Operating instructions General safety information

FV 40.2

- 5 -

Open the door very carefully during the program cycle, as otherwise

wash water could splash out.

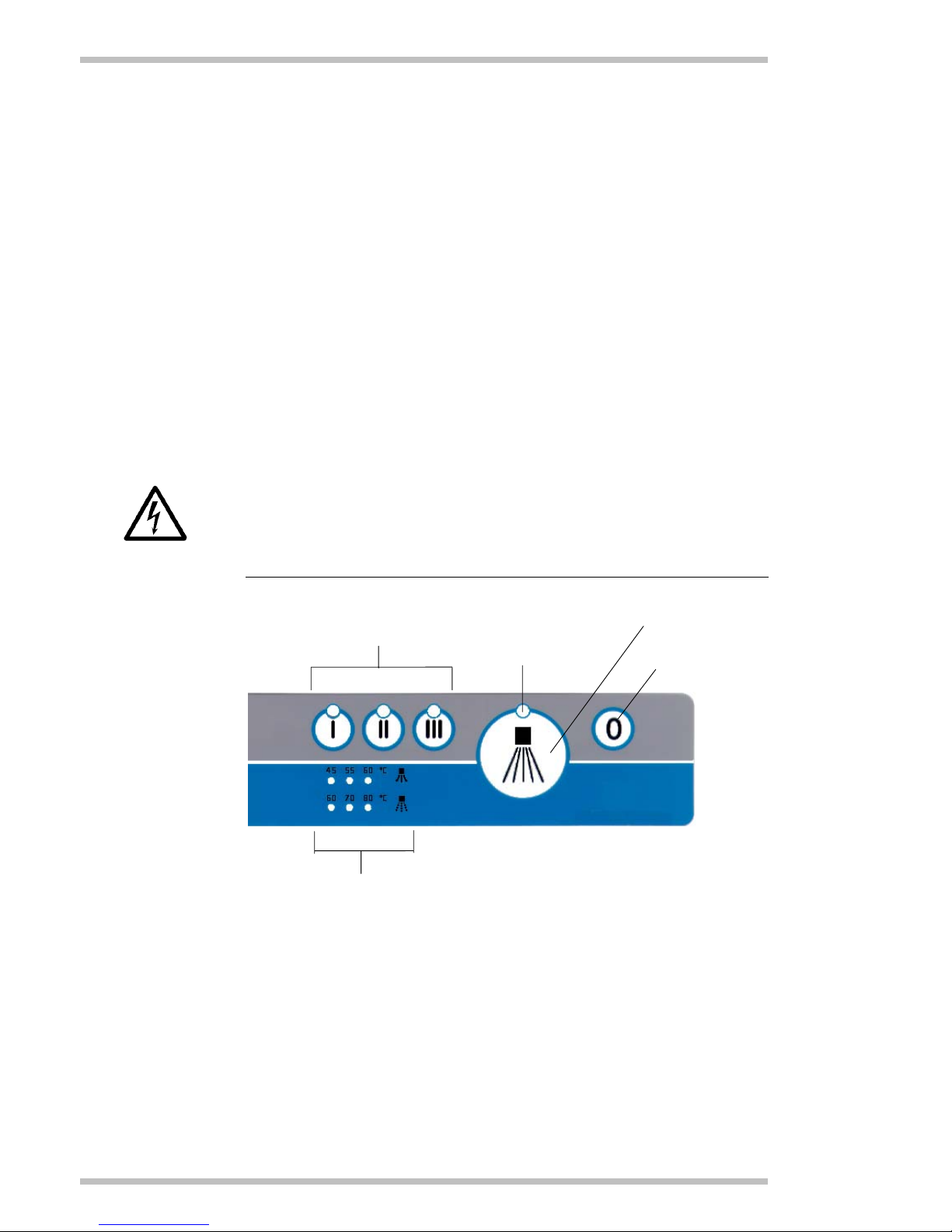

3.3.1 Emergency switch

Ø Set the local main switch to ”OFF“ or disconnect the local main fuse.

3.4 Authorized users / operators

It is assumed that two groups of users will come into contact with the

appliance:

1. Service engineers from the manufacturer or the agency or installation

engineers from the authorised dealer: these are qualified technicians

and have good product knowledge.

2. Operators - with basic knowledge (our customers must instruct the

operators).

Customers’ responsibility relating to the groups of users

q The persons responsible for safety must fully guarantee that only

qualified persons carry out connection, adjustment or maintenance

works on the open appliance.

q Permission for carrying out this type of work is given by the person

responsible for the safety of staff and of the appliance to persons

qualified because of their training, education, experience or

instructions; or because of their knowledge regarding standards,

regulations, accident-prevention regulations and the circumstances

of the installation.

q The persons responsible for safety must instruct the operators with

regard to the operation and the safety aspects of the appliance.

q Steps must be taken to ensure that the operating instructions

supplied are available for both user groups. Service personnel must

also have the documentation relating to the order available for them

when undertaking any work and observe these instructions in order

to avoid any hazard and/or damages.

3.5 Chemicals for the operation of the appliance

Only detergents and rinse-aids suitable for the use in industrial

dishwashers may be used. Relevant information is provided by the

manufacturers of these products.

If unsuitable products are used, the life expectancy of the dosing units

can be reduced considerably.

Observe the dosing instructions of the manufacturer.

Detergents and rinse-aids can present a health hazard if they are not

correctly used. Observe the manufacturers’ instructions on the original

packing and on the safety data sheets.

If a de-scaling agent is used, observe the manufacturer’s instructions

strictly regarding handling and safety. After such an agent has been

used the product must be completely removed from the machine, as

even small residues are sufficient to destroy plastic parts and sealing

materials.

3.6 Environmentally acceptable measures, measures for disposal

Each discarded appliance is to be made immediately unserviceable in

order to avoid accidents at a later date.