Contents

Contents

1 General guidelines ...............................................................................................................................................................5

Symbols used.......................................................................................................................................................................5

Formatting rules ...................................................................................................................................................................5

MELAconnect App ...............................................................................................................................................................5

2 Safety.....................................................................................................................................................................................6

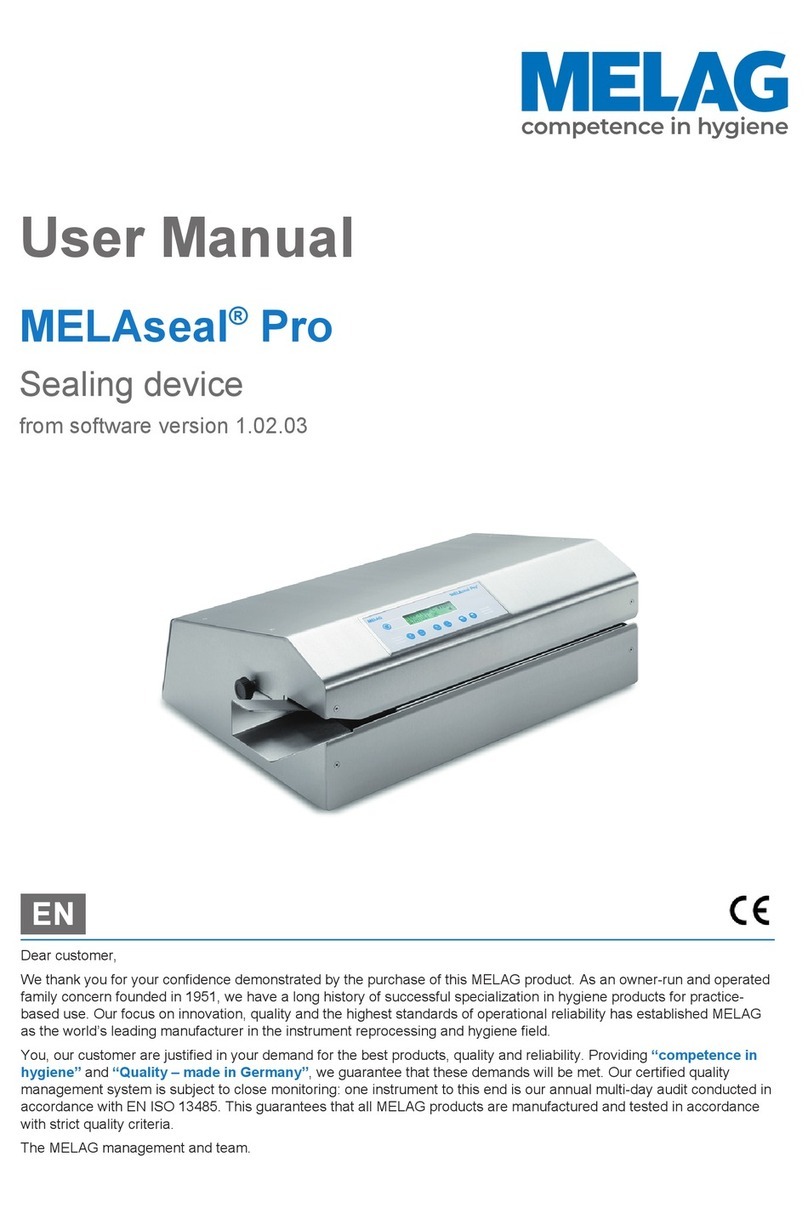

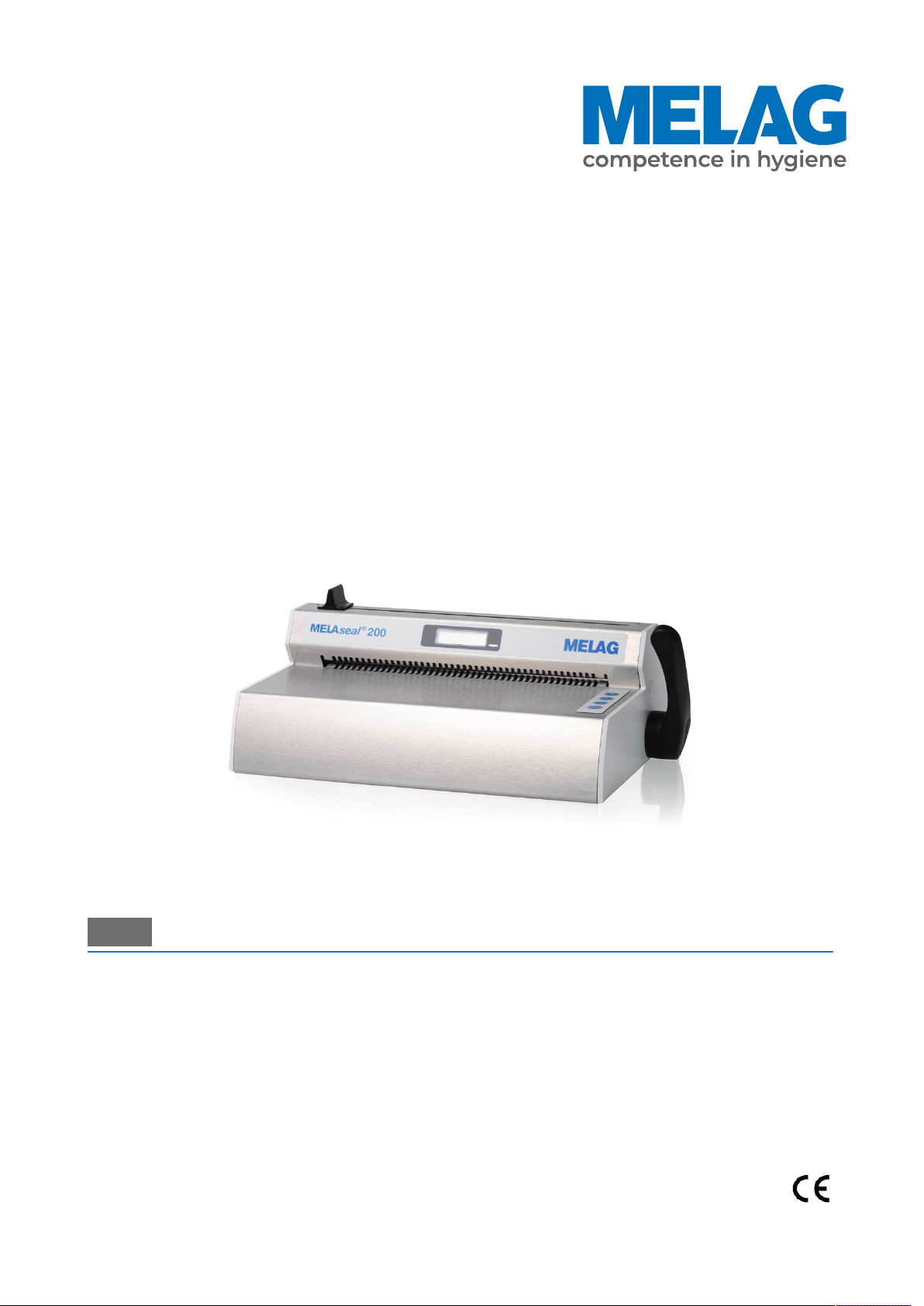

3 Description of the device.....................................................................................................................................................7

Intended use ........................................................................................................................................................................7

Scope of delivery..................................................................................................................................................................7

Views of the device ..............................................................................................................................................................8

Symbols on the device.........................................................................................................................................................9

Menu structure ...................................................................................................................................................................10

Status display and acoustic signals ...................................................................................................................................11

4 Commissioning...................................................................................................................................................................12

Requirements of the installation location ...........................................................................................................................12

Space requirements...........................................................................................................................................................12

Connecting the sealing device ...........................................................................................................................................13

Switching on the sealing device.........................................................................................................................................13

5 Sealing.................................................................................................................................................................................14

Sealing procedure with pre-finished film bags ...................................................................................................................14

Sealing procedure for film rolls...........................................................................................................................................15

6 Logging ...............................................................................................................................................................................18

Documenting the sealing process......................................................................................................................................18

Using the USB flash drive as an output medium................................................................................................................18

Computer as output medium..............................................................................................................................................19

Structure of the log files .....................................................................................................................................................19

7 Function tests.....................................................................................................................................................................21

Function test with MELAG Seal Check ..............................................................................................................................21

8 Settings ...............................................................................................................................................................................23

Access settings menu ........................................................................................................................................................23

Time ...................................................................................................................................................................................23

Date....................................................................................................................................................................................24

Sealing temperature...........................................................................................................................................................24

Signal tones .......................................................................................................................................................................25

User administration ............................................................................................................................................................25

Eco Mode and Standby......................................................................................................................................................26

Force calibration.................................................................................................................................................................27

9 Maintenance........................................................................................................................................................................28

Cleaning and regular controls ............................................................................................................................................28

Maintenance.......................................................................................................................................................................28

Validation ...........................................................................................................................................................................28

Software update.................................................................................................................................................................28