Contents

Contents

1 General guidelines ...............................................................................................................................................................4

Symbols used ......................................................................................................................................................................4

Formatting rules...................................................................................................................................................................4

Symbols on the device.........................................................................................................................................................4

Disposal ...............................................................................................................................................................................5

2 Safety.....................................................................................................................................................................................6

3 Description of the device.....................................................................................................................................................7

Scope of delivery .................................................................................................................................................................7

Intended use ........................................................................................................................................................................7

Compatibility with MELAG products ....................................................................................................................................7

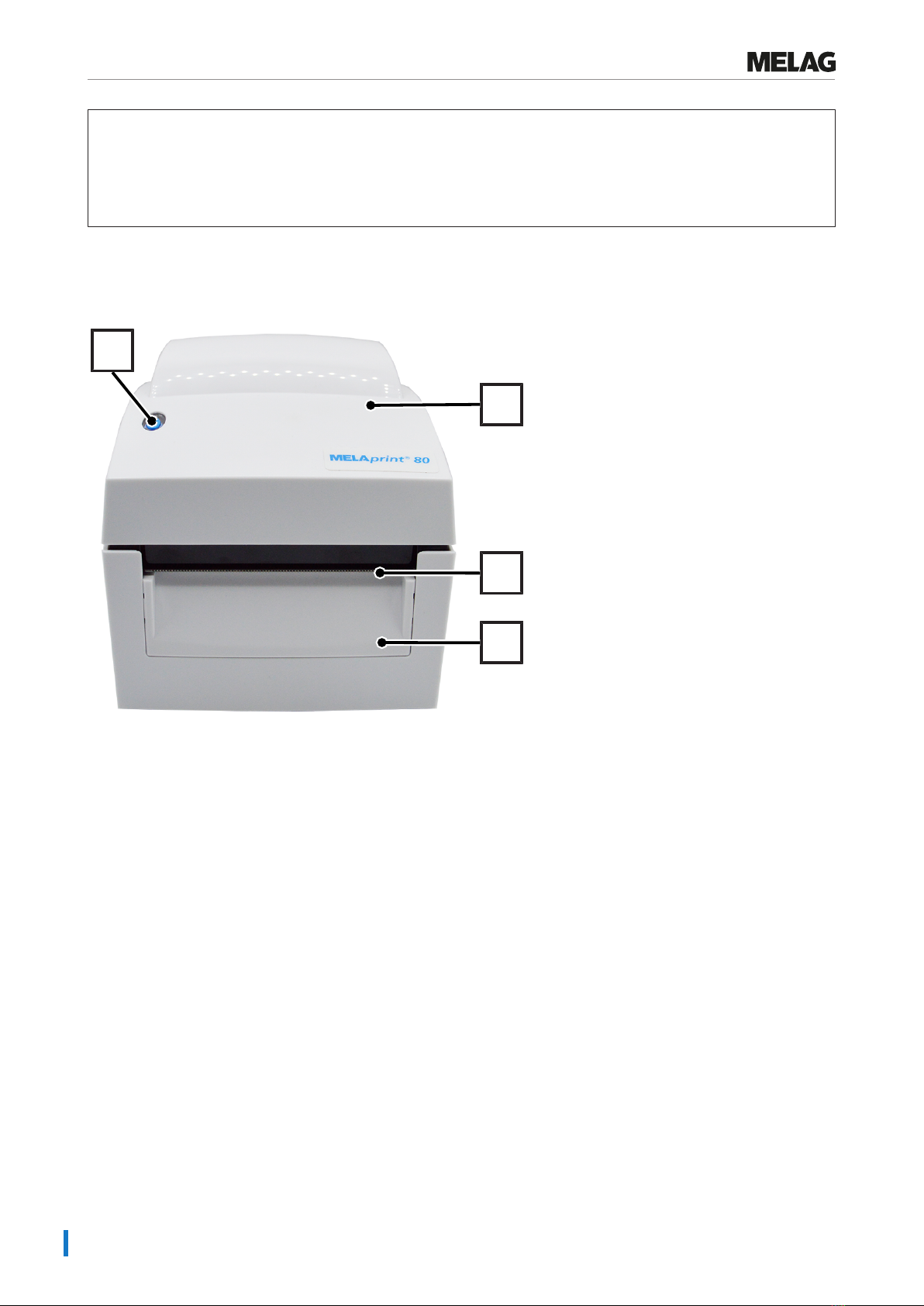

Views of the device..............................................................................................................................................................8

4 Commissioning...................................................................................................................................................................11

Loading printing material ...................................................................................................................................................11

Switching on the printer .....................................................................................................................................................14

Automatic detection of material length...............................................................................................................................15

Setting up the printer at the steam sterilizer ......................................................................................................................15

Reading out the printer configuration (print self-test).........................................................................................................20

Daily operation...................................................................................................................................................................20

5 Troubleshooting .................................................................................................................................................................21

General malfunctions.........................................................................................................................................................21

LED status .........................................................................................................................................................................22

6 Maintenance........................................................................................................................................................................23

Routine maintenance.........................................................................................................................................................23

Replacing the print head....................................................................................................................................................24

7 Technical data ....................................................................................................................................................................26

8 Accessories ........................................................................................................................................................................27