Mercoid SA1100 Series Installation and operating instructions

Series SA1100 Pressure Switches Weatherproof, Explosion-Proof

Specications - Installation and Operating Instructions

Bulletin IN-1100

Series SA1100 Pressure Switches Weatherproof, Explosion-Proof actuate one

or two single pole, double throw (SPDT) snap switches in response to increasing or

decreasing pressure of compatible gases or liquids. Three eld adjustable operating

ranges are available allowing setpoints up to 500 psig (35 kg/cm2). All models are

weather-proof and suitable for hazardous locations as detailed in the chart at lower

right. Read and understand these instructions completely before proceeding with

installation or operation.

SPECIFICATIONS

Temperature Limits: -30 to 180°F (-35° to 82°C) standard; ATEX and IECEx

compliant at ambient temperature: -4 to 146°F (-20 to 63.6°C).

Process Temperature: -4 to 146°F (-20 to 63.6°C).

Maximum Operating Pressure: 1200 psig (82.6 bar).

Maximum Pressure Without Bursting: 3000 psig (210 kg/cm2).

Process Connection: 1/4˝ or 1/2˝ female NPT.

Electrical Ratings: SPDT or DPDT contacts rated 15A @ 125/250/480 VAC

(V~), 1/8 HP @ 125 VAC (V~), 1/4 HP @ 250 VAC (V~), 1/2A @ 125 VDC

(V ) resistive, 1/4A @ 250 VDC (V ) resistive.

Wiring Connections: 3 screw type.

Conduit Connections: 3/4˝ female NPT.

Setpoint Adjustment: 7/16˝ hex nut, eld adjustable.

Housing Material: Die cast aluminum.

Finish: Textured gray polyurethane.

Connection Material: Aluminum, brass or 316 SS.

Diaphragm: Buna-N or uorocarbon.

Weight: 3-1/2 lbs (1.59 kg).

Enclosure Ratings: Weatherproof and Explosion-proof. Listed with UL and CSA

for Class I, Groups B, C and D; Class II Groups E, F and G. UL-NEMA 4X, CSA-

NEMA 4. ATEX Compliant 2813 II 2 G Ex d IIC T6 Gb -20 ≤ Tamb ≤63.6°C.

Process Temperature ≤63.6°C. Type Certicate No.:KEMA 04ATEX2186 X. IP56

without drain and IP 54 with drain. ATEX Standards: EN 60079-0: 2009; EN60079-

1: 2007. IECEx Certied: For Ex d IIC T6 Gb -20 ≤ Tamb ≤63.6°C Process

Temperature ≤63.6°C. IECEx Certicate of Conformity: IECEx DEK 11.0095 X;

IECEx Standards: IEC 60079-0: 2007; IEC 60079-1: 2007.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219-879-8000

Fax: 219-872-9057

www.dwyer-inst.com

e-mail: [email protected]

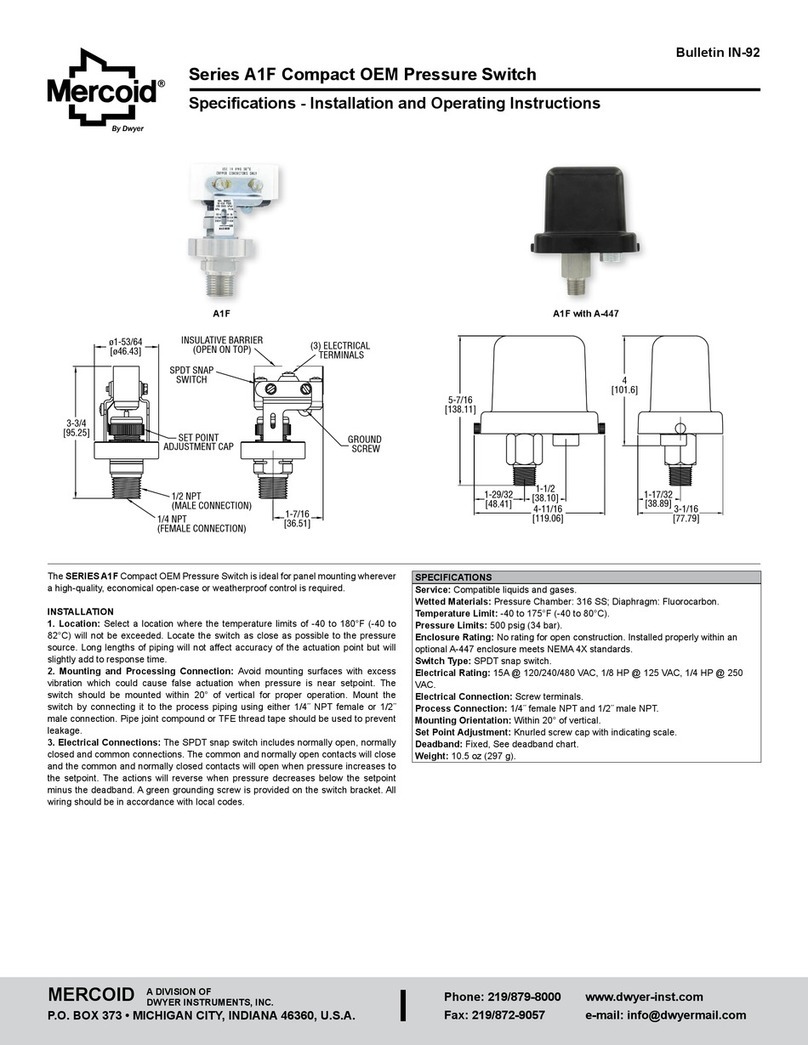

3-3/8

[84.58]

2-1/4

[57.17]

7-7/16

[188.25]

4-5/8

[116.89]

3-9/16

[91.19]

4 [102.04]

1-13/16

[45.88]

5-25/32

[147.07]

3-3/8

[84.91]

3-31/32

[100.62]

ADJUSTMENT

COVER

PROCESS

CONNECTION

OPTIONAL

BREA

THER

DRAIN

COVER

SET SCREW

SWITCH

COVER

3/4 NPT

CONDUIT CONNECTION

3/16 [4.8] DIA.

BRACKET MOUNTING

HOLES

Attention: Units without the “AT” sufx are not Directive 2014/34/EU (ATEX) compliant. These units are not intended for use in potentially hazardous atmospheres in the EU.

These units may be CE marked for other Directives of the EU.

MODEL CHART

Example SA11 13 E -A 4-K 1 SA1113E-A4-K1

Construction SA11 Series designator, weatherproof NEMA 4X, explosion-proof NEMA 7, 9

Adjustable

Pressure Ranges

11

12

13

10 to 150 psig (0.7 to 10 bar)

20 to 250 psig (1.4 to 17.2 bar)

30 to 500 psig (2.0 to 34.0 bar)

Circuit (Switch)

Options

E

HS

HG

Snap action switch rated 15A @ 125/250/480 VAC, 1/8 HP @ 125 VAC,

1/4 HP @ 250 VAC, 1/2 A @ 125 VDC resistive, 1/4 A @ 250 VDC resistive.

Hermetically sealed snap action switch rated 5 A@ 125/250 VAC, 5 A resistive @ 30 VDC*

Hermetically sealed snap action switch with gold contacts rated 1 A @ 125 VAC, 1 A resistive @ 30 VDC*

Pressure Chamber

Material

A

B

S

Aluminum

Brass

316 SS

Diaphragm

Material

4

5

Buna-N diaphragm and O-ring

Fluorocarbon diaphragm and O-ring

Circuit (Switch)

Type

K

L

SPDT

DPDT (not available with HS or HG switch options)

Process

Connection

1

2

1/4˝ female NPT

1/2˝ female NPT

Options AT

IEC

DR

ATEX certied construction

IEC IECEx certied construction

Housing with drain - allows condensate to be drained from inside enclosure (meets NEMA 3R instead of 4X)

*Options that do not have ATEX.

INSTALLATION

1. Location: Select a location where the temperature limits of -30 to 180°F (-35 to

82°C). For standard units and -4 to 146°F (-20 to 63.6°C) for ATEX and IECEx units

will not be exceeded. Locate the switch as close as possible to the pressure source

for best response. Long lengths of piping will not affect the accuracy of the actuation

point but will increase response time.

2. Mounting: Avoid mounting surfaces with excess vibration which could cause false

actuation when pressure is near setpoint. Attach switch with two 3/16” screws or

bolts (not included) through mounting bracket. The switch must be mounted within

20° of vertical for proper operation.

3. Pressure Connection: The pressure connection is standard 1/4˝ or 1/2˝ female

NPT. Pipe joint sealing material should be used to insure a pressure tight joint.

4. Electrical Connections: One or two SPDT snap switches are provided, each with

normally open contacts closing and normally closed contacts opening when

pressure increases beyond the high setpoint. The contacts reverse, returning to

their “normal” condition when pressure decreases below the low setpoint. Wire in

accordance with local electrical codes.

For convenience, two ground screws are provided. One is located inside the housing

and the other on the exterior, adjacent to the 3/4˝ NPT conduit connection. Internal

grounding terminal must be used for equipment grounding and the external terminal

is for a supplementary bonding connection where local codes or authorities permit or

requires such connection. Replace cover after wiring connections are complete.

ATEX AND IECEX INSTALLATION INSTRUCTIONS

Cable Connection

The cable entry device shall be an Ex d certied cable gland suitable for conditions of

use and correctly installed. For Tamb 63.6°C, cable gland rated ≥ 80°C shall be used.

Use cable rated 30°C higher than maximum Tamb.

Conduit Connection

An Ex d certied seal device such as a conduit seal with setting compound suitable for

conditions of use and correctly installed shall be provided immediately to the entrance

of the electrical housing. For Tamb 63.6°C, conduit seal and setting compound rated ≥

80°C shall be used. Use cable rated 30°C higher than maximum Tamb.

All wiring, conduit and enclosures must meet applicable codes for hazardous areas.

Conduits and enclosures must be properly sealed. For outdoor or other locations

where temperatures vary widely, precautions should be taken to prevent condensation

inside switch or enclosure. Electrical components must be kept dry at all times.

For units supplied with both internal ground and external bonding terminals, the ground

screw inside the housing must be used to ground the control. The external bonding

screw is for supplementary bonding

when allowed or allowed by local code. When external bonding conductor is required,

conductor must be wrapped a minimum of 180° about the external bonding screw.

Refer to Certicate No. IECEx 11.0095 X for conditions of safe use for IECEx compliant

units.

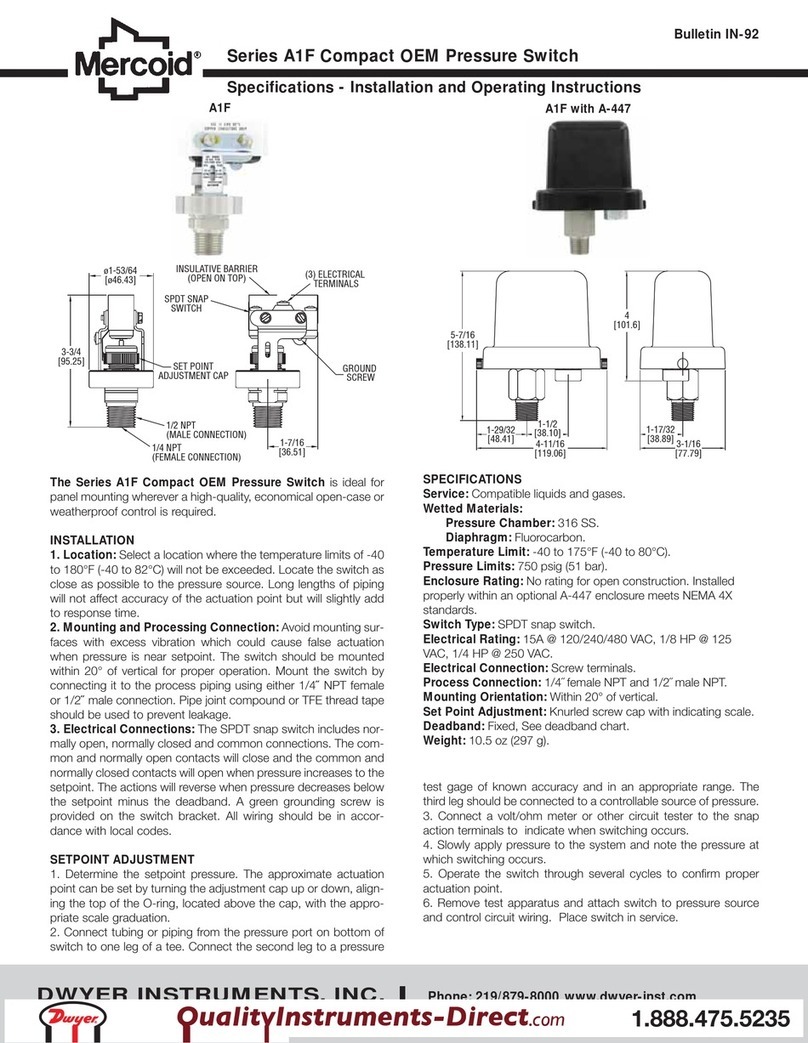

ADJUSTMENT

1. Determine the low and high setpoint pressures.

2. Connect tubing or piping from the pressure port on bottom to one leg of tee.

Connect the second leg to a pressure gage of known accuracy and in an appropriate

range. The third leg should be connected to a controllable source of pressure.

3. Connect a volt/ohm meter or other circuit tester to the snap switch terminals to

indicate when switching occurs.

4. Slowly apply pressure to the system and note the pressure at which switch

actuates. If adjustment is necessary, remove the clear plastic cover over the lower

half of the switch. It is held in place by four machine screws.

5. Adjust the low setpoint rst by using a 7/16˝ open end wrench on the left, range

spring adjustment nut. As viewed from above, turn nut clockwise to increase,

counter-clockwise to decrease the low setpoint (deactuation point).

6. Adjust the high setpoint by turning the deadband spring adjustment nut, on right,

clockwise to increase, counter-clockwise to decrease, the high setpoint (actuation

point).

7. Operate the switch through several pressure cycles to conrm proper setpoint

adjustment. Replace plastic cover.

MAINTENANCE

The ame path dimensions differ from EN 60079-1 requirements. Repairs to be by

Dwyer Instruments, Inc.

The moving parts of these switches need no maintenance or lubrication. The setpoint

is the only user adjustment. On models with optional drain tting, periodically rotate

the small captive screw from side to side several times to keep drain path clear. Units

in need of repair should be returned to the factory prepaid.

When cleaning exterior surfaces use a damp cloth to avoid

electrostatic charge.

WARNING

To prevent ignition of hazardous atmospheres, disconnect the

device from the supply circuit before opening. After disconnection,

delay 2 minutes before opening. Keep assemblies tightly closed when in use.

CAUTION

Deadband spring

adjustment nut

Range spring

adjustment nut

Limited Warranty: The Seller warrants all Dwyer Instruments and equipment to be free from defects in workmanship or material under normal use and service for a period of one year from date of

shipment. Liability under this warranty is limited to repair or replacement F.O.B. factory of any parts which prove to be defective within that time or repayment of the purchase price at the Seller’s option

provided the instruments have been returned, transportation prepaid, within one year from the date of purchase. All technical advice, recommendations and services are based on technical data and

information which the Seller believes to be reliable and are intended for use by persons having skill and knowledge of the business, at their own discretion. In no case is Seller liable beyond replacement

of equipment F.O.B. factory or the full purchase price. This warranty does not apply if the maximum ratings label is removed or if the instrument or equipment is abused, altered, used at ratings above the

maximum specied, or otherwise misused in any way.

THIS EXPRESS LIMITED WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER REPRESENTATIONS MADE BY ADVERTISEMENTS OR BY AGENTS AND ALL OTHER WARRANTIES, BOTH

EXPRESS AND IMPLIED. THERE ARE NO IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE FOR GOODS COVERED HEREUNDER.

Buyers Remedies: THE BUYER’S EXCLUSIVE AND SOLE REMEDY ON ACCOUNT OF OR IN RESPECT TO THE FURNISHING OF NONCONFORMING OR DEFECTIVE MATERIAL SHALL BE TO

SECURE REPLACEMENT THEREOF AS AFORESAID, THE SELLER SHALL NOT IN ANY EVENT BE LIABLE FOR THE COST OF ANY LABOR EXPENDED ON ANY SUCH MATERIAL OR FOR ANY

SPECIAL, DIRECT, INDIRECT, OR CONSEQUENTIAL DAMAGES TO ANYONE BY REASON OF THE FACT THAT IT SHALL HAVE BEEN NON-CONFORMING OR DEFECTIVE.

CLAMP

CLAMP PLATE

SCREW

LOCKWASHER

CONDUCTOR

Front view Side view detail

Printed in U.S.A. 11/20 FR# 442112-00 Rev. 8©Copyright 2020 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219-879-8000

Fax: 219-872-9057

www.dwyer-inst.com

e-mail: [email protected]

This manual suits for next models

2

Other Mercoid Switch manuals