MEIER-BRAKENBERG MBHOT900 User manual

MBHOT900/1320 1

OPERATION MANUAL

(Original Operation Manual)

MBHOT900/1320

Meier-Brakenberg GmbH & Co. KG

Brakenberg 29

32699 Extertal

Germany

Telephone +49(0)52 62/993 99-0

Telefax +49(0)52 62/993 99-3

E-mail info@meier-brakenberg.de

Internet www.meier-brakenberg.de

Keep for future use!

© Meier-Brakenberg GmbH & Co. KG

This operation manual and any illustrations contained therein are protected by copyright. Any use

beyond the limits of copyright law without the prior written consent of the publisher is inadmissible

and liable to prosecution. This applies especially for copies, translations, microfilming, storage, and

processing in electronic systems.

2 Safety

2Meier-Brakenberg GmbH & Co. KG

Contents

1.1 Means of Depiction................................................................................................................. 5

1.2 Warranty and Liability............................................................................................................. 7

1.3 Copyright................................................................................................................................. 7

1.4 Warranty Policy....................................................................................................................... 8

1.5 Service / After-sales Service.................................................................................................... 8

2Safety .....................................................................................................................................9

2.1 Intended Use........................................................................................................................... 9

2.1.1 Constructional Changes to the Machine ................................................................. 10

2.1.2 Foreseeable Misuse................................................................................................. 11

2.2 Personnel Requirements....................................................................................................... 11

2.2.1 Responsibilities ........................................................................................................ 12

2.2.2 Obligations of Personnel.......................................................................................... 12

2.2.3 Unauthorised Persons ............................................................................................. 12

2.2.4 Instructions and Training......................................................................................... 13

2.3 General Safety Information................................................................................................... 13

2.4 Safety Measures for Environmental Protection.................................................................... 15

2.5 Special Hazards Information ................................................................................................. 16

2.5.1 Used Symbols on the Machine ................................................................................ 16

2.5.2 Dangers due to Electrical Energy............................................................................. 16

2.5.3 Dangers due to Water Pressure............................................................................... 17

2.5.4 Dangers due to Hot Surfaces ................................................................................... 18

2.5.5 Dangers due to Noise............................................................................................... 18

2.5.6 Dangers caused by the Use of Incorrect Spare Parts............................................... 18

2.6 Personal Protective Equipment ............................................................................................ 19

2.7 Safety and Protective Equipment ......................................................................................... 20

2.8 Advice for Emergency Cases ................................................................................................. 20

2.9 Obligations of the Operating Company ................................................................................ 21

3Machine Description .............................................................................................................23

3.1 Overviews.............................................................................................................................. 23

3.1.1 Overview Functional Components .......................................................................... 23

3.1.2 Overview Control Panels ......................................................................................... 26

3.1.3 Type Plate ................................................................................................................ 27

3.2 Functional Description .......................................................................................................... 28

3.2.1 Safety Equipment .................................................................................................... 28

3.2.2 Description of Control Elements.............................................................................. 29

3.2.2.1 Control Panel............................................................................................ 29

3.2.2.2 Pressure Reading...................................................................................... 29

3.2.2.3 Gun Trigger............................................................................................... 29

3.2.2.4 Knurled Screws of Cover .......................................................................... 30

3.2.2.5 Manual Crank (optional) .......................................................................... 30

3.2.2.6 Hose Guide (optional) .............................................................................. 30

3.2.2.7 Stop Lever (MBH line optional) ................................................................ 31

3.2.2.8 Injector (MBH line optional)..................................................................... 31

3.2.2.9 Oil dip stick............................................................................................... 31

3.3 Technical Data....................................................................................................................... 32

3.3.1 General .................................................................................................................... 32

3.3.2 Airborne Noise Emissions ........................................................................................ 32

3.3.3 Ambient Conditions................................................................................................. 32

3.3.4 Equipment ............................................................................................................... 33

1.1 Means of Depiction

MBHOT900/1320 3

4Transportation and Storage................................................................................................... 35

4.1 Inspection on Acceptance by the Recipient ..........................................................................35

4.2 Packaging...............................................................................................................................35

4.3 Information on Risks during Transportation .........................................................................35

4.4 Temporary Storage ................................................................................................................37

6. Commissioning ...................................................................................................................... 38

7. Operation............................................................................................................................. 39

a. Safety Measures in Normal Operation ..................................................................................39

b. Preparatory Measures ...........................................................................................................40

i. Change of Diesel Canister.........................................................................................40

ii. Change of Lances......................................................................................................42

iii. Use of Detergents.....................................................................................................42

c. Switch Machine on/off ..........................................................................................................44

d. Setpoint Value Adjustment....................................................................................................45

e. Cleaning Surfaces...................................................................................................................46

f. Finish Cleaning Operations ....................................................................................................48

8. Malfunction.......................................................................................................................... 49

a. Malfunctions and Corrective Measures.................................................................................49

9. Maintenance ........................................................................................................................ 51

9.1 Safety Measures during Maintenance......................................................................................51

a. Inspections and Maintenance................................................................................................53

i. Maintenance Intervals..............................................................................................53

ii. Preparatory Measures..............................................................................................54

iii. Maintenance –Daily.................................................................................................54

1. Visual Inspection.......................................................................................54

iv. Maintenance –Yearly...............................................................................................55

1. Inspection by technical specialist..............................................................55

2. Check screw connections..........................................................................55

3. Burner .......................................................................................................55

v. Special Maintenance Intervals .................................................................................55

1. Oil change .................................................................................................55

2. High-pressure hose ...................................................................................56

3. Burner .......................................................................................................57

10.1 Disposal.................................................................................................................................58

11 Annex................................................................................................................................... 59

b. EU Declaration of Conformity................................................................................................59

2 Safety

4Meier-Brakenberg GmbH & Co. KG

1 Introduction

This operation manual provides you with all information needed for the smooth

operation of MBHOT900/1320 (hereinafter referred to as the machine).

The operation manual must be read, understood and applied by all those entrusted with

the operation, maintenance, cleaning and troubleshooting of the machine. This

particularly applies for the listed safety instructions.

After studying the operation manual you know how to

–operate the machine in accordance with safety requirements,

–maintain the machine in accordance with the specifications,

–clean the machine in accordance with the specifications,

–take appropriate action in case of malfunction.

In addition to the operation manual the generally applicable, legal, and other binding

regulations governing the prevention of accidents and environmental protection of the

country where the machine is used must be observed.

The operation manual must always be available at the place where the machine is used.

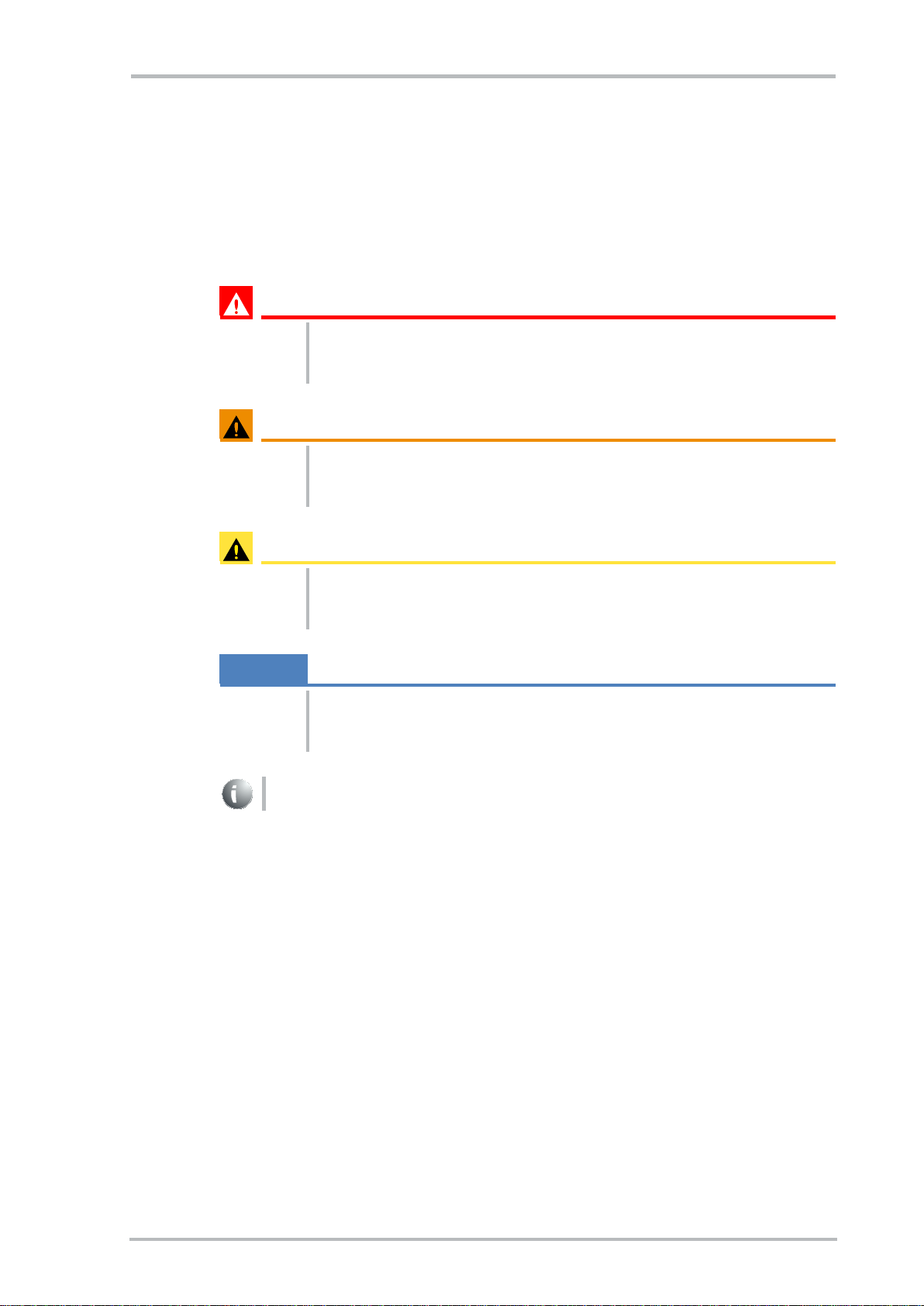

1.1 Means of Depiction

MBHOT900/1320 5

1.1 Means of Depiction

References to and direct warnings of hazards in this operation manual are sections

which require particular attention and they are marked as follows:

DANGER

This warning characterises dangers with high a degree of risk which, if not

avoided, result in death or severe physical injury.

CAUTION

This warning characterises dangers with mean degree of risk which, if not

avoided, may result in death or severe physical injury.

ATTENTION

This warning characterises dangers with low degree of risk which, if not

avoided, may result in minor or moderate physical injury.

NOTE

This warning characterises dangers with low degree of risk which, if not

avoided, may result in damage to property.

The info symbol refers to useful information.

Furthermore the following means of depiction are used:

–

Texts following this marking are part of a list.

Texts following this marking describe activities which must be carried out in the

specified order.

„ “

Texts enclosed in double quotation marks are a reference to other sections or

paragraphs.

‚.‘

Texts enclosed in single quotation marks designate the name of a component.

ON

Texts written in capital letters identify a push button/switch on control elements.

2 Safety

6Meier-Brakenberg GmbH & Co. KG

Symbols used in this manual

Warnings which identify particular risks are additionally marked as follows:

Mortal danger due to electric current

This symbol cautions against mortal dangers caused by electric current.

Direct mortal danger in case of contact with live components.

Warning of suspended loads

This symbol cautions against dangers when entering areas underneath

suspended loads.

Hot surfaces

This symbol cautions against risk of burns caused by hot surfaces.

1.2 Warranty and Liability

MBHOT900/1320 7

1.2 Warranty and Liability

The agreed obligations, the General Terms and Conditions, as well as the Delivery Terms

for the machine and the legal provisions valid at the time of the conclusion of the

contract do apply.

All specifications and information contained in this operation manual are based on due

consideration of valid standards and regulations, latest technology as well as our many

years of knowledge and experience.

Warranty and liability claims for personal injury or damage to property are excluded if

they are due to one or several of the following causes:

–Use of the machine for any other purpose than the intended use or inappropriate

use.

–Improper installation, commissioning, operation, maintenance, and cleaning of the

machine.

–Operating the machine in spite of defect safety equipment or improper or inoperable

safety and protection equipment.

–Failure to observe the operation manual and information contained in the operation

manual relating to the installation, commissioning, operation, maintenance, and

cleaning of the machine.

–Deployment of unqualified or untrained personnel.

–Constructional changes to the machine (reconstruction or any other changes to the

machine are not permitted without prior written authorisation by Meier-Brakenberg

GmbH & Co. KG. In case of non-compliance the machine’s EC conformity lapses).

–Improper repair.

–Use of unauthorised spare parts or use of spare parts which do not comply with the

technical specifications.

–Event of disaster, external influences, and force majeure.

We reserve the right to make technical changes within the terms of improvement of

performance characteristics and further development.

1.3 Copyright

This operation manual is protected by copyright and only intended for internal

purposes.

2 Safety

8Meier-Brakenberg GmbH & Co. KG

Transfer of the manual to third parties, duplication of any kind and form –even in

extracts –as well as utilisation and/or communication of the contents is not permitted

without written authorisation by Meier-Brakenberg GmbH & Co. KG, except for internal

purposes.

Contraventions are subject to compensation for damages. We reserve the right to assert

further claims.

1.4 Warranty Policy

The warranty policy is included in the general terms and conditions of the Meier-

Brakenberg GmbH & Co. KG.

1.5 Service / After-sales Service

Please contact our after-sales service for technical information:

Telephone: +49(0)52 62/993 99-0

Moreover, our colleagues are always interested in new information and

experience made when using our products. Such information can be very

valuable for the improvement of our products.

MBHOT900/1320 9

2Safety

CAUTION

Failure to observe the following safety advice may have serious

consequences:

–Endangerment of persons caused by electrical, mechanical, or chemical

influences,

–Failure of important machine functions,

–Environmental damages due to escaping hazardous substances.

Read the safety advice and hazard warnings contained in this section

carefully before commissioning the machine.

Observe the generally valid safety and accident prevention regulations in

addition to the advice included in the manual.

The operating company must observe the applicable national work

regulations, operating regulations, and safety regulations in addition to

the advice included in this manual. Existing internal works regulation need

to be equally observed.

2.1 Intended Use

The operational safety of the machine is only guaranteed when it is used as intended.

The machine is solely intended for cleaning of stables and agricultural machinery.

The machine is not intended for any other purpose except as stated herein. Use other

than for the intended purpose shall be deemed to be unauthorised use. In particular it is

prohibited to

–transport persons with the machine,

–fill in or transport other materials or hazardous goods,

–use the machine in potentially explosive areas,

–pull or push the machine laterally,

–use the machine on uneven surfaces,

–direct the water jet onto persons or animals.

2 Safety

10 Meier-Brakenberg GmbH & Co. KG

Intended use also includes

–observance of all advice included in the operation manual,

–compliance with the inspection and maintenance intervals,

–use of operating materials and supplies in accordance with applicable safety

regulations,

–observance of operating conditions,

–immediate replacement of defective high-pressure hoses,

–avoidance of contact with chemicals,

–inspection of water lines and connections for leakages and damages for each use.

Technical specifications as stated in the technical data must be observed without

exceptions.

Use the machine for the intended purpose only. Otherwise safe operation is not

guaranteed.

Not the manufacturer, but the company or user operating the machine is

responsible for any personal injury or damage to property resulting from use

other than the intended use!

2.1.1 Constructional Changes to the Machine

Construction and manufacturer approval are based on the Product Safety Act

(Produktsicherheitsgesetzes ProdSG). Changes, modifications, and additions to the

machine are subject to the without prior written approval by Meier-Brakenberg GmbH &

Co. KG.

Failure to comply with this requirement results in the machine’s loss of EU conformity.

In this event the manufacturer’s warranty obligations become void. The same also

applies for welding work on load-bearing parts.

Immediately replace components which are not in perfect condition.

Use only original spare parts /wear parts /accessories. These parts are specially designed

for the machine. Parts manufactured by third parties provide no guarantee that they

have been designed and manufactured to meet the operational demands and safety

requirements.

Parts and special equipment not supplied by Meier-Brakenberg GmbH & Co. KG are not

approved for use on the machine.

2.2 Personnel Requirements

MBHOT900/1320 11

2.1.2 Foreseeable Misuse

Any use of the machine exceeding the intended use and/or other than the intended use

may result in serious injury.

–Use the machines only for the intended purpose.

–Do not use the machine to clean clothing or shoes.

2.2 Personnel Requirements

The machine must only be operated, maintained, and repaired by qualified and/or

trained persons. These persons must be familiar with this operation manual and act

accordingly. Respective authorisations for personnel must be clearly defined.

The manual includes the following qualifications for various areas of operation:

Personnel in training

Personnel in training, such as apprentices or temporary workers, are not fully aware of

all the hazards which may occur when operating the machine. These persons are only

permitted to operate the machine under supervision of qualified or trained personnel.

Trained personnel

Trained personnel has been instructed in the task entrusted to them and the are

informed by the operating company or by qualified personnel about any possible

hazards which may occur due to inappropriate behaviour.

Qualified personnel

Based on technical training, knowledge, and experience as well as the knowledge about

relevant provisions qualified personnel are capable of carrying out the tasks entrusted to

them and they are capable of identifying and avoiding possible hazards independently.

Certified electrician

Based on technical training, knowledge, and experience as well as the knowledge about

relevant standards and provisions a certified electrician is capable of carrying out work

on electrical equipment and of identifying and avoiding possible hazards independently.

Certified electricians are trained for the special field of work they are working in and

they are familiar with the relevant standards and provisions.

2 Safety

12 Meier-Brakenberg GmbH & Co. KG

2.2.1 Responsibilities

Inappropriate handling may result in serious personal injury and damage to property.

Therefore all work should only be carried out by qualified personnel.

The operating company is responsible for instructing their personnel.

–Personnel are only persons who are expected to perform their work reliably. Persons

whose ability to respond is affected by drug abuse, alcohol, medication, or similar are

not permitted to operate the machine.

–Comply with the legally required break times.

–All persons operating the machine must confirm by signature that they have read and

understood this operation manual.

–Personnel in training is initially only allowed to operate the machine under

supervision of qualified personnel. Successful completion of training requires written

confirmation.

2.2.2 Obligations of Personnel

Before starting work, all persons entrusted with the operation of the machine are

obliged to

–comply with the fundamental regulations on work safety and accident prevention,

–read the operation manual and to confirm that they have understood the safety

advices and warnings contained in this operation manual.

2.2.3 Unauthorised Persons

Unauthorised persons who do not meet the qualification requirements for personnel are

not aware of the hazards in the working environment.

–Do not allow unauthorised persons to have access to the work area.

–In case of doubt, address these persons and instruct them to leave the work area.

–Suspend work as long as unauthorised persons are in the work area.

2.3 General Safety Information

MBHOT900/1320 13

2.2.4 Instructions and Training

Personnel must be regularly instructed by the operating company. Record conducted

training for better traceability.

Date

Name

Type of training /

instructions

Training /

instructions

conducted by

Signature

2.3 General Safety Information

–The machine must only be operated and maintained after having read this operation

manual.

–Only use this machine as intended (see section „Fehler! Verweisquelle konnte nicht

gefunden werden. Fehler! Verweisquelle konnte nicht gefunden werden.“).

–Do not start the machine if there are any other persons in the danger zone .

–Refrain from modes of operation which could impair the safety of persons or the

machine.

–Never operate the machine without the respective protection and safety equipment.

Never decommission any integrated safety equipment.

–Always keep the machine’s work area clean and tidy to avoid hazards caused by dirt

or objects left lying around.

–Do not exceed the technical performance data (see section „3.2.2.8 Injector (MBH

line optional)

2 Safety

14 Meier-Brakenberg GmbH & Co. KG

Injector HZ073 and HZ073 to connect at

pressure side, between pressure pump and hose

coiler.

Components:

-Chemical connection with integrated

non-return valve

-Intake hose with filter

ATTENTION:

Observe user’s manual of injector!

Check the use of right dosing nozzle!

2.3.1.1 Oil dip stick

Checking at oil dip stick (1): check in oil tank

about 2 cm

Oil change at first time after 50 hours of

operation, in the following work-time after 300

hours of operation.

At minimum every 6 month’s

–Technical Data“).

–Keep all safety advice and warnings at the machine in a legible condition and replace

them, if necessary.

–Operation of and work with the machine must only be carried out by qualified or

instructed personnel (see section „Fehler! Verweisquelle konnte nicht gefunden

werden. Fehler! Verweisquelle konnte nicht gefunden werden.“).

–Immediately decommission the machine in case of malfunction. Have any

malfunction rectified by trained experts or by Meier-Brakenberg GmbH & Co. KG.

–Always keep the operation manual at the machine’s site of operation. It must be

ensured that all persons who are working with or on the machine can consult the

operation manual at any time.

–The machine must only be lifted by two persons.

–Be careful when lifting weight. Rise from your knees as you lift the load.

2.4 Safety Measures for Environmental Protection

MBHOT900/1320 15

2.4 Safety Measures for Environmental Protection

When working with the machine observe the regulations with regard to waste

prevention and proper waste processing or disposal.

In particular during installation or maintenance work as well as during decommissioning

it must be ensured that groundwater endangering substances, such as grease, oils,

solvent-containing cleaning agents or the like do not contaminate the ground or reach

the sewage system. Such substances must be collected, kept and transported in suitable

containers and they must be disposed of in compliance with national legislation.

2 Safety

16 Meier-Brakenberg GmbH & Co. KG

2.5 Special Hazards Information

2.5.1 Used Symbols on the Machine

Mortal danger due to electric current

This symbol cautions against mortal dangers caused by electric current.

Direct mortal danger in case of contact with live components.

Hot surfaces

This symbol cautions against risk of burns caused by hot surfaces

Keep all safety advice and warnings at the machine in a legible condition and

replace them, if necessary.

2.5.2 Dangers due to Electrical Energy

DANGER

When touching live parts there is the danger of electric shock.

–Always keep electrical components closed.

–Work on electrical equipment must only be carried out by certified

electricians who are specially trained for working on electrical

equipment and who can identify and avoid dangers.

–Observe five safety rules:

1. Disconnect

2. Secure against restarting

3. Determine voltage free status

4. Earth and short-circuit

5. Cover or block live parts

DANGER

Electric shock may cause secondary accidents due to fright (e. g. fall).

–Observe the five safety rules when working on electrical equipment.

–Have work on electrical equipment carried out only be certified

electricians.

2.5 Special Hazards Information

MBHOT900/1320 17

–Switch the machine off, disconnect from power supply, and secure against

inadvertent restart before working on the machine’s electrical equipment.

–Work on electrical equipment must only be carried out by competent certified

electricians –e.g. the company electrician.

–Regularly check electrical equipment for defects such as lose connections or scorched

cables. Have defects removed immediately.

–Have electrical equipment and stationary electrical equipment checked by a certified

electrician at least once every 4 years.

Stationary electrical equipment is fixed equipment or equipment which do not have

any carrying fixtures and which mass is too high to be moved easily. This also applies

for electrical equipment which is temporarily fixed and which is operated using

moveable electrical connection cables.

–Have mobile electrical equipment, connection cables including plugs and extension

leads including plug connection, if used, checked by a certified electrician at least

once every 6 months.

Mobile equipment is such equipment which can be operated while carrying voltage

and at the same time in accordance with the standard and intended use. This also

includes the HDR10.

–Modifications carried out after the tests must comply with DIN EN 60204-1.

–Regularly check all safety equipment of the machine for their function.

–Only use original fuses.

–Always keep doors of the control cabinet closed.

–Damaged casings and damaged lines must be immediately repaired or replaced.

2.5.3 Dangers due to Water Pressure

Liquids emerging under high pressure may cause serious injury!

–Only specially skilled and experienced experts are allowed to work on and at the

high-pressure components.

–Switch the machine off before working at the high-pressure components and secure

the machine against restart.

–Depressurise system sections and pressure lines before starting repair work.

–Inspect all high-pressure hoses and screw connections regularly for leakages and

visible damages. Any damages must be repaired immediately.

–Replace high-pressure hoses in adequate time intervals even if there are no visible

safety relevant defects.

2 Safety

18 Meier-Brakenberg GmbH & Co. KG

–Do not pull at the high-pressure hose when it has loops or bends.

–Do not pull the high-pressure hose over sharp edges.

–Do not let any vehicles pass over the high-pressure hose.

–Do not direct the water jet onto electrical equipment such as power outlets.

2.5.4 Dangers due to Hot Surfaces

Contact with hot components may cause burns.

–Principally wear protective clothing and protective gloves whenever working next to

hot components.

–Allow components to cool down to ambient temperature before maintenance or

repair work.

2.5.5 Dangers due to Noise

Being permanently exposed to the sound pressure level in the working area may lead to

permanent hearing damages.

–The operating company must provide hearing protection as of a sound pressure level

of 80 dB(A).

–It is compulsory to wear hearing protection as of a sound pressure level of 85 dB(A).

2.5.6 Dangers caused by the Use of Incorrect Spare Parts

Incorrect or defect spare parts may lead to damages, malfunction, or complete failure

and they can impair the safety.

–Only use original spare parts.

–Purchase spare parts from Meier-Brakenberg GmbH & Co. KG. Necessary information

on spare parts is included in the parts lists or in section „1.4 Warranty Policy

–The warranty policy is included in the general terms and conditions of the Meier-

Brakenberg GmbH & Co. KG.

–Service / After-sales Service “.

2.6 Personal Protective Equipment

MBHOT900/1320 19

2.6 Personal Protective Equipment

Wear personal protective equipment to minimise health risks when operating the

machine.

–Always wear the necessary protective equipment during operation which is required

for the work carried out.

–Observe the instructions which refer to personal protective equipment in the

working area.

The symbols have the following meaning:

Hooded protective workwear

Hooded protective workwear includes close-fitting clothing with low tear

strength, tightly fitting sleeves and does not have any protruding parts.

Protective workwear mainly serves to protect against getting caught by

moving machine parts.

Do not wear any rings, chains or other jewellery.

Safety footwear

Wear anti-slip safety footwear which provides protection against injury due

to heavy, falling objects or against slipping on low-grip surfaces.

Protective gloves

Wear protective gloves to protect your hands against friction, graze, cuts,

or deep wounds, as well as against contact with hot surfaces or chemical

substances.

Face protection

Wear face protection to protect you against media emerging under high

pressure, splashing dirt and flying objects.

Hearing protection

Wear hearing protection to protect you against hearing damages.

Breathing protection

Wear breathing protection to protect you against aerosols in case of being

exposed to biological working substances in form of aerosol.

The operating company must provide protective equipment which complies with the

applicable requirements.

Moreover, national provisions and, where appropriate, internal instructions of the

operating company must be observed.

2 Safety

20 Meier-Brakenberg GmbH & Co. KG

2.7 Safety and Protective Equipment

–Each time before switching on the machine check that all safety and protective

equipment is correctly installed and in operational condition.

–During operation it is prohibited to bypass, remove or otherwise decommission any

safety and protective equipment.

–Protective equipment may be removed only during shutdown times and after

securing against restart of the machine.

–Regularly check all protective equipment of the machine for proper function.

2.8 Advice for Emergency Cases

Preventive measures

–Always be prepared for accidents or fire.

–Keep first aid equipment (first aid kit, blankets etc.) and fire-extinguishing agents in

reach and ready to hand.

–Familiarise personnel with accident reporting systems, first aid equipment, fire

extinguishing agents and devices, as well as emergency facilities.

–Keep access routes clear for rescue vehicles.

Measures in case of accidents

–If available, activate emergency stop.

–Rescue persons from the danger zone.

–In the event of cardiac and/or respiratory arrest initiate first aid measures

immediately.

–In case of personal injury inform the person responsible for first aid and an

emergency physician or emergency rescue service immediately.

–Clear access routes for rescue vehicles. Where appropriate, second someone to show

rescuers the way.

–Extinguish burning oil/grease with a CO2-extinguisher or a powder fire extinguisher.

–Extinguish fire in the electrical control system with a CO2fire extinguisher.

This manual suits for next models

1

Table of contents

Other MEIER-BRAKENBERG Pressure Washer manuals