MENEGOTTI 400L PROFESSIONAL User manual

Before operate Menego equipament,

read this technical manual, itself will inform and

instruct the operator about the operaon.

By the way, you avoid possible working accidents

and early maintenance on at the equipment.

Attention:

Imagen ilustrava.

MENEGOTTI TECHNICAL MANUAL

CONCRETE MIXER 400L

RENTAL - PROFESSIONAL

www.discount-equipment.com

www.discount-equipment.com

Discount-Equipment.com is your online resource for commercial and industrial

quality parts and equipment sales.

Locations:

Florida (West Palm Beach): 561-964-4949

Outside Florida TOLL FREE: 877-690-3101

Need parts? Check out our website at www.discount-equipment.com

Can’t find what you need?

Click on this link: http://www.discount-equipment.com/category/5443-parts/ and fill out

the request form.

Please have the machine model and serial number available in order to help us get

you the correct parts. One of our experienced staff members will get back to you with

a quote for the right part that your machine needs.

We sell worldwide for the brands: Genie, Terex, JLG, MultiQuip, Mayco, Toro/Stone,

Diamond Products, Magnum, Airman, Mustang, Power Blanket, Nifty Lift, Atlas Copco,

Chicago Pneumatic, Allmand Brothers, Essick, Miller Spreader, Skyjack, Lull, Skytrak,

Tsurumi, Husquvarna/Target, Whiteman-Concrete/Mortar, Stow-Concrete/Mortar, Baldor,

Wacker, Sakai, Snorkel, Upright, Mi-T-M, Sullair, Neal, Basic, Dynapac, MBW, Weber,

Bartell, Bennar Newman, Haulotte, Ditch Runner, Blaw-Knox, Himoinsa, Best, Buddy,

Crown, Edco, Wyco, Bomag, Laymor, Terremite, Barreto, EZ Trench, Takeuchi, Basic, Bil-

Jax, Curtis, Gehl, Heli, Honda, ICS/PowerGrit, Puckett, Waldon, ASV, IHI, Partner, Imer,

Clipper, MMD, Koshin, Rice, Gorman Rupp, CH&E, Cat Pumps, Comet, General Pump,

Giant,AMida, Coleman, NAC, Gradall, Square Shooter, Kent, Stanley, Tamco, Toku, Hatz,

Kohler, Robin, Wisconsin, Northrock, Oztec, Toker TK, Rol-Air, Small Line, Wanco, Yanmar

www.discount-equipment.com

02

Congratulaons, you have just purchased a Menego product!

With the highest quality, projected and built especially to serve your

needs.

This manual was elaborated to provides the informaons and key instruc-

ons to use and mantain our product, in addicon presents their technical

characteriscs.

Before use the product for the first me, read and pay aenon at the

informaons in this manual.

The product durability only depends the way you treat it in service (opera-

on) and the sasfactory working is consequence of yours regular work

carefully.

Menego is preparaded to offer you all technical assistance, and aend

all your needs about replacement parts.

Welcome, you are part of the huge Menego “customers familiy”.

Aer sales Departament

and Technical Assistance MENEGOTTI.

Index

Aenon: For beer comodity, store and keep this manual in a properly

spot so it can be easily checked.

The Company

The Product

Safety Informaons

Technical Specificaons

Main Parts

Operaon Condions

Cleaning and Conservaon

Earthing the Equipment

Equipment Lubricacion

Transport, Liing and Storage

Wiring Diagram

Equipment Operaon

Equipment Maintenance

Assembly Procedures

Main Diferences

Parts List

Product Warranty

Term of Warranty

03

03

03

04

05

06

06

06

07

07

08

09

10

10

12

13

19

19

www.discount-equipment.com

03

The Company

The Product

Safety Informaons

Note: Anyone who performs any type of operaon with this equipment must read this manual and the safety instrucons.

Reference in civil construcon, present in more than 40 countries and naonal leader in concrete mixer sales, Menego

Metallurgical Ltda., offers innovave products that result in greater profitability for the business of its clients. A genuinely

Brazilian company, based in Jaraguá do Sul, SC, Brazil, develops, produces, markets and distributes a range of products,

from Mixer lines, Soil Compacon, Load Handling, Liing, Concrete Technology, Coangs and Finishing , Building Site and

Tools, which assists its clients in each stage of the work.

The concrete mixer 400l was designed for heavy civil construcon work . It is composed of a drum with a mixing capacity of up to 310 liters. The drum is moved

by a drive (electric/diesel/Petrol), which is acvated by a driven /drive system with a “V” belt . The unloading system is manual.

• With the aim of constantly improving their equipment, Menego reserves the right to change the features of the product without noce.

• Before using this equipment, carefully read this manual and follow the Manufacturer`s instructions, such as how to reduce the risk of accidents in

operation.

• It is expressly prohibited to remove or alter any safety device or characteristic, should this occur MENEGOTTI will not be held responsible.

• Use the equipment according to the instructions in this manual.

• In the case of damaged or missing pieces, contact MENEGOTTI by phone at +55 47 3275 8058 for replacement of same.

• With the machine turned off, conduct a daily inspection of the machine parts . In the case of problems, immediately contact the MENEGOTTI

authorized service.

• Maintain a limited area exclusive for working with the equipment, always keeping the place clean, without obstructions and with good lighting;

• The operator must be trained or qualified to operate this equipment;

• Do not use clothing that is too loose and which might get caught in the machine.

• Always use gloves, safety goggles and ear protection.

• The engines must be installed by qualified professionals.

www.discount-equipment.com

04

• Perform the maintenance recommended in this manual with qualified people and within the stipulated periods.

• Inspect all electrical extensions, mainly for cuts, cable friction and broken connections;

• Never use extensions that are not in good condition.

• Never use wet extensions or operate in wet environments (e.g. Pools of water).

• When cleaning the equipment, never throw water on the engine.

• Whenever performing maintenance on this equipment, disconnect the power cable from the source..

• Avoid contact with hot surfaces.

• Before performing any activity or maintenance, first let the engine cool down.

• Avoid contact with rotating parts.

Technical Specificaons

SPECIFICATIONS 400L CONCRETE MIXER

Drum Capacity 400 Liters

Mix Capacity 310 Liters

Drum Rotaon 30 Rpm

Number of Cycles/Hour 15

Esmated hourly producon 4,65 m³

Eletric: 2 CV

Combuson: 5 - 5.5 HP

Eletric*: 110/220/380 V

Combuson: Gasoline/Diesel

Net weight (without drive) 220 Kg

Dimensions(H x L x W) 1576 x 2045 x 1145 mm

Drive Capacity

Power Supply

* Consult availability and instrucon for changing switch selector to electrical supply.

www.discount-equipment.com

05

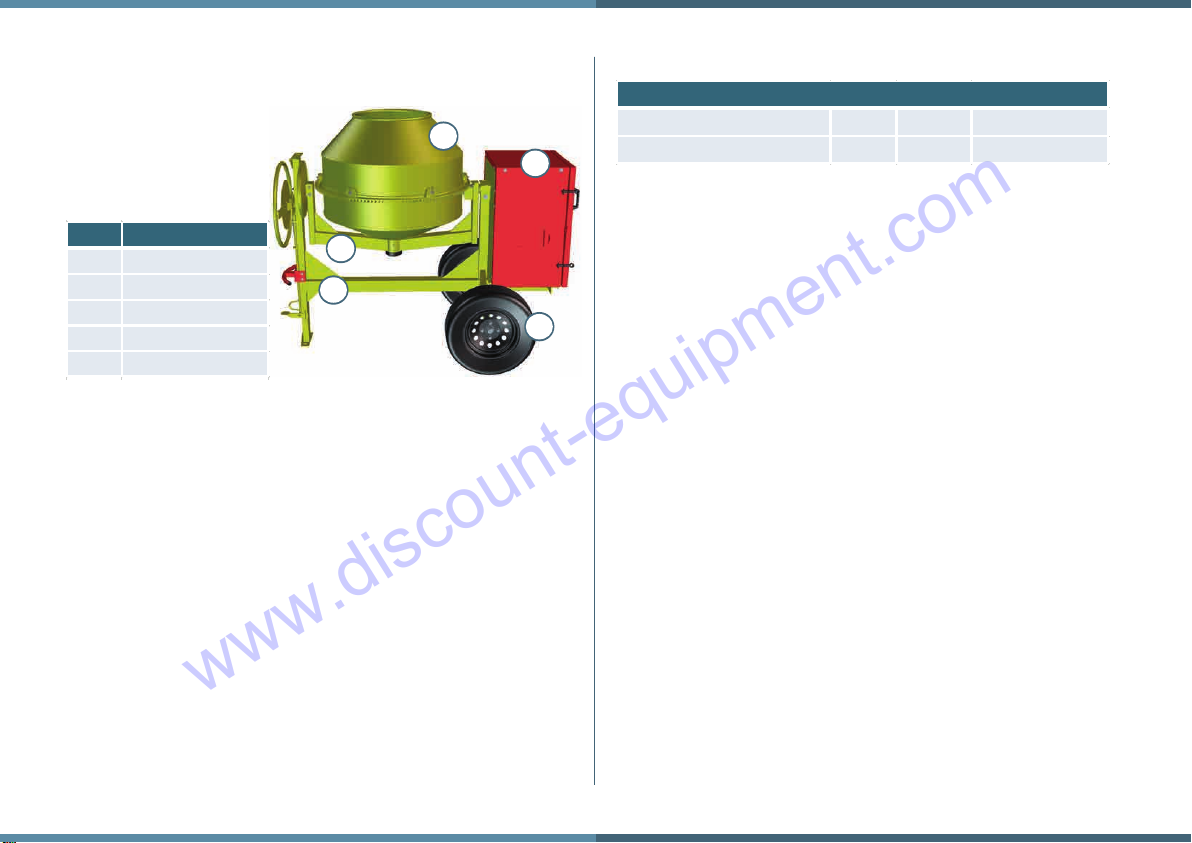

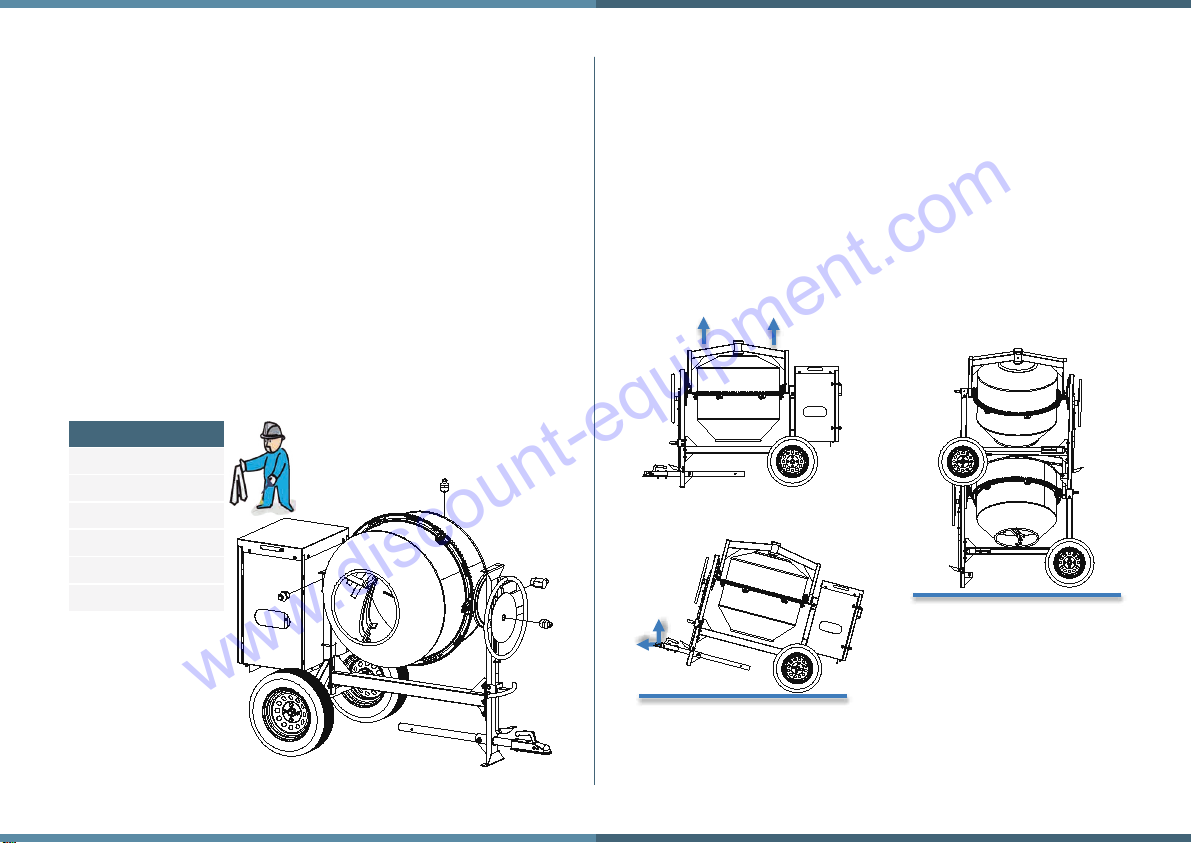

Main Parts

Equipment supplied without Electric Engine

The engine installaon, electrical appliances and their installaons and

grounding must be made in accordance with current standards in the

region and accompanied by a responsible qualified funcon. In the

absence of such standards, should be carried out according to interna-

onal standards, doubts when installing contact the authorized

service.

Equipment supplied with Combuson Engine

• Never inhale exhaust fumes as this can be harmful to your health;

• The Carbon monoxide from the exhaust of internal combuson

engines can cause death if used in confined spaces;

• Do not operate or refuel the gasoline or diesel engine in a confined

space without sufficient venlaon;

• Do not fuel the equipment when the engine is hot, this could become

very dangerous and ensure that there is sufficient venlaon during

this procedure;

• Do not touch the engine when it is running as it can burn your skin;

• Use fuel according to engine model;

• Do not use fuel of doubul origin;

• To prevent electric shock, never touch the spark plug while the

engine is running;

• The correct use, cleaning and maintenance of combuson engines

must always be in accordance with the instrucons contained in the

manual of the engine manufacturer.

Equipment supplied with Eletric Engine

• Before switchn your concret mixer, check if the supply voltage corres-

ponds to the voltage indicated on the identy plate of the electric

engine. Switching on the engine when connected to different voltage

from the voltage indicated on the identy plate of the electric engine will

result in damage to the engine;

• For without voltage selector equipment, contact the authorized service

prior to any change.

• The engine drive in a different voltage voltage on the electric engine

plate resulng in engine damage;

• Make sure circuit breakers, electric cables, sockets, grounding are

compable with the specified engine;

• Accepted voltage variaon must not exceed variaons above or below

10%, otherwise running failures may occur or even burning of the engine;

• For use of an extension electric, we recommend the table:

POS.DESCRIPTION

1 Drum

2Steel Yoke

3 Motor Box

4 Chassi

5Wheel

Extension electric 0 a 20m 20 a 30m above de 30m

Diameter of the electric wire 4,0 mm² 6,0 mm² not recommended

CONCRETE MIXER 400L

1

2

3

4

5

www.discount-equipment.com

06

Earthing the Equipment

• Correct earthing of the concrete mixer is vitally important in reducing

the risk of electrical shocks;

• Thus, before switching on your concrete mixer, make sure that the

socket has an earth pin and that this is correctly installed. If your socket

is not earthed, arrange for an earth to be installed before using the

concrete mixer;

• Should use copper rod length and recommended depth of 2 meters;

• The ground wire to pass through the on / off switch should not be

interrupted or connected to contacts.

• Do not connect the ground wire directly into the mixer neutral wire

mains.

• Grounding must be made according to the standards in the region and

accompanied by a responsible qualified funcon. In the absence of such

standards, should be carried out according to internaonal standards,

doubts when the installaon please contact your authorized service;

Operaon Condions

• Concrete mixers can be used in both indoor and outdoor environments;

• When filling a concrete mixer with a spade, do not place the spade inside

the drum;

• Improper use of this equipment, other than that for which it was projec-

ted, can pose a physical threat to the operator;

• Read this instrucon manual carefully;

• The operator must be trained or qualified to use this equipment;

• Set aside an exclusive area for working with the equipment. Keep this

area clear of obstacles and well lit at all mes;

• Whenever performing maintenance on this equipment, disconnect the

cable from the power supply.

• Pneumac wheel rim 13" calibraon: between 26 and 30 p.s.i (pound

force per square inch);

Noise level during operaon:

Since the noise level during mixer operaon, with the addion of stone

and gravel into the drum to simulate a maximum noise level, can reach up

to 95 decibels, the use of ear protect ion is recommended during prolon-

ged operaon.

Cleaning and Conservaon

• It must be disconnected from the mains and the cleaning operaon is

always performed at the end of ulizaon;

• Cleaning the drum with water, removing any residue of the blades and

all internal and external part of the drum;

• Clean the rack and pinion, removing all abrasive material to compo-

nents;

• Do not put water on electrical components and engine;

Standardizaon of

plugs and sockets

32A 220V/380V.

Ground point

exisng engine.

Ground point exisng machine.

www.discount-equipment.com

07

Equipment Lubricaon

• Keep machine rotang parts lubricated, such as: pinion, rack gear,

bushings, and bearings;

• Lubricate the equipment at the beginning of operaon, applying

grease to all lubricaon points;

• Lubricaon of the pinion/rack gear assembly is not recommended due

to the fact that aggregates such as sand, cement and gravel dust, among

others, can adhere to the lubricang agent, causing the mixture to

become extremely abrasive, thus resulng in premature wear.

• When lubricang the pimion sha bearing, the concrete mixer drum

must be in a posion where the steel yoke arm is perpendicular (90°) in

relaon to the machine column and the drum mouth must be turned to

the same side where the grease fing is. If not, the bearings will not be

lubricated;

Esso: Beacon 2

Mobil: Mobilux 3

Shell: Shell Avania R2

Texaco: MulFlax EPO

Castrol: Graxa LM2

Atlanc: Litholine 2

Recommended Greases

Transport, Liing and Storage

• It has yoke just to raise a few cenmeters of soil and carry through the

movement of the wheels;

• They should be used by lng, with the barrel facing down, while

maintaining the flatness of the mixer;

• Feature based on the columns for storing one on the other, fixaon is

by screws, use only one level of stacking;

Transport

Liing

Storage

www.discount-equipment.com

08

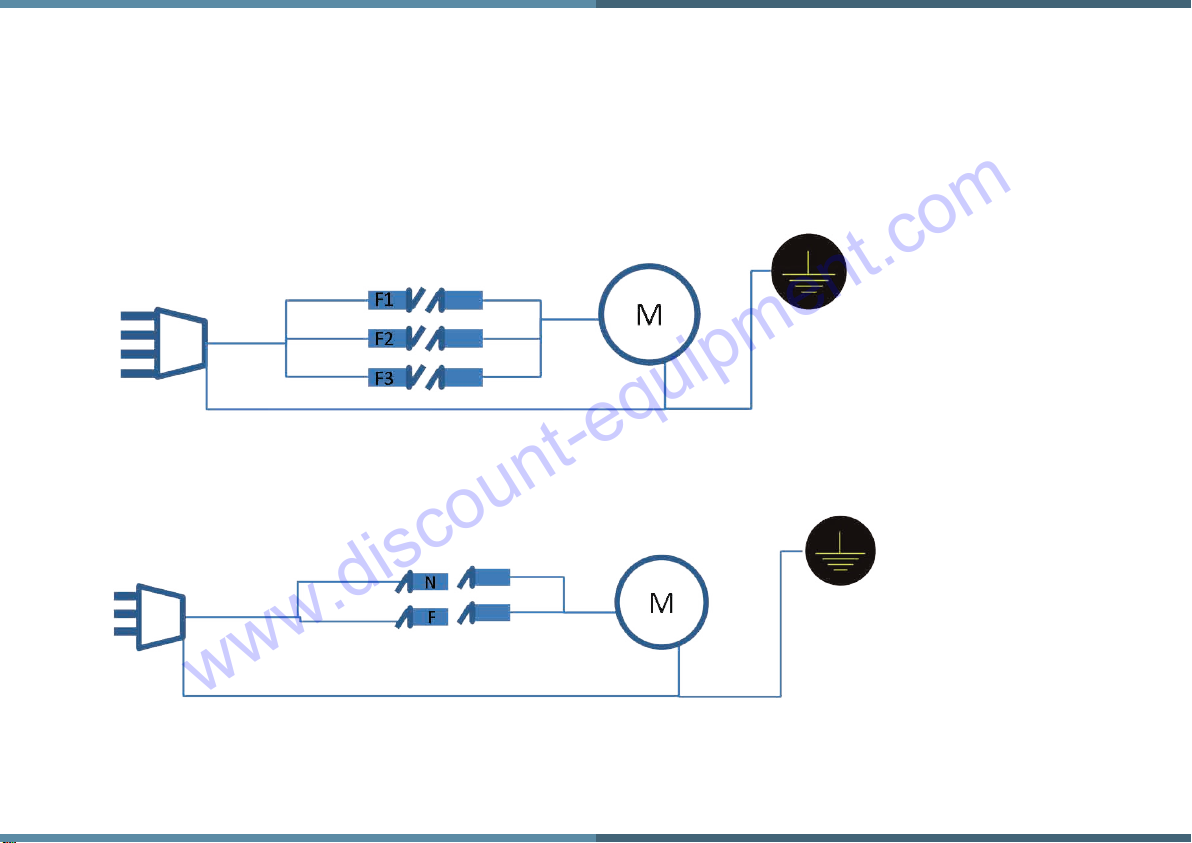

Wiring Diagram

Eletric Engine 220/380V

T3P + T

Ground point

exisng machine.

Ground point

exisng machine.

T2P + T

Eletric Engine 110/220V

www.discount-equipment.com

09

Equipment Operaon

Illustrave images and orientave informaon

1.

Make use of a measure (bucket)

to quantate the components.

2. Add the aggregate (gravel) in

the cement mixer on.

3. Make use of a measure (bucket)

to quantate the components.

4. Add the cement. 5. Finally add the sand and the

rest of the water.

6.

Let the concrete mixer rotate for 2,5

minutes before using the concrete.

• Posion the mixer on a flat, firm surface, so that facilitates the process of loading and unloading;

• Turn the switch that is aached to the engine enclosure;

• lng the drum to the desired angle. This movement should be done by turning the steering wheel and at the same me stepping on the pedal,

unlocking the swivel rocker;

• Set the desired angle and lock again, this movement occurs when the pedal is released;

• Load the drum and let blending;

• Once the mixture, lng the drum to dump all the dough;

• Throughout the cycle the drum must be spinning or whatever equipment is always on;

www.discount-equipment.com

10

Equipment Maintenance

Rack Gear Replacement

• Remove the damaged rack gear screws (07), and replace them

according to assembly recommendaons;

• Use two Ø 5 mm pins (C) to adjust the gap between teeth, necessary

for the perfect running of the pinion and rack gear;

• Adjust the alignment between the rack gear and pinion by reference

face “A”, (07) (42) compensang the difference with flat washers;

Assembly Procedures

Check List

1) Assemble the steering wheel (1) on the pinion sha (2), and fasten

with self-locking hexagonal nut 3/4’’ (3). Assemble the tow bar (4) on

chassi (5) with

hexagonal bol t 1/2"x 3.1/2 (6).

1

3

2

4

5

6

Chassi1

Chassi motor s upport 1

Whee l rubber solid 2

Tow ba r 1

Ste ering whe el1

Ste el yoke 1

Bearing support 1

Drum 1

Lowe r gui de 1

Larger gui de 1

Checklist - Concrete mixer

Motor support 2

Pull ey1

Top cover1

Le side of the box 1

Ri ght side of the box 1

Uppe r end of the box 1

Box door 1

Motor pulley1

Belt V – A 2

Checklist - Concrete mixer

www.discount-equipment.com

11

4) Posion the steel yoke (1) in 30° angle. Place the drum (2) on the steel

yoke (1) and ghtening the hexagonal bolt 7/8’’x2.1/4’’ (3).

2) Assemble the chassi motor support (1) on lower column (2), fasten with

the hexagonal bolt 3/8’’x 1’’ (3). Then, fasten the lower guide (4) and larger

guide (5) on the chassi motor support (1) with hexagonal bolt 3/8’’x 1’’ (3).

Fasten the motor support (6) on guides with hexagonal bolt 3/8’’x 2’’ (7).

3) Assemble the steel yoke (1) on reducer (2) with hexagonal bolt

3/8’’x4.1/2’’ (3). Assemble the bearing support (4) on the steel yoke (1) and

fasten on the lower column (5) with bolt 3/8’’x 3.1/2’’ (6).

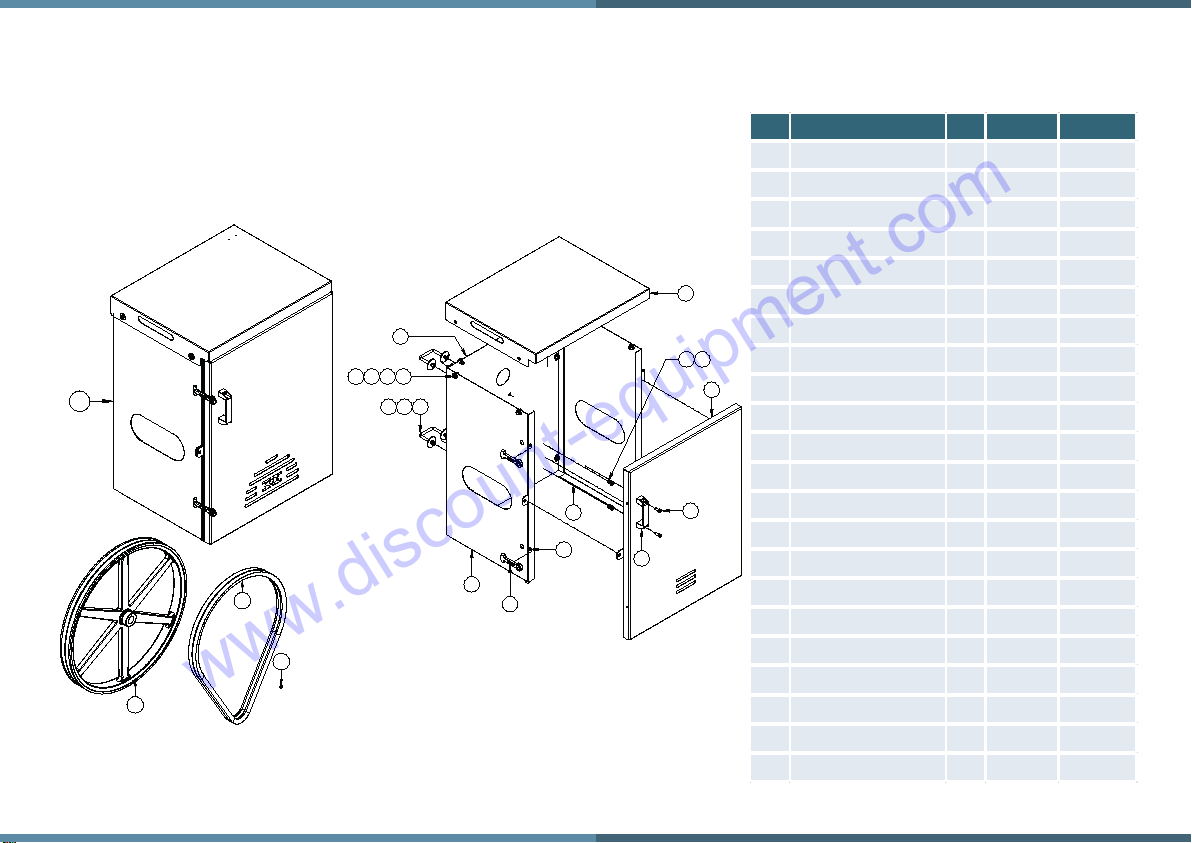

5) Assemble the motor box. Fix the upper end (1) in the lower column (2)

with U-bolt (3). Then assemble the sides (4) and the top cover (5), fasten

with hexagonal bolt 5/16”x3/4” (6). Assemble the door (7).

1

3

2

4

65

7

1

3

2

4

6

5

3

1

2

1

2

3

4

6

7

5

www.discount-equipment.com

12

6) Fit pulley (1) on the pinion sha (2), securing with retaining ring E-20 (3)

and key 6x6x30.

7) Complete assembly.

Main Diferences

POS.CONCRETE MIXER 400L PROFESSIONAL 400L RENTAL

1 Flywheel PlateThicknes 4,75mm Thicknes 6,35mm

2Steering Wheel Lock Thicknes 3,75mm Thicknes 4,75mm

3 Differenal Painng BlueRed

4 Drum- Contour with Weld

5 Drum Corps Thicknes 1,90mm Thicknes 2,66mm

6 Steel Yoke - With Reinforcements

7Tagger - With Tagger

8Warranty 12 Months 18 Months

www.discount-equipment.com

13

Parts List

16

19

17

18

15

14

12

5

3

20

8910

7

1

2122

13

11

2

6

4

Motor Box

POS.DESCRIPTION QTY.CODE DRAWING

1 Door 1 32040079 3108152

2 Le Si de 1 32030035 3108151

3Right Si de 1 320300363108150

4Top Cover1 32420059 3108299

5Beam Rubber2 24030221 4122071

6 Stop Rubber2 24030222 4122072

7 Upper end 1 -3108373

8 Hex. Bol t 5/16”X3/4” 14 21010268-

9 Flat Wa s her 5/16” 28 21030252 -

10 Hex Nut 5/16” 14 21021052 -

11 Spring Was her 5/16” 14 21030112 -

12 Hex Nut 5/16” 2 21030252 -

13 Spring Was her 5/16” 2 21030112 -

14 Handle 1 24070164-

15 Hex. Bol t 5/16”X3/4” 2 21010523 -

16Motor Box 1 -3108372

17 Pull ey Ø450MM 1 291122063108301

18 V-Belt 2- -

19 Bolt 1/4“ X 1/4" 2 21010919 -

20 U-Bol t 3/8” 2 21012480 -

21 Flat Washer 3/8” 4 30100070 -

22 Hex Nut 3/8” UNC4 21021059 -

www.discount-equipment.com

14

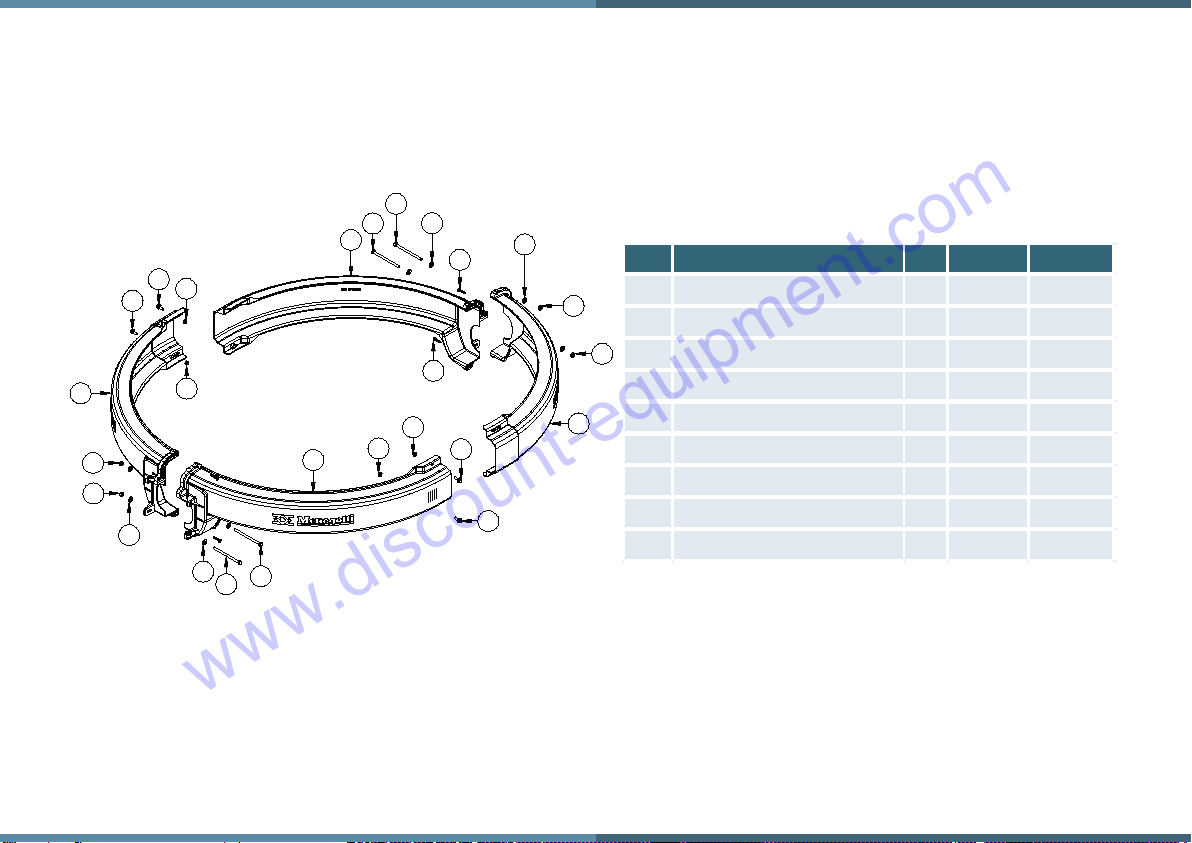

Steel Yoke

POS.DESCRIPTION QTY.CODE DRAWING

1 Flat Wa sher DN261 30100079 4122006

2Bearing 30210 1 22020608 -

3Bearing 30209 1 22020607 -

4Coer Pi n 3/16”X1.1/2" 1 21050106 -

Steel Yoke 400L Profes s i onal 1 324600563106047

Steel Yoke 400L Renta l 1 32460057 3106049

6 Central Axis 1 31020463 3114039

7Cover1 24110102 4122007

8 Pini on Sha 1 310200263114002

9 Pini on Z-11 1 31030007 4123001

10 Drum Was her1 21030232 4122008

11 Bearing 6204 2 22020202 -

12 Hex Bol t 7/8"x 2.1/4" 1 21013442 -

13 Rack Gea r Protec on 1 32030067 3119147

14 Elas c ring E-20 1 21060118 -

15 Castl e Nut 1” 1 21020959 -

16Elas c ring E-17 1 21060115 -

17 Hex Bol t 3/8"x 4.1/2" 2 21010250 -

18 Cover wi th Hole 1 24110168 4122183

19 Greas e fi ng 1/8” Strai ght1 24040101 -

20 Key 6X6X30MM 2 30160002 4122009

21 Flat Wa s her 3/8” 4 21030251 -

22 Spring Wa s her 3/8” 2 21030163-

23 Hex Nut 3/8” 2 21020117 -

5

1

2

3

4

5

6

7

8

9

10 11

11

14

15

16

20

19

22

23

21

17 13

12

18

24

20

www.discount-equipment.com

15

01

02

03

06

04

07

05

04

Drum

POS.DESCRIPTION QTY.CODE DRAWING

Drum 400L Profes s i onal 1 34600034 2107002

Drum 400L Renta l 1 34600038 2107004

2Segmented Crown Rack Gea r 631180004 2124011

3 Hex Bol t 3/8”X2” 621010241 -

4 Flat Was her 3/8” 12 21030230 -

5 Hex Nut 3/8” 621021059 -

6Drum Wa sher 6 30100070 4107003

7Sealing Wa s her 6 30100114 4107002

1

POS.DESCRIPTION JG.CODE DRAWING

2 a o 7 Rack Gea r Segmented

(segmented, washer, nut, bolt)

1 31180013 2124020

www.discount-equipment.com

16

4

4

5

5

6

6

6

8

8

1

1

2

2

3

3

4

4

6

2

5

5

3

3

2

7

7

POS.DESCRIPTION QTY.CODE DRAWING

1Screw M5x25mm 4 21011022 -

2 Hex Bolt M6x16mm 4 21012986 -

3 Hex Nut M64 21021208 -

4 Hex Nut 1/4" 4 21021004 -

5 Flat Was her 1/4" 8 21030214 -

6Hex Bol t 1/4“X4” 4 21010184 -

7Right - Rack Gea r Protec on 2 24110200 3119146

8 Le - Ra ck Gea r Protec on 2 24110199 3119145

10 Le - Pinion Protec on 1

Rack Gear Protecon

www.discount-equipment.com

17

Chassi

www.discount-equipment.com

18

POS.DESCRIPTION QTY.CODE DRAWING

1 Grease Fing 1/8” Strai ght2 24040101 -

2 Hex Nut 3/4" 1 21021011 -

3 Flat Wa s her 3/4" 1 21030225 -

Steering Wheel 400L Professional 1 31200018 3122048

Steering Wheel 400L Rental 1 31200021 3122089

5 Grease Fing1/8” 1 24040105 -

6 Retai ning Ri ng E-54 1 21060146 -

7Trac on Spring 1 210901163117038

8Sha wi th Gea r 1 31020414 4114005

9Reduci ng 1 31220021 3121004

10 Hex Bol t 3/8"x1" UNC10 21010266 -

11 Coer Pi n 1/8”X1.1/2” 2 21050103 -

12 Tow Bar 1 32490012 3110008

13 Hex Nut 1/2'' CH3/4'' 1 21020207 -

14 Flat Washer 1/2'' 2 21030250 -

15 Hex Nut 3/8" UNC8 21021059 -

16Externa l Protecon Cube 2 30130024 4122078

17 Hex Bol t 3/8"X 4" UNC2 21010124 -

18 Wa s her 3/8" 17 21030251 -

19 Hex Bol t 3/8” X 3.1/2” 1 21013826 -

20 Bearing support 1 31140055 3116001

21 Chassi Motor Suport 1 31020053 3125117

22 Castl e Nut 5/8 " 2 21020956 -

4

POS.DESCRIPTION QTY.CODE DRAWING

23 Fla t Washer 5/8 " 2 21030208 -

24 Greas e Fing 1/8 " Straight2 24040101 -

25 Hex Bol t M12x22mm 8 21015320 -

26Lower Gui de 1 32180017 3112012

27 Motor Suport 2 32060144 3112013

28 Larger Gui de 1 321800163112011

29 Hex Bol t 5/16”X2” 4 21010228 -

30 Hex Nut 5/16” 4 21021052 -

31 Spring Was her 5/16” 4 21030112 -

32 Fla t Washer 5/16” 4 21030252 -

33 Thick Fl a t Was her 3/8” 12 21030230 -

34 Pneumac Wheel Aro 13" 2 31260050 4115011

35 Hex Nut 3/8” 11 21020117 -

36 Spring Washer 3/8” 8 21030163-

37 Hex Bol t 3/8”X2” 4 21010241 -

38 Hex Bol t 1/2"x3.1/2 1 21010433 -

39 Plasc Cap 2 24110100 4122034

40 Tagger 400L Rental 1 31230007 3122097

41 Bearing Rol l er LM11749-LM11710 2 22020617 -

42 O-ring A30 2 24020659 -

43 Bearing Rol l er L45449-L45410 2 22020615 -

44 Rub Wheel2 31150023 3137014

Chassi 400L Profes s i onal 1- -

Chassi 400L Rental 1 32420006 2.105.059

45

www.discount-equipment.com

The condions and terms of this warranty are non transferable and go into

effect on the date of purchase of this equipment, proven by presentaon of

the sales invoice issued to the first end user. At the me of delivery of the

equipment, the customer must be provided with the informaon and

technical orientaons according to the contents of this manual.

Not, however, included in this warranty are defects arising from improper

use, negligence, imprudence or malpracce, nor are repairs or alteraons

to any part and/or component of the equipment. Also not included are: the

assembly of any sets of parts by technicians not from the Factory itself or

from an Authorized Technical Assistant, applicaon other than which it was

specified, mechanical or electrical overloading as well as lack of phase, use

in environments for which it was not designed, incorrect voltages and

frequencies, incorrect lubricaon, damage caused by accidents of any

nature, such as floods, gales, fire, landslides or due to transportaon.

Removal or any alteraon to the series numbers originally placed on the

product will render the warranty null, where the Sales invoice and Warran-

ty Cerficate must be presented in relaon to the equipment in queson.

This warranty is limited to the repair, replacement of parts or assembly of

parts in which, through examinaon by a Menego Authorized Technical

Assistant with prior authorizaon from the Factory, any manufacturing

defect will be verified. This repair or replacement will be performed by the

authorized Technical Assistant, where the purchaser will be responsible for

risks and expenses arising from transport to and from the authorized

Technical Assistant, and where labor and parts will not be charged

according to the terms of this warranty.

This warranty replaces any other warranty, implicit or explicit, as well as all

any obligaon or responsibility on the part of our company in relaon to

the above menoned product.

MENEGOTTI Post Sales Department and Technical Assistance.

Product Warranty

By the present CERTIFICATE provided from original purchaser, Menego

guarantees this product against manufacturing defects, for a period of 12

(twelve) months for Professional model, being: the first 3 (three) months of

legal guarantee, and the last 9 (nine) months a special warranty guaranteed

by Menego, and 18 (eighteen) months for Rental model, being: the first 3

(three) months of legal guarantee, and the last 15 (fieen) months a special

warranty guaranteed by Menego, counted from the invoice issue date of

the first final consumer. Not included in this equipment warranty are

components subject to wear through use such as: bearings, steel cable,

electrical plugs, gears and engine breaking.

This warranty includes the replacement of parts and repairs due to

manufacturing defects duly noted by the factory or Authorized Technical

Assistant. This warranty will be rendered null and void in the case of

damages arising from accidents, acts of nature, applicaon other than

which it was designed, connecon to improper electrical supply or subjec-

ted to extensive power fluctuaons, or, if opened by persons or workshops-

not authorized by Menego.

The consumer will be responsible for freight expenses for transporng the

product to the technical assistant or factory.

Menego has an ample network of Technical Assistants throughout the

country.

The equipment includes and electric motor and this warranty covers

internal defects in the motor originang from its manufacture. Defects not

covered in this warranty include: overloading due to lack of or excessive

phase, use of voltage outside that specified, broken or crushed casing due

to negligence during transporng /or storage, coupling or energizing

outside specificaons and general defects from improper use and/or

incorrect installaon.

In agreement with these terms,

Term of Warranty

Customer:

Model: Serial Number:

City: Date:

Customer Menego Authorized Service

19

www.discount-equipment.com

This manual suits for next models

1

Table of contents