MEIRUIKE RK9950 Series User manual

RK9950 series program-controlled leakage current test instruction manual

MEIRUIKE INSTRUMENT

Manual

RK9950 series

Program controlled leakage current tester

Instruction manual

Shenzhen Meiruike Electronic Technology

Co., Ltd.

RK9950 series program-controlled leakage current test instruction manual

Version history:

Due to the possible errors or omissions in the manual, improvement and perfection of

instrument functions, updating of technology and upgrading of software, the manual will be

adjusted and revised accordingly and continuously improved for the convenience of use.

Please pay attention to the software version and manual version.

October 2020.........................................Vision 1

Statement: the company may improve and improve the performance, function, software,

structure, appearance, accessories, packaging and instruction manual of the product.

Any modification is subject to no further notice!

If in doubt, please contact us.

RK9950 series program-controlled leakage current test instruction manual

Contents

Chapter 1 Safety Rules................................................................................................................... 1

1.1 General Provisions.................................................................................................................1

1.2 Maintenance......................................................................................................................... 1

1.3 Test environment...................................................................................................................2

1.3.1 Working position........................................................................................................ 2

1.3.2 Input power................................................................................................................2

1.3.3 workplace................................................................................................................... 3

1.4 Operator Regulations............................................................................................................ 3

1.4.1 Operator Qualification............................................................................................... 3

1.4.2 Safety rules.................................................................................................................3

1.4.3 Clothing regulations................................................................................................... 3

1.4.4 Medical regulations....................................................................................................3

1.5 Safety grounding regulations................................................................................................ 4

1.6 Regulations on fuse replacement......................................................................................... 4

1.7 Test safety regulations...........................................................................................................4

1.8 Test exception provisions...................................................................................................... 4

1.9 Safety points..........................................................................................................................5

Chapter 2 Overview and technical indicators..................................................................................... 5

2.1 Product Overview..................................................................................................................5

2.2 Technical Indicators............................................................................................................... 7

Chapter 3 Front and back panel description................................................................................... 9

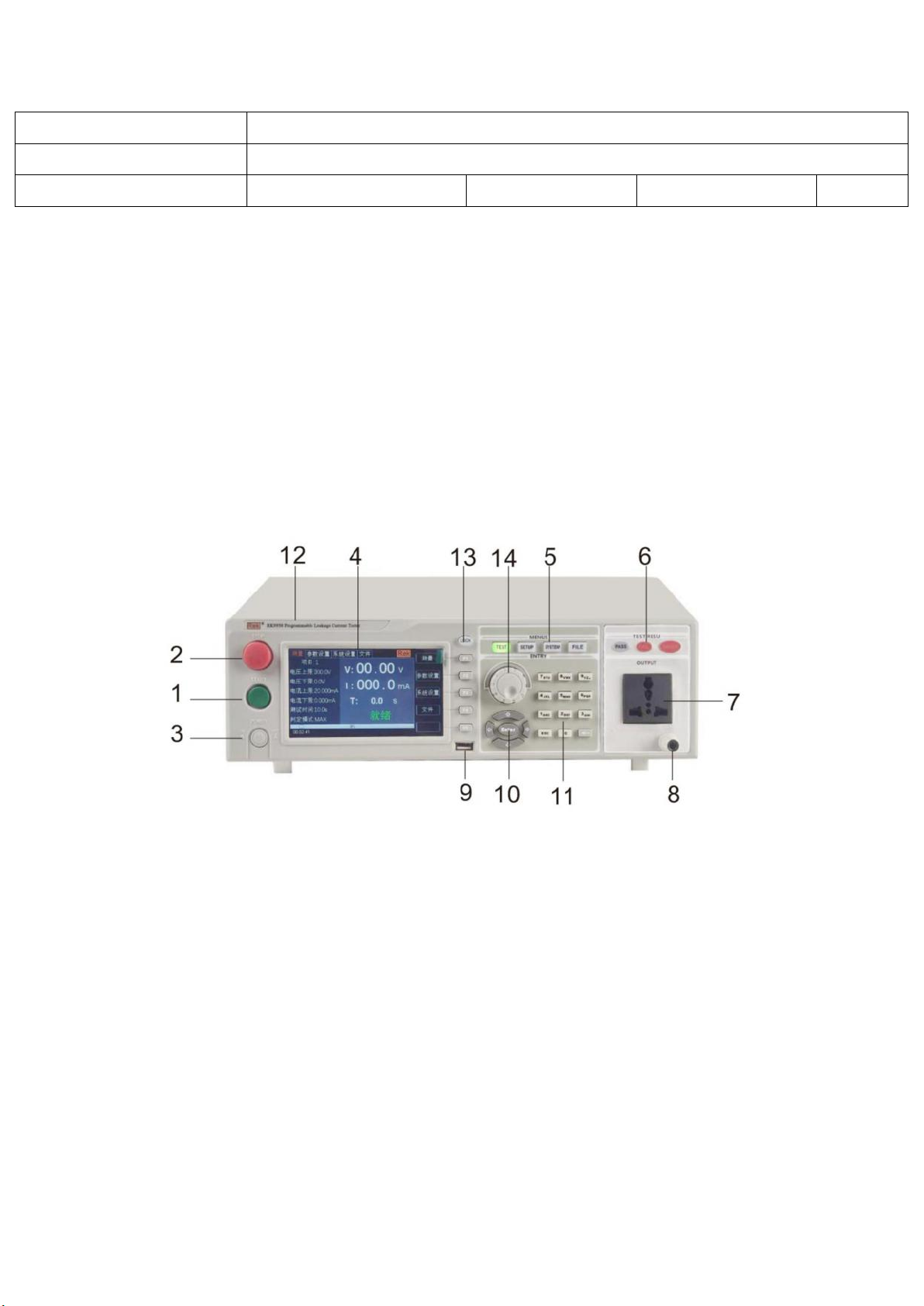

3.1 Front panel structure............................................................................................................ 9

3.1.1 Schematic diagram of front panel..............................................................................9

3.1.2 front panel description.............................................................................................. 9

3.1.3 Description of indication function area................................................................... 11

3.1.4 Parameter function area description.......................................................................11

3.2 Rear panel structure............................................................................................................12

3.2.1 Schematic diagram of rear panel.............................................................................12

3.2.2 Rear panel description............................................................................................. 12

3.3 Screen display area definition.............................................................................................13

3.3.1 Measurement display page area..............................................................................13

3.3.2 File domain...............................................................................................................14

3.3.3 Soft key area.............................................................................................................14

3.3.4 Display area of measurement results...................................................................... 14

3.3.5 Parameter setting area.............................................................................................14

3.3.6 System settings.........................................................................................................14

3.3.7 Time display area..................................................................................................... 14

3.4 Main menu buttons and corresponding displayed pages.................................................. 14

3.4.1 Main menu button of measurement display...........................................................14

3.4.2 Main menu button of parameter setting.................................................................15

3.4.3 system setting main menu button...........................................................................15

RK9950 series program-controlled leakage current test instruction manual

3.4.4 Main menu button of file management.................................................................. 16

Chapter 4 Operating Instructions......................................................................................................16

4.1 Boot instructions and boot screen......................................................................................16

4.2 Operation steps................................................................................................................... 17

4.2.1 Setting tester parameters........................................................................................ 17

4.2.2 Connect the tester to the object............................................................................. 17

4.2.3 Press the "start" button to start the test.................................................................18

4.2.4 determination of qualified products....................................................................... 18

4.2.5 determination of unqualified products................................................................... 18

4.2.6 Operation instructions of START and STOP.......................................................... 19

Chapter 5 PLC remote control interface........................................................................................... 19

Chapter 6 Parameter setting............................................................................................................. 20

6.1 Instrument power on self test............................................................................................ 20

6.2 Parameter setting mode..................................................................................................... 22

6.3 Parameter setting description.............................................................................................25

6.4 System settings parameter description.............................................................................. 31

6.5 Description of document parameters.................................................................................33

Chapter 7 Remote control.................................................................................................................34

7.1 RS232C interface description.............................................................................................. 34

7.2 RS485 / 232C interface description.................................................................................... 35

7.3 USBTMC remote control system......................................................................................... 36

Chapter 8 SCPI serial port instruction reference.............................................................................. 36

8.1 Brief description of instruction format:..............................................................................36

8.2 SCPI instruction set............................................................................................................. 37

8.3 DISPLAY subsystem command set.......................................................................................37

8.4 FUNCtion subsystem command set.................................................................................... 38

Chapter 9 Maintenance guide...........................................................................................................47

9.1 Daily maintenance...............................................................................................................47

9.2 Simple troubleshooting.......................................................................................................48

9.3 Software upgrade steps of instrument system...................................................................48

RK9950 series program-controlled leakage current test instruction manual

1

Chapter 1 Safety Rules

The contents of the manual are subject to change without prior notice

Please contact our company directly if there is anything unknown in the manual

Regulations and matters needing attention before testing!

Warning: to prevent failure or damage to the tester, please use the tester within

the specified voltage range.

1.1 General Provisions

Before using the tester, please read the manual carefully to understand the operation procedures

and relevant safety signs to ensure safety.

Before turning on the input power switch, please select the correct input voltage specification.

Chassis earthing symbol

Warning: it should be noted that the operation,

application or condition carried out is highly dangerous,

which may lead to personal injury or death.

The current generated by the tester is enough to cause casualties. In order to prevent accidental

injury or death, when moving and using the tester, please observe clearly before operating.

1.2 Maintenance

1.2.1 in order to prevent electric shock, non professionals should not open the cover of the tester.

All parts inside the tester should not be replaced without permission. If the tester is abnormal,

please ask our company or the designated dealer for help.

RK9950 series program-controlled leakage current test instruction manual

2

1.2.2 regular maintenance

The tester, power line, test line and related accessories should be carefully inspected and

calibrated at least once a year to ensure the safety of operators and the accuracy of the tester.

1.2.3 user modification

The user is not allowed to change the circuit or parts of the tester by himself, otherwise the

warranty of our company will be invalid and we will not be responsible for the consequences.

1.3 Test environment

1.3.1 Working position

When operating the tester, it must be ensured that the tester is placed in a place that ordinary

personnel cannot touch at will. If it cannot be done because of the arrangement of the

production line, the test area must be isolated from other facilities and specially marked with

"test work area".

1.3.2 Input power

The tester uses single-phase power supply of 220 V / 110 V and 50 Hz / 60 Hz. Before turning on

the power switch, please ensure whether the power supply voltage meets the requirements.

The test area power supply must have a separate switch, installed at the entrance of the test area,

to ensure that all personnel can identify. In case of emergency, turn off the power immediately.

In order to prevent the tester from failure, please use it within

the specified voltage range.

RK9950 series program-controlled leakage current test instruction manual

3

1.3.3 workplace

Use non-conductive material as much as possible. The test site must be kept neat and clean

at all times, and no disorder is allowed. Please put the unused tester and test line in a fixed

position, so that all personnel can immediately distinguish the tested object, the object to be

tested and the object to be tested.

The air in and around the test area shall not contain combustible gas, and the tester shall

not be used beside combustible materials.

1.4 Operator Regulations

1.4.1 Operator Qualification

The output current of the tester is enough to cause personal injury or death in case of

electric shock due to wrong operation, so it must be used and operated by trained and qualified

personnel.

1.4.2 Safety rules

Operators must give education and training at any time to make them understand the

importance of various operation rules, and operate the tester according to the safety rules, so as

to ensure the safety of the tester.

In order to prevent the occurrence of electric shock accidents, please wear insulating gloves

before using the tester.

1.4.3 Clothing regulations

Operators are not allowed to wear metal ornamented clothes or metal hand ornaments and

watches. These metal ornaments are easy to cause accidental electric shock.

When you get an electric shock, the consequences will be even more serious.

1.4.4 Medical regulations

The tester must not be operated by people with heart disease or wearing a heart rate

regulator.

RK9950 series program-controlled leakage current test instruction manual

4

Incorrect grounding or ungrounded may lead to electric shock accident.

1.5 Safety grounding regulations

The tester must be well grounded, and the ground wire must be well grounded before the test

to ensure the safety of the operator. If the ground connection on the power plug is not reliable,

an additional protective ground terminal is provided on the back panel of the tester to connect to

the safe ground.

Incorrect grounding or ungrounded may lead to electric shock accident.

1.6 Regulations on fuse replacement

Please turn off the input power switch and disconnect the power plug

before replacing the fuse,the Standard Fuse (100v-120v 47hz-63hz 3.15a; 200v-240v 47hz-63hz

5a) should be replaced.To avoid electric shock, be sure to replace the fuse after disconnecting the

power cord.

1.7 Test safety regulations

After connecting the test line to the object to be tested, the connection shall be reliable. The

operator must make sure that the switch and remote control switch can be operated completely

independently and can not be controlled by other personnel. When the remote control switch is

not in use, it should be placed in a fixed position and can not be placed at will.

Never use a tester on a live circuit board or equipment! Do not touch the

test object or the object connected with the test object during the test!

1.8 Test exception provisions

RK9950 series program-controlled leakage current test instruction manual

5

Under some specific conditions, the tester will not respond to the reset key, the test time

value will not move, and the display will be black screen, which is very dangerous. When these

situations occur, please be sure to turn off the power switch and disconnect the power plug, do

not use, please contact our company.

When the test is abnormal, turn off the power switch immediately

and unplug the power plug!

1.9 Safety points

■Unqualified operators and irrelevant personnel should stay away from the test area.

■The test area must be kept in a safe and orderly state at all times.

■During the test, it is not allowed to touch the test object or any object connected with

the tested object.

■In case of any problem, please turn off the output and input power immediately.

Chapter 2 Overview and technical indicators

2.1 Product Overview

Thank you for purchasing and using our products. Before using this instrument, please confirm it

according to the "accessories" in the last chapter of this manual,

If there is any discrepancy, please contact us as soon as possible to protect your rights and

interests.

2.1.1 Program controlled leakage current tester is 5 inch TFT LCD display, the tester uses 32 bit

high-speed MCU and large scale digital circuit design.

Built in GB9706.1-2007 (IEC60601-1:1998) body impedance simulation network, the card card

MD network interface contains MD-A (coincidence GB/T12113-2003 、GB4793.1-2007) 、

MD-B( GB/T12113-2003、GB4793.1-2007、GB4706.1-2005、

RK9950 series program-controlled leakage current test instruction manual

6

GB4943.1-2011、GB8898-2011 、GB7000.1-2015)、MD-C( GB/T12113-2003、GB7000.1-2015)、

MD-D(GB4793.1-2007)、MD-E( GB4943.1-2011、GB4793.1-2007)、MD-F( GB7000.1-2015).

Load voltage and current overrun protection; MD network multiple fast protection, safe and

reliable. Dynamic and static two power test states; leakage current test automatically switches L

(phase line) and N (zero line). Its setting and operation are very simple, and provides PLC remote

control interface, RS232C, RS485, USB and other interfaces, which is convenient for users to

quickly combine into a comprehensive test system.

2.1.2 The tester has the functions of unqualified identification, sound and light alarm and

automatic control of test time, which can meet the needs of production line or quality inspection.

2.1.3 The tester can be used for leakage current test of household appliances, electronic

instruments, electronic equipment, electric tools, electric heating appliances, etc.

2.1.4 Service conditions

Power supply voltage: 110V / 220V (±10%)

Power frequency: 50 Hz / 60 Hz (±5%)

2.1.5 Ambient temperature and humidity

Normal working temperature: 0 ℃- 40 ℃, humidity: < 90% RH

Measuring environment temperature: 20 ℃± 8℃, humidity: < 80% RH

Transportation environment temperature: 0 ℃- 55 ℃, humidity: ≤93% RH

2.1.6 Preheating

Preheating time after startup: ≥30 minutes

2.1.7 Insulation resistance

Under metering working conditions, the insulation resistance between the power terminal and

the shell shall not be less than 50m Ω.

Under the condition of hot and humid transportation, the insulation resistance between the

power terminal and the shell shall not be less than 2m Ω.

2.1.8 Insulation strength

Under the metering working conditions, the power supply terminal and the shell can withstand

the rated voltage of 1.5kV and frequency of 50 Hz AC power supply for 1 minute without

RK9950 series program-controlled leakage current test instruction manual

7

breakdown and flashover.

2.1.9 Electromagnetic compatibility and compliance standards

The transient sensitivity of the power supply is GB6833.4. Conduction sensitivity is GB6833.6.

Radiation interference is required according to GB6833.10.

Standard for household electrical appliances (IEC60335, GB4706.1-2005) and luminaire standard

(IEC60598-1-1999,GB7000.1-2007),information standard(GB8898-2011, GB12113 ,

GB4943.1-2011, IEC60065, IEC60590) and so on.

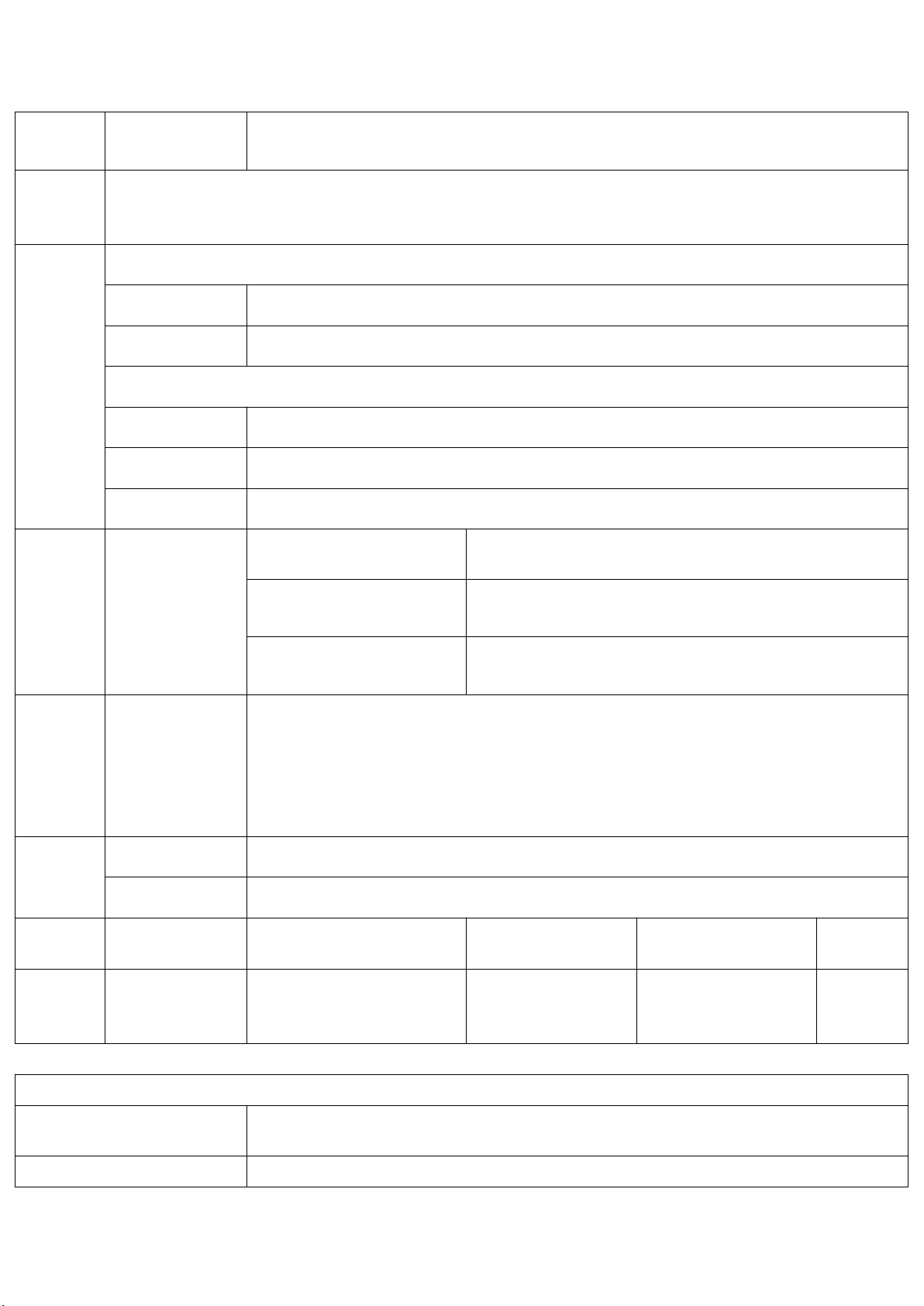

2.2 Technical Indicators

1、Specific parameters

Model

RK9950(Passive)

RK9950A(500VA)

RK9950B(1000VA)

RK9950C

Basic

functions

Screen size

5-inch TFT LCD screen

Number key

Parameter setting digital input

Coding switch

Parameter selection and confirmation function

Up, down, left and

right

function keys

Parameter setting up and down selection function

LOCK keyboard

locking function

Prevent accidental modification of test conditions or prohibit modification of test conditions

Alarm function

Voice alarm

Communication

interface

RS232C、RS485、USB

USB interface

Copy, copy and storage functions

Control interface

HANDLER(PLC)

Test method

Dynamic, static

Load

voltage(AC)

Range

0-300V

Accuracy

+ (2% ×display value +0.5V)

Frequency

50/60Hz

RK9950 series program-controlled leakage current test instruction manual

8

Load

current(AC)

Maximum

25A

Over

current

protection

Sound and light alarm, cut off the load output

Leakage

current

setting

Upper limit setting

Range

0.001-20.00mA

Resolution

<10mA,0.001/step >10mA,0.01mA/step

Lower limit setting

Range

0.000-20.00mA

Resolution

<10mA,0.001/step >10mA,0.01mA/step

Explanation

The lower limit is set to 0 without judgment

Leakage

current

measureme

nt

Range and accuracy

0.001-0.050mA DC-10KHz

±(5% ×display value + 5 words)

0.050-20.00mA DC-10KHz

±(2% ×display value + 2 words)

0.050-20.00mA

10KHz-1MHz

±(5% ×display value + 5 words)

MD

simulated

human

network

8 standard

networks

MD-A(GB/T12113-2003 、GB4793.1-2007) 、MD-B B1(GB/T12113-2003 、GB4793.1-2007 、

GB4706.1-2005、GB4943.1-2011、GB8898-2011、GB7000.1-2015)、MD-C(GB/T12113-2003、

GB7000.1-2015)、MD-D(GB4793.1-2007)、MD-E(GB4943.1-2011、GB4793.1-2007)、

MD-F(IEC60598-1:2014 、GB4793.1-2007) 、MD-G(GB4943.1-2011 、IEC60950-1:2005 、

GB4793.1-2007、IEC61010-1:2001)

Test time

Range

Single timing test: 0.1-999s ±1%; closing time is continuous test

Explanation

When setting 0S test, only N-wire is tested,no L conversion

Output

power

Passive

500VA

1000VA

Three phase

passive

External

power

supply

External connection

Built in

Built in

External

connection

2、General technical index

General technical index

Working temperature and

humidity

0℃-40℃,≦75%RH

Power Supply

100V-121V,198V-242V,47.5-63Hz 5A 250V

RK9950 series program-controlled leakage current test instruction manual

9

Chapter 3 Front and back panel description

3.1 Front panel structure

3.1.1 Schematic diagram of front panel

3.1.2 front panel description

1. start key (START)

The green instantaneous contact switch has the following functions:

Start switch for testing voltage output

2.reset key (STOP)

The red instantaneous contact switch has the following functions:

Fuse size

5A 250V 10A 110V

External volume(D×H×W)

430mm×105mm×350mm

Weight

13KG

16KG

18KG

14KG

RK9950 series program-controlled leakage current test instruction manual

10

In the setting mode, it acts as a switch to leave the setting mode.

When testing, it can be used as a switch to interrupt the test.

At the end of the test, it is used as a switch to exit the test and enter the next state to be tested.

3. Power switch

Working power input of tester

4. LCD screen

Display various setting information and test data.

5. Function area

Operation area of various settings

6. Test result indication area

When the tester outputs current, the indicator light will be on, indicating that "there is current

output, under test", indicating that the test has passed and failed.

7. Output terminal

Test the output voltage of the tested part

8. Ground return terminal

As the loop grounding terminal of the tested part. Suitable for two core power plug without

ground wire.

9. USB storage area

As the interface of file data copy and copy.

10. up and down, left and right, and ENTER confirm key.

It is used to adjust the options when setting the parameter function. Enter is the confirmation

function key.

11. 0-9 number pad

Enter the numeric value of the parameter

RK9950 series program-controlled leakage current test instruction manual

11

12. Tester model indication

13. LOCK lock key

It is used to press the panel function keys, and light up and lock the panel functions during the

test, except stop and start keys.

14. Rotary encoder potentiometer

For parameter setting, you can adjust the potentiometer and press the key to confirm the setting.

3.1.3 Description of indication function area

1. Qualified lamp

It contains green LED indicator light, which will be on when the object to be tested passes the

test.

2. Unqualified lamp

It contains red LED indicator light, which will be on when the test fails.

2. When the light is on, it means that the instrument should pay attention to safety

during the test.

3.1.4 Parameter function area description

Key is the function of test status, select this key to enter the test; key is the

parameter setting key, select this key to enter the test parameter setting of the tester;

Key is the function setting key of the tester system. Select this key to set various

functions of the tester system;

Key is the function key of tester file. Select this key to copy, copy and delete the test data

file.

RK9950 series program-controlled leakage current test instruction manual

12

3.2 Rear panel structure

3.2.1 Schematic diagram of rear panel

3.2.2 Rear panel description

1. Power socket

The standard input power socket provides working power for the tester. Pay attention to turn off

the input power switch and disconnect the power plug before replacing the fuse, and replace the

Standard Fuse (3.15A/250VAC, 5A / 110VAC).

2. 115V / 230V power conversion

3. Ground terminal

The safety grounding terminal of the tester must be properly grounded to ensure the safety of

the operator.

4. PLC signal terminal

A standard 9-core D-type female terminal block provides remote control monitoring and control

signal interface.

5. RS232C interface

RS232C serial communication function is provided

RK9950 series program-controlled leakage current test instruction manual

13

6. RS485 interface

Provide RS485 serial communication function

7. USB interface

Provide USB computer to connect U disk function

8. AC source input

L、N single phase AC source input.

9. Name plate

Tester model name, date of manufacture and serial number.

3.3 Screen display area definition

RK9950 uses 480 * 272 LCD 5 inch display. The contents displayed in the display are divided into

the following display areas.

3.3.1 Measurement display page area

This area indicates the measurement parameter name of the current page.

RK9950 series program-controlled leakage current test instruction manual

14

3.3.2 File domain

Move the cursor to this area for file management. File management includes loading, saving and

deleting.

3.3.3 Soft key area

This area is used to display the function definition of the soft key. The definition of soft key has

different function definition according to the location of the cursor area.

3.3.4 Display area of measurement results

This area displays test result information and current test conditions.

3.3.5 Parameter setting area

This area displays the parameter settings

3.3.6 System settings

This area displays the parameter settings of the system.

3.3.7 Time display area

This area displays the current working time.

3.4 Main menu buttons and corresponding displayed pages

3.4.1 Main menu button of measurement display

Used for all kinds of measurement and display the home page. The function pages of this part

include (use the "soft key" to select the following page functions, the same below):

Measurement display

Measurement setup

System settings

Document management

RK9950 series program-controlled leakage current test instruction manual

15

3.4.2 Main menu button of parameter setting

It is mainly used to enter the measurement setting interface corresponding to the measurement

display. The main interfaces are as follows:

3.4.3 system setting main menu button

Used to enter the system settings home page. It is mainly about system settings. The function

pages of this part are as follows:

RK9950 series program-controlled leakage current test instruction manual

16

3.4.4 Main menu button of file management

Used for file management settings.

Chapter 4 Operating Instructions

4.1 Boot instructions and boot screen

Before the power cord plug is connected to the mains, please turn off the input "power

switch", check whether the specification of the fuse is correct, and connect the safety ground

This manual suits for next models

4

Table of contents

Other MEIRUIKE Test Equipment manuals

Popular Test Equipment manuals by other brands

PCB Piezotronics

PCB Piezotronics Y482C15 Installation and operation manual

BGS technic

BGS technic 40105 manual

Rohde & Schwarz

Rohde & Schwarz R&S CMW-KM300 user manual

Omega

Omega CDH-93 instruction sheet

Hella Gutmann

Hella Gutmann CSC-Tool operating instructions

Dostmann Electronic

Dostmann Electronic PH CHECK 5040-0301 Operating instruction