Meijer KOOI ReachControl Technical reference manual

INSTRUCTIONS

AND PARTS

MANUAL

Flow meter BA

Flow meter CA

Autostop valve 12VDC

Autostop valve 24VDC

Controller

MA15032019-05EN 04/20/2021 English

Original instructions

Table of contents

Note 4

Declaration of Conformity 5

Icons 6

Safety information 6

Warning 7

Caution 9

eneral 11

Training 11

Modules 12

Flow meter with integrated angle sensor

12

Application 13

Identification 13

Specifications 13

Dimensions 14

Hydraulic installation on K I-

REACHF RKS® 15

Forks with flow divider – flow meter without

Autostop 15

Forks with flow divider – flow meter with

Autostop 16

Forks with master-slave function – flow meter

without Autostop 17

Forks with master-slave function – flow meter

with Autostop 18

Electrical installation 19

Without Autostop – battery (re)placement 19

With Autostop 20

Working with the flow meter 21

Maintenance 21

Controller 22

Identification 22

Specifications 22

Dimensions 23

Installation 24

Working with the Controller 25

Maintenance 25

ReachControl app 26

Installation 26

Android devices 26

iOS devices 26

Working with the app 27

etting started 27

App functions 29

Troubleshooting 31

Clear data and cache for the ReachControl

app (Android only) 36

Replacement parts lists 37

Flow meter 37

Autostop valve 38

2

Note

© Copyright 2019, Meijer Handling Solutions B.V. All rights reserved.

Unless otherwise indicated, information provided in this manual, including but not

limited to illustrations and text, may not be reproduced without the prior written

permission of Meijer Handling Solutions.

The information in this manual is provided without any form of guarantee. Under no

circumstances shall Meijer Handling Solutions B.V. be held liable for accidents or

damages arising from the use of this manual.

Please note that information in this manual may be changed at any time without prior

notice and that it may contain technical inaccuracies and typing errors. Meijer Handling

Solutions B.V. makes every effort to avoid errors in this manual, but cannot guarantee

this. Please let us know if you encounter any typing errors or technical inaccuracies, or

if you have any suggestions.

KOOI® and KOOI-REACHFORKS® are registered trademarks of Meijer Handling

Solutions.

Android™ is a trademark of oogle LLC.

The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth

SI , Inc.

Other trade or product names used in this manual, but not mentioned here, are the

trademarks of their respective holders.

4

Declaration of Conformity

Product : KOOI® ReachControl system

Date : 03/18/2019

Manufacturer : Meijer Handling Solutions B.V. Address : Oudebildtdijk 894

ZIP code : 9079 N City : Sint Jacobiparochie

Country : The Netherlands

Herewith declares that the above named machinery conforms to the provisions as

stipulated by the following directives and national statutory legislation implemented in

line with these directives:

•Low Voltage Directive 2006/95/EC

•Electromagnetic compatibility Directive 2004/108/EC

The following (parts of) harmonized norms are applied:

•NEN-EN-ISO 12100:2010 Safety of machinery - eneral principles for design -

Risk assessment and risk reduction

Done at : Sint Jacobiparochie

By : H. Meijer Function : CEO

Signature :

5

Icons

Warning. Failure to comply with safety warnings can result in serious injury

or death

Caution: Failure to comply with safety cautions can cause injury or property

damage.

Note: note, tips or additional information

Tools: required tools for described procedure.

Safety information

Please read the following safety information before using the KOOI® ReachControl

system.

The term ‘Controller’ refers to the touchscreen unit which can optionally be

supplied with your KOOI® ReachControl system.

The term ‘device’ refers to either the Controller or an Android / iOS device

obtained from a party other then the manufacturer of the KOOI®

ReachControl system.

The term ‘module’ refers to all separately sold articles in the KOOI®

ReachControl product family, including the Controller and the available app

for Android and iOS devices.

6

arning

Do not use damaged power cords and plugs, or loose electrical sockets.

Unsecured connection can cause electrical shock or fire.

Do not touch electrical devices, power cords, plugs or electrical sockets with

wet hands or other wet body parts. Doing so may cause electric shock.

Do not pull the power cord excessively when disconnecting it

Doing so may cause electric shock or fire.

Do not bend or damage the power cord. Doing so may cause electric shock

or fire.

Do not drop or cause excessive impact to the Controller.

•This may damage your Controller or battery, cause the Controller to

malfunction, or shorten its lifespan.

•This may also cause overheating, combustion, fire, or other hazards.

Handle and dispose of the Controller with care.

•Never dispose of the battery or Controller in a fire. Never place the

battery or Controller on or in heating devices. The Controller may

explode when overheated. Follow all local regulations when disposing of

used battery or device.

•Never crush or puncture the Controller.

•Avoid exposing the Controller to high external pressure, which can lead

to an internal short circuit and overheating.

7

Protect the Controller, battery and charger from damage

•Avoid exposing your Controller and battery to very cold or very hot

temperatures.

•Extreme temperatures can damage the Controller.

•Do not directly connect together the battery’s positive and negative

terminals and prevent them from coming into contact with metal objects.

Doing so may cause the battery to malfunction.

•Never use a damaged battery.

Do not store the Controller in areas with high concentrations of dust or

airborne materials.

•The battery may leak.

•Your device may overheat and cause a fire.

Do not handle a damaged or leaking battery.

For safe disposal of your batteries, please follow local law and regulations.

Do not operate a device while driving. Not being focused on driving might

lead to collisions and injuries. Always make sure the lift truck is stationary

when using the Controller.

Do not operate a device while operating other controls in the lift truck. Not

being focused on lift truck controls while using them might lead to collisions

and injuries.

When using your own device (e.g. smartphone, tablet) to control the KOOI®

ReachControl system, always follow the safety instructions available for you

device.

When installing the Controller make sure the operators sight to his/her

surroundings is not reduced to the extended that is may result in dangerous

situations.

8

Be aware of a reduced field of vision when using equipment with a Controller

installed.

Caution

Avoid using the Controller within a 15 cm range of a pacemaker, if

possible, as the Controller can interfere with the pacemaker.

Electronic devices in your lift truck may malfunction, due to radio

interference from your Controller. Contact your supplier for

more information.

Do not expose the Controller to heavy smoke or fumes. Doing so may damage

the outside of the Controller or cause it to malfunction.

Do not use the Controller near devices or apparatuses that emit radio

frequencies, such as sound systems or radio towers. Radio frequencies may

cause the Controller to malfunction.

Turn off the Controller in potentially explosive environments

•Always comply with regulations, instructions and signs in potentially

explosive environments.

•Do not use your device at refueling points (petrol stations), near fuels or

chemicals, or in blasting areas.

•Do not store or carry flammable liquids, gases, or explosive materials in

the same compartment as the device, its parts, or accessories.

If any part of the Controller is broken, smokes, or emits a burning odor, stop

using the device immediately. Use the device again

only after it has been repaired at a certified dealer.

9

•Broken glass or acrylic could cause injury to your hands and face.

•When the device smokes or emits a burning odor, it may result in battery

explosion or fire.

Do not remove any parts from the Controller, including the back cover.

Removing parts will lead to parts getting damaged.

Do not paint or put stickers on the Controller. It may result in damage to the

Controller.

Install mobile devices and equipment with caution.

•Ensure that any mobile devices or related equipment installed in your

vehicle are securely mounted.

Do not disassemble, modify, or repair KOOI® ReachControl modules.

•Any changes or modifications made without prior written consent from

the manufacturer will void warranty. If any KOOI® ReachControl devices

or sensors need servicing, contact you local dealer.

•Exception to the above are part replacement as mentioned in this

manual. Follow the instructions in this manual to avoid voiding warranty.

When cleaning the Controller, mind the following:

•Wipe the Controller using a clean towel or microfiber cloth.

•Do not use chemicals or detergents. Doing so may result in discolor or

corrosion to the outside of the Controller, or may result in electric shock

or fire.

Do not use KOOI® ReachControl devices or sensors for anything other than

its intended purpose.

10

Only qualified personnel, arranged through your local dealer or the

manufacturer are allowed to service KOOI® ReachControl devices.

The Control devices contains Wi-Fi functionality. It is only to be used by

installed software to connect to the internet or local Wi-Fi network for

software updates, license/module activation, or sending log data. Do not use

the Controller to access the internet in any other way to prevent malfunction

of the KOOI® ReachControl software, malware or virus infections or data

loss.

Do not install 3rd party software on the Controller. It may lead to malfunction

of the KOOI® ReachControl software, malware or virus infections or data

loss. It may void warranty.

Do not change settings on the Android OS running on the Controller. It may

lead to malfunction of the KOOI® ReachControl software and may void

warranty.

General

The KOOI® ReachControl product family contains modules which can consist of

sensors, display and control units used to measure and display various types of

information from (forklift) attachments of hydraulic cylinders. The modules are primarily

used on lift trucks.

Training

When using the KOOI® ReachControl system on a forklift truck or other heavy

equipment, the operator should have sufficient training in accordance with local laws

and regulations. No further specific training is required.

11

Modules

Below is a list with the possible modules which are available in the KOOI®

ReachControl product family. You may have purchased one or more of them. Please

follow the cross references to the page containing the specific information and

instructions for your module(s):

If your system contains a Flow meter with integrated angle sensor (optional), please

continue at page 12.

If your system contains a Controller (optional), please continue at page 22.

For information on the ReachControl app (required), please continue at page 26.

Flow meter with integrated angle sensor

The term ‘forklift’ will be used for any forklift truck, lifter or similar vehicle

used for lifting and transporting loads.

The term ‘left’ and ‘right’ when used in combination with ‘forklift’ refer to the

left or right as seen from the driver’s seat.

The ‘KOOI-REACHFORKS®‘ are hydraulically extendable forklift forks that are

sold under this trademark. From here on they are referred to as ‘forks’.

The flow meter can be used with virtual any set of hydraulically extendable

forks regardless of the manufacturer / brand.

Keep the hose length between flow meter and KOOI-REACHFORKS® /

hydraulic cylinder as short as possible to reduce deviation in the

measurement system due to expansion of the hoses.

12

Application

The flow meter with integrated angle sensor (form hereon the ‘flow meter’) can be used

to measure the length of a cylinder or cylinder controlled system like the KOOI-

REACHFORKS®. Furthermore, the angle at which the flow meter is located can also be

measured with respect to the ground. A possible application for the angle measurement

is as a ‘tilt indicator’ for a forklift mast.

Identification

See serial number on flow meter body.

Specifications

Hydraulic data

Operating pressure: max. 250 bar / max. 3626 psi

Nominal flow: max. 25 L/min / max. 6.6 gal/min

Filtration: Class 21/19/16 according to ISO 4406 or cleaner

Weight: 0.98 kg / 2.2 lb

Media operating temperature range: min. 0 °C to max. +100 °C

Ambient operating temperature range: min. 0 °C to max. + 60 °C

Medium Hydraulic oil (ISO HH, ISO HL,

ISO HM or ISO HV)

Electrical data

Power supply: without Autostop Battery, size A, 3.6V (3.60 Ah)

with Autostop Wired 12 or 24 VDC

Current drawn at

20° C (Autostop):

2 A at 12 VDC

1.3 A at 24 VDC

Data connection Low power Bluetooth®

Table 1: hydraulic and electrical specifications

13

Dimensions

14

Wireless flow meter

Flow meter with

Autostop

Autostop valve

(optional)

Hydraulic installation on KOOI-REACHFORKS®

The flow meter has no dedicated pressure or return ports.

All flow meters and valves are delivered with plugs in the hydraulic ports. Remove these

before starting assembly.

All hydraulic equipment need to be installed by an authorized technician.

Forks with flow divider – flow

meter without Autostop

The flow meter needs to be

connected to the return flow of the

flow divider. Remove the plugs from

the flow meter. Connect one port of

the flow meter to the ‘R’ port on the

flow divider.

Connect the other port of the flow

meter to the return hose of the lift

truck.

Check all connections for leakage

before operation. Fully extend and

retract the forks five times to remove

any air from the hydraulic system.

15

T P

Lift truck

Flow meter

Left fork Right fork

P R

PR

P

BA

Flow divider

R

R R

Forks with flow divider – flow

meter with Autostop

The flow meter needs to be

connected to the return flow of the

left fork. Remove the plugs from

the flow meter. Connect one port

of the flow meter to the ‘R’ port on

the flow divider.

Connect the other port of the flow

meter to port ‘1’ of the 3/2 valve for

the Autostop function. Connect

port ‘3’ of the 3/2 valve with a T-

coupling to the ‘P’ port on the flow

divider. Finally connect port ‘2’ of

the 3/2 valve to the return hose of

the lift truck.

Check all connections for leakage

before operation. Fully extend and

retract the forks five times to

remove any air from the hydraulic

system.

16

T P

Lift truck

Flow meter

Left fork Right fork

PR

PR

P

BA

Flow divider

R

2

31

3/2 valve

R R

Forks with master-slave function

– flow meter without Autostop

The flow meter needs to be

connected to the return flow of the

left fork. Remove the plugs from the

flow meter. Connect one port of the

flow meter to the ‘R’ port on the left

fork.

Connect the other port of the flow

meter to the return hose of the lift

truck.

Check all connections for leakage

before operation. Fully extend and

retract the forks five times to remove

any air from the hydraulic system.

17

T P

Lift truck

Flow meter

Left fork Right fork

OC

CR

Forks with master-slave function

– flow meter with Autostop

The flow meter needs to be

connected to the return flow of the

left fork. Remove the plugs from the

flow meter. Connect one port of the

flow meter to the ‘R’ port on the left

fork.

Connect the other port of the flow

meter to port ‘1’ of the 3/2 valve for

the Autostop function. Connect port

‘3’ of the 3/2 valve with a T-coupling to

the ‘O’ port on the right fork. Finally

connect port ‘2’ of the 3/2 valve to the

return hose of the lift truck.

Check all connections for leakage

before operation. Fully extend and

retract the forks five times to remove

any air from the hydraulic system.

18

2

31

T P

Lift truck

Flow meter

Left fork Right fork

OC

C R

3/2 valve

Electrical installation

Without Autostop – battery (re)placement

Remove battery insulator tab before first use, using instructions below.

Be careful when removing the cap to prevent damage to wiring. The cap is

connected to the flow meter by wiring.

19

1

2

3

5

4

Allen key 2.5 mm.

See the replacements parts list at

page for battery information.

With Autostop

The solenoid connector is not part of the KOOI® ReachControl package.

Connector specs. DIN connector to EN 175301-803 (type 40-1836).

Cables are not part of the KOOI® ReachControl package. Cable should

support the required power supply (see chapter Specifications at page 13.

All cables and connectors need to be assembled by a certified electrician.

Required power supply from the forklift (at 20° C): 2A at 12 VDC or 1.3 A at 24 VDC,

depending on the supplied solenoid spool on the Autostop valve. Connect the power

supply from the forklift to the flow meter and solenoid connector. See the next image

and the pin assignments in Table 2.

20

+

-

-+

Flow meter

Forklift

Valve

Pin assignments

connector solenoid

(valve)

Pin assignments

connector flow meter

41

2

3

12

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

T

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

TW

Table of contents

Popular Controllers manuals by other brands

Aventics

Aventics Marex ECS Assembly instructions

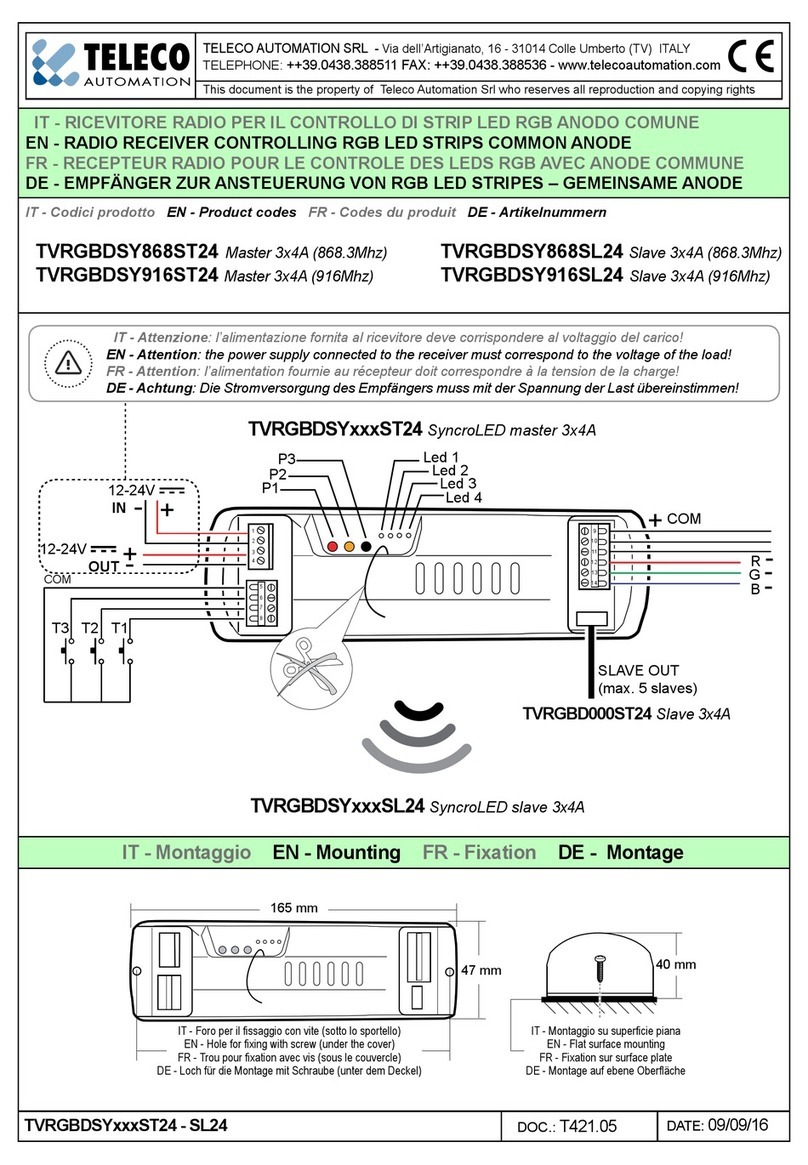

TELECO AUTOMATION

TELECO AUTOMATION TVRGBDSY ST24 Series manual

Koheron

Koheron PI200 user guide

gefran

gefran 1000 Installation and operation manual

Toho Electronics

Toho Electronics TTM-P4W Series instruction manual

Panasonic

Panasonic Minas A4 Series Connection guide