OperatOr’sManual

RAMTEQ®14275 NORTHWEST FREEWAY HOUSTON, TX 77040 PHONE: 713.983.6000 FAX: 713.983.6405 300-00011-01 8/05

page 7

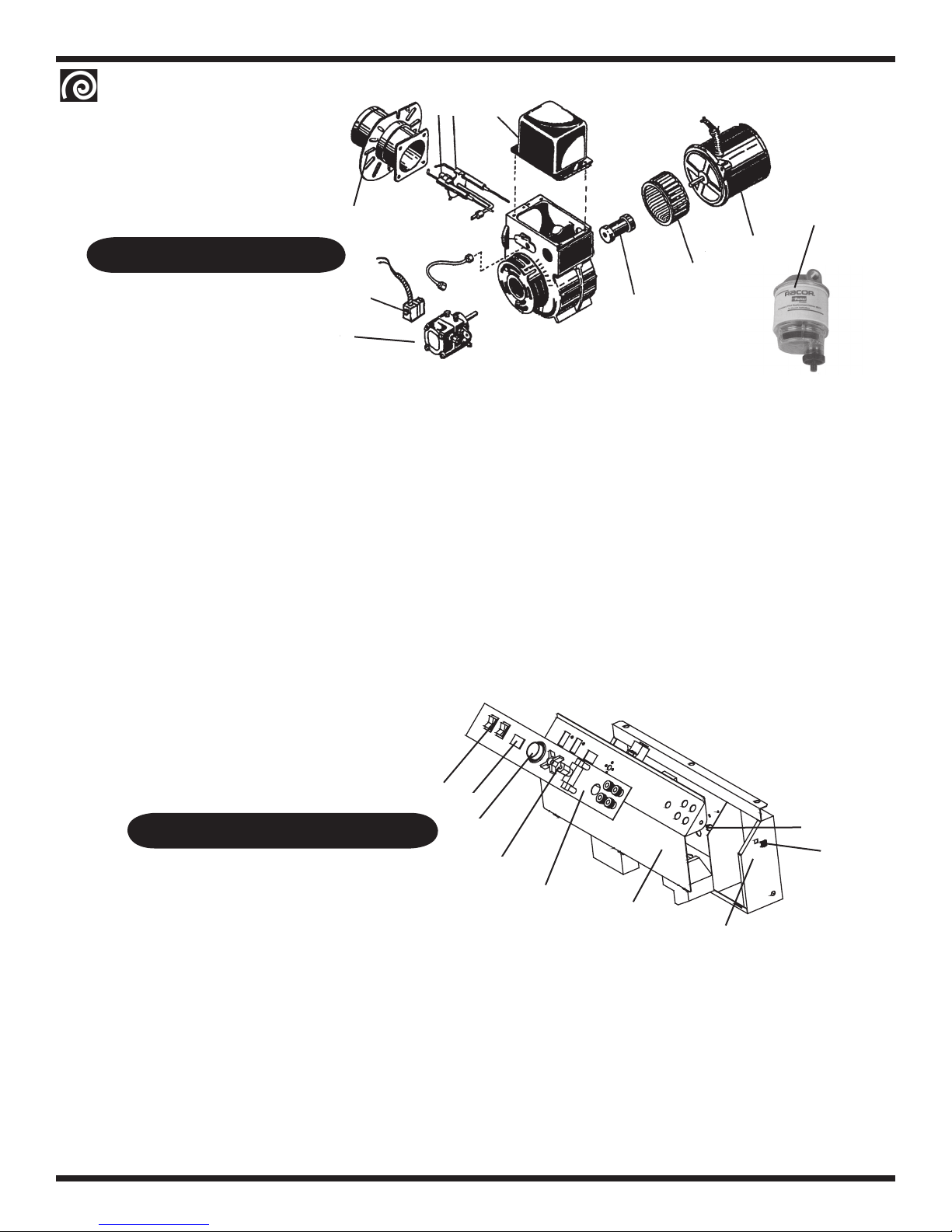

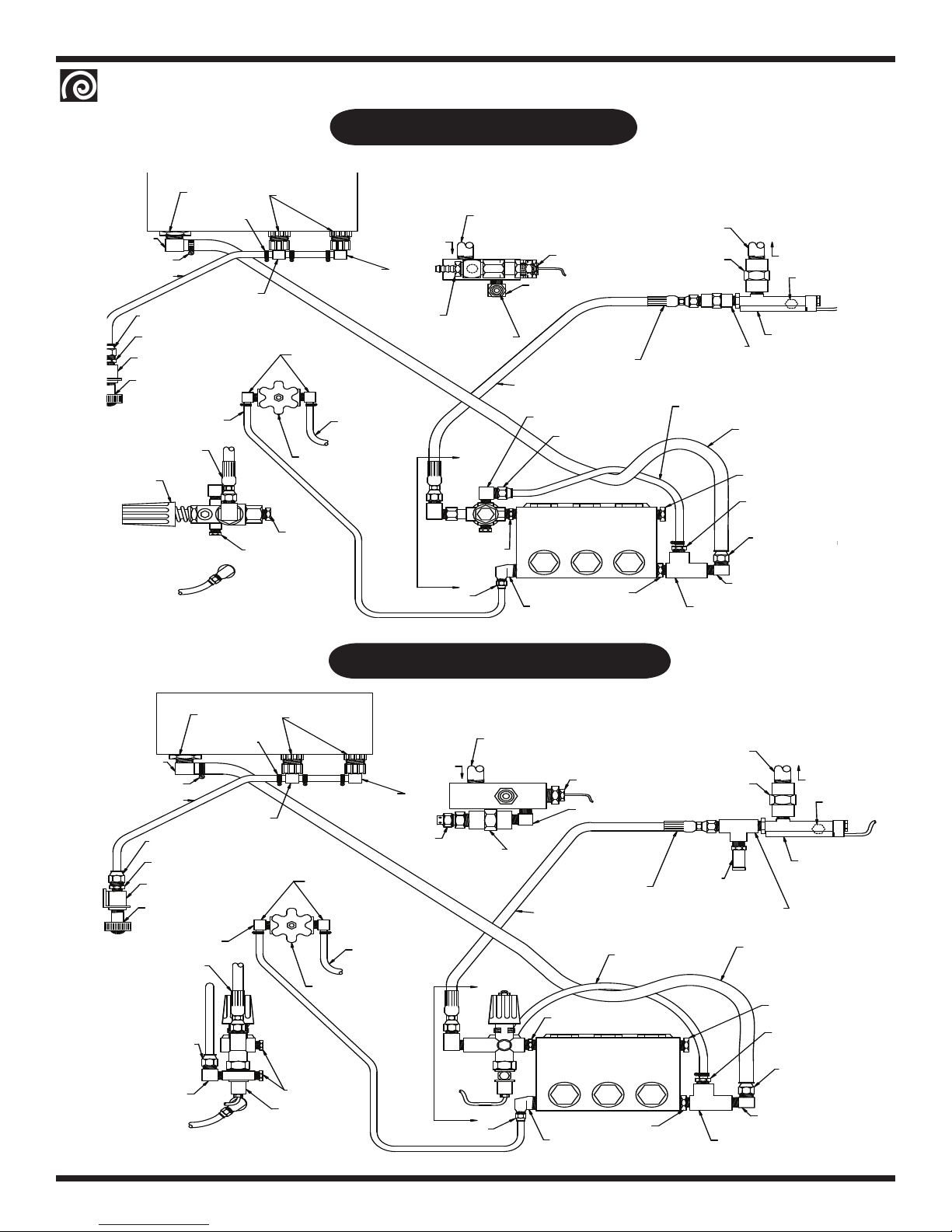

Ref.# Part # Description Qty.

1 180-00043-01 Panel, Closeout Front/Back 1

2a 200-00009-01 Motor, 5.0hp 208/230/1 Baldor L1410T 1

2b 200-00005-01 Motor, 5.0hp 208/230/3 Baldor M3218T 1

2c 200-00012-01 Motor, 6.0hp 208/230/1 1

2d 200-00006-01 Motor, 7.5hp 208/230/3 Baldor M3311T 1

2e 200-00007-01 Motor, 10.0hp 230/460/3 Baldor M3313T 1

3 180-00023-01

Plate, Power 1

4a 170-00005-01 Wheel, Casters Fixed 8” 2

4b 170-00004-01 Wheel, Casters Swivel 8” 2

5 170-00002-01 Wheel, Caster Swivel 6” 2

6 170-00003-01 Wheel, Pneumatic Split Rim 2

7 180-00052-01 Bracket, Four Wheel Configuration 2/4

8 175-00001-02 Axle, Two and Four Wheel Configuration 2/4

9 516-00001-01

Bushing, Wheel Collar, 5/8” 4

10 050-00008-01 Chassis, BV and BH Series 1

11 180-00056-01 Plate, Closeout Top 1

12 190-00002-01 Fuel, Tank 9 Gallon Green 1

13 140-00001-01 Cap, Fuel Gauge Diesel Black 1

14 180-00022-01 Handle, Frame BH Series 1

15 180-00044-01 Bracket, Coil Horizontal Rest 1

16 155-00005-01 Coil, Large Diesel Fired 1

191-00006-01 Insulation Blanket 1”x24”w, 4# (not shown) 1

17a 250-00002-01 Burner Assembly (208/230v) 1

17b 250-00003-01 Burner Assembly (110v) 460 volt machines 1

18 180-00025-01 Cap, SS End Burner 1

19 191-00001-01 Insulation, Burner 17.65”x3.44” 1

20 180-00018-01 Shell, SS Outer Top 1

21 191-00002-01 Insulation, Exhaust 17.55”x1” 1

22 180-00024-01 Cap, End Closed 1

23 180-00017-01 Shell, SS Outer Bottom 1

24 055-00030-01 Float Tank Assembly 1

25a 220-00004-01 Pump, General T1011-R (BH 500,BH 600) 1

25b 220-00009-01 Pump, General TS2021-R (BH 750 / BH 1000) 1

26 180-00048-01 Bracket, Pump Belt Tension (not shown) 1

584-00003-11 Pulley, 2BK50H (BH 500,BH600) 1

584-00002-09 Pulley, 2BK80H (BH 500,BH600) 1

516-00002-03 Bushing, SP Split Taper, H 1-1/8” 1

516-00002-01 Bushing, SP Split Taper H-24mm 1

586-00004-04 Belt, BX36 (BH 500; BH 750) 2

584-00002-08 Pulley, 2BK45H (BH 750) 1

584-00002-09 Pulley, 2BK80H (BH 750) 1

516-00002-04 Bushing, SP Split Taper, H 1-3/8” (BH 500/600/750/1000) 1

584-00002-04 Pulley, 2BK57H (BH 1000) 1

584-00002-06 Pulley, 2BK70H (BH 1000) 1

586-00004-04 Belt, BX36 (BH 1000) 2

13

23

14

17

19

18 20

22

24

1

2

3

4

5

8

7

10

Exploded

view on

page 9.

25

26

15

BH Parts Diagram 21

12

11

6

9