Megmeet MTC-08-NT User manual

1

MTC-08-NT Thermostat User Manual

Version V1.0

Archive time 2012.7

2

Shenzhen megmeet control technology co., ltd. provides customers with a full range of technical

support, users can contact with the nearest agents or technical service center of Shenzhen

megmeet control technology co., ltd., or directly with the headquarters of the company.

All rights reserved. Contents are subject to change without prior notice.

Shenzhen megmeet control technology co., ltd.

Add:5th Floor,Block B Unisplendour Information Harbor, Langshan Road, Shenzhen

Tel:400-666-2163 ,(86)0755-86600500

Fax:(+86)0755-86600999

Code:518067

Web:www.megmeet.com

3

Prompt

Before starting to use, please read the instructions and precautions carefully to reduce the

occurrence of accidents. The personnel responsible for the installation and operation of the

product must receive strict training, comply with the safety standards of the relevant industry,

strictly comply with the notes and special safety instructions of the relevant equipment provided

in this manual, and carry out the operation of the equipment according to the correct operation

method.

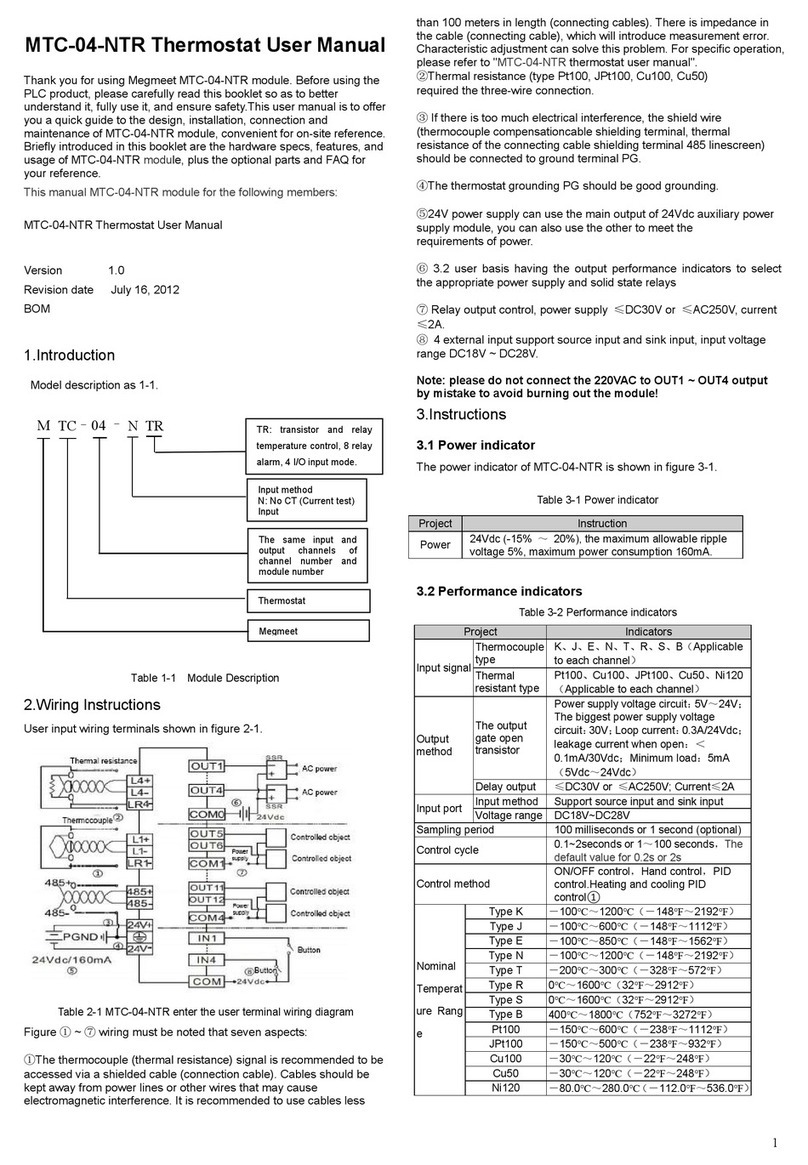

Model Description

TT:Indicates transistor temperature

control output

Input method

N: No CT (Current test) Input

The number of temperature channels

collected by the module

Thermostat

Megmeet

T

M

TC

08

-

-

N

4

1.Product Introduction

MTC-08-NT temperature controller is a multi - channel high precision temperature control

product developed by megmeet, suitable for various occasions of temperature control. Its

main features are compatible with thermocouple and thermal resistance, high precision

temperature measurement, rich functions, easy to use. This chapter introduces the

appearance structure, installation size, parts, technical parameters, buffer and

accessories of MTC-08-NT.

1.1Appearance structure and installation dimensions

The user terminal of the MTC-08-NT thermostat is shown in figure 1-1

Top view Side view

Figure 1-1 MTC-08-NT outline structure diagram

The mounting dimensions of MTC-08-NT are shown in figure 1-2

Figure 1-2 MTC-08-NT installation dimensions (unit: mm)

1.2 Terminal introduction

5

MTC-08-NT user terminal is shown in figure 1-3

Figure 1-3 MTC-08-NT user terminal diagram

The definition of MTC-08-NT user terminal is shown in table 1-1

Table 1-1 MTC-08-NT terminal definitions

1.3 Light description

The indicator description is shown in Table 1-2

Table 1-2 indicator description

Name

Status

Definition

24V

ON

24V power on

OFF

24V power off

RUN

Flash quickly(10Hz~15Hz)

Normal

Flash slowly(0.5Hz~1Hz)

There is an error. See

BFM#735 for the error status

information

LED1~8(OUT1~OUT8)

ON

The corresponding channel

Mark

Definition

24V-

Power supply 24V positive

24V+

Power supply 24V negative

Ground

485-

RS485 negative terminal

485+

RS485 positive terminal

L1+~L8+

Channel 1 to 8 are positive for thermocouple (thermal resistance) signal

input

L1-~L8-

Channel 1 to 8 are negative for thermocouple (thermal resistance) signal

input

LR1-~LR8-

Channel 1 ~ 8 are negative for thermal resistance signal input

OUT1~OUT8

Channel 1 ~ 8 output control terminal

COM0

OUT1 ~OUT4 output common ground

COM1

OUT5 ~OUT8 output common ground

6

output is ON

OFF

The corresponding channel

output is OFF

1.4 Technical parameter

1.4.1 Power indicator

The power specifications of MTC-08-NT are shown in Table 1-3.

Table 1-3 Power indicator

Project

Instruction

Power

24Vdc (-15% ~20%), the maximum allowable ripple voltage

5%, maximum power consumption 120mA.

1.4.2 Performance indicators

The performance indicators of MTC-08-NT are shown in table 1-4

Table 1-4 Performance indicators

Item

Indicators

Input

signal

Thermocouple type

K、J、E、N、T、R、S、B

Thermal resistance

type

Pt100、Cu100、JPt100、Cu50、Ni120

Output

method

Open gate transistor

output

Power supply voltage circuit:5V~24V;The maximum

power supply voltage circuit:30V;loop current:

0.3A/24Vdc;Leakage current when open:<

0.1mA/30Vdc;Minimum load:5mA(5Vdc~24Vdc)

Sampling cycle

100ms or 1s(optional)

Control cycle

0.1~10s or 1~100s,default 0.2s or 2s.Determined by

the characteristics of the temperature control object

Control method

Manual control,ON/OFF control,PID control,Heat and

cool PID control

Rate

temperat

ure range

Type K

-100℃~1200℃(-148℉~2192℉)

Type J

-100℃~1200℃(-148℉~2192℉)

Type E

-100℃~850℃(-148℉~1562℉)

Type N

-100℃~1200℃(-148℉~2192℉)

Type T

-200℃~300℃(-328℉~572℉)

Type R

0℃~1600℃(32℉~2912℉)

Type S

0℃~1600℃(32℉~2912℉)

Type B

400℃~1800℃(752℉~3272℉)

Pt100

-150℃~600℃(-238℉~1112℉)

JPt100

-150℃~500℃(-238℉~932℉)

Cu100

-30℃~120℃(-22℉~248℉)

Cu50

-30℃~120℃(-22℉~248℉)

Ni120

-80.0℃~280.0℃(-112.0℉~536.0℉)

Accuracy

Thermocouple

Input range±0.3%,Ambient temperature

7

compensation error ≤2℃

Thermal resistance

Input range±0.5%

Isolation

The sampling channel is isolated from the power supply,

the sampling channel is isolated from the output, and

no isolation between channels

Note: 1. Through the appropriate input type selection Settings, two kinds of data can be

obtained: ℃and ℉.

2. Standard for thermocouple and thermal resistance:

K, J, E, N, T, R, S, BIEC 60584-1-1995

PT100 IEC60751 - AM2-1995

JPT100 JIS C1604-1997

Cu100, Cu50 JJG 229-1998

1.5 Buffer description

MTC-08-NT and the main module exchange information through the buffer (BFM), using Modbus

or MCbus. The cache that reads and writes properties can use MODBUS or MCBUS instructions to

write and read the contents of any cell in the BFM region. If the reserved cell is read, it will get a

value of 0. Save mark as Y represents the use of parameter save function, can be written to flash,

mark as N means can not be written to flash. The content of the BFM unit is as follows:

1. Channel operation monitoring.

2. Channel feature setting.

3. Control function setting.

4. Multi-step function setting.

5. Alarm function setting.

6. Litre/temperature limit setting.

7. Save and set BFM parameters.

8. The other.

1.5.1 Channel operation monitoring

The channel operation monitoring content of the buffer zone (BFM) of MTC-08-NT is shown in

Table 1-5

Table 1-5 MTC-08-NT buffer (BFM) channel operation monitoring

BFM

Contents

Remarks

nat

ure

Sa

ve

CH1/CH5

CH2/CH6

CH3/CH7

CH4/CH8

#701/#705

#702/#706

#703/#707

#704/#708

Measured value(PV)

*1

Units: 0.1 ℃and 0.1

℉

R

N

#709/#713

#710/#714

#711/#715

#712/#716

Heat side control

output (MV) * 2

The default value:

0.0% (percentage

show)

R

N

#717/#721

#718/#722

#719/#723

#720/#724

More paragraphs of

the currently executing

period control * 3

Default value: 0.0%

(expressed as a

percentage)

R

N

#725/#729

#726/#730

#727/#731

#728/#732

Multi-step control

current execution

segment * 3

Default value:0

Range:0~8

R

N

#733

Output state of

refrigeration end *4

Default value:0

R

N

#735

Error status word * 5

Default value:0

R

N

8

BFM

Contents

Remarks

nat

ure

Sa

ve

CH1/CH5

CH2/CH6

CH3/CH7

CH4/CH8

#736

Set value range error

address*6

0:normal

Other values:

setting the wrong

BFM address

R

N

#737

Cold junction

temperature*7

Default value:0

R

N

#738/#742

#739/#743

#740/#744

#741/#745

Work status word * 8

Default value:0

R

N

* 1. #701 ~ #708:The measured value of channel 1~l 8. The unit is determined according to the

input type (#901 ~ #908). When the mode is Celsius, the unit is 0.1 ℃; when the mode is

Fahrenheit, the unit is 0.1℉.

* 2. #709 ~ #716:Heating side control output value MV; #717 ~ #724: cooling hot side control

output value MV; The control output value of the channel obtained by the control algorithm.

* 3. #725 ~ #732: Each channel Multi-step setting executes the current segment. The segment

number being executed when multiple segment Settings are displayed. 0: indicates that the

execution state is not set in multiple segments or that multiple segments are completed.

* 4. #733: Output status of refrigeration end. Bit0 corresponds to the output state of the

refrigeration end of channel 1, Bit1 corresponds to the output state of the refrigeration end of

channel 2, and so on. When is 1, the output of the refrigeration end is effective; when is 0, the

output of the refrigeration end is invalid.

* 5. The failure status information of #735 is shown in table 1-6

Table 1-6 status information for BFM#735

A state of BFM#735

ON(1)

OFF(0)

b0:Error

When b1 ~ b15 any error occurs, this flag is 1

(b1 ~ b2 in any one of 1, stop all channel AD

converter)

Correct

b1:Save

-

-

b2:Hardware fault

AD converter or other hardware failure

Hardware normal

b3:Set value backup error

When the interference and the MTC due to an

internal error occurs, the flag will change

to 1. Then if you turn the power off, still

not be clear error, please contact the sales

agent or our

Data backup normal

b4:The cold end

temperature compensation

error

b5:AD transform digital

range errors

AD transform digital output value is less than -1

or greater than 4096, the flag is 1

Digital output value is

normal

b6:Set data recovery error

When the interference and the MTC due to an

internal error, if error reading backup data, the

flag is 1

-

b7:Save

-

-

b8~b15:Broken

accidentally detection (only

support thermocouple)

1 ~ 4 channel thermocouple broken

accidentally, the flag is 1

No broken

accidentally wrong

channel

9

* 6. #736: error address setting value range. Incorrect BFM area code is displayed.

* 7. #737: reflects the current cold end temperature.

* 8. #738 ~ #745: status word for each channel. Shows the error state and control state of each

channel, #738 corresponds to channel 1, #739 corresponds to channel 2, and so on. See table 1-7

for specific information.

Table 1-7 Error status and control of the state of each channel

Bite

Definition

ON(1)

OFF(0)

b0~b3

Alarm 1 ~ 4 state

Alarm

No alarn

b4

Sign of Initialization

complete

Initialization complete

Initialization

unfinished

b5

Auto-tuning state

Auto-tuning state

Status of no

auto-tuning

b6

Control state

Control state

uncontrolled state

b7

Control completion status

The temperature reaches setting and

in a stable state

Incomplete control

b8~b15

Save

-

-

1.5.2 Channel characteristics set

MTC-08-NT buffer (BFM) channel characteristics set as table1-8

Table 1-8 MTC-08-NT buffer (BFM) channel characteristics set

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1/CH5

CH2/CH6

CH3/CH7

CH4/CH8

#200

Restore factory

setting*1

Default value:0

R/W

N

#201

Change Settings

allowed*2

Default value:1,Allows

to change

0:Not Allowed To

Change

R/W

N

#801/#805

#802/#806

#803/#807

#804/#808

Digital filter set of

one step

Default value:0

Range:0~100

(Seconds)

R/W

Y

#809/#813

#810/#814

#811/#815

#812/#816

D0*3

Default value:0

R/W

Y

#817/#821

#818/#822

#819/#823

#820/#824

D1*3

Default value:12000

(With the input type

change)

R/

W

Y

#825/#829

#826/#830

#827/#831

#828/#832

A0*3

Default value:0

R

N

#833/#837

#834/#838

#835/#839

#836/#840

A1*3

Default value:12000

(With the input type

change)

R

N

* 1. After #200 is set to 1, all BFM units of the module are reset to their default values.

* 2. Change Settings allowed for BFM. Setting BFM#201 to 0 will prevent the user from making

inadvertent adjustments to BFM. Once the disable Settings feature is set, it remains in effect until the

allow command is set (#201 = 1).

* 3. #801 ~ #808: set the data cache D0 for each channel; #809 ~ #812: each channel feature sets the

data cache D1. Use the two-point method to set channel characteristics, D0, D1 represents the channel

output digital quantity, A0, A1 represents the channel actual input temperature value, each channel

occupies 4 words. Considering the convenience of the user's setting, and without affecting the realization

of the function, A0 was fixed as 0℃, and A1 was fixed as the maximum of the measurement range in the

current mode. If you change the D0 and D1 values of the channel, you can change the channel

characteristics. D0 and D1 can be adjusted ±1000 on the basis of factory setting. If the current mode

uses Celsius, the adjustment range is ±100℃; if the current mode uses Fahrenheit, the adjustment

range is ±100℉. If a value is set beyond this range, the MTC will not accept it and will keep the original

valid setting.

1.5.3 Control function setting

10

MTC-08-NT buffer (BFM) set the control function of the content to table1-9.

Table 1-9 MTC-08-NT buffer (BFM) the control function of the set

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1/CH5

CH2/CH6

CH3/CH7

CH4/CH8

#901/#905

#902/#906

#903/#907

#904/#908

Input type *1

Default value:0

R/W

Y

#909/#913

#910/#914

#911/#915

#912/#916

Set value (SV) * 2

Default value:0.0

Unit:0.1℃/℉

R/W

Y

#917/#921

#918/#922

#919/#923

#920/#924

Control output cycle

set * 3

Default value:2

Range:1~100

R/W

Y

#925/#929

#926/#930

#927/#931

#928/#932

Heat side

proportional band

Default value:30

Unit:0.1%

Range:0.1%~

1000.0%

R/W

Y

#933/#937

#934/#938

#935/#939

#936/#940

Heat side integrativ

e time

Default value:240

Range:1~3600

(Seconds)

R/W

Y

#941/#945

#942/#946

#943/#947

#944/#948

Heat side

derivative

time

Default value:60

Range:0~3600

(Seconds)

R/W

Y

#957/#961

#958/#962

#959/#963

#960/#964

Cool side

proportional band

Default value:30

Unit:0.1%

Range:0.1%~

1000.0%

R/W

Y

#965/#969

#966/#970

#967/#971

#968/#972

Cool side integrativ

e time

Default value:240

Range:1~3600

(Seconds)

R/W

Y

#973/#977

#974/#978

#975/#979

#976/#980

Cool side

Derivative

time

Default value:60

Range:0~3600

(Seconds)

R/W

Y

#981/#985

#982/#986

#983/#987

#984/#988

Overlap/Deadband*

4

Default value:0

No overlapped

non-inductive belt

Setting range:-input

range~+input range

R/W

Y

#989/#993

#990/#994

#991/#995

#992/#996

Undershoot

suppression

factor*5

Water-cooled default

Air-cooled default

Range:0~1000

R/W

Y

#997

Control start/stop

setting of CH1- CH4

*6

Default value:B0000

0:Stop 1:Start

R/W

Y

#998

Control start/stop

setting of CH5- CH8

*6

Default value:B0000

0:Stop 1:Start

R/W

Y

M0/M4

M1/M5

M2/M6

M3/M7

Control start/stop

setting of CH1- CH8

*6

Default value:B0000

0:Stop 1:Start

R/W

Y

#999

Auto-tuning setting

of CH1- CH8 *7

Default value:B0000

0:Not self-tuning or aut

o-tuning has been

completed

1:Auto-Tune

R/W

Y

11

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1/CH5

CH2/CH6

CH3/CH7

CH4/CH8

M8/M12

M9/M13

M10/M14

M11/M15

Auto-tuning setting

of CH1- CH8 *7

Default value:0

0:Not self-tuning or aut

o-tuning has been

completed

1:Auto-Tune

R/W

Y

#1000/#10

04

#1001/#10

05

#1002/#10

06

#1003/#10

07

Control mode

setting

Default value:2

0:Hand 1:ON/OFF

3:PID

R/W

Y

#1008/#10

12

#1009/#10

13

#1010/#10

14

#1011/#10

15

Heat/cool action*8

Default value:1

0:Cooling

1:Heating

2:Heating and cooling

(air cooling)

3:Heating and cooling

(water cooling)

4:Position ratio PID

R/W

Y

#1016/#10

20

#1017/#10

21

#1018/#10

22

#1019/#10

23

Manual output of set

value

Default value:0

Range:0.0~100.0(%)

R/W

Y

#1024/#10

28

#1025/#10

29

#1026/#10

30

#1027/#10

31

Adjust sensitivity

Setting(ON/OFF

control method is

effective)

Default value:100

Unit:0.1℃/℉

Range:0~999

R/W

Y

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1/CH5

CH2/CH6

CH3/CH7

CH4/CH8

#1032/#10

36

#1033/#10

37

#1034/#10

38

#1035/#10

39

Auto-tuning

deviation setting

Default value:0

Unit:0.1℃/℉

Range:±input range

R/W

Y

#1101/#11

05

#1102/#11

06

#1103/#11

07

#1104/#11

08

Heat side

proportional band

adjusting factor

Default value:100%

Setting range:0~1000%

R/W

Y

#1109/#11

13

#1110/#11

14

#1111/#11

15

#1112/#11

16

Heat side integral

time adjusting factor

Default value:100%

Setting range:0~1000%

R/W

Y

#1117/#11

21

#1118/#11

22

#1119/#11

23

#1120/#12

4

Heat side derivative

time adjusting factor

Default value:100%

Setting range:0~1000%

R/W

Y

#1125/#11

29

#1126/#11

30

#1127/#11

31

#1128/#11

32

Cool side

proportional band

adjusting factor

Default value:100%

Setting range:0~1000%

R/W

Y

#1133/#11

37

#1134/#11

38

#1135/#11

39

#1136/#11

40

Cool side integral

time adjusting factor

Default value:100%

Setting range:0~1000%

R/W

Y

#1141/#11

45

#1142/#11

46

#1143/#11

47

#1144/#11

48

Cool side derivative

time adjusting factor

Default value:100%

Setting range:0~1000%

R/W

Y

#1149/#11

53

#1150/#11

54

#1151/#11

55

#1152/#11

56

Set change rate

limit rise * 10

Default value:0

Range:0~range,

Unit:℃/second

R/W

Y

#1157/#11

61

#11581162

#1159/#11

63

#1160/#11

64

Set change rate

limit drop * 10

Default value:0

Range:0~range,

Unit:℃/second

R/W

Y

12

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1/CH5

CH2/CH6

CH3/CH7

CH4/CH8

#1165/#11

69

#1166/#11

70

#11671171

#1168/#11

72

Selection of

temperature control

object

characteristics * 11

Default value:0

0:Slow heating object

1:Slow heating object

R/W

Y

#1173/#11

77

#1174/#11

78

#1175/#11

79

#1176/#11

80

PID algorithm

selection

Default value:1

0:Fuzzy PID algorithm

1:Intelligent PID

algorithm

R/W

Y

#1181/#11

85

#1182/#11

86

#1183/#11

87

#1184/#11

88

PID output upper

limit setting

Default value:0.0%

Setting

range:0.0%~100.0%

R/W

Y

#1189/#11

93

#1190/#11

94

#1191/#11

95

#1192/#19

6

PID output lower

limit setting

Default value:0.0%

Setting

range:0.0%~100.0%

R/W

Y

#1197/#12

01

#1198/#12

02

#1199/#12

03

#1200/#12

04

PID output dead

zone

Default value:0.0%

Setting

range:0.0%~100.0%

R/W

Y

#1205/#12

09

#1206/#12

10

#1207/#12

11

#1208/#12

12

Manual / automatic

bumpless switching

setting * 12

Default value:0

0:Turn off bumpless

switching

1:Turn on bumpless

switching

R/W

Y

* 1. #901 ~ #908: input type selection. Select the input type and temperature mode of each channel, #901

corresponds to channel 1, #902 corresponds to channel 2, and so on. When the channel is set to 0, the

channel is closed and the corresponding channel does not perform A/D conversion. The meaning of the

pattern is shown in table 1-10.

Table1-10 Model specification

NO.

value

(decimal)

Significance

1

1

K-type thermocouple input range:-100.0~200.0℃

2

2

K-type thermocouple input range:-100.0~400.0℃

3

3

K-type thermocouple input range:-100.0~1200.0℃

4

4

K-type thermocouple input range:-148.0~800.0℉

5

5

K-type thermocouple input range:-148.0~2192.0℉

6

6

J-type thermocouple input range:-100.0~200.0℃

7

7

J-type thermocouple input range:-100.0~400.0℃

8

8

J-type thermocouple input range:-100.0~600.0℃

9

9

J-type thermocouple input range:-148.0~752.0℉

10

10

J-type thermocouple input range:-148.0~1112.0℉

11

11

E-type thermocouple input range:-100.0~200.0℃

12

12

E-type thermocouple input range:0.0~850.0℃

13

13

E-type thermocouple input range:-148.0~1562.0℉

14

14

N-type thermocouple input range:-100.0~1200.0℃

15

15

N-type thermocouple input range:-148.0~2192.0℉

16

16

T-type thermocouple input range:-200.0~200.0℃

17

17

T-type thermocouple input range:-200.0~300.0℃

18

18

T-type thermocouple input range:0.0~300.0℃

19

19

T-type thermocouple input range:-328.0~400.0℉

20

20

T-type thermocouple input range:-328.0~572.0℉

21

21

T-type thermocouple input range:0.0~572.0 ℉

22

22

R-type thermocouple input range:0.0~1600.0℃

23

23

R-type thermocouple input range:32.0~2912.0℉

24

24

S-type thermocouple input range:0.0~1600.0℃

25

25

S-type thermocouple input range:32.0~2912.0℉

26

26

Pt100,input range:-50.0~150.0℃

13

NO.

value

(decimal)

Significance

27

27

Pt100,input range:-150.0~600.0℃

28

28

Pt100,input range:-238.0~300.0℉

29

29

Pt100,input range:-238.0~1112.0℉

30

30

JPt100,input range:-50.0~150.0℃

31

31

JPt100,input range:-150.0~500.0℃

32

32

JPt100,input range:-238.0~300.0℉

33

33

JPt100,input range:-238.0~932.0℉

34

34

Cu100,input range:-30.0~120.0℃

35

35

Cu100,input range:-22.0~248.0℉

36

36

Cu50,input range:-30.0~120.0℃

37

37

Cu50,input range:-22.0~248.0℉

38

38

Ni120,input range:-80.0℃~280.0℃

39

39

Ni120,input range:-112.0℉~536.0℉

40

40

PT100,input range::-150.0~300.0℃

41

41

B-type thermocouple, input range: 400.0 ~ 1800.0℃

42

42

B-type thermocouple, input range: 752.0~3272.0℉

43

43

K-type thermocouple, -100.0~600.0℃

44

44

K-type thermocouple, -100.0~800.0℃

45

45

J-type thermocouple, -100.0~800.0℃

46

46

J-type thermocouple, -100.0~1200.0℃

47

47

J-type thermocouple,-148.0~2192.0℉

48

48

T-type thermocouple,-200.0~400.0℃

49

49

T-type thermocouple,-328.0~752.0℉

Explanation:Celsius=5/9×((Fahrenheit)-32)

* 2. #909 ~ #916: temperature setting. Set the target value of each channel temperature control. The unit

is determined according to the input type (#901 ~ #908). When the mode is Celsius, the unit is 0.1℃;

when the mode is Fahrenheit, the unit is 0.1℉.

* 3. #917 ~ #924: control the output cycle setting value. The control output cycle of each channel is set,

the setting range is 1 ~ 100, the default value is 2, the unit is determined according to the temperature

control object characteristic selection of #1165 ~ #1172, when the temperature control object is selected

for slow temperature rise, the unit of temperature control period is seconds, but when the temperature

control object is selected for fast temperature rise, the unit of temperature control period is hundreds of

milliseconds.

* 4. #981 ~ #988: Overlap /deadband.

* 5. #989 ~ #996:Undershoot suppression factor.

* 6. #997,#998: Start/stop action. Bit0 corresponds to channel 1, Bit1 corresponds to channel 2, and so

on. Is 1 when the channel opens the heating temperature control, is 0 when the channel closes the

heating temperature control; M0 ~ M7 elements map directly to Bit0 ~ Bit3 of #997, and the start and stop

of each channel can be directly controlled by setting M0 ~ M7 elements.

* 7. #999: Auto-tuning enable. Bit0 corresponds to channel 1, Bit1 to channel 2, and so on. When is 0, it

means auto-tuning is closed or self-tuning is completed; when is 1, it means self-tuning is opened (at this

time, the channel should be set in the state of temperature control and heating); M8 ~ M15 elements map

directly to Bit0 ~ Bit3 of #999. By setting M8 ~ M15 elements, you can also directly control the opening

and closing of each channel self-tuning.

* 8. #1008 ~ #1011: heating/cooling operation selection. When the "position proportional PID" mode is

14

selected, the MV value of temperature control output is the change of PID output value.

* 9. #1016 ~ #1023: manually output Settings. Set the duty cycle of the constant output of each channel,

the setting range is: 0 ~ 1000 (unit is 0.1%), the default value is 0.

* 10.# 1149 ~# 1156: Set the rate of change to limit the increase. # 1157 ~# 1164: Set the change

rate to limit the decline. Range 0 ~ Range range, when set to 0, it means there is no limit to temperature

rise / cooling, the unit is ℃/ min.

* 11. # 1165 ~# 1172: Selection of temperature control object characteristics. When the slow heating

object is selected, the temperature control output period, integration time, and derivative time are in

seconds; when the rapid heating object is selected, the temperature control output period, integration

time, and derivative time are in hundred milliseconds;

* 12. #1205 ~ #1212: manual/automatic no disturbance switch Settings. When the manual/automatic

non-disturbance switch setting is effective, the module will switch from manual mode to automatic mode

or from automatic mode to manual mode, and the temperature control output MV value will switch

smoothly to the next output state.

1.5.4 Multi-step function

The Multi-step function Settings of MTC-08-NT buffer (BFM) are shown in table 1-11

Table 1-11 Multi-step function Settings for the buffer (BFM) of MTC-08-NT

BFM

Content

Remarks

Nat

ure

Sa

ve

CH1/CH5

CH2/CH6

CH3/CH7

CH4/CH8

#400/#476

#419/#495

#438/#514

#457/#533

Step 1 temperature

* 1

Default value :0.0,

denoted by 0.1℃

R/W

Y

#401/#477

#420/#496

#439/#515

#458/#534

Step 2 temperature

* 1

Default value :0.0,

denoted by 0.1℃

R/W

Y

#402/#478

#421/#497

#440/#516

#459/#535

Step 3 temperature

* 1

Default value :0.0,

denoted by 0.1℃

R/W

Y

#403/#479

#422/#498

#441/#517

#460/#536

Step 4 temperature

* 1

Default value :0.0,

denoted by 0.1℃

R/W

Y

#404/#480

#423/#499

#442/#518

#461/#537

Step 5 temperature

* 1

Default value :0.0,

denoted by 0.1℃

R/W

Y

#405/#481

#424/#500

#443/#519

#462/#538

Step 6 temperature

* 1

Default value :0.0,

denoted by 0.1℃

R/W

Y

#406/#482

#425/#501

#444/#520

#463/#539

Step 7 temperature

* 1

Default value :0.0,

denoted by 0.1℃

R/W

Y

#407/#483

#426/#502

#445/#521

#464/#540

Step 8 temperature

* 1

Default value :0.0,

denoted by 0.1℃

R/W

Y

#408/#484

#427/#503

#446/#522

#465/#541

Step 1 time * 2

Default value :0,

time 0 ~

900(minutes)

R/W

Y

#409/#485

#428/#504

#447/#523

#466/#542

Step 2 time * 2

Default value :0,

time 0 ~

900(minutes)

R/W

Y

#410/#486

#429/#505

#448/#524

#467/#543

Step 3 time * 2

Default value :0,

R/W

Y

15

time 0 ~

900(minutes)

#411/#487

#430/#506

#449/#525

#468/#544

Step 4 time * 2

Default value :0,

time 0 ~

900(minutes)

R/W

Y

#412/#488

#431/#507

#450/#526

#469/#545

Step 5 time * 2

Default value :0,

time 0 ~

900(minutes)

R/W

Y

#413/#489

#432/#508

#451/#527

#470/#546

Step 6 time * 2

Default value :0,

time 0 ~

900(minutes)

R/W

Y

#414/#490

#433/#509

#452/#528

#471/#547

Step 7 time * 2

Default value :0,

time 0 ~

900(minutes)

R/W

Y

#415/#491

#434/#510

#453/#529

#472/#548

Step 8 time * 2

Default value :0,

time 0 ~

900(minutes)

R/W

Y

#416/#492

#435/#511

#454/#530

#473/#549

Repeat start step *

3

Default value :2,

range:1~8

R/W

Y

#417/#493

#436/#512

#455/#531

#474/#550

Repeat end step * 4

Default value :0,

Range:0~99

R/W

Y

#418/#494

#437/#513

#456/#532

#475/#551

Multi-step control

state * 5

Default value :0,

Range:0~99

R/W

Y

#552

Multi-step control

execution flag of

CH1 ~CH8 * 6

Set 1-8 channels,

default

value :B0000

R/W

Y

0:No multi-stage

control

R/W

Y

1: perform

Multi-step control

R/W

Y

* 1. #400 ~ #407, #419 ~ #426, #438 ~ #445, #457~#464,#476~#483,#495~#502,#514~#521,

#533~#540: temperature Settings for each channel segment. The unit is determined according to each

input type. When the mode is Celsius, the unit is 0.1℃; when the mode is Fahrenheit, the unit is 0.1℉.

* 2. #408 ~ #415, #427 ~ #434, #446 ~ #453, #465 ~ #472,#484~#491,#503~#510,#522~#529,

#541~#548: execution time of each channel segment. When running multi-step Settings, the first stage

execution time of each channel cannot be set to 0.

* 3. #416, #435, #454, #473,#482,#491,#500,#509: the starting segment number that needs to be

repeated when setting the multi-step setting of each channel.

* 4. #417, #436, #456, #474,#493,#512,#531,#550: the termination number that needs to be repeated

when setting the multi-step setting of each channel. The end segment number must not be less than the

start segment number of the channel, otherwise an execution error will result.

* 5. #418、#437、#457、#475、#494、#513、#522、#541: set the number of repeats for each channel.

* 6. #552: multi-step set enabled. #552 is effective with 8 bits less, the multi-step set function of Bit0

control channel 1 is start, the multi-step setting function of Bit1 control channel 2 is started, and so on.

16

When the mark is 0, start multi-step setting; When the flag is 1, a multi-step setting is performed. When

the multi-step setting is executing, write 0 to stop the multi-step setting. When you write 1 again, the

multi-step setting will be reexecuted from the first step.

1.5.5 Alarm function setting

The setting contents of the alarm function of the buffer of MTC-08-NT (BFM) are shown in table 1-12.

Table 1-12 MTC-08-NT buffer (BFM) alarm function Settings

BFM

Content

Remarks

Natu

re

Sa

ve

CH1/CH5

CH2/CH6

CH3/CH7

CH4/CH8

#600

Alarm 1 mode

setting * 1

Default value :0

R/W

Y

#601

Alarm 2 mode

setting * 1

Default value :0

R/W

Y

#602

Alarm 3 mode

setting * 1

Default value :0

R/W

Y

#603

Alarm 4 mode

setting * 1

Default value :0

R/W

Y

#604

Alarm dead zone

setting * 2

Default

value :10,denoted

by 0.1℃

R/W

Y

#605

Alarm delay times *

3

Default

value :0,range:0~2

55

Range:0~999

R/W

Y

#606/#622

#610/#626

#614/#630

#618/#634

Alarm 1 setting

value * 4

Default value :0

R/W

Y

#607/#623

#611/#627

#615/#631

#619/#635

Alarm 2 setting

value * 4

Default value :0

R/W

Y

#608/#624

#612/#628

#616/#632

#620/#636

Alarm 3 setting

value * 4

Default value :0

R/W

Y

#609/#625

#613/#629

#617/#633

#621/#637

Alarm 4 setting

value * 4

Default value :0

R/W

Y

* 1. #600 ~ #603: alarm enable, from which the user can determine the type of alarm required to enable.

#600 set the alarm type 1, #601 set the alarm type 2, and so on. MTC-08-NT offers 14 alarm types, four

of which can be selected simultaneously (see 5.3.1 alarm type). For different channels, the alarm values

of 1 ~ 4 alarm determined by #600 ~ #603 are set by #606 ~ #609, #610 ~ #613, #614 ~ #617, #618~

#621 、#622~#625、#626~#629、#630~#633、and #634~#637 respectively.

* 2. #604: set the dead zone for each channel's alarm mode. In order to avoid repeated occurrence of

alarm state and non-alarm state when the measured value fluctuates near the alarm setting value, an

alarm dead zone can be set. Setting range: 0 ~ 999; Default value: 10; Unit: 0.1℃/℉. See 5.3.2 alarm

dead zone.

* 3. #605: number of alarm delay. Set the range from 0 to 255. If the measured value in the alarm range is

still within the alarm range after the set number of delayed alarm, the alarm will be given. See 5.3.3 alarm

delay.

17

* 4.#606~#609、#610~#613、#614~#617、#618~#621、#622~#625、#626~#629、#630~#633、#634~

#637:1 ~ 4 alarm settings in channel 1 ~ 4. For different channels, the same alarm need to set different

alarm value. User enabled via #600 ~ #603

1.5.6 Parameter save setting

The BFM parameter saving Settings of MTC-08-NT buffer (BFM) are shown in table 1-13

Table 1-13 save Settings for BFM parameters of MTC-08-NT buffer (BFM)

BFM

Content

Remarks

Nature

Save

CH1

CH2

CH3

CH4

#700

Module parameter saving*1

Default value: 0 (no

parameter saved)

1: parameter save start

R/W

N

* 1. #700: when the user save the parameter, and this position is 1, the module save the parameter set by

the current user. Operating instructions are as follows:

1) when #700 is set to 1, start the data backup. At this point, you need to wait for a few seconds before

the power is cut off, otherwise the parameter may be saved incorrectly. After MTC save the parameters,

#700 will automatically clear.

2) Parameter saving errors may occur when there are errors due to interference and temperature

controller. The parameters should be saved again. If the parameter is saved in error, the parameter will

be restored to the factory default value.

3) When there is a set value error, the original parameters of the unit will be saved.

1.5.7 Other

The rest of the buffer (BFM) of MTC-08-NT is shown in table 1-14

Other contents of the buffer (BFM) of table 1-14 MTC-08-NT

BFM

Content

Remarks

Nature

Save

CH1

CH2

CH3

CH4

#4094

Module software version information*1

0x2000

R

N

#4095

Thermostat identification code*2

0xB442

R

N

* 1. #4094: module software version information.

* 2. #4095: module identifier. Ctc-04-nvt is identified by 0xB444. The user program in the programmable

controller can use this identifier in the program to confirm the thermostat before transmitting/receiving

data.

1.6 Attachment List

The terminal blocks supplied with the MTC-08-NT terminals are shipped with the terminal. The details are

shown in the table below.

Table 1-15 List of accessories

Terminal head model

Number

3.5mm pitch 5pin plug

2

3.5mm pitch 6pin plug

4

5.08mm pitch 2pin plug

1

5.08mm pitch 3pin plug

1

18

2.Installation wiring

This chapter introduces the installation and wiring of MTC-08-NT.

2.1 Mechanical installation

2.1.1 Installation location requirements

As shown in figure 2-1, MTC-08-NT shall be installed horizontally on the back panel of the electric cabinet,

installed up and down and maintaining the air space above and below it. Other direction installation is not

conducive to their own heat dissipation, for the improper installation. The distance between MTC-08-NT

and the equipment above and below or the cabinet wall should be greater than 15cm, and there should

be no heating equipment below.

Figure 2-1 Installation location requirements

2.1.2 Installation step

Use DIN slot to install and fix

Generally, a 35mm width DIN slot can be used for installation, as shown in Figure 2-2.

Figure 2-2 Fixing with DIN slot

The specific installation steps are as follows:

1. Fix the DIN groove horizontally on the mounting back plate;

19

2. Pull out the DIN slot clasp at the bottom of the module;

3. Attach the module to DIN;

4. Press the buckle back to the original position and lock the module;

5. Finally, the two ends of the module are fixed with DIN slots to avoid sliding left and right.

Fixed with screw installation

For occasions where there may be a large impact, screw hole installation can be adopted, as shown in

figure 2-3. The MTC - 04 - NVT with fixed screws shell two Ф 4 screw hole to fix module on the electric

cabinet on the back of recommended M3 screws.

Figure 2-3 Fixing with screws

2.2 Connection

2.2.1 Wiring precautions

danger

1.Do not use MTC in the following places: places with dust, lampblack, conductive dust, corrosive gas

and combustible gas; Exposure to high temperature, dew, wind and rain; There are vibration, shock

occasions. Electric shocks, fires, and misoperation can also lead to product damage and deterioration.

2.During screw hole processing and wiring, do not let metal scraps and wire tips fall into the vent hole of

the controller, which may cause fire, failure and wrong operation.

3.Remove the foreign body immediately after installation and wiring. Please cover the terminal cover of

the product before electrifying to avoid electric shock.

4.At the end of the installation of the newly purchased MTC, it is necessary to ensure that there is no

foreign body on the ventilation surface, including dust-proof paper and other packaging items, otherwise

it may lead to poor heat dissipation during operation, causing fire, failure and wrong operation.

5.Avoid wiring and unplugging cables in live state, or electric shock or circuit damage will be easily

caused.

6.Installation and wiring must be firm and reliable. Poor contact may lead to incorrect operation.

7.The input or output cables of high frequency signals and the cables transmitting analog signals should

be twiped shielded cables to improve the anti-disturbance performance of the system.

8.Please access 24Vdc power supply according to the instructions in this manual. Connecting ac power

20

to the terminal will burn MTC.

9.The input and output signal lines connected to MTC shall not be arranged side by side with other

high-power or high-interference lines to reduce interference.

2.2.2 Wiring instructions

User terminal input wiring is shown in Figure 2-4.

Table 2-1 MTC-08-NT enter the user terminal wiring diagram

Figure ①~⑦wiring must be noted that seven aspects:

①The thermocouple (thermal resistance) signals suggested accessing by shieded compensation cable. Cables away

from power lines or other wires may produce electromagnetic interference. It is recommended to use less than

100 m compensation cable (connecting cable) that be suscepted by noise interference Compensation cable (cable)

exist resistance, will introduce measurement error, adjusting feature to resolve this issue, please refer to the specific

operation "MTC-08-NT thermostat user manual."

②Thermal resistance (type Pt100, JPt100, Cu100, Cu50) required the three-wire connection.

③It is recommended to short connect the positive and negative terminals L+ and L- of the channel that is not used, so

as to prevent incorrect data from being detected on this channel.

④If there is too much electrical interference, connect the shield wire (the shield end of thermocouple compensation

cable, the shield end of thermal resistance connection cable, the shield end of 485 communication wire) to the

temperature controller ground end PG.

⑤The thermostat grounding PG should be good grounding.

⑥24V power supply can use the auxiliary output 24Vdc power supply of the main module, or other power supply that

meets the requirements.

⑦Users need to select the appropriate power supply and solid state relay according to the output mode of 1-4

performance indicators.

2.2.3 Cable specifications

When wiring for MTC-08-NT applications, it is recommended to use multi-ply copper conductors and

prefabricate insulated terminals to ensure the wiring quality. The cross-sectional area and model of the

recommended conductor are shown in table 2-1.

Table 2-1 recommended MTC connection cable wire model

Table of contents

Other Megmeet Thermostat manuals

Popular Thermostat manuals by other brands

THERMOFOL

THERMOFOL TF-H6 WIFI Operating And Manual instructions

Siemens

Siemens BRTRF operating instructions

Dennerle

Dennerle DUOMAT 1200 Comfort operating instructions

BASETech

BASETech 1405335 operating instructions

meitav-tec

meitav-tec FMH-220-FAN-COIL-SUPER 3 owner's manual

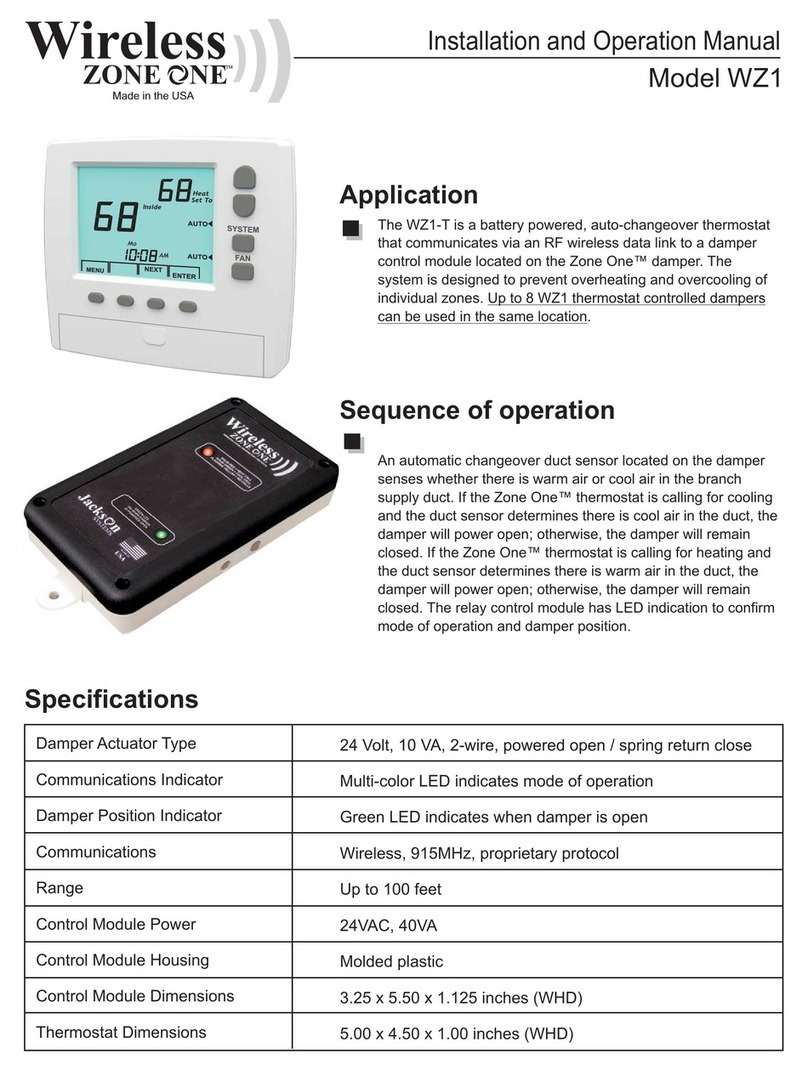

Jackson Systems

Jackson Systems WZ1 Installation and operation manual