Merlin Swing L 300 MGL Series User manual

This manual containsIMPORTANT SAFETY information

DO NOT PROCEED WITH THE INSTALLATION BEFORE READING THOROUGHLY

MGLX

Linear Actuator Gate Opener

(MGLSK / MGLDK / MGLSK-LV / MGLDK-LV)

Installation and Operating Instructions

Owners Copy: SAVE THESE INSTRUCTIONS for future reference

gomerlin.com.au

gomerlin.co.nz

Visit the Swing L 300 landing pages for:

• Product features

• Purchase compatible accessories

• Handy tips & how-to videos

• Digital copy of this manual

• Register your warranty

2

SAFETY INSTRUCTIONS

WARNING!

START BY READING THESE IMPORTANT SAFETY INSTRUCTIONS

ST

About this Manual

These instructions are the original operating instructions according to the AS/NZS 60335.1 in conjunction with AS/NZS 60335.2.103.

The instruction manual must be read carefully to understand important product information. Pay attention to the safety and warning

notices.

Keep the instructions in a safe place and make sure that they can be viewed by the user at all times. Keep the manual for future

reference and to make it available to all persons for inspection, service, maintenance and repair. After installation pass the complete

documentation to the owner.

After installation and programming, all users must be instructed in the function and operation of the gate opener for correct and safe

operation.

Before first use and based on the standard requirements the installer must inspect gates regarding their safe condition.

Before you begin the installation:

This product must be installed by a professional installer.

The installer must understand the following:

• The operation of the drive and potential hazards

• The operation of the manual emergency release mechanism

• The regular maintenance, inspection and care according to the Standards

• The installer must instruct other uses on the safe operation of the gate opener

Please read the operating instructions and especially the precautions. The following symbols are placed in front of instructions to avoid

personal injury or damage to property. Read these instructions carefully.

Warning Symbols

The general warning symbol indicates a danger that can lead to injuries or death. In the text section, the general warning symbols are

used as described below.

DANGER Symbol WARNING Symbol CAUTION Symbol ATTENTION Symbol

Indicates an imminent

hazardous situation which, if not

avoided, will result in death or

serious injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in minor or

moderate injury.

Indicates practices not

related to personal injury.

Intended Use

The gate opener is exclusively designed and tested for the operation of smooth-running residential gates.

The maximum permissible gate size and the maximum weight must not be exceeded. The gate must open and close smoothly by

hand. Use the opener on gates which comply with the applicable standards and guidelines. Regional conditions of wind loads must

be taken into account when using door or gate panels. Observe the manufacturer’s specifications regarding the combination of gate

and opener. Possible hazards within the meaning of AS/NZS 60335.1 in conjunction with AS/NZS 60335.2.103 are to be avoided

by designing and installing the gate according to the relevant instructions. This gate mechanism must be installed and operated in

accordance with the appropriate safety rules.

Improper Use

The construction of the gate opener is not designed for the operation of heavy-duty gates. It is not permitted on gates that travel with

incline/decline.

Any improper use of the gate opener could increase the risk of accidents. The manufacturer assumes no liability for such usage. With

this gate opener, automated gates must comply with the current, valid local standards, guidelines and regulations, AS/NZS 60335.1 in

conjunction with AS/NZS 60335.2.103.

Only Merlin genuine and approved accessories may be connected to the gate opener. Incorrect installation and/or failure to comply

with the following instructions may result in serious personal injury or damage to property.

DANGER WARNING CAUTION ATTENTION

• Failure to comply with the following instructions may result in serious personal injury or property damage.

• Read and follow all instructions carefully.

• The gate opener is designed and tested to offer safe service, provided it is installed and operated in strict accordance with the

instructions in this manual.

3

SAFETY INSTRUCTIONS

During operation, the gate should not under any circumstances obstruct public path ways and roads (public area). When using tools

and small parts to install or carry out repair work on a gate, exercise caution and do not wear rings, watches or loose clothing.

To avoid serious personal injury due to entrapments, remove any locking device fitted to the gate in order to prevent damage to the

gate.

Installation and wiring must be in compliance with your local building and electrical installation regulations. Power cables must only be

connected to a properly earthed supply.

Disconnect electric power to the system before installation, maintenance, repairs or removing covers. A dual pole isolating switch

must be provided to the mains power supply (permanently-wired installation) to guarantee all-pole disconnection (isolating switch or by

a separate fuse). The repairs and electrical installations may be performed only by an authorized electrician. Emergency Stop Button

must be installed for emergency case based on the risk assessment.

Any possible entrapment caused by the moving gate leaf(s) between gate & walls must be eliminated by respecting the given safety

distances in accordance with the AS/NZS 60335.1 in conjunction with AS/NZS 60335.2.103 and/or with safety devices (e.g. safe

edge).

Testing of the safety function of the drive system is recommended to be carried out at least once a month. Refer also to

manufacturers instruction of the gate system components.

After the installation a final test of the full function of the system and the safety devices must be made.

After installation and commissioning, all users must be instructed in the function and operation of the swing gate opener.

It is important to make sure that the gate always runs smoothly. Gates which stick or jam must be repaired immediately. Employ a

qualified technician to repair the gate, never attempt to repair it yourself. This device is not intended for use by persons (including

children) with restricted physical, sensory or mental abilities or lack of experience or knowledge, unless they are supervised by a

person responsible for their safety or have received instruction in how to use the device. If necessary, control equipment MUST be

mounted within sight of the gate and out of reach of children. Children should be supervised to ensure that they do not play with the

device. Do not allow children to operate push button(s) or remote(s). Misuse of the gate opener system can result in serious injury.

4

CONTENTS

1

2345

678

910 11

12

13

Manual

14

Quick

Reference

guide

15

SAFETY INSTRUCTIONS ........................................................................................................................................... 2-3

INTRODUCTION ....................................................................................................................................................... 5-10

Specifications .........................................................................................................................................................................................5

Sales Kit Inventory.............................................................................................................................................................................. 5-6

Tools Needed.........................................................................................................................................................................................7

Overview of Gate Operator.....................................................................................................................................................................7

Planning ........................................................................................................................................................................................... 8-10

INSTALLATION ....................................................................................................................................................... 11-14

Post Bracket Installation .......................................................................................................................................................................11

Gate Bracket Installation.......................................................................................................................................................................11

Hard Stops Installation .........................................................................................................................................................................12

Release Mechanism .............................................................................................................................................................................12

Install the Control Box ..........................................................................................................................................................................13

WIRING .................................................................................................................................................................... 14-16

Electrical Safety....................................................................................................................................................................................14

Opener 1 and Opener 2 Connection ....................................................................................................................................................14

Wiring Diagram.....................................................................................................................................................................................15

Install Entrapment Protection Devices ..................................................................................................................................................16

Connect a Battery Backup to the Control Box (Optional)......................................................................................................................16

PROGRAMMING ..................................................................................................................................................... 17-19

LCD Screen Menu................................................................................................................................................................................17

Programming Overview .................................................................................................................................................................. 17-18

Initial Setup...........................................................................................................................................................................................19

BASIC SETTINGS.................................................................................................................................................... 20-25

Limit and Force Learning......................................................................................................................................................................20

Remote Control Behaviour ...................................................................................................................................................................20

IR Behaviour.........................................................................................................................................................................................20

Input Command ...................................................................................................................................................................................21

Pedestrian Command...........................................................................................................................................................................21

Delay Motor 2 in Open and Close Direction.................................................................................................................................... 21-22

Timer To Close (TTC)............................................................................................................................................................................22

Reversal Time.......................................................................................................................................................................................23

E-Lock & Ram Blow Motor 1 for E-Lock ........................................................................................................................................ 23-24

Flashing Light - Pre-Flashing ................................................................................................................................................................24

Special Contact....................................................................................................................................................................................25

Soft & Hard Stop in Open and Close Direction.....................................................................................................................................25

Maintenance Counter ...........................................................................................................................................................................25

ADVANCED SETTINGS .......................................................................................................................................... 26-29

Password ............................................................................................................................................................................................26

Force Motors 1 & 2 Open and Close (Password Protected) ................................................................................................................27

Speed Motors 1 & 2 in Open and Close Direction (Password Protected) .............................................................................................28

Soft-Stop Speed in Open and Close Direction (Password Protected)...................................................................................................28

FACTORY RESET .........................................................................................................................................................29

WIRELESS PROGRAMMING ................................................................................................................................. 30-33

Remote Control Programming..............................................................................................................................................................30

MyQ Set-up.................................................................................................................................................................................... 31-33

OPERATION AND MAINTENANCE ....................................................................................................................... 34-37

Error Codes.................................................................................................................................................................................... 34-35

Accessories and Gate Hardware .................................................................................................................................................... 36-37

PROGRAMMING FLOW CHART............................................................................................................................ 38-42

CHAMBERLAIN LIMITED WARRANTY ................................................................................................................. 43-44

5

INTRODUCTION

Main AC Supply:…….…………………...........……….……………..220-240 Vac; 50/60 Hz

Motor Voltage: …………..…………………..........………………….24 Vdc

Input Power (single arm): .…………..…………………..........……50 W

Ambient Temperature Range: …………..…………………...........-20 ~ +55˚C

Maximum Weight for single Gate.........…………..……………… 300 kg/2 m, 250 kg/2.5 m, 200 kg/3 m

Maximum Width for single Gate ........…………..………………...1.8 m, 2.5 m

Maximum Pull Force:…………………………….............………….1500 N

Maximum Open Angle: …………..…………………..........………..120˚

Running Time: ................…………..…………………..........……….5 minutes

Ingress Protection:…………..…………….…..........……………….IP 44 (Opener MGLX), IP 65 (Control Box MGEB) Suitable for

outdoor installation

Transmitter Frequency: …………..…………………..........……….433.30 MHz/ 433.92 MHz/ 434.54 MHz

Memory registers:….....................................………………………64 handset codes (max. 4 keypad devices - 1 code each.)

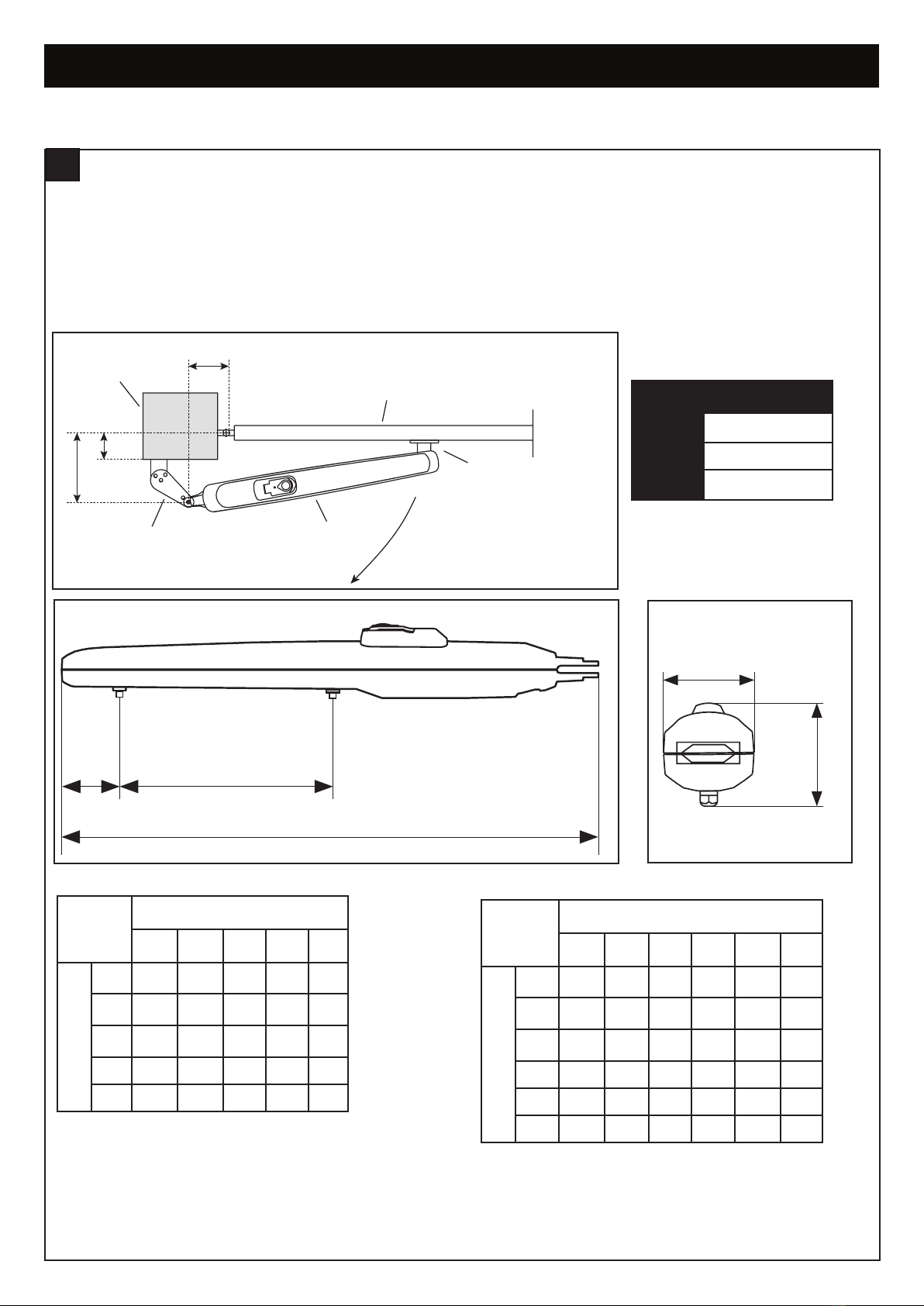

Dimensions

Gate Opener Height:…………………………….............…………..137 mm

Gate Opener Width:………..…………………….............………….835 mm

Gate Opener Depth:…………………………….............…………...95 mm

Gate Opener Weight:…………………………….............………….6 kg

SPECIFICATIONS – SWING L 300 – MGLSK / MGLDK / MGLSK-LV / MGLDK-LV

1

1

2345

678

910 11

12

13

Manual

14

Quick

Reference

guide

15

SALES KIT INVENTORY - MGLSK MAINS VOLTAGE 240V OR MGLSK-LV LOW VOLTAGE

24V SWING GATE OPENER LINEAR ACTUATOR SINGLE KIT

2

(1) Opener (MGLX)

(2) Control Box (MGEB)

(3) Instruction Manual

(4) 2 x Release Keys

(5) Fixed Post Bracket

(6) Live Post Bracket

(7) Hairpin Clip

(8) Clevis Pin

(9) 4 x M8x60 Masonry Anchors

(10) Gate Mounting Bracket

(11) 2 x M10x30 Bolts

(12) 13mm Bolt and Washer

(13) 2 x Four Button Remotes (E970M)

(14) Quick Reference Guide

(15) Gate Transformer 240-24V 120VA (MGTR3-120VA)

NOTE: Only for low voltage MGLSK-LV sales kit.

Your gate opener is packed in separate cartons. The Swing L 300 MGLSK or MGLSK-LV opener sales kit contains the opener, its

hardware, accessories and a transformer MGTR3-120VA (only for the MGLSK-LV sales kit).

6

INTRODUCTION

12345

678

9

10 11

12 13

Manual

14

Quick

Reference

guide

15

SALES KIT INVENTORY - MGLDK MAINS VOLTAGE 240V OR MGLDK-LV LOW VOLTAGE

24V SWING GATE OPENER LINEAR ACTUATOR DUAL KIT

2

(1) 2 x Opener (MGLX)

(2) Control Box (MGEB-LV)

(3) Instruction Manual

(4) 4 x Release Keys

(5) 2 x Fixed Post Bracket

(6) 2 x Live Post Bracket

(7) 2 x Hairpin Clip

(8) Clevis Pin

(9) 8 x M8x60 Masonry Anchors

(10) 2 x Gate Mounting Bracket

(11) 4 x M10x30 Bolts

(12) 2 x 13mm Bolt and Washer

(13) 2 x Four Button Remotes (E970M)

(14) Quick Reference Guide

(15) Gate Transformer 240-24V 120VA (MGTR3-120VA)

NOTE: Only for low voltage MGLDK-LV sales kit.

Your gate opener is packed in separate cartons. The Swing L 300 MGLDK or MGLDK-LV opener sales kit contains the opener, its

hardware, accessories and a transformer MGTR3-120VA (only for the MGLDK-LV sales kit).

7

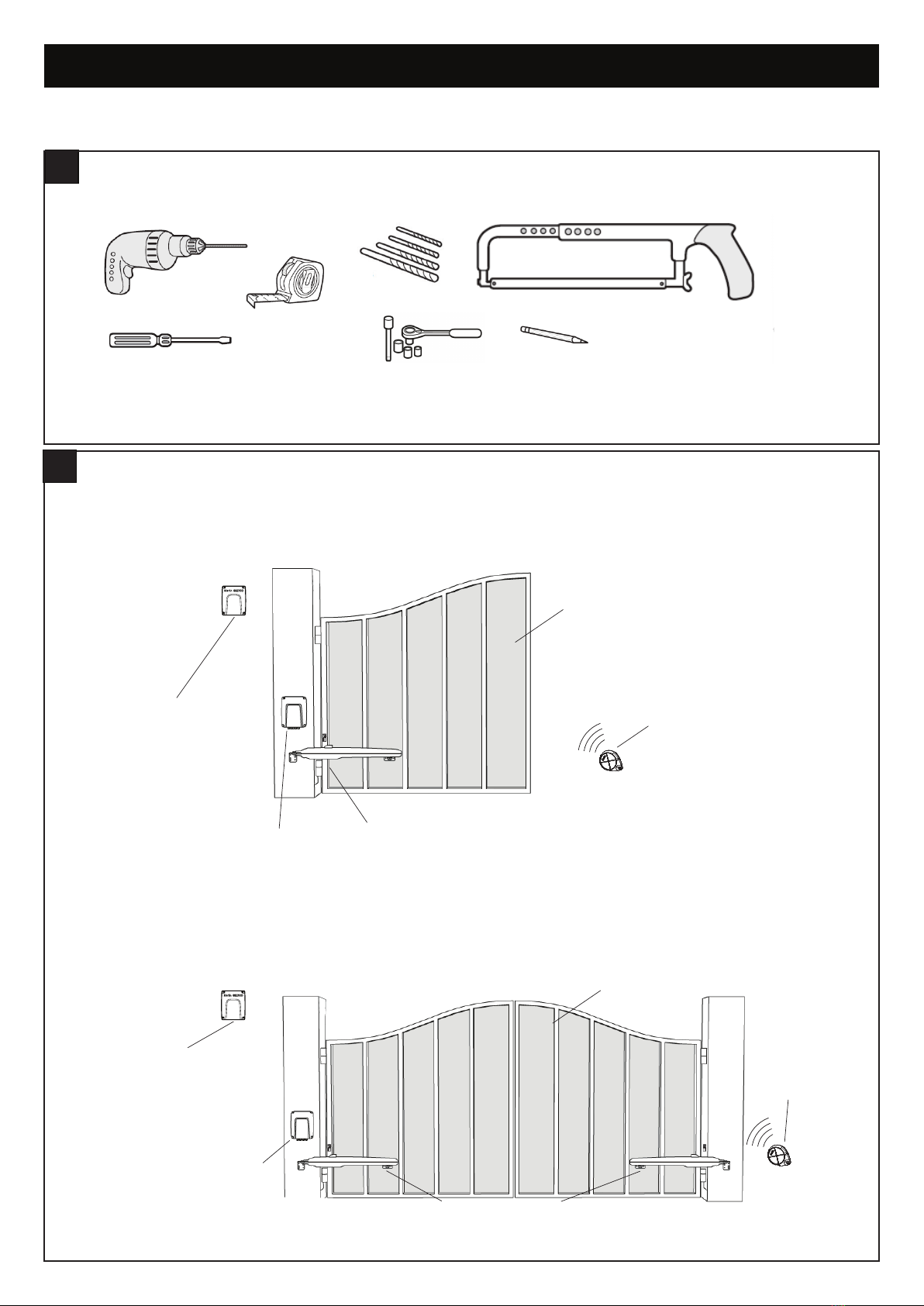

TOOLS NEEDED

3

INTRODUCTION

MGLSK – MAINS VOLTAGE 240V SWING GATE OPENER LINEAR ACTUATOR SINGLE KIT OR

MGLSK-LV – LOW VOLTAGE 24V SWING GATE OPENER LINEAR ACTUATOR SINGLE KIT

MGLDK – MAINS VOLTAGE 240V SWING GATE OPENER LINEAR ACTUATOR DUAL KIT OR

MGLDK-LV – LOW VOLTAGE 24V SWING GATE OPENER LINEAR ACTUATOR DUAL KIT

OVERVIEW OF THE GATE OPENER

4

Gate Opener

(MGLX)

Remote

Control

Single

Swing Gate

Control Box

(MGEB or MGEB-LV)

Control Box

(MGEB or

MGEB-LV) Gate Opener (MGLX)

Remote

Control

Double

Swing Gate

T

ransformer Box

mounted near 240V

power supply

(MGTR3-120VA)

NOTE: Only required

for MGLSK-LV low

voltage 24V sales kit

Transformer Box

mounted near 240V

power supply

(MGTR3-120VA)

NOTE: Only required

for MGLDK-LV

low voltage 24V

sales kit

8

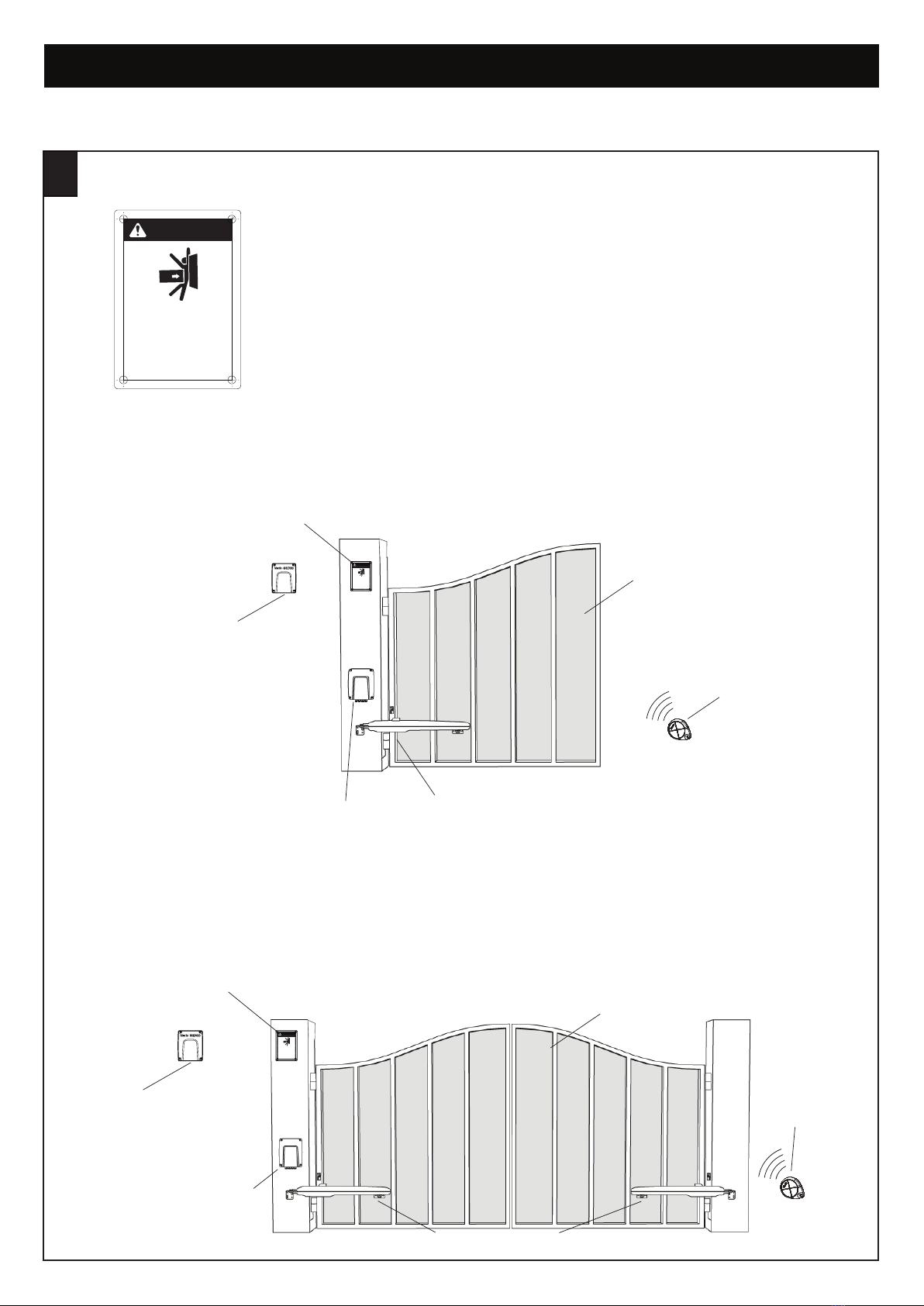

INTRODUCTION

Warning Label is provided with each sales kit (MGLSK, MGLDK,

MGLSK-LV & MGLDK-LV). The warning label must be placed on the

inside of the post.

INSTALLING THE WARNING LABELS

5

Persons are to keep clear! The gate is able to

be moved without prior warning.

Do not let children operate the gate or play in

the gate area.

Moving Gate Can Cause

Serious Injury Or Death

WARNING

132A3224-01

Gate Opener

(MGLX)

Remote

Control

Single

Swing Gate

Control Box

(MGEB or MGEB-LV)

Control Box

(MGEB or

MGEB-LV) Gate Opener (MGLX)

Remote

Control

Double

Swing Gate

Warning Label

placed within

the inside of

the post

Personsare to keep clear! The gate is able to

bemoved without prior warning.

Donot let children operate the gate or play in

thegate area.

Moving Gate Can Cause

Serious Injury Or Death

132A3224-01

WARNING

Warning Label

placed within

the inside of

the post

Personsare to keep clear! The gate is able to

bemoved without prior warning.

Donot let children operate the gate or play in

thegate area.

Moving Gate Can Cause

Serious Injury Or Death

132A3224-01

WARNING

Transformer Box

mounted near 240V

power supply

(MGTR3-120VA)

NOTE: Only required

for MGLDK-LV

low voltage 24V

sales kit

Transformer Box

mounted near 240V

power supply

(MGTR3-120VA)

NOTE: Only required

for MGLDK-LV

l

ow voltage 24V

sales kit

Gate Opener

(MGLX)

Remote

Control

Single

Swing Gate

Control Box

(MGEB or MGEB-LV)

Control Box

(MGEB or

MGEB-LV) Gate Opener (MGLX)

Remote

Control

Double

Swing Gate

Warning Label

placed within

the inside of

the post

Personsare to keep clear! The gate is able to

bemoved without prior warning.

Donot let children operate the gate or play in

thegate area.

Moving Gate Can Cause

Serious Injury Or Death

132A3224-01

WARNING

Warning Label

placed within

the inside of

the post

Personsare to keep clear! The gate is able to

bemoved without prior warning.

Donot let children operate the gate or play in

thegate area.

Moving Gate Can Cause

Serious Injury Or Death

132A3224-01

WARNING

Transformer Box

mounted near 240V

power supply

(MGTR3-120VA)

NOTE: Only required

for MGLDK-LV

low voltage 24V

sales kit

Transformer Box

mounted near 240V

power supply

(MGTR3-120VA)

NOTE: Only required

for MGLDK-LV

l

ow voltage 24V

sales kit

MGLSK – MAINS VOLTAGE 240V SWING GATE OPENER LINEAR ACTUATOR SINGLE KIT OR

MGLSK-LV – LOW VOLTAGE 24V SWING GATE OPENER LINEAR ACTUATOR SINGLE KIT

MGLDK – MAINS VOLTAGE 240V SWING GATE OPENER LINEAR ACTUATOR DUAL KIT OR

MGLDK-LV – LOW VOLTAGE 24V SWING GATE OPENER LINEAR ACTUATOR DUAL KIT

9

INTRODUCTION

Before installing the gate opener, ensure that the gate is opening smoothly. Determine the dimensions based on

the opening angle provided in Table 1 (below) to confirm the position where the post bracket will be mounted.

Ensure that all the required cables (power cable, accessory cables etc) are prepared and laid correctly.

NOTE: All crushing points must be secured by an entrapment protection according to AS/NZS 60335.1 in conjunction with

AS/NZS 60335.2.103.

PLANNING

6

Wind Load Rating for Swing Gate Operators

We do not have wind load ratings on our gate openers, as Chamberlain is not responsible for how gate installers design their gates.

Recommendations

• Do not use a solid leaf/panel gate in windy areas.

• Use a light weight picketed slide or swing gate to minimize the wind force.

• Try using a maglock or e-lock to keep the gate securely shut.

• It may be needed to hold the gate(s) open or close, in windy applications.

• When selecting an opener, be sure to select the correct opener for the size of gate.

• You may need to adjust the gate force margins in high wind applications.

Power Wiring

1. The 240V AC opener is supplied with a mains power plug pre-assembled ready for installation.This may require mains power

supply to be provided close to the opener by a licensed electrician.

2. The 24V AC opener will require a low-voltage power supply from the transformer box (MGTR3-120VA) to the gate opener.

3. The recommended cable sizes for the connection between the transformer box and the Low Voltage (LV) openers:

• Flexible 3 core cable:

• Less than 20m, minimum 1.5mm²

• 20m to 50m, minimum 2.5mm²

• 50m to 100m, minimum 4mm²

4. It is recommended that the Low Voltage (LV) power cable is run inside conduit to the opener as per local installation requirements.

Suitable cable glands must be used that provide sufficient cable restraint against a minimum of 30 N pull force.

Earthing Recommendations

Proper earthing of the opener is recommended to improve the radio range of transmitters and wireless accessories.

• The 240V AC unit is earthed using the standard AC power plug provided

• For the Low Voltage unit earthing can be achieved by running an earth wire back to the transformer box

• Alternatively connect the earth wire supplied with the LV unit to a suitable earth point on the operator base plate

• The use of an extension antenna kit SWG-ANT-EV may also be used to improve the radio range.

Additional Accessories

The vehicle loops allow the gate to stay open when vehicles are obstructing the gate path. Suggested for vehicles 4.2m or longer.

Vehicle loops are not required but are recommended. Before installing any accessories be sure to complete a site check to determine

the best device(s) the site needs.

10

INTRODUCTION

Gate

Post Bracket

Gate Bracket

Gate Post

B

A

c

Gate Operator

Dimensions of Gate Opener

2.0m 300kg

2.5m 250kg

3.0m 200kg

mm A Table 1

100 120 140 160 180

B 100 na 120° 110° 100° 95°

120 120° 110° 100° 95° 90°

140 110° 100° 95° 90° 80°

160 100° 95° 90° 80° 75°

180 95° 90° 80° 75° 70°

mm A Table 1

100 120 140 160 180 200

B 100 na 120° 120° 115° 110° 100°

120 120° 120° 115° 110° 100° 100°

140 120° 115° 110° 110° 100° 90°

160 115° 110° 110° 100° 90° 85°

180 110° 110° 110° 90° 85° 80°

200 100° 100° 100° 85° 80° 75°

MGLX with hardstop, using max travel 300mm. MGLX without hardstop, using max travel 350mm.

835mm

350mm

55mm Max. 350mm (w/o hardstops)

Max. 300mm with hardstops

95mm

137mm

figure 1

figure 2 figure 3

DETERMINE THE POSITION OF THE POST BRACKET

7

1. Determine the A and B dimension in base on the opening angle provided in Table 1 to confirm the position where the post bracket

will be mounted.

2. The max dimension for C, should be the B dimension minus the 60mm (refer to the tables below).

3. For optimal mechanical advantage A and B dimension shall be equal or close. Therefore limit the difference between A and B

within 40mm.

NOTE: Smaller A and B dimensions determine higher peripheral speed of the leaf. Higher differences between cause greater speed and

force variations during the gate opening and closing movement. It is always good practice use all available travel of the operator.

11

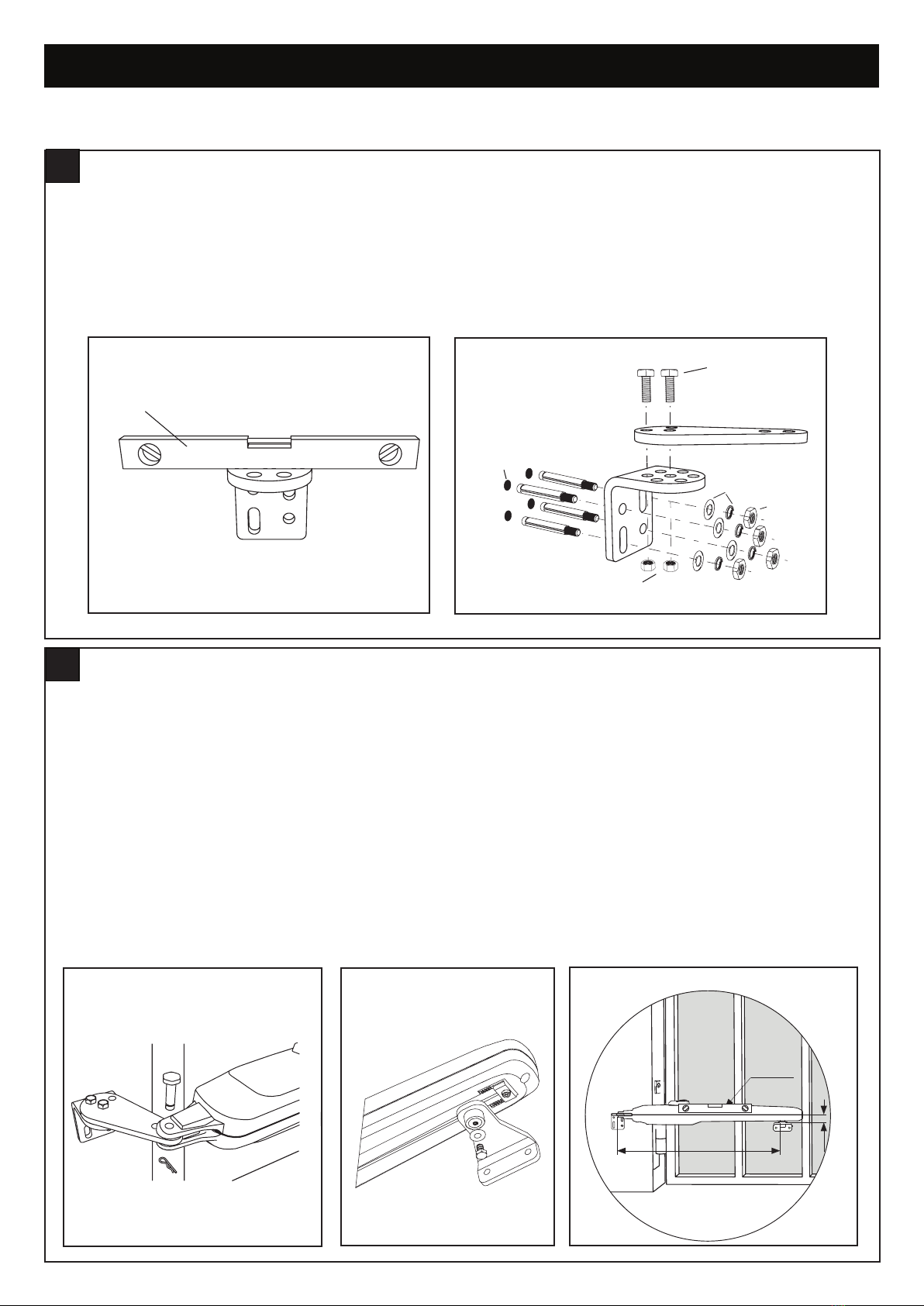

INSTALLATION

1. Using the fixed post bracket as a reference, mark and drill the holes for the post bracket.

2. Attach the post bracket to the post using appropriate fixings. Masonry fixings are supplied, if required. The correct fastening

material must be used based on existing installation (building / material substance). Please consult the gate manufacturer.

3. The slots on the post bracket allow for alignment. When the post bracket is level (see figure 1), tighten the nuts.

4. Attach the live post bracket to the fixed post bracket as per figure 2.

Level

M10x30 Screw

Non-slip nut

Drill hole

Washers

Nut

figure 1

1. Bring gate to the "closed“ position.

2. Attach the opener to the assembled post bracket using the clevis pin and secure with a hairpin clip (figure 1).

3. Assemble the assembled gate mounting bracket onto the arm using the fasteners & washers provided (figure 2).

4. Release the opener manual release with the release key. See section 11.

5. Position the gate mounting bracket as shown (figure 3).

6. Temporarily secure the gate bracket to the gate with a clamp.

7. Manually open and close the gate to the required positions. Ensure the opener does not bind. If the opening and closing positions

are OK, proceed to Step 8. If there is an issue with the desired opening position, change the gate bracket position or check if the

A and B dimensions of the post bracket were chosen correctly.

NOTE: Be sure that during the manual movement from close to open and vice versa, there is no obstruction or impact of

the arm against the leaf or pillar.

8. Close the gate and re-engage the release mechanism.

9. Connect the gate bracket securely to the gate in the chosen position with appropriate fasteners (not provided).

1115 mm

Spirit level

43.5 mm

730 mm with hardstops

750 mm w/o hardstops

Spirit level

1115 mm

Spirit level

43.5 mm

730 mm with hardstops

750 mm w/o hardstops

Spirit level

1115 mm

Spirit level

43.5 mm

730 mm with hardstops

750 mm w/o hardstops

Spirit level

figure 1 figure 3

figure 2

GATE BRACKET INSTALLATION

9

POST BRACKET INSTALLATION

8

Level

M10x30 Screw

Non-slip nut

Drill hole

Washers

Nut

figure 2

12

INSTALLATION

HARD STOPS INSTALLATION

10

1. Release the opener manual release with the release key. See section 11.

2. Using the internal opener hardstops to adjust the gate’s travelling distance, loosen each of the adjustment screws with a 5mm Allen

key.

3. Move the gate to the desired close position and reposition the hardstop to suit and secure the hardstop with a 5mm Allen key (not

supplied).

4. Move the gate to the open position and secure the hardstop in the desired position using the Allen key. Re-engage the release

mechanism.

5. If the internal opener hardstops are not used, it is mandatory to install external hardstops in the open and close positions.

NOTE: Combination of internal and external hardstops can be used.

5 mm

figure 1

DISENGAGEMENT OF THE MANUAL RELEASE

11

1. Remove the small front plastic cover from the opener.

2. Put the key into the keyhole and turn right.

3. Pull the lever down.

NOTE: To re-engage the opener, follow the procedure in reverse.

13

INSTALLATION

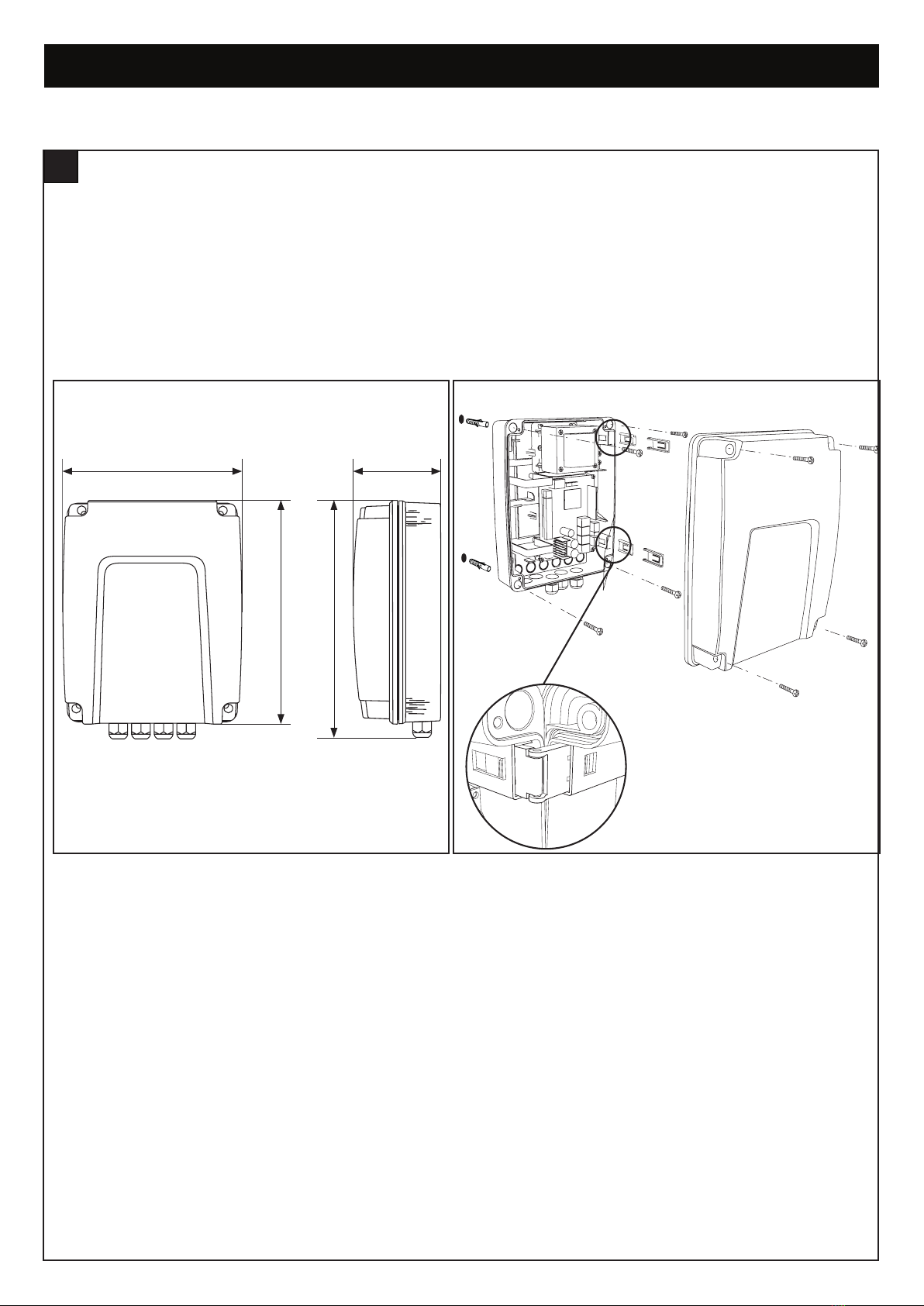

The control box must be installed at a safe location that enables the installer to have access at all times to the logic board without the

risk of the gates crushing or trapping.

It is advised that you must have full view of the gates when programming the logic board.

Install the control box in an appropriate and accessible position. The installation has to be done in accordance with local electrical

regulation.

INSTALL THE CONTROL BOX

12

8 8

225 mm 110 mm

280 mm

310 mm

Ø 6 mm drilling holes

8 8

225 mm 110 mm

280 mm

310 mm

Ø 6 mm drilling holes

figure 1 figure 2

14

WIRING

ELECTRICAL SAFETY

13

To reduce the risk of SEVERE INJURY or DEATH:

• BEFORE installing the power wiring or control stations be sure to follow all specifications and warnings. Failure to do so

may result in SEVERE INJURY to persons and/or damage to the opener.

• ALL electrical connections MUST be made by a licensed electrician.

• DO NOT install any wiring or attempt to run the opener without consulting the wiring diagram.

• ALL power wiring should be on a dedicated circuit and well protected.

• ALL power and control wiring MUST be run in separate conduit.

• Disconnect power at the fuse box BEFORE proceeding.

• ANY maintenance to the opener or in the area near the opener MUST NOT be performed until disconnecting the electrical

power (AC and battery). Upon completion of maintenance the area MUST be cleared and secured, at that time the

unit may be returned to service.

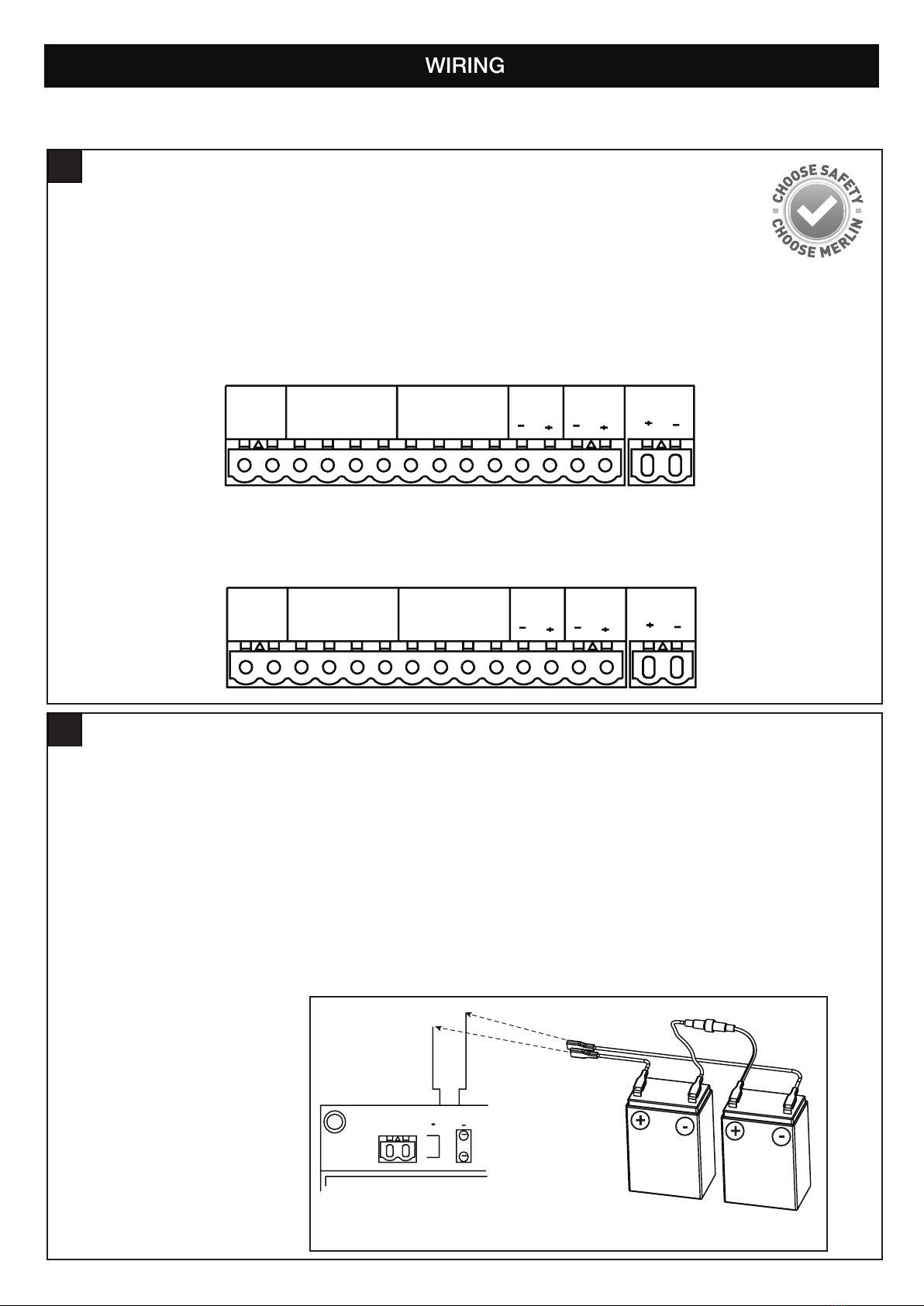

Motor1 Connection

NOTE: The opener wired to the MOTOR 1 terminal will always open first and close last.

1. Feed the motor1 cable through the selected cable gland.

2. Connect motor cables to the MOTOR1 terminals as follows: red cable to RED terminal, green cable to GRN terminal , white cable

to WHT terminal on control board.

Motor 2 Connection

NOTE: The opener wired to the MOTOR 2 terminal will always open last and close first.

1. Feed the motor 2 cable through the selected cable gland.

2. Connect motor cables to the MOTOR2 terminals as follows: red cable to RED terminal, green cable to GRN terminal , white cable

to WHT terminal on control board.

OPENER CONNECTION 1 AND 2

14

1. Isolate the power by turning power off at the isolation switch and/or circuit breaker.

2. Select a hole in bottom of the control box to be used for the incoming AC power.

3. Insert an IP rated gland into the bottom of the control box and tighten with nut.

4. Insert the 240V mains supply cables through the IP rated gland.

5. Connect the mains supply to the PCB.

6. Tighten the IP rated gland.

POWER WIRING

15

15

WIRING

12

10

13

55

5

5

9

10

12

10

0

0

0

0

4321

1

2

3

3 12

1

2

12

13

14

4

11

10

9

8

7

6

5

1

3

2

34 2 1

3

2

1

2 13

2 13

2

1

2

1

1

2

1

22

1

2

11

2

1

2

5

432

1

678910

2

1

11

1

2

11

1

1

IN1

IN1

IN2

IN2

IN3

IN3

WIRING DIAGRAM

16

16

WIRING

24 V BAT

POW

24 V

POWER BOARD

THE PROTECTOR SYSTEM™ (IR BEAMS) (OPTIONAL)

NOTE: Merlin strongly recommends that The Protector System™ (IR Beams) be installed on all gate openers.

Compatible Protector System™ (IR Beams) are 772ANZ and GPS15 Monitored Safety Beams.

The Protector System™ (IR Beams) can be configured to function differently when connected to IR1, IR2 or IR3

inputs.

1. Connect the Protector System™ (IR Beams) to IR1/GND or IR2/GND and or IR3/GND.

2. The IR Beams can be configured to monitor in the open or close direction or both (see section 22 IR Behaviour).

3. The IR Beams will automatically learn to the opener after they have been connected and are default to monitor the close direction.

4. If you need to remove the IRs, you will need to unlearn them from the opener. This is done by switching off the mains power off

and on again twice.

INSTALL ENTRAPMENT PROTECTION DEVICES

17

EDGE SENSOR

The Edge sensor can only be connected to the Edge inputs.

1. Remove the 8.2k resistor from the Edge inputs.

2. Connect the 8.2k compatible edge sensor to the Edge inputs.

EDGE

SE SE

IR SENSOR

GND IR3 IR2 IR1

COMMAND

GND IN3 IN2 IN1

FLA E-LK SPEC

EDGE

SE SE

IR SENSOR

GND IR3 IR2 IR1

COMMAND

GND IN3 IN2 IN1

FLA E-LK SPEC

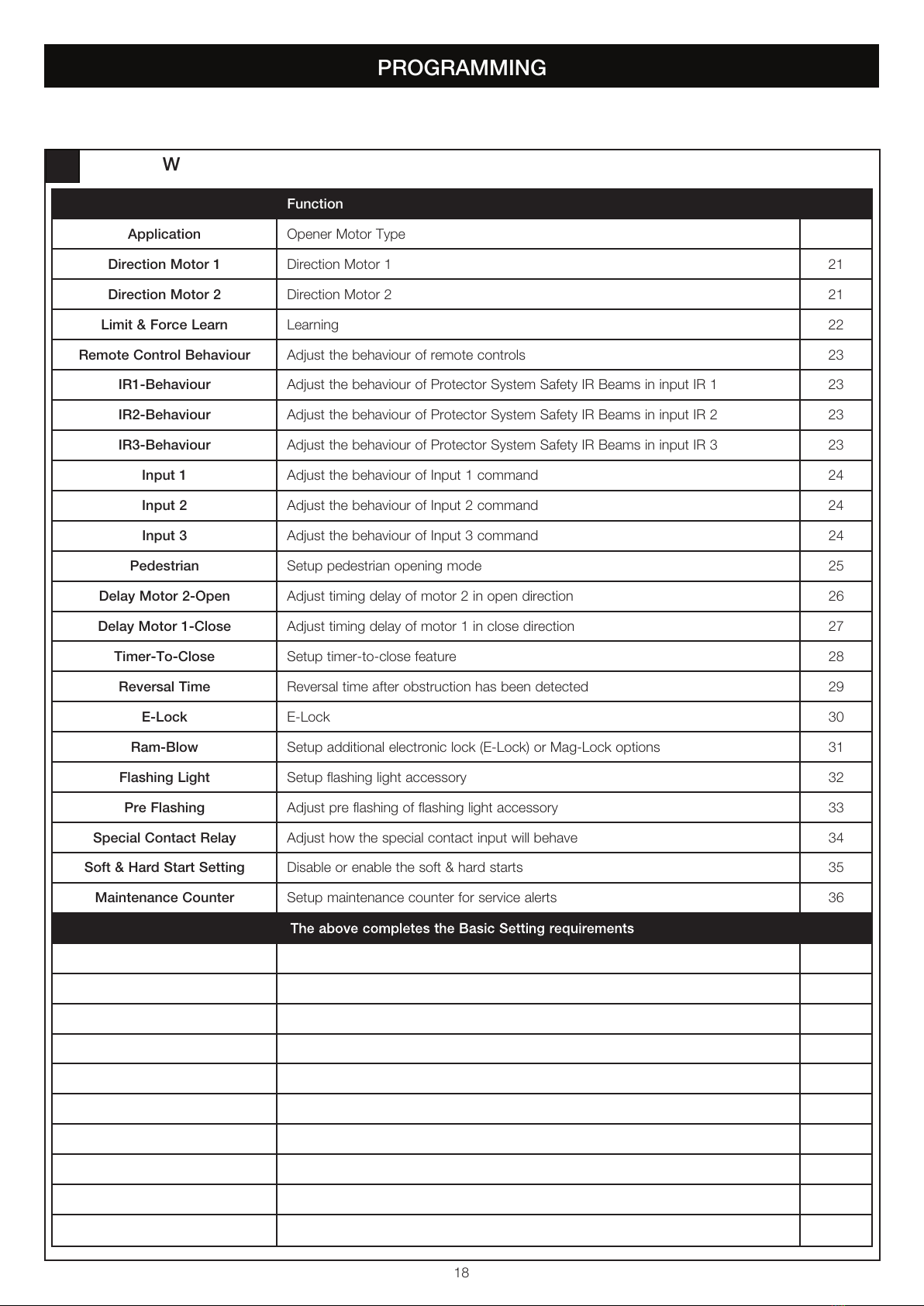

BATTERY BACKUP (OPTIONAL)

18

The batteries are charged in the circuit by the integrated transformer. Recommended items for a battery backup application (separate

accessory purchase) 2 x 12V 2.2Ah SLA batteries (model MGBBU).

1. Disconnect AC power to the opener.

2. Insert the battery power wires through the same hole as the AC power wires.

3. Connect the battery cable to the BATTERY terminals on the power board.

4. Place the batteries inside the opener.

5. Connect a jumper with an in-line fuse (10A) between the positive (+) terminal on one battery and the negative (-) terminal on the

other battery.

6. Connect the positive battery cable wire to the positive (+) terminal on the PCB.

7. Connect the negative battery cable wires to the negative (-) terminal on the PCB.

8. Reconnect AC power to the opener.

9. Place cover on the opener.

17

PROGRAMMING

Programming buttons function (4 buttons):

LCD SCREEN MENU

19

Button Function

SProgram / delete remote controls and

specific functions

P

Enter programming mode, select

function and save.

NOTE long press of P button will save

the setting and exit out to the menu

screen.

+/- Navigate through the menu and change

the value on display

The programming of the boards is divided in two steps:

1. Basic - including Initial Setup

2. Advanced - Password Protected Settings

Initial Set-up includes:

• Selection of motor type

• Motor direction

• Limits

• Forces.

After the Initial Set-up is complete, the opener will work as per default Basic Settings.

Initial Set-up is mandatory, if they are not completed, the opener will not work.

Initial Set-up is required before any further changes to Basic or Advanced settings can be made

OVERVIEW

20

18

PROGRAMMING

OVERVIEW

20

Legend Function Section

Application Opener Motor Type 21

Direction Motor 1 Direction Motor 1 21

Direction Motor 2 Direction Motor 2 21

Limit & Force Learn Learning 22

Remote Control Behaviour Adjust the behaviour of remote controls 23

IR1-Behaviour Adjust the behaviour of Protector System Safety IR Beams in input IR 1 23

IR2-Behaviour Adjust the behaviour of Protector System Safety IR Beams in input IR 2 23

IR3-Behaviour Adjust the behaviour of Protector System Safety IR Beams in input IR 3 23

Input 1 Adjust the behaviour of Input 1 command 24

Input 2 Adjust the behaviour of Input 2 command 24

Input 3 Adjust the behaviour of Input 3 command 24

Pedestrian Setup pedestrian opening mode 25

Delay Motor 2-Open Adjust timing delay of motor 2 in open direction 26

Delay Motor 1-Close Adjust timing delay of motor 1 in close direction 27

Timer-To-Close Setup timer-to-close feature 28

Reversal Time Reversal time after obstruction has been detected 29

E-Lock E-Lock 30

Ram-Blow Setup additional electronic lock (E-Lock) or Mag-Lock options 31

Flashing Light Setup flashing light accessory 32

Pre Flashing Adjust pre flashing of flashing light accessory 33

Special Contact Relay Adjust how the special contact input will behave 34

Soft & Hard Start Setting Disable or enable the soft & hard starts 35

Maintenance Counter Setup maintenance counter for service alerts 36

The above completes the Basic Setting requirements

Password Setup, enter and change password in order to enter into the Advance settings 37

Force Motor 1-Open (PW) Adjust the forces of motor 1 in open direction 38

Force Motor 1-Close (PW) Adjust the forces of motor 1 in close direction 38

Force Motor 2-Open (PW) Adjust the forces of motor 1 in open direction 38

Force Motor 2-Close (PW) Adjust the forces of motor 2 in close direction 38

Speed-Motor 1 & 2 Open (PW) Adjust the speed of motor 1 and 2 in open direction 39

Speed-Motor 1 & 2 Close (PW) Adjust the speed of motor 1 and 2 in close direction 40

Soft Stop Speed (PW) Adjust the soft speed, which is the remaining speed towards the end of the travel 41

Factory Reset Reset opener 42

Finish and Exit Complete and exit screen N/A

19

PROGRAMMING

INITIAL SETUP

21

SP

+-

LINEAR ARM

SINGLE

SP

+-

SP

+-

MAIN MENU

DIRECTION MOTOR1

PRESS & HOLD “+”

GATE OPENING?

YES “P”, NO “S”

SP

+-

MAIN MENU

DIRECTION MOTOR1

SP

+-

MAIN MENU

SELECT

APPLCATION

SP

+-

CYCLES: 000, 000

BEGIN SETUP

SP

+-

MAIN MENU

SELECT

APPLCATION

SP

+-

MAIN MENU

SELECT

APPLCATION

SP

+-

MAIN MENU

LIMITED & FORCE

LEARN

SP

+-

MAIN MENU

SELECT

APPLCATION

SP

+-

MAIN MENU

LIMITED & FORCE

LEARN

SP

+-

CYCLES 000,000

STANDBY

GATE CLOSED

figure 1

figure 2

figure 3

Energise the opener. Release the opener manual

release with the key, and move the gate(s) to a mid

open position. Re-engage the manual release.

The LCD screen will display the Cycle count.

1. Press and hold the “P” button for approximately 5

seconds to enter into the Main Menu. MAIN

MENU SELECT APPLICATION will be displayed

on the LCD.

2. Press the “P” button once to enter this Menu

option.

3. Use the “+” or “-” to scroll though the motor

application options. When “LINEAR ARM SINGLE

OR LINEAR ARM DUAL” is shown, press the “P”

button to select. The screen will change to show

MAIN MENU SELECT APPLICATION.

4. Press the “+” button once to scroll to the next

menu option. “MAIN MENU DIRECTION

MOTOR1” will be displayed on the LCD.

5. Press the “P” button to select. The screen will

change to show PRESS & HOLD “+” GATE

OPENING? YES “P”, NO “S”.

6. Press and hold “+”. The gate will start to move.

a) If it moves in the OPEN direction, press “P” to

confirm”. The screen will change to show MAIN

MENU DIRECTION MOTOR!

b) If the gate moves in the CLOSE direction, press

“S” to confirm. The screen will change to

EXECUTE MOTOR DIRECTION CHANGE.

Press “P” to confirm.

Once the direction has been confirmed, the

screen will change to MAIN MENU DIRECTION

MOTOR. If there is a second slide gate opener to

be setup, press the ”+” button to scroll to the

next menu option “MAIN MENU DIRECTION

MOTOR2 and follow the steps 5 and 6.

7. Press the “+” button once to scroll to the next

menu option. “MAIN MENU LIMIT&FORCE

LEARN” will be displayed on the LCD.

8. Press the “P” button to select.

The gate will start

to move.

The screen will change and

LIMIT&FORCE LEARN will flash on the screen.

9. Once complete, the gate will stop moving and the

screen will change to CYCLES: 000,000

STANDBY GATE CLOSED.

Initial setup is now complete. The opener will now

operate using default Basic Settings.

NOTE: If the LIMIT&FORCE LEARN setup needs

to be stopped, press the “S” button. The Screen

will display LIMIT&FORCE LEARN INTERRUPTED.

After 5 seconds, the screen will display

LIMIT&FORCE LEARN. Repeat step 8 to complete

basic setup.

20

BASIC SETTINGS

Within the Basic Setting, navigate through the menu screen until you find “MAIN MENU

IR1-BEHAVIOUR”.

1. Press the “P” button to enter this setting (figure 1).

2. Press the “+” or “-“ buttons to navigate through the options.

3. You can select the following options:

• IR1-CLOSE DIR

• IR1-OPEN DIR

• IR1-OPEN & CLOSE DIR

• IR1-CLOSE DIR + IMMEDIATE CLOSE

4. To confirm the setting, press the “P” button to save and return to the

main menu screen.

NOTE: The above process is the same for IR2 & IR3 Behaviour.

SP

+-

MAIN MENU

IR1-BEHAVIOUR

NOTE: If Timer To Close (TTC) is activated,

during the pause time, when released after 2

seconds it will close immediately.

figure 1

REMOTE CONTROL BEHAVIOUR

23

Within the Advance Setting, navigate through the menu screen until you find “MAIN MENU

REMOTE CONTROL BEHAVIOUR”.

1. Press the “P” button to enter this setting.

2. Press the “+” or “-“ buttons to navigate through the options.

3. You can select the following options:

• OPEN-CLOSE-OPEN

• OPEN-STOP-CLOSE-STOP

• OPEN-STOP-CLOSE-OPEN

• OPEN ONLY

4. To confirm the setting, press the “P” button to save and return to the main menu

screen.

SP

+-

MAIN MENU

REMOTE CONTROL

BEHAVIOUR

figure 1

LIMIT AND FORCE LEARNING

22

Within the Basic Setting, navigate through the menu screen

until you find “MAIN MENU LIMIT & FORCE LEARN”.

1. Press the “P” button to enter this setting (figure1).

2. The menu screen will begin flashing “LIMIT & FORCE

LEARN” while this sequence is in progress and

the

gate will start to move.

3. Three seconds after successfully completing the

“LIMIT & FORCE LEARN” setup, the display will return

to the main menu in standby mode.

Note: If the LIMIT & FORCE LEARN setup needs to be

stopped, press “S” button. The screen will display

“LIMIT & FORCE LEARN INTERRUPTED” (figure 2).

After 5 seconds, the screen will display “LIMIT & FORCE

LEARN”.

SP

+-

MAIN MENU

LIMIT & FORCE LEARN

SP

+-

LIMIT & FORCE LEARN

INTERRUPTED

SP

+-

LIMIT & FORCE LEARN

SP

+-

MAIN MENU

SELECT

APPLCATION

SP

+-

MAIN MENU

LIMITED & FORCE

LEARN

SP

+-

MAIN MENU

LIMITED & FORCE

LEARN

SP

+-

CYCLES 000,000

STANDBY

GATE CLOSED

figure 1 figure 2

figure 3

IR BEHAVIOUR

24

This manual suits for next models

4

Table of contents

Other Merlin Gate Opener manuals

Merlin

Merlin Swing L300 User manual

Merlin

Merlin Slide 600 User manual

Merlin

Merlin G930 User manual

Merlin

Merlin XLR8 MGS524 User manual

Merlin

Merlin G703 User manual

Merlin

Merlin G915D User manual

Merlin

Merlin G900 User manual

Merlin

Merlin G940 User manual

Merlin

Merlin G950 User manual

Merlin

Merlin G950 User manual

Merlin

Merlin G740A User manual

Merlin

Merlin G950 User manual

Merlin

Merlin prolift 430R User manual

Merlin

Merlin G930 User manual

Merlin

Merlin Swing A 200 User manual

Merlin

Merlin Slide 600 User manual

Merlin

Merlin WingMate 3 User manual

Merlin

Merlin MGL400-24 User manual

Merlin

Merlin G703 User manual

Merlin

Merlin Swing L 300 MGLSK User manual