www.driair.com | www.rti-pbe.com(800) 521-9200 @RTiPBE @rti_pbe

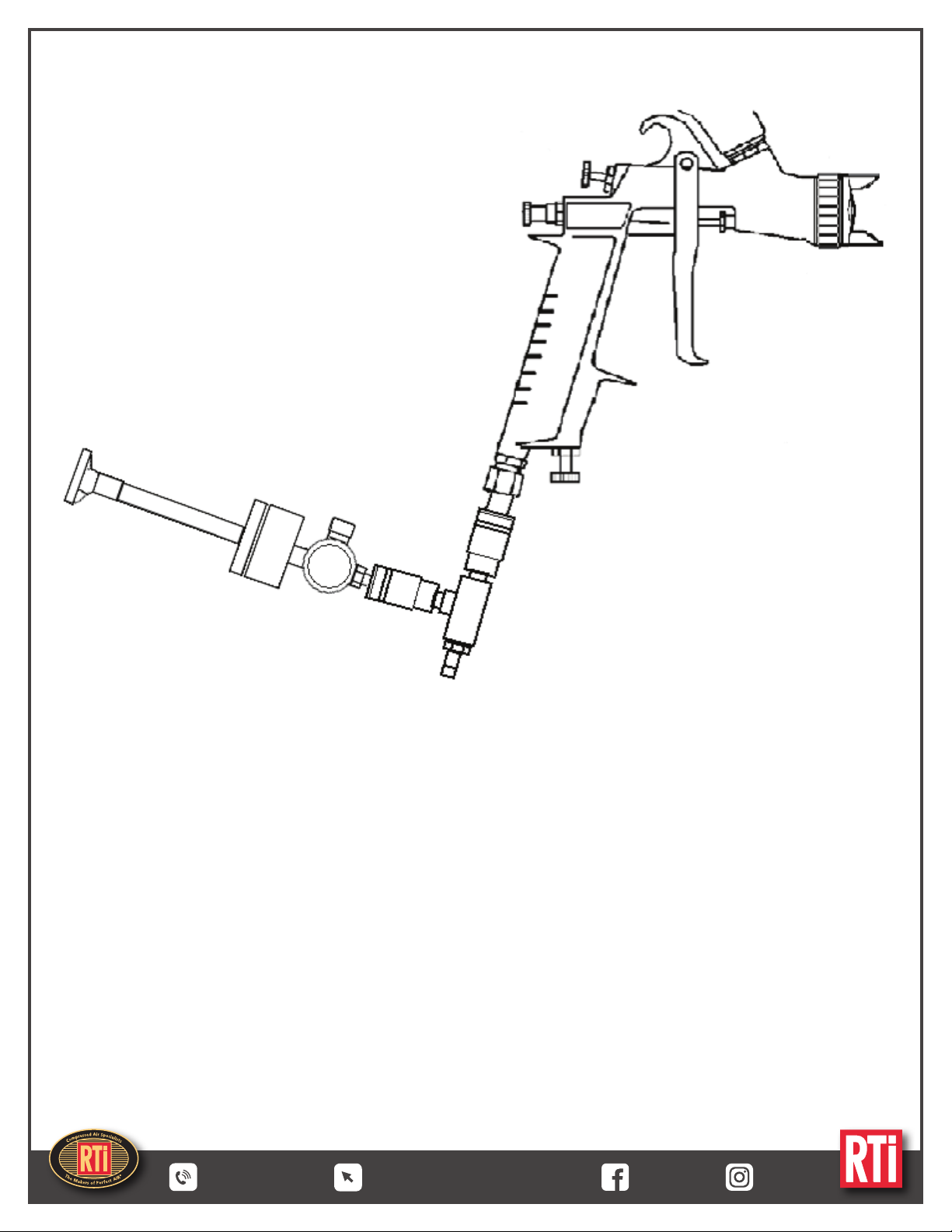

RTi-QAT Quality Air Test Kit w/ Digital Hygrometer

Rev. 9/2017

Save thousands of dollars by identifying the three (3) major causes of renish problems:

• Inadequate compressed air supply

• Compressed air humidity

• Particulate and/or oil contamination

A few minutes spent testing your air supply will save your business thousands of dollars by avoiding renish problems.

COMPRESSED AIR SUPPLY

Using RTi’s special high volume air adjusting valve (this test is intended to give four elements of information

concerning compressed air).

1. Static air pressure at the gun.

2. Dynamic air pressure at the gun.

3. Air pressure drop from the compressed air source to the point of use.

4. Adequate or inadequate compressed air supply.

PROCEDURE FOR THE TEST:

1. Static air pressure at the gun:

• Attach the air valve to the gun.

• Connect the air supply to the air valve

• Read the gauge. This reading will be the static reading (make a note of the reading).

2. Dynamic air pressure at the gun:

• Set the fan and the material control knobs in the wide-open position.

• For the dynamic reading depress the trigger to the full back position or to the material stroke.

• While the trigger is in the full back position, read the gauge (make a note of the reading).

3. Air pressure drop from the compressed air source to the point of use:

• Subtract the dynamic reading from the static reading. The total is the pressure drop from the compressed air

source to the point of use.

4. Adequate or inadequate compressed air supply:

• While the gun is set in the wide-open position and the trigger in the full back position, set the gauge at the

desired pressure. Hold this for two minutes.

• If there is no pressure drop, there is adequate compressed air to operate that particular spray gun.

• If the gun is unable to maintain the needed air pressure, DO NOT ATTEMPT TO SPRAY. Spraying with

inadequate air can only lead to unsatisfactory renish work.

COMPRESSED AIR HUMIDITY

TO TEST HUMIDITY LEVEL:

1. Install humidity gauge manifold into RTi-QAT housing. Turn on tester.

2. Connect RTi-QAT to air supply at location you want to test.

3. Adjust regulator until the pressure gauge is at 50 PSI.

4. Let run until gauge stabilizes (the number displayed is compressed air humidity).

COMPRESSED AIR HUMIDITY (CAH):

A. The gauge assembly only needs to be tightened until you feel it touch the o-ring.

B. Disconnect the air supply before unscrewing the gauge manifold.

C. CAH less than 10% at 70°F or less than 3% for waterborne for most paint applications.

For trouble free renish applications, CAH is best at 0, but allowable up to 10% for solvent.

RTi-QAT Quality Air Test Kit w/ Digital Hygrometer