8

SECTION 3:

OPERATION

First Use

Sharpening the Blade

Your spokeshave ships with a coating of rust-inhibiting oil to ensure it arrives to

you in good condition, but this must be removed prior to use.

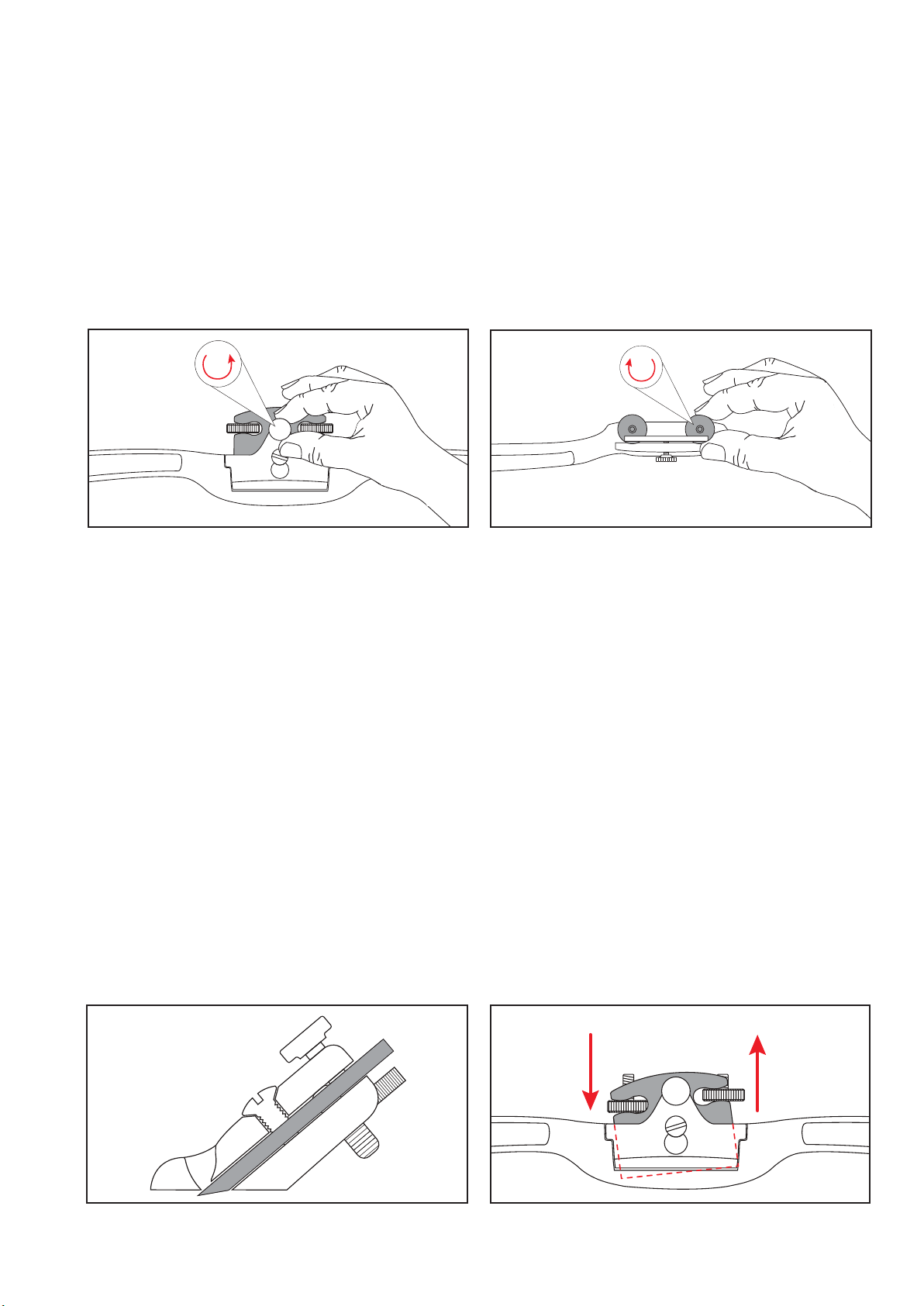

Remove the lever cap and blade, taking care with the sharp edge of the

blade.

Note: If the blade appears stuck it may be retracted hard against the central

boss - try advancing the blade a couple of turns (see ‘Setting the Blade’).

Using a rag, wipe all components to remove all but the lightest coating of oil,

being careful to avoid the cork handle inserts.

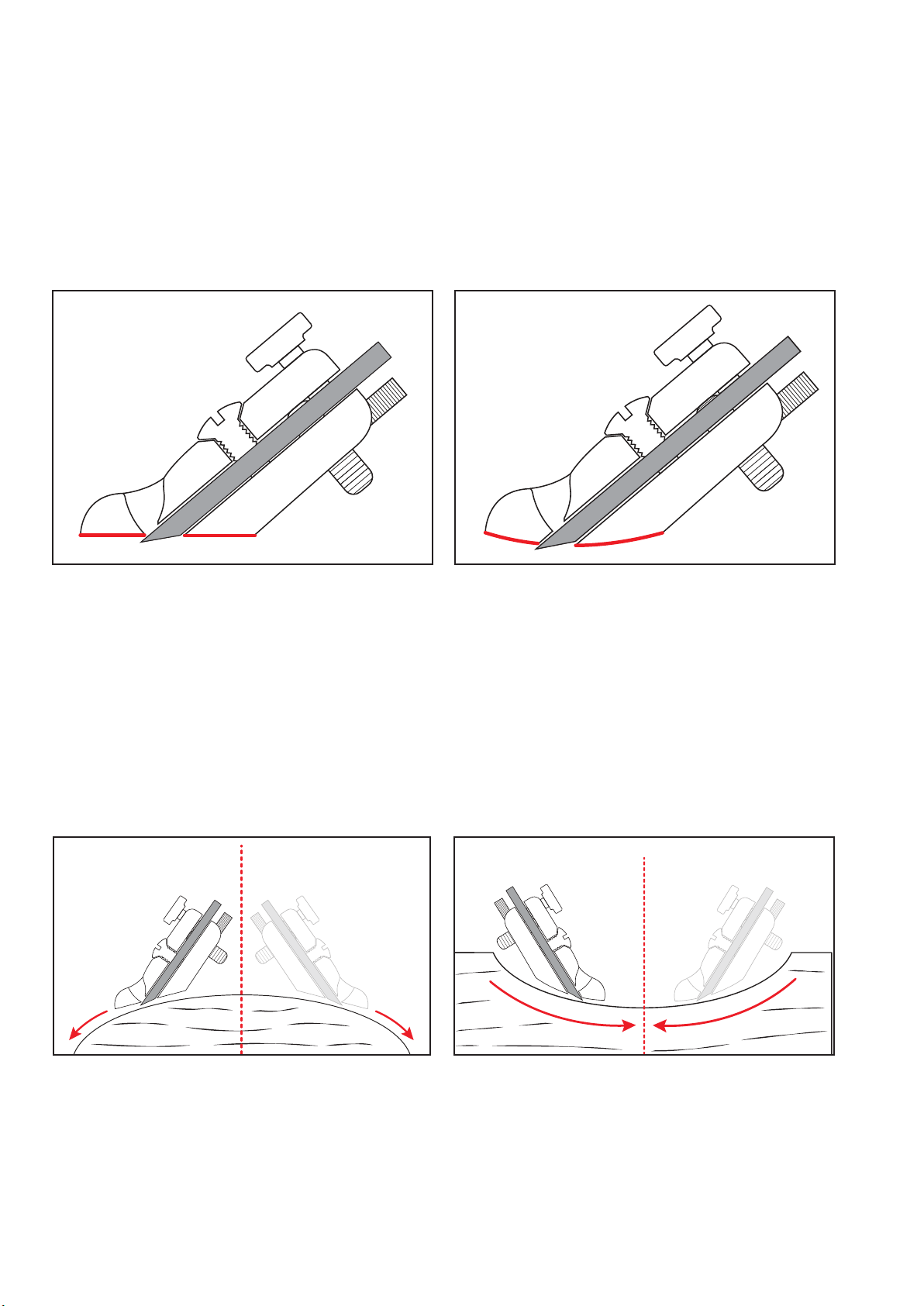

The blade is ground to the correct angle but will require sharpening before

use. The back of the blade may also benefit from final flattening.

Reassemble the Spokeshave, noting the correct orientation of the blade

(bevel facing down) and taking care not to damage the edge.

Do not overtighten the cap iron thumbscrew – it only needs one 1/8th of a turn

or so once the slack is taken out.

Periodically check the condition of the blade and resharpen as required – a

sharp blade is the single biggest factor in enjoying the use of your spokeshave

and the quality of the surface it produces.

When replacing the blade check the bed is free from wood shavings and any

build-up of wax or oil.