CONTENT

Page.

1 Features and Benefits..........................................................................................................................................................01

2 - Safety.................................................................................................................................................................................02

2.1 - Safety - General................................................................................................................................................03

2.2 - Safety in preparation.........................................................................................................................................03

2.3 - Safety in operation............................................................................................................................................04

2.4 - Safety in maintenance. .....................................................................................................................................05

2.5 - Personal Safety. ...............................................................................................................................................05

2.6 - Transportation safety........................................................................................................................................06

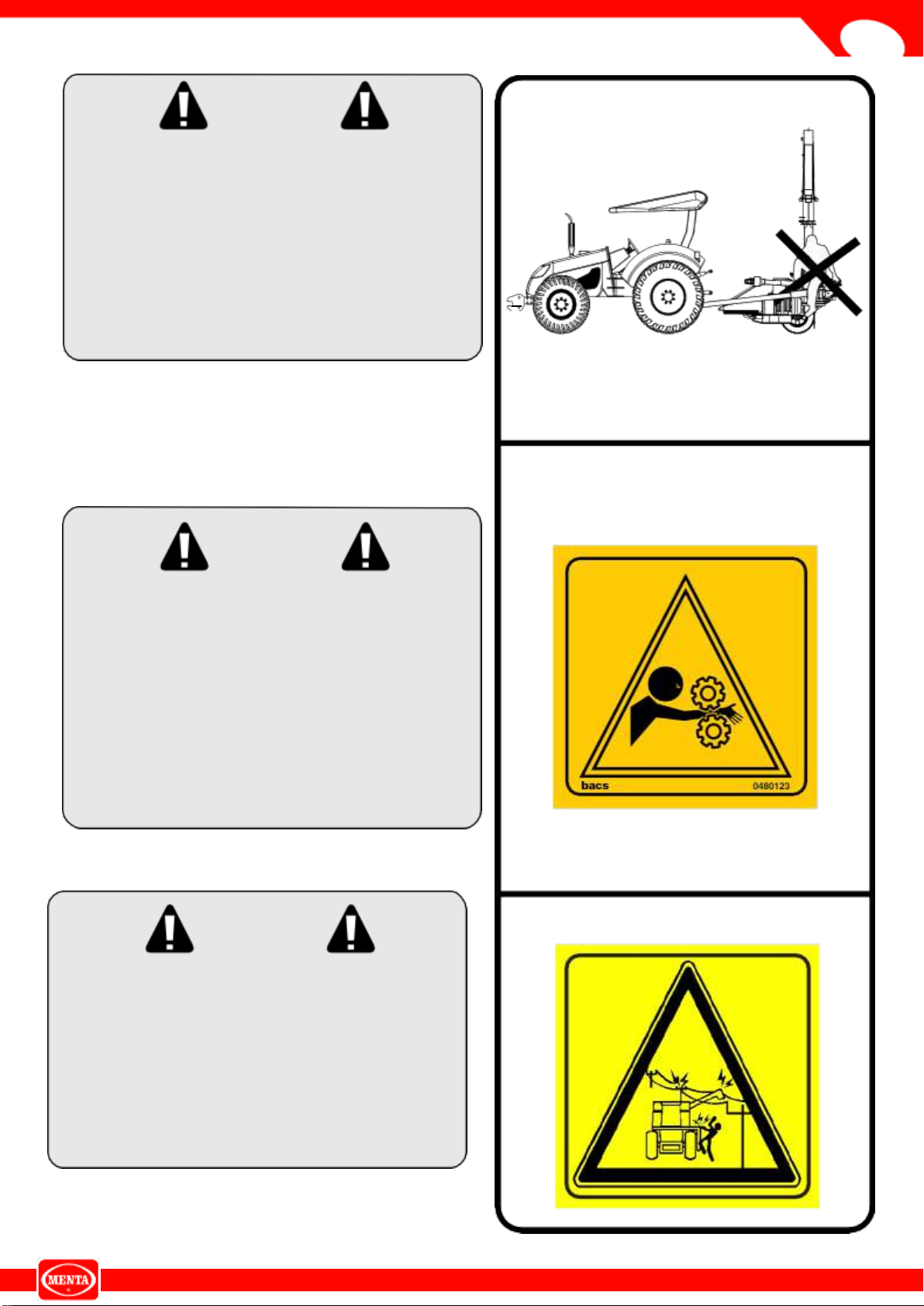

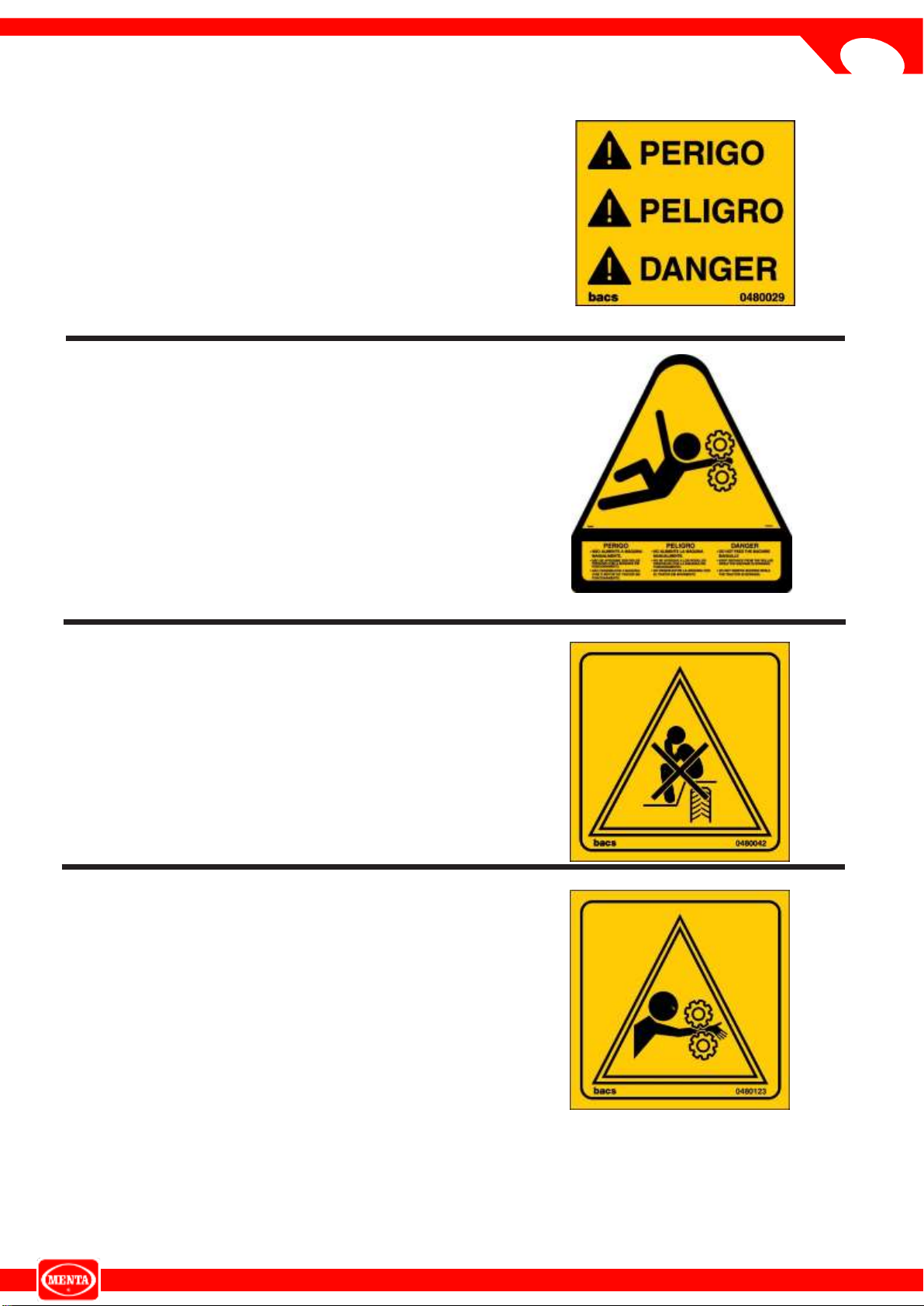

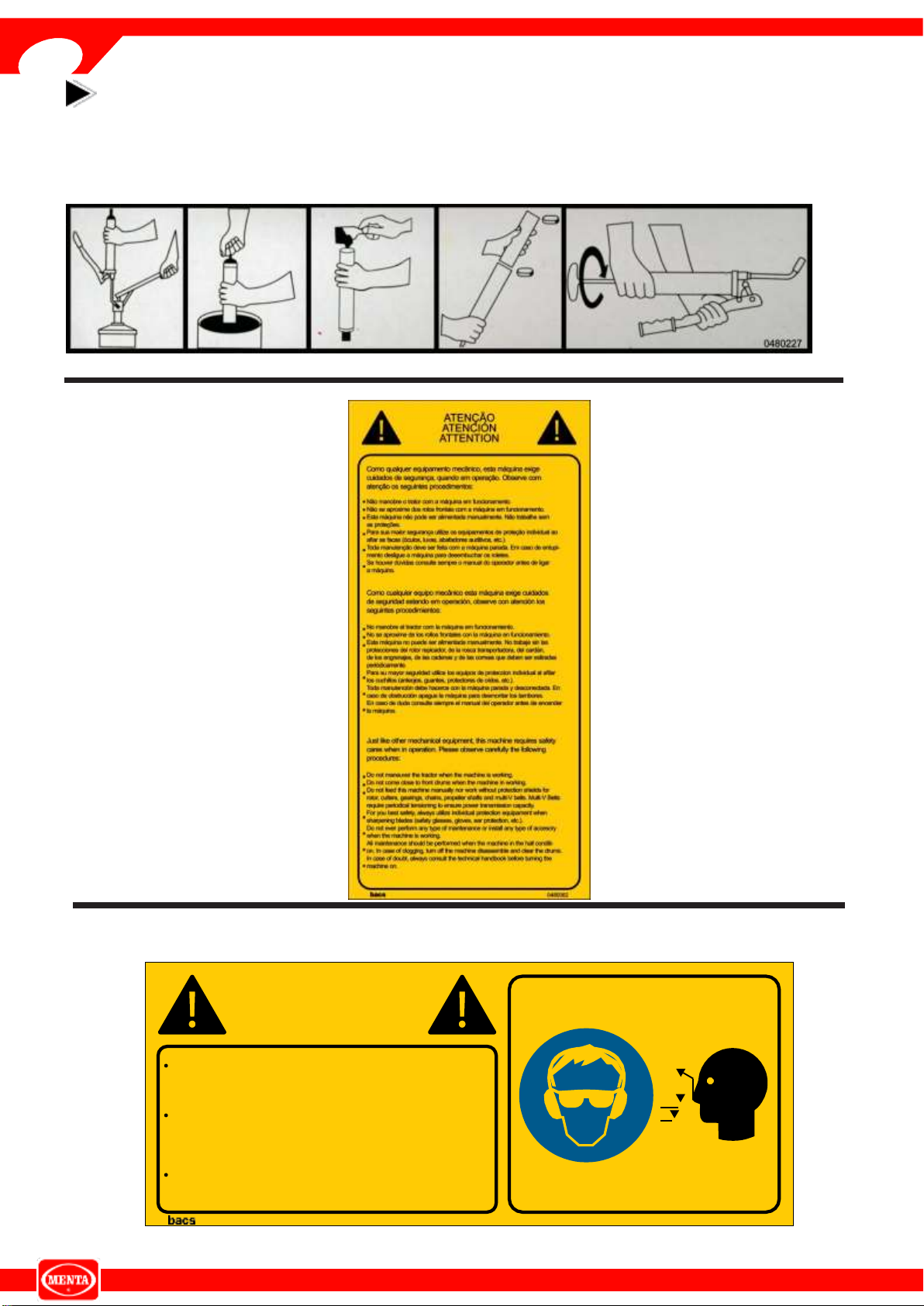

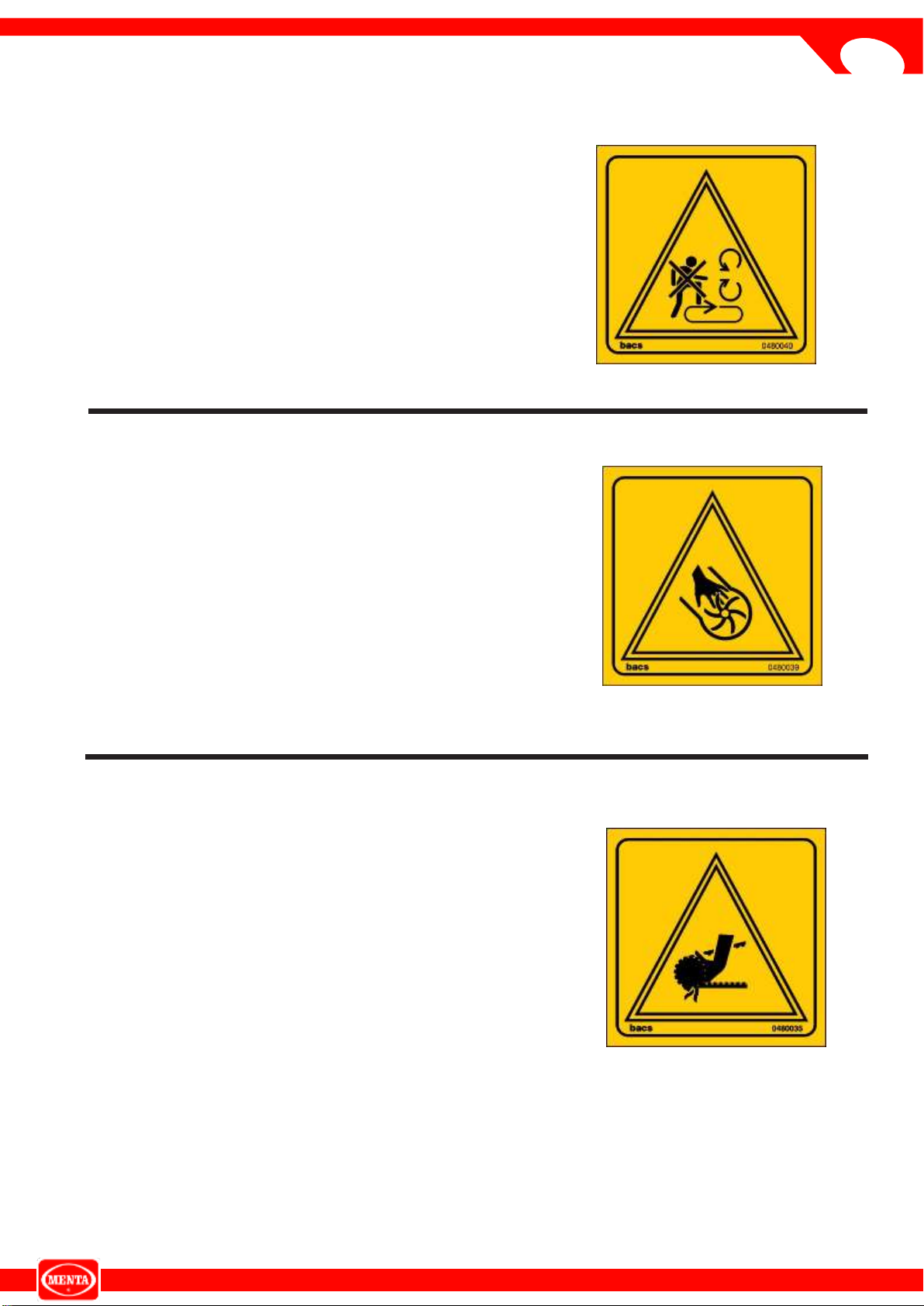

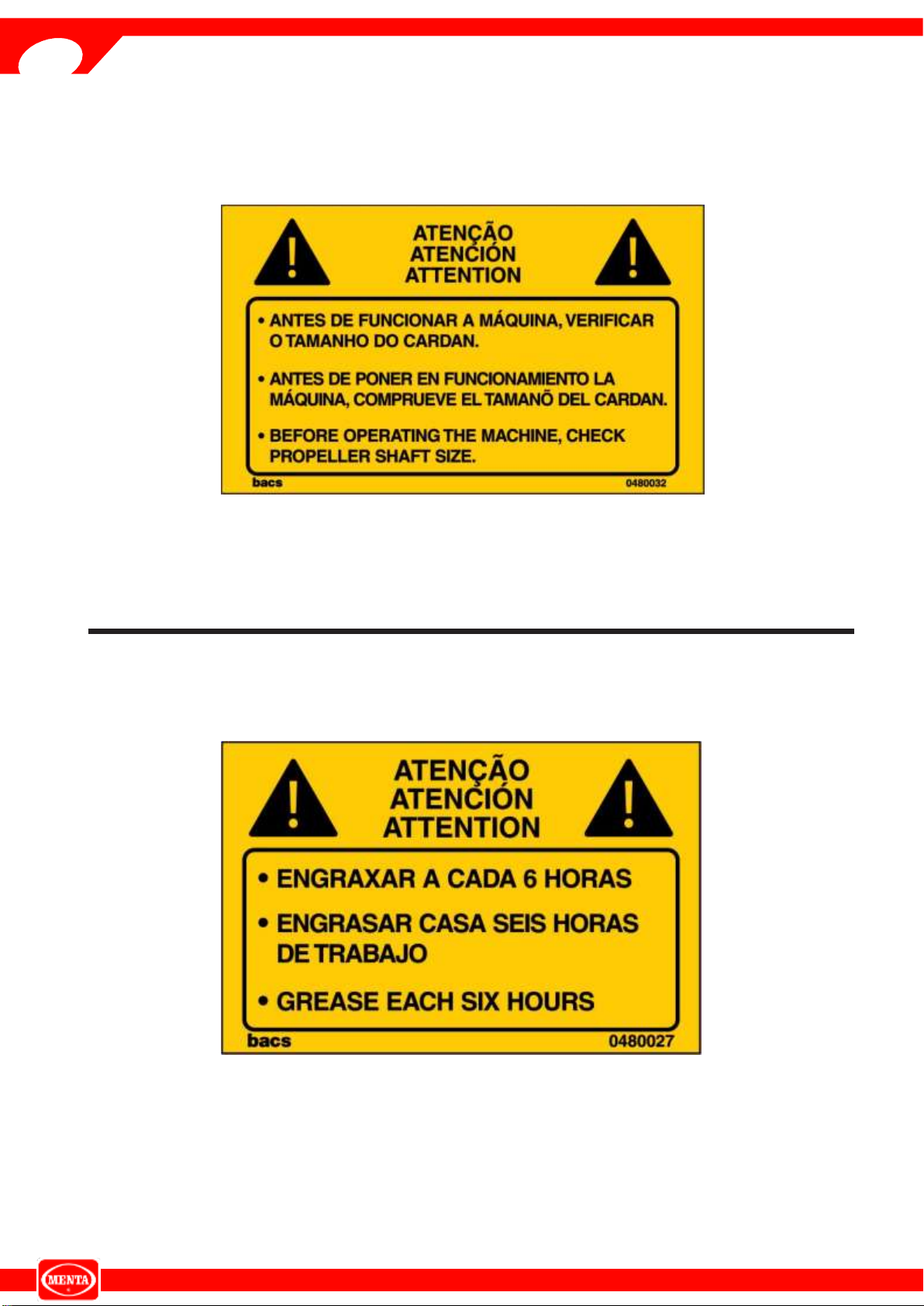

2.7 - Illustration of warning and safety stickers. ........................................................................................................09

2.8 - Illustration of the orientation and operational stickers.......................................................................................13

3 - Protections and Safety...................................................................................................................................................... 15

3.1 - Suggestions......................................................................................................................................................16

3.2 - Prohibitions.......................................................................................................................................................16

4 - Knowing the MENTA ATMF 3.2.........................................................................................................................................17

4.1 - Truck transport. ................................................................................................................................................18

4.2 - Loading and unloading.....................................................................................................................................18

4.3 - Intended Use. ...................................................................................................................................................19

4.4 - Tractor required................................................................................................................................................19

4.5 - Operation..........................................................................................................................................................19

4.6 - Optionals. .........................................................................................................................................................19

4.7 - Available version...............................................................................................................................................20

4.8 - Coupling to the tractor21

4.9 Levelling..............................................................................................................................................................22

4.9.1 - PTO gimbal....................................................................................................................................................23

5 Assembly .............................................................................................................................................................................26

5.1 - Outlet Nozzle Assembly. ..................................................................................................................................26

5.2 - Assembly of the Double Cylinder Hydraulic Cylinder........................................................................................ 28

5.3 - Connection of Double Jet Breaker Hydraulic Hoses.........................................................................................28

5.4 - Connection of Hydraulic Motor Hoses..............................................................................................................29

5.5 - Connecting the Hydraulic Hose Lift hoses........................................................................................................29

5.6 - Turning the Nozzle...........................................................................................................................................30

5.7 - Moving the Double Jet Breaker........................................................................................................................31

5.8 - Lowering the Exit Spout for Transport..............................................................................................................32

5.9 - Adjusting the Cut Variation...............................................................................................................................33

5.9.1 - Support Wheel...............................................................................................................................................34

5.9.2 - Tomb Regulator35

6 Operating instructions..........................................................................................................................................................36

6.1 - Important Recommendations Before You Begin36

6.2 - Turning off the machine....................................................................................................................................37

6.3 - Disconnecting hoses.........................................................................................................................................37

6.4 - Uncoupling the Tractor Machine 37

7 - Preventive Basic Maintenance...........................................................................................................................................38

7.1 - Chipping Rotor Knives Synchronization 39

7.2 - Lubrication points

......................................................................................................................................................................................................

....................................................................................... ..................................................................................... 40

7.3 - Changing the gearbox oil.................................................................................................................................. 42

7.4 - Care in the maintenance of the Hydraulic System............................................................................................ 45

7.5 - Tire Calibration. ................................................................................................................................................45

7.6 Drive chains........................................................................................................................................................ 46

8 CORRECTIVE MAINTENANCE .......................................................................................................................................... 47

8.1 - Sharpening the Main Rotor Knives...................................................................................................................47

8.2 - Sharpening and replacing the Counter Knife and Upper Counter Knife48

8.3 - Replacing the rotor knives49

8.4 - Replacing the Drive Box Drive Cardan and Transmission Case.......................................................................50

8.5 Replacing the Fuse............................................................................................................................................. 50

8.6 - Replacing the front rollers.................................................................................................................................51

8.7 - Sharpening and replacing the MENTA Knurled Knives. ...................................................................................55

8.8 - Using the Reversing Key. .................................................................................................................................56

9 - Technical Specifications and General Dimensions............................................................................................................57

10 - Abnormalities, Causes and Solutions..............................................................................................................................58

11 WARRANTY CERTIFICATE.............................................................................................................................................. 59