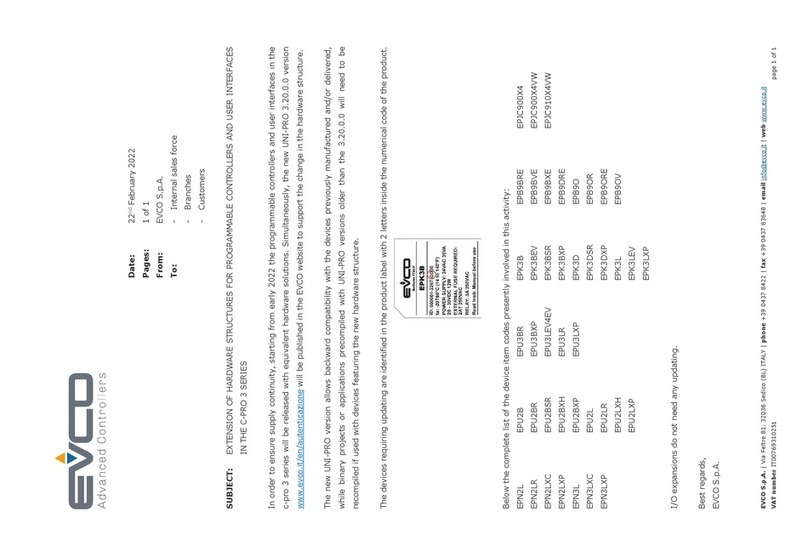

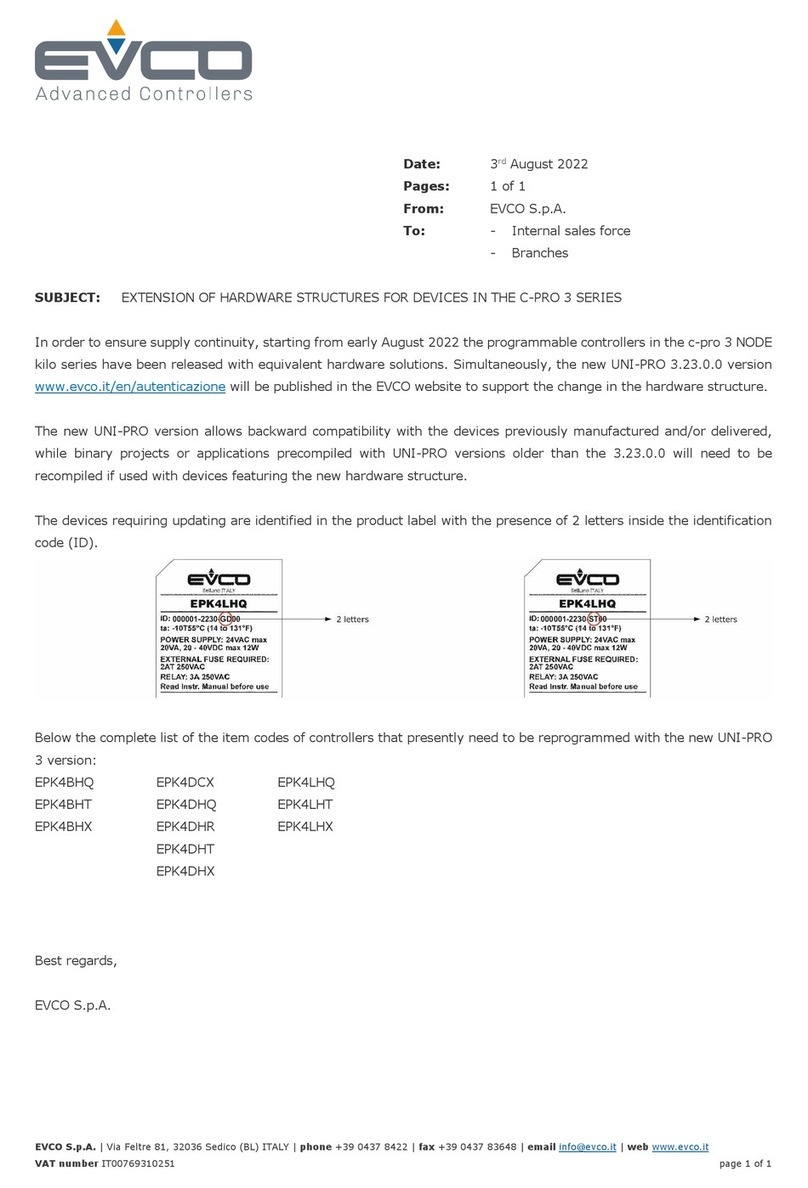

EVCO S.p.A. c-pro 3 micro and c-pro 3 kilo | Hardware manual ver. 1.0 | Code 114CP3UKE104

page 3 of 62

Index

1.

INTRODUCTION.......................................................................................................................................................................5

1.1.

Introduction................................................................................................................................................................................5

2.

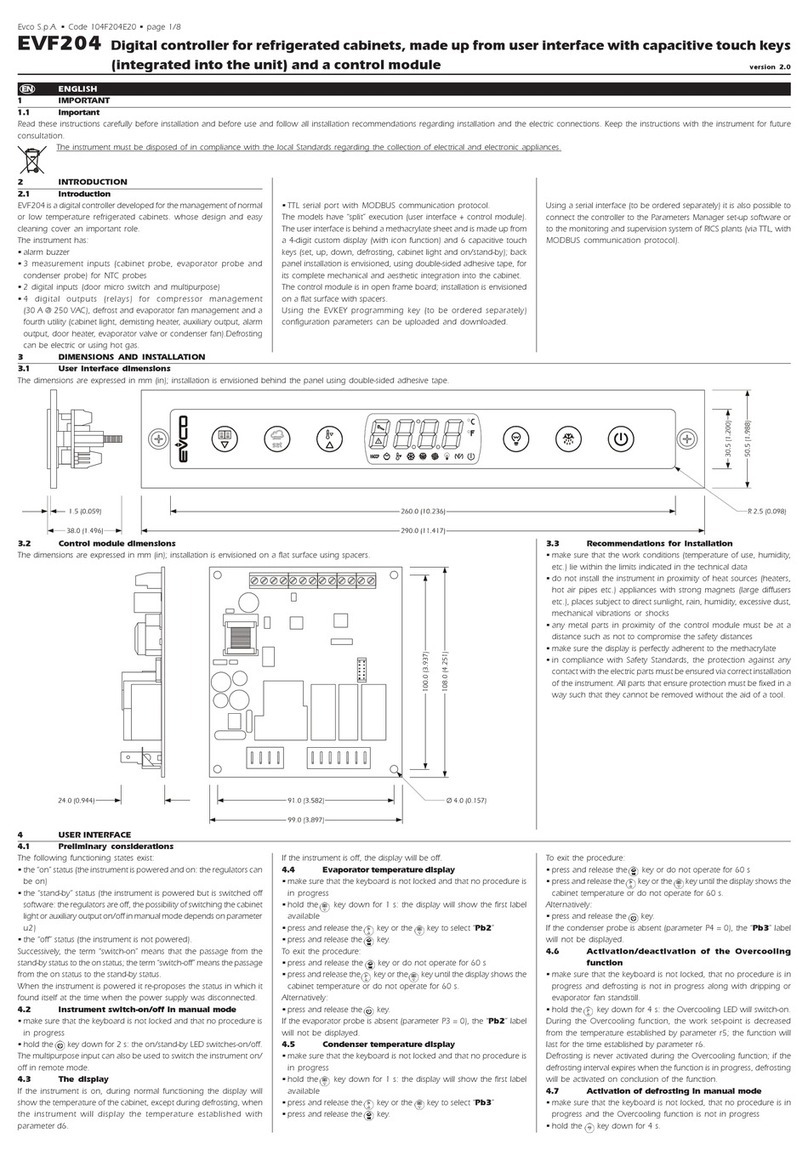

DESCRIPTION..........................................................................................................................................................................6

2.1.

Description programmable controllers........................................................................................................................................6

2.2.

Description I/O expansions........................................................................................................................................................8

3.

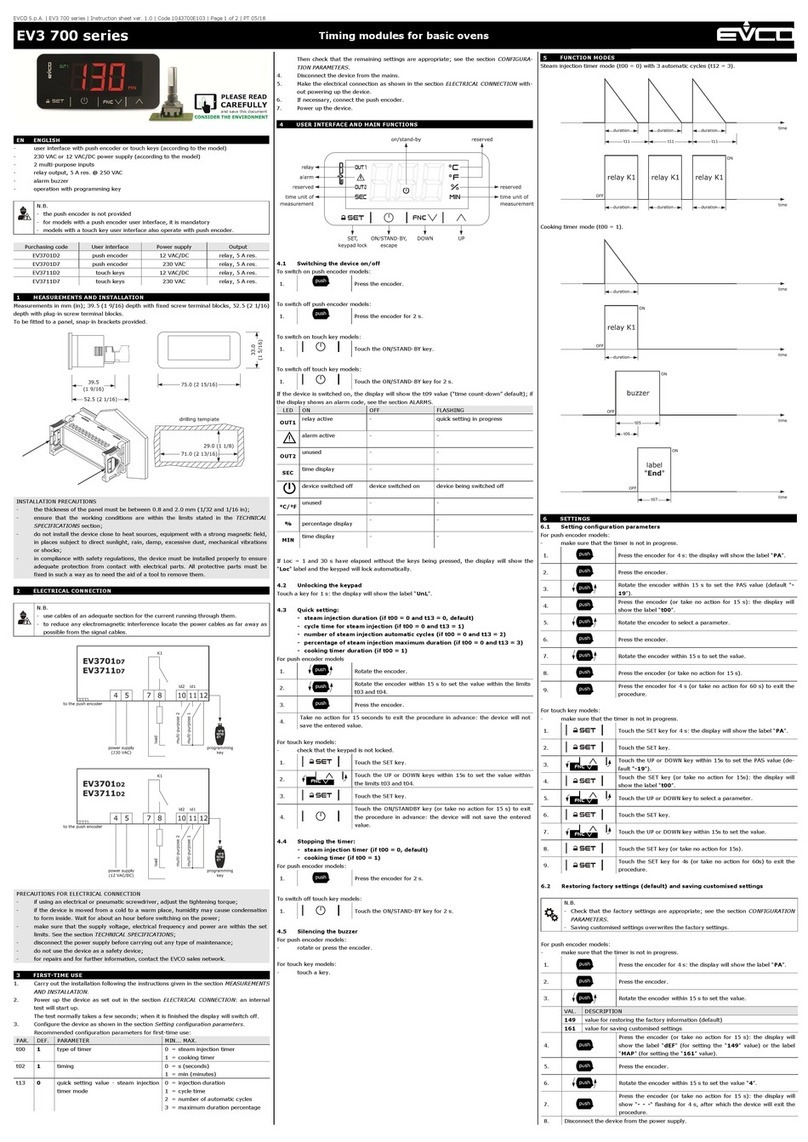

SIZE AND INSTALLATION........................................................................................................................................................9

3.1.

Size programmable controllers...................................................................................................................................................9

3.2.

Size I/O expansions...................................................................................................................................................................9

3.3.

Installation ...............................................................................................................................................................................10

3.4.

Additional information for installation........................................................................................................................................10

4.

ELECTRICAL CONNECTION..................................................................................................................................................11

4.1.

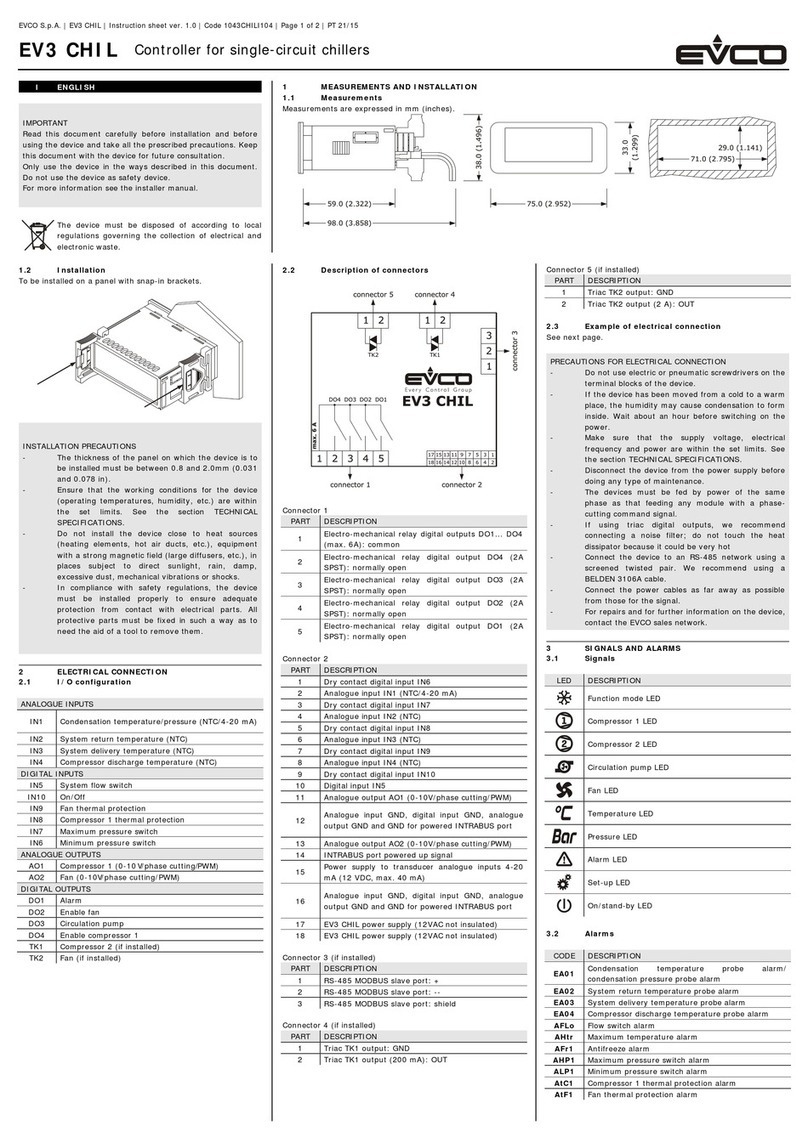

Connectors programmable controllers .....................................................................................................................................11

4.2.

Connectors I/O expansions......................................................................................................................................................13

4.3.

Meaning of connectors.............................................................................................................................................................15

4.3.1.

Example of electrical connection....................................................................................................................................23

4.4.

Additional information for electrical connection.........................................................................................................................24

5.

USER INTERFACE..................................................................................................................................................................25

5.1.

Keyboard.................................................................................................................................................................................25

5.2.

Signalling LEDs .......................................................................................................................................................................25

5.2.1.

LEDs at the front of the device.......................................................................................................................................25

6.

CONFIGURATION...................................................................................................................................................................27

6.1.

Configuring a programmable controller ....................................................................................................................................27

6.1.1.

Configuring a built-in programmable controller...............................................................................................................27

6.1.2.

Configuring a blind programmable controller ..................................................................................................................29

6.2.

Configuring an I / O expansion.................................................................................................................................................30

6.3.

Configuring a device through an user interface (Vgraph, Vtouch, Vroom or Vcolor) ................................................................31

6.4.

List of configuration parameters...............................................................................................................................................32

7.

USER INTERFACES...............................................................................................................................................................46

7.1.

Preliminary information............................................................................................................................................................46

7.2.

Vgraph.....................................................................................................................................................................................46

7.2.1.

Introduction....................................................................................................................................................................46

7.2.2.

Summarizing table of the main features and available models........................................................................................46

7.2.3.

Size................................................................................................................................................................................47

7.3.

Vtouch.....................................................................................................................................................................................48

7.3.1.

Introduction....................................................................................................................................................................48

7.3.2.

Summarizing table of the main features and available models........................................................................................48

7.3.3.

Size................................................................................................................................................................................49

7.4.

Vroom......................................................................................................................................................................................50

7.4.1.

Introduction....................................................................................................................................................................50

7.4.2.

Summarizing table of the main features and available models........................................................................................50

7.4.3.

Size................................................................................................................................................................................51

7.5.

Vcolor......................................................................................................................................................................................52

7.5.1.

Introduction....................................................................................................................................................................52

7.5.2.

Summarizing table of the main features and available models........................................................................................52

7.5.3.

Size................................................................................................................................................................................53

8.

TECHNICAL DATA..................................................................................................................................................................54

8.1.

Technical data .........................................................................................................................................................................54