Megmeet MTCV Series User manual

1

MTCV series thermostat quick start

Note: this manual takes MTCV-16NT as an example. Other models are

subject to the actual model.

Thank you for using MTCW series thermostat of Megmeet . Before using

the product, please carefully read this booklet so as to better understand

it, fully use it, and ensure safety.

This user manual is to offer you a quick guide to the design, installation,

connection and maintenance of MTCV series thermostat, convenient for

on-site reference. Briefly introduced in this booklet are the hardware

specs, features, and usage of MTCV series thermostat, plus the

optional parts and FAQ for your reference.

For more information, see the MTCV series thermostat user manual.

This manual is suitable for the following members of the MTCV series:

MTCV-16-NT

MTCV-08-NT

MTCV-04-NT

Version:1.0

Data:2018-12-07

BOM:

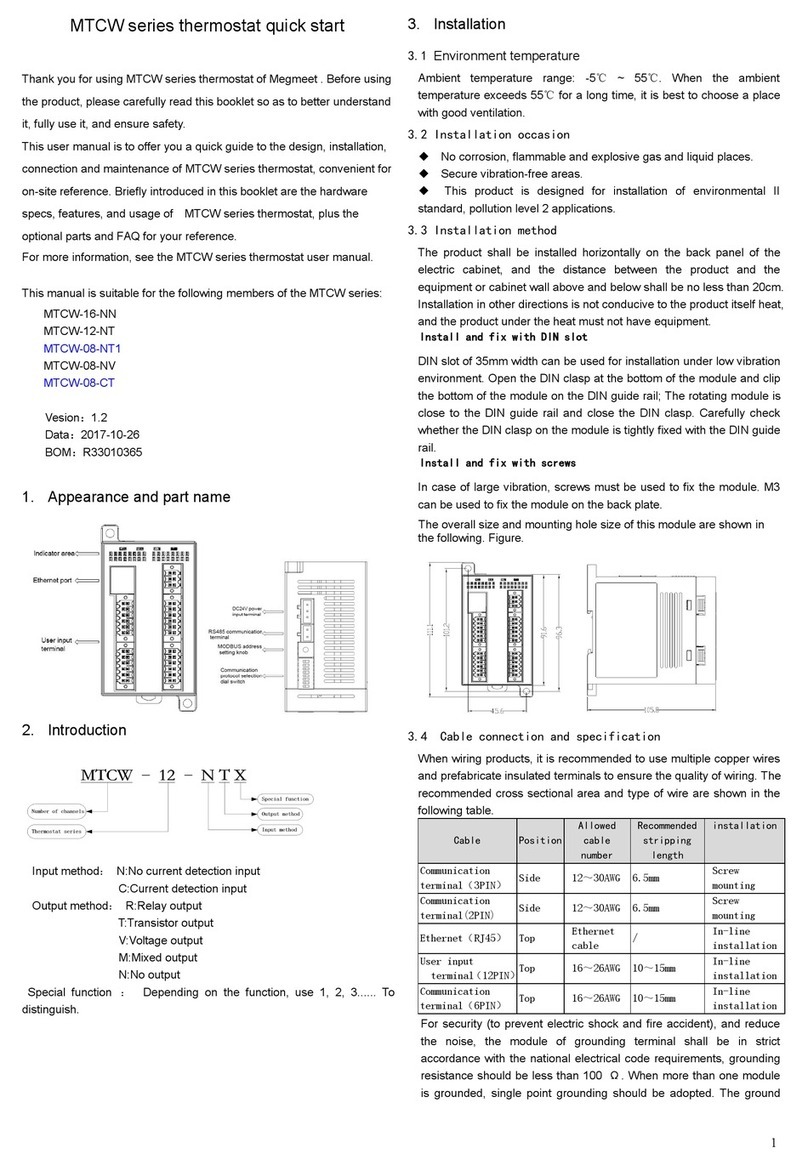

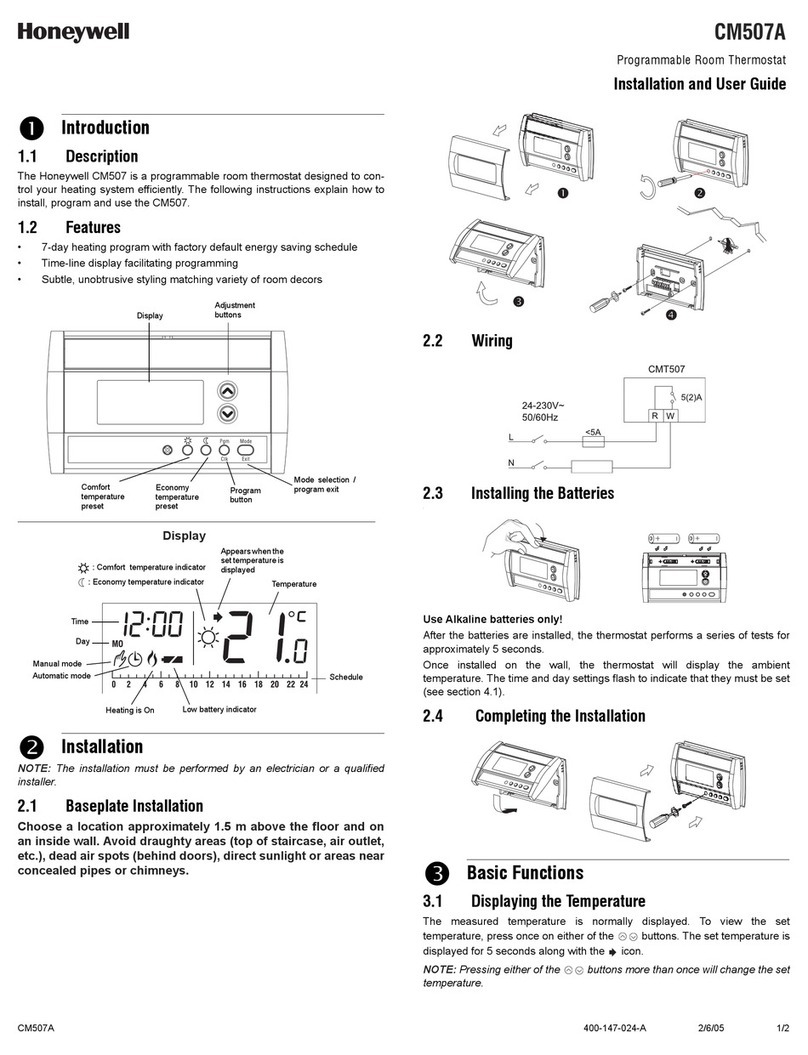

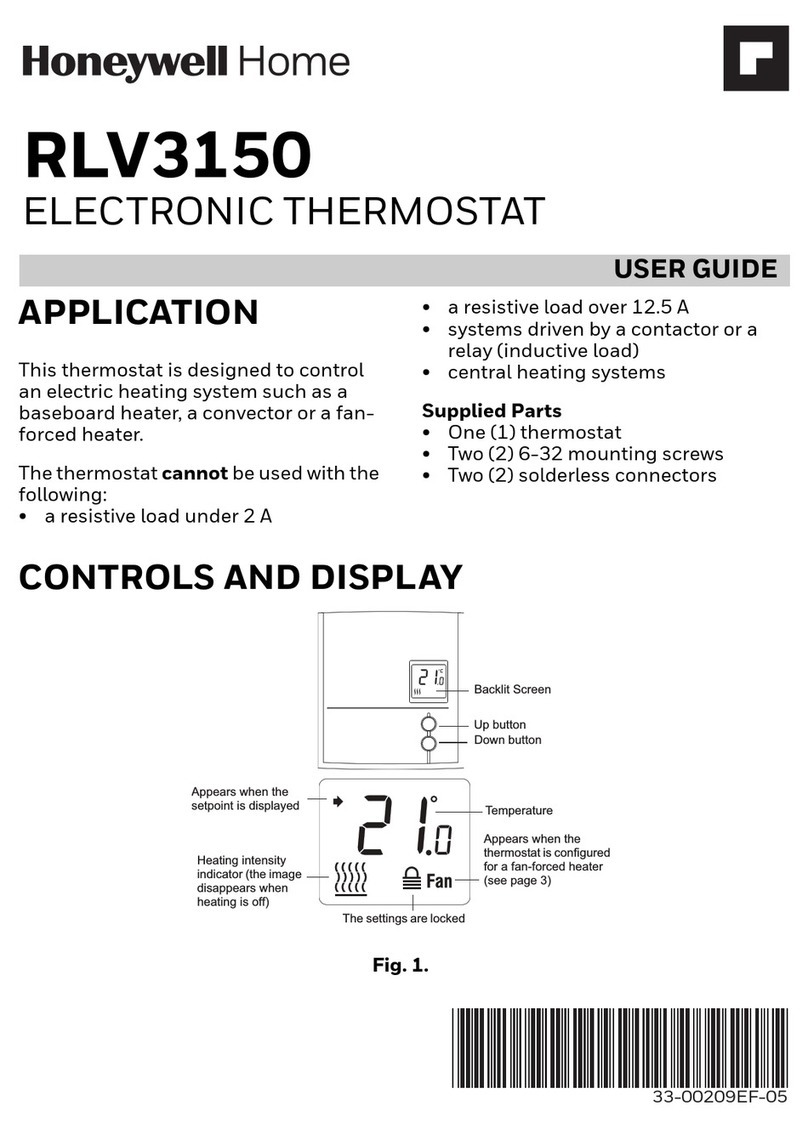

1. Appearance and part name

2. Introduction

current detection:N:No current detection input

C:Current detection input

Output method:R:Relay output

T:Transistor output

V:Voltage output

I:Current output

M:Mixed output

N:No output

Special function :Depending on the function, use 1, 2, 3...... To

distinguish.

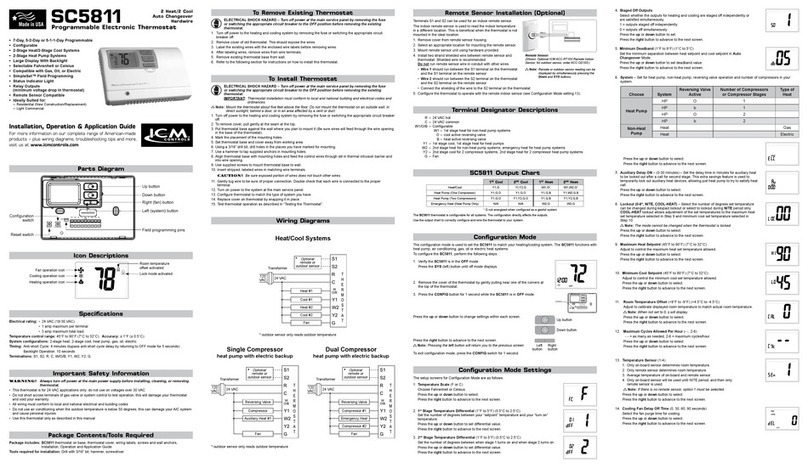

3. Installation

3.1Environment temperature

Ambient temperature range: -5℃~ 55℃.

3.2Installation occasion

◆Please do not use it in the environment where there are flammable,

explosive, corrosive gases or liquids.

◆Please do not mix metal or wire debris into the product, or it may

cause fire or malfunction.

◆In order not to hinder the heat dissipation, please keep the air

circulation around the product.

◆Use of environmental humidity <85%RH, no condensation.

3.3 Installation method

The product shall be installed horizontally on the back panel of the

electric cabinet, and the distance between the product and the

equipment or cabinet wall above and below shall be no less than 20cm.

Installation in other directions is not conducive to the product itself heat,

and the product under the heat must not have equipment.

Install and fix with DIN slot

DIN slot of 35mm width can be used for installation under low vibration

environment. Open the DIN clasp at the bottom of the module and clip

the bottom of the module on the DIN guide rail; The rotating module is

close to the DIN guide rail and close the DIN clasp. Carefully check

whether the DIN clasp on the module is tightly fixed with the DIN guide

rail.

Install and fix with screws

In case of large vibration, screws must be used to fix the module. M3

can be used to fix the module on the back plate.

The overall size and mounting hole size of this module are shown in

the following. Figure.

3.4 Cable connection and specification

When wiring products, it is recommended to use multiple copper wires

and prefabricate insulated terminals to ensure the quality of wiring. The

recommended cross sectional area and type of wire are shown in the

following table.

Cable

Positi

on

Allowed

cable

number

Recommended

stripping

length

installa

tion

Communication

terminal(3PIN)

Side

12~30AWG

6.5mm

Screw

mounting

Communication

terminal(2PIN)

Side

12~30AWG

6.5mm

Screw

mounting

Ethernet(RJ45)

Top

Ethernet

cable

/

In-line

installa

tion

User input terminal

(12PIN)

Top

16~26AWG

10~15mm

In-line

installa

tion

2

Communication

terminal(6PIN)

Top

16~26AWG

10~15mm

In-line

installa

tion

For security (to prevent electric shock and fire accident), and reduce

the noise, the module of grounding terminal shall be in strict

accordance with the national electrical code requirements, grounding

resistance should be less than 100 Ω. When more than one module

is grounded, single point grounding should be adopted. The ground

wire cannot form a circuit. As shown in the following figure

4. Terminal Introduction

4.1User terminal

MTCW-12-NT terminal silk screen

User terminal definition table

Remark

Description

24V+,24V-

Input power DC 24V

Ground

A0,B0

RS485(COM0)

T1+~T16+

Channels 1 to 16 are positive for thermocouple

signal input

T1-~T16-

Channels 1 to 16 are negative for thermocouple

signal input

CJ+,CJ-

The external cold junction compensation is

positive and negative. (Note)

Y01~Y08,COM0

Switch output port channel 1~8

Y09~Y16,COM1

Switch output port channel 9~16

Note:CJ+ and CJ- are external thermocouple cold end compensation

terminals (optional), connected with PT100 thermal resistance. When the

connection is not connected or the measured value exceeds the range of

-20℃~ 80℃, it is automatically switched to the internal cold end

compensation.

4.2 User connection mode

5 things to pay attention to when wiring:

1All the input and output signal connections and communication

cables shall be shielded layer cables.

2The thermocouple signal uses the compensation line, the dividing

number should be consistent, positive and negative to

correspond.

3The signal cable should be away from other cables that may cause

electromagnetic interference, such as the unavoidable set of

metal pipe or wire slot.

4The metal case of thermocouple should be grounded reliably.

5The thermostat grounding PGND should be good grounding.

5. Electrical indicator

5.1 Power indicator

Item

Unit

Min

value

Typical

value

Max

value

Remark

Input voltage

range

Vdc

20

24

30

Normal start-up and

working range

Input current

A

/

0.08

/

Normal temperature

rated full load

5.2 Performance indicators

Item

Indicator

Input

signal

Thermocoup

le type

K、J、E、N、T、R、S、B

Input

method

Transistor

output with

open gate

Power supply voltage circuit: 5V ~ 24V; The

maximum circuit power supply voltage circuit:

30V; Loop current: 0.3A /24Vdc; Leakage current

when open:<0.1mA/30Vdc;Minimum load:5mA

(5Vdc~24Vdc)

Control

cycle

Fast

1~100,the unit is 0.1s.The specific value is

determined by the characteristics of the

temperature controlled object

Slow

1~100,the unit is 1s.The specific value is

determined by the characteristics of the

temperature controlled object

Control method

ON/OFF,Hand,PID

Rated

Type K

-100℃~1200℃(-148℉~2192℉)

3

Item

Indicator

temperat

ure range

Type J

-100℃~1200℃(-148℉~1112℉)

Type E

-100℃~850℃(-148℉~1562℉)

Type N

-100℃~1200℃(-148℉~2192℉)

Type T

-200℃~300℃(-328℉~572℉)

Type R

0℃~1600℃(32℉~2912℉)

Type S

0℃~1600℃(32℉~2912℉)

Type B

400℃~1800℃(752℉~3272℉)

Accuracy

Thermoco

uple

Full range ±0.3%

Environmental

compensation error

<1℃(external cold end compensation)

Isolation

Isolation between sampling channel and power

supply, isolation between sampling channel and

output, isolation between channels and

channels, communication and power supply

isolation

5.3 Communication specification

Name

Communication

protocol

Port remark

Communication

method

Communicatio

n port

Modbus RTU slave

A0,B0

RS485

5.4 Indicator description

Name

Status

Indicator

PWR

ON

24V power supply is normal

RUN

Flashes quickly

(10Hz~15Hz)

Normal

Flashes slowly

(0.5Hz~1Hz)

There is an error, see # 3612, # 3613

for the error status

COMM0

Flashes

Normal communication

Y01~Y16

ON

Corresponding channel output is ON

6. BFM

MODBUS supports 01, 03, 05, 06 and 16 functions. 01, 05 function

code to the bit register operation, 03, 06, 16 function code to the

integer register operation, if read the undefined register, will get 0 value.

Up to 100 BFM units can be read or written at a time.

Function

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

CH9

CH10

CH11

CH12

CH13

CH14

CH15

CH16

Measured value(PV)

1500

1501

1502

1503

1504

1505

1506

1507

1508

1509

1510

1511

1512

1513

1514

1515

Heating side

control output(MV)

1532

1533

1534

1535

1536

1537

1538

1539

1540

1541

1542

1543

1544

1545

1546

1547

Multi-segment

control of current

execution segment

1564

1565

1566

1567

1568

1569

1570

1571

1572

1573

1574

1575

1576

1577

1578

1579

Working status

word

1596

1597

1598

1599

1600

1601

1602

1603

1604

1605

1606

1607

1608

1609

1610

1611

Digital filter set

of one step

1628

1629

1630

1631

1632

1633

1634

1635

1636

1637

1638

1639

1640

1641

1642

1643

D0

1788

1789

1790

1791

1792

1793

1794

1795

1796

1797

1798

1799

1800

1801

1802

1803

D1

1820

1821

1822

1823

1824

1825

1826

1827

1828

1829

1830

1831

1832

1833

1834

1835

A0

1724

1725

1726

1727

1728

1729

1730

1731

1732

1733

1734

1735

1736

1737

1738

1739

A1

1756

1757

1758

1759

1760

1761

1762

1763

1764

1765

1766

1767

1768

1769

1770

1771

Input type

1660

1661

1662

1663

1664

1665

1666

1667

1668

1669

1670

1671

1672

1673

1674

1675

Set value(SV)

1692

1693

1694

1695

1696

1697

1698

1699

1700

1701

1702

1703

1704

1705

1706

1707

Proportional cycle

time

1852

1853

1854

1855

1856

1857

1858

1859

1860

1861

1862

1863

1864

1865

1866

1867

Heat side

proportional band

1884

1885

1886

1887

1888

1889

1890

1891

1892

1893

1894

1895

1896

1897

1898

1899

Heat side integral

time

1916

1917

1918

1919

1920

1921

1922

1923

1924

1925

1926

1927

1928

1929

1930

1931

Heat side

derivative time

1948

1949

1950

1951

1952

1953

1954

1955

1956

1957

1958

1959

1960

1961

1962

1963

Control action

1980

1981

1982

1983

1984

1985

1986

1987

1988

1989

1990

1991

1992

1993

1994

1995

Heat/cool action

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

2023

2024

2025

2026

2027

Hand output value

2044

2045

2046

2047

2048

2049

2050

2051

2052

2053

2054

2055

2056

2057

2058

2059

Adjust sensitivity

2076

2077

2078

2079

2080

2081

2082

2083

2084

2085

2086

2087

2088

2089

2090

2091

Auto-tuning

deviation

2108

2109

2110

2111

2112

2113

2114

2115

2116

2117

2118

2119

2120

2121

2122

2123

Step 1 temperature

2140

2141

2142

2143

2144

2145

2146

2147

2148

2149

2150

2151

2152

2153

2154

2155

Step 2

1temperature

2172

2173

2174

2175

2176

2177

2178

2179

2180

2181

2182

2183

2184

2185

2186

2187

Step 3 temperature

2204

2205

2206

2207

2208

2209

2210

2211

2212

2213

2214

2215

2216

2217

2218

2219

Step4 temperature

2236

2237

2238

2239

2240

2241

2242

2243

2244

2245

2246

2247

2248

2249

2250

2251

Step 5 temperature

2268

2269

2270

2271

2272

2273

2274

2275

2276

2277

2278

2279

2280

2281

2282

2283

Step 6 temperature

2300

2301

2302

2303

2304

2305

2306

2307

2308

2309

2310

2311

2312

2313

2314

2315

Step 7 temperature

2332

2333

2334

2335

2336

2337

2338

2339

2340

2341

2342

2343

2344

2345

2346

2347

Step 8 temperature

2364

2365

2366

2367

2368

2369

2370

2371

2372

2373

2374

2375

2376

2377

2378

2379

Step 1 time

2396

2397

2398

2399

2400

2401

2402

2403

2404

2405

2406

2407

2408

2409

2410

2411

Step 2 time

2428

2429

2430

2431

2432

2433

2434

2435

2436

2437

2438

2439

2440

2441

2442

2443

Step 3 time

2460

2461

2462

2463

2464

2465

2466

2467

2468

2469

2470

2471

2472

2473

2474

2475

Step 4 time

2492

2493

2494

2495

2496

2497

2498

2499

2500

2501

2502

2503

2504

2505

2506

2507

Step 5 time

2524

2525

2526

2527

2528

2529

2530

2531

2532

2533

2534

2535

2536

2537

2538

2539

Step 6 time

2556

2557

2558

2559

2560

2561

2562

2563

2564

2565

2566

2567

2568

2569

2570

2571

Step 7 time

2588

2589

2590

2591

2592

2593

2594

2595

2596

2597

2598

2599

2600

2601

2602

2603

Step 8 time

2620

2621

2622

2623

2624

2625

2626

2627

2628

2629

2630

2631

2632

2633

2634

2635

Repeat start step

2652

2653

2654

2655

2656

2657

2658

2659

2660

2661

2662

2663

2664

2665

2666

2667

Repeat end step

2684

2685

2686

2687

2688

2689

2690

2691

2692

2693

2694

2695

2696

2697

2698

2699

Repeat count

2716

2717

2718

2719

2720

2721

2722

2723

2724

2725

2726

2727

2728

2729

2730

2731

The value alarm 1

2748

2749

2750

2751

2752

2753

2754

2755

2756

2757

2758

2759

2760

2761

2762

2763

The value alarm 2

2780

2781

2782

2783

2784

2785

2786

2787

2788

2789

2790

2791

2792

2793

2794

2795

The value alarm 3

2812

2813

2814

2815

2816

2817

2818

2819

2820

2821

2822

2823

2824

2825

2826

2827

The value alarm 4

2844

2845

2846

2847

2848

2849

2850

2851

2852

2853

2854

2855

2856

2857

2858

2859

Cooling side

control output

(MV)

2876

2877

2878

2879

2880

2881

2882

2883

2884

2885

2886

2887

2888

2889

2890

2891

Overlap/Deadband

3036

3037

3038

3039

3040

3041

3042

3043

3044

3045

3046

3047

3048

3049

3050

3051

Undershoot

suppresion factor

3068

3069

3070

3071

3072

3073

3074

3075

3076

3077

3078

3079

3080

3081

3082

3083

Heat side

proportional band

adjusting factor

3164

3165

3166

3167

3168

3169

3170

3171

3172

3173

3174

3175

3176

3177

3178

3179

Heat side integral

3196

3197

3198

3199

3200

3201

3202

3203

4

band adjusting

factor

3204

3205

3206

3207

3208

3209

3210

3211

Heat side

derivative band

adjusting factor

3228

3229

3230

3231

3232

3233

3234

3235

3236

3237

3238

3239

3240

3241

3242

3243

Cool side

proportional band

adjusting factor

3260

3261

3262

3263

3264

3265

3266

3267

3268

3269

3270

3271

3272

3273

3274

3275

Cool side integral

band adjusting

factor

3292

3293

3294

3295

3296

3297

3298

3299

3300

3301

3302

3303

3304

3305

3306

3307

Cool side

derivative band

adjusting factor

3324

3325

3326

3327

3328

3329

3330

3331

3332

3333

3334

3335

3336

3337

3338

3339

PID group

selection

5735

5736

5737

5738

5739

5740

5741

5742

5743

5744

5745

5746

5747

5748

5749

5750

Regional action

6855

6856

6857

6858

6859

6860

6861

6862

6863

6864

6865

6866

6867

6868

6869

6870

Region 1

6887

6888

6889

6890

6891

6892

6893

6894

6895

6896

6897

6898

6899

6900

6901

6902

Region 2

6919

6920

6921

6922

6923

6924

6925

6926

6927

6928

6929

6930

6931

6932

6933

6934

Region 3

6951

6952

6953

6954

6955

6956

6957

6958

6959

6960

6961

6962

6963

6964

6965

6966

Regional

hysteresis

6983

6984

6985

6986

6987

6988

6989

6990

6991

6992

6993

6994

6995

6996

6997

6998

Operation output

ratio

6791

6792

6793

6794

6795

6796

6797

6798

6799

6800

6801

6802

6803

6804

6805

6806

Manipulation

output offset

6823

6824

6825

6826

6827

6828

6829

6830

6831

6832

6833

6834

6835

6836

6837

6838

Output selection

7339

7340

7341

7342

7343

7344

7345

7346

7347

7348

7349

7350

7351

7352

7353

7354

Heat side

proportional band

1

6023

6024

6025

6026

6027

6028

6029

6030

6031

6032

6033

6034

6035

6036

6037

6038

Heat side

integration time 1

6055

6056

6057

6058

6059

6060

6061

6062

6063

6064

6065

6066

6067

6068

6069

6070

Heat side

derivative time 1

6087

6088

6089

6090

6091

6092

6093

6094

6095

6096

6097

6098

6099

6100

6101

6102

Heat side

proportional band

2

6183

6184

6185

6186

6187

6188

6189

6190

6191

6192

6193

6194

6195

6196

6197

6198

Heat side

integration time 2

6215

6216

6217

6218

6219

6220

6221

6222

6223

6224

6225

6226

6227

6228

6229

6230

Heat side

derivative time 2

6247

6248

6249

6250

6251

6252

6253

6254

6255

6256

6257

6258

6259

6260

6261

6262

Heat side

proportional band

3

6343

6344

6345

6346

6347

6348

6349

6350

6351

6352

6353

6354

6355

6356

6357

6358

Heat side

integration time 3

6375

6376

6377

6378

6379

6380

6381

6382

6383

6384

6385

6386

6387

6388

6389

6390

Heat side

derivative time 3

6407

6408

6409

6410

6411

6412

6413

6414

6415

6416

6417

6418

6419

6420

6421

6422

Heat side

proportional band

4

6503

6504

6505

6506

6507

6508

6509

6510

6511

6512

6513

6514

6515

6516

6517

6518

Heat side

integration time 4

6535

6536

6537

6538

6539

6540

6541

6542

6543

6544

6545

6546

6547

6548

6549

6550

Heat side

derivative time 4

6567

6568

6569

6570

6571

6572

6573

6574

6575

6576

6577

6578

6579

6580

6581

6582

Cool side

proportional band

1

5767

5768

5769

5770

5771

5772

5773

5774

5775

5776

5777

5778

5779

5780

5781

5782

Cool side

integration time 1

5799

5800

5801

5802

5803

5804

5805

5806

5807

5808

5809

5810

5811

5812

5813

5814

Cool side

derivative time 1

5831

5832

5833

5834

5835

5836

5837

5838

5839

5840

5841

5842

5843

5844

5845

5846

Cool side

proportional band

2

5863

5864

5865

5866

5867

5868

5869

5870

5871

5872

5873

5874

5875

5876

5877

5878

Cool side

integration time 2

5895

5896

5897

5898

5899

5900

5901

5902

5903

5904

5905

5906

5907

5908

5909

5910

Cool side

derivative time 2

5927

5928

5929

5930

5931

5932

5933

5934

5935

5936

5937

5938

5939

5940

5941

5942

Cool side

proportional band

3

5959

5960

5961

5962

5963

5964

5965

5966

5967

5968

5969

5970

5971

5972

5973

5974

Cool side

integration time 3

5991

5992

5993

5994

5995

5996

5997

5998

5999

6000

6001

6002

6003

6004

6005

6006

Cool side

derivative time 3

6119

6120

6121

6122

6123

6124

6125

6126

6127

6128

6129

6130

6131

6132

6133

6134

Cool side

proportional band

4

6151

6152

6153

6154

6155

6156

6157

6158

6159

6160

6161

6162

6163

6164

6165

6166

Cool side

integration time 4

6279

6280

6281

6282

6283

6284

6285

6286

6287

6288

6289

6290

6291

6292

6293

6294

Cool side

derivative time 4

6311

6312

6313

6314

6315

6316

6317

6318

6319

6320

6321

6322

6323

6324

6325

6326

Energy saving time

proportional

action

7111

7112

Energy saving

delay time

7113

7114

7115

7116

7117

7118

7119

7120

7121

7122

7123

7124

7125

7126

7127

7128

Main side /

auxiliary side

selection

7145

7146

Time ratio

secondary channel

7147

7148

7149

7150

7151

7152

7153

7154

7155

7156

7157

7158

7159

7160

7161

7162

Control start /

stop (lower four

bits are valid)

3628

3629

3930

3931

Set the rate of

change to limit the

rise

3356

3357

3358

3359

3360

3361

3362

3363

3364

3365

3366

3367

3368

3369

3370

3371

Set the rate of

change to limit the

decline

3388

3389

3390

3391

3392

3393

3394

3395

3396

3397

3398

3399

3400

3401

3402

3403

Selection of

temperature

control object

characteristics

3420

3421

3422

3423

3424

3425

3426

3427

3428

3429

3430

3431

3432

3433

3434

3435

Control algorithm

selection

3452

3453

3454

3455

3456

3457

3458

3459

3460

3461

3462

3463

3464

3465

3466

3467

Auto-tuning

algorithm

6695

6696

6697

6698

6699

6700

6701

6702

6703

6704

6705

6706

6707

6708

6709

6710

PID output upper

limit setting

3484

3485

3486

3487

3488

3489

3490

3491

3492

3493

3494

3495

3496

3497

3498

3499

PID output lower

limit setting

3516

3517

3518

3519

3520

3521

3522

3523

3524

3525

3526

3527

3528

3529

3530

3531

Error status word

(system

error)

3612

Error status word

(broken even

error)

3613

Set value range

error address

3616

3617

Channel

characteristics

confirmation

command

3624

3625

Auto-tuning

setting value

3637

3640

Reset

3640

Change settings

allowed

3644

CH1-CH16

multi-stage

control execution

3648

3649

5

flag

Alarm 1 mode

setting

3652

Alarm 2 mode

setting

3656

Alarm 3 mode

setting

3660

Alarm 4 mode

setting

3664

Alarm dead zone

setting

3668

Alarm delay times

3672

Operation amount

selection at alarm

6727

6728

6729

6730

6731

6732

6733

6734

6735

6736

6737

6738

6739

6740

6741

6742

Operation amount

at the time of

alarm

6759

6760

6761

6762

6763

6764

6765

6766

6767

6768

6769

6770

6771

6772

6773

6774

External input

status

3680

3681

Cold junction

temperature

3620

Module parameter

saving

3684

Module software

version

information

3688

Thermostat

identification

code

3692

System error status word(3612)

Bit status

ON(1)

OFF(0)

Bit0:Error

When any one of b1 ~ b7 is 1, this

flag is 1.

No error

Bit1:Remain

-

-

Bit2:Hardware

malfunction

AD converter or other hardware

failure, all channels AD conversion

stop

The

hardware

is normal

Bit3:Parameter

setting error

When there is an error in the

internal parameters of MTCV, this

flag will become 1.

Data

backup is

normal

Bit4:Cold junction

temperature

compensation error

Cold junction measurement

temperature abnormal

The cold

junction

is normal

Bit5:Remain

-

-

Bit6:Remain

-

-

Bit7~Bit15:Remain

-

-

Broken even error status word(3613)

Bit status

ON(1)

OFF(0)

Bit0 ~ Bit15 broken

couple detection

When the thermocouple of channel 1 ~

16 is broken, the flag bit is 1

No

channel

break

fault

7. Common problems and solutions

When the module does not work properly, please check in turn:

(1) the connection of the power line and the condition of the relevant

switches and protection appliances, so as to ensure the reliable power

supply of the module;

(2) whether the wiring of user terminals is firm;

(3) check whether the 24Vdc power supply is overloaded.

(4) check the application to ensure that the correct operation method

and parameter range are selected in the application. Special attention

should be paid to the BFM area with special operation timing.

If you still cannot work after the above check, please refer to the

following table.

Phenomenon

Possible Causes

Countermeasures

POWER and

other LED are

off

Loss of power supply or low

voltage

Check the power status and

eliminate

Power switch off or fuse

blown

Check the condition of the

switch, wire or fuse and

eliminate it

Abnormal power wiring

Power supply is damaged

Check and confirm: whether

the voltage between 24V +

and 24V- terminals is within

the normal range

POWER LED

flashes

intermittently

Unstable power supply

Module damaged

RUN LED is off

or on

Module shutdown or crash

Replace the module

RUN LED

flashes slowly

Possible system error

Please check the 3612, 3613

Broken couple error

The output

cannot be

turned off

(OFF)

External wiring contact

short circuit

Check connection and

troubleshoot

The output transistor is

damaged

Replace the module

The output

status indicator

is inconsistent

with the actual

output status

The output transistor is

aging or damaged, or the

indicator is damaged

The serial port

cannot

communicate

normally

The cable connection is

poor, or the signal

properties of the connection

line are wrong, such as A0

and B0 are reversed

Connect the positive and

negative signal lines correctly

Inconsistent setting of

communication

master-slave

characteristics, such as

baud rate, parity, data bits,

address

Set the communication

parameters to be consistent

The communication protocol of

the master and slave is

inconsistent, set the

communication protocol to be

consistent

1.Warranty scope refers to the programmable controller body.

2.The warranty period is 18 months, during the warranty period of

normal use, the product failure or damage, our company free

maintenance.

3.The warranty period starts from the date of production. The

machine code is the only basis to judge the warranty period. The

equipment without machine code shall be treated as overinsured.

4. Even within the warranty period, a certain maintenance fee will be

charged if:

(1)Failure to operate according to the user's manual;

(2)Machine damage caused by fire, flood, abnormal voltage, etc.

(3)Damage caused when a programmable controller is used for

unusual functions.

(4)Self-disassembly programmable controller

5. The service fee shall be calculated according to the actual cost. If

there is another contract, the contract shall take precedence.

6.If you have any problem, you can contact the agent or contact us

directly.

SHENZHEN MEGMEET CONTROL TECHNOLOGY CO., LTD

Add:5th Floor, Block B Unisplendour Information Harbor, Langshan Road,

Shenzhen

Tel:400-666-2-163

fax:(+86)0755-86600999

Postcode:518057

Web:www.megmeet-ia.com

This manual suits for next models

3

Table of contents

Other Megmeet Thermostat manuals