parameter

s

R/

W

N

Note:When the startup parameter is saved, #700 automatically zeros.

1. BFM # 700: When the user parameters are stored, this bit is set, the

module will save the current user to set parameters. Instructions are as

follows:

1) BFM # 700 to set the value from 0 to 1, the start data

backup, then wait a few seconds beforepower, or it may lead

to incorrect parameter save.

If re-backup, to be given to re-level change;

2) When the internal temperature due to interference and error,

the error may save parameters.Then the parameters should be

re-saved. If the parameter is saved when an error

Power restart, then the parameters back to factory defaults;

3) When there is setting an error, save the original parameters of

the unit;

4) The parameter is saved, the user must own this bit

to 0, for saving the next

3. 3.5 Others

MTC-04-NTR buffer (BFM) of the other content shown in Table 3-10.

Table 3-10 MTC-04-NTR buffer (BFM) of the other content

BFM

Content

Remarks

Na

tur

e

Sa

ve

CH1

CH2

CH3

CH4

#4094

Module

software

version

information

*1

0x2000

R

N

#4095

Identificatio

n of the

thermostat

*2

0xB443

R

N

*1.BFM#4094:Module software version information.

*2.BFM#4095:Module identification number. MTC-04-NTR

identification number is 0xB443. Programmable logic controller of user

program can be used in a program in the identification number, in

transmitting/receiving data confirm that this before the thermostat.

4.Operation check

4. 1 Routine check

1. Check the wiring meets the requirements of the analog

input (reference 2 wiring instructions).

2. Check the MTC-04-NTR's reliability into the first terminal

MTC-04-NTR.

3. Check available to MTC-04-NTR of the 24Vdc power supply is

overloaded.

4. Check the application to ensure that the application is selected in

the correct methods of operation and parameter range, with particular

attention to the timing of the BFM with special

operations area regulations required timing operation.

4. 2 Fault inspection

If MTC-04-NTR run normally, please check the following projects.

Check 24 V indicator state.

Light: 24 Vdc power supply normal;

Extinguish: 24 Vdc power supply may fault; If 24 Vdc power supply

normal, the MTC-04-NTR fault.

Check the state RUN indicator

High-speed flash: MTC-04-NTR is operating normally.

Slow Flashing: Check BFM # 735, BFM # 736 in the information.

Always on or off::MTC-04-NTR crash.

Notice to users

1. Warranty means the thermostat body.

2. Warranty period is 18 months, under normal use during the warranty

period, product failure or damage, my company free of maintenance.

3. Warranty start date time manufacturing factory, the machine code

is the sole basis to determine the warranty

period, no machine-coded equipment out of warranty.

4. Even during the warranty period, the following

situations, certain maintenance costs will be charged:

Not caused by user manual for operating the machine failure.

Due to fire, flood, abnormal voltage and other damage caused

by machinery.

The thermostat function for non-normal damage.

Disassemble the thermostat.

5. Service charges based on actual costs, such as another contract,

the contract principle of priority treatment.

6. If you have any question please contact the distributor or

directly contact me.

Shenzhen Megmeet Control Technology Co.,Ltd

Address: 5th Floor,Block B,Ziguang Information Harbor, Langshan Rd,

Science& Technology Park, Nahshan District, Shenzhen

Homepage: www.megmeet.com

All rights reserved. The contents in this document are subject to change

without notice.

Table of contents

Other Megmeet Thermostat manuals

Popular Thermostat manuals by other brands

Friedrich

Friedrich WRT2 Installation and operation guide

ensto

ensto eVahti Operation & installation instructions

Robertshaw

Robertshaw 9610 user manual

Friedrich

Friedrich RT7P Installation and operation guide

Bosch

Bosch Room thermostat II Quick instructions

Doepke

Doepke Dupline DRT 1 operating instructions