Merlino FUTURA S Series User manual

USER MANUAL

Designed and produced in accordance with EEC directives

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MB

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

ITALIA-UE Tel & Fax ++39-039-2450296

Partita I.V.A. e Codice Fiscale 03398650964

Pag. 1

MISU_UK-0642 - 2.0

“FUTURA-S”

SERIES

ACTIVE OPTO-ELECTRONIC

PROTECTIVE DEVICE “AOPD”

IN COMPLIANCE WITH THE

MACHINERY DIRECTIVE

2006/42/EEC

2006/42

PREFACE

This manual provides the user and/or installer with the information required for correct use

of the "FUTURA" device in the application for which it was designed, and in safety and risk-

prevention.

The manual must be kept carefully in such a way as to be immediately available should it be

required.

Contact the manufacturer for clarification, explanations or additional copies or updates of

the manual itself.

The manufacturer reserves the right to vary products and the manual without being

obliged to update previous products and manuals.

MISU_UK 2.0 - Revision 2.0 of 14-April-2010

CONTENTS

2

PAG.1

PAG.2

PAG.3

PAG.4

PAG.5

PAG.6

PAG.7

PAG.8

PAG.9

PAG.10

PAG.11

PAG.12

PAG.13

PAG.14

PAG.15

PAG.16

PAG.17

PAG.18

Pag. 2

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

1. Preface ......................................................................................

2. Contents ...................................................................................

3. Warranty - Supplied material ................................................

4. Legend ......................................................................................

5. Precautions ..............................................................................

6. Installation - FUTURA3/FUTURA4 ........................................

7. Light indicators and setting controls - TX ............................

.

7.1 Light indicators and setting controls - RX ............................

8. Rating plate ..............................................................................

9. Determining the safe distance ...............................................

10. Technical characteristics - FUTURA14 FUTURA38 .............

10.1 Technical characteristics - FUTURA76 FUTURA114 ...........

11. Electrical connections - TX .....................................................

11.1 Electrical connections - RX .....................................................

12. Mechanical data .......................................................................

13. Maintenance and controls - Spare parts ..............................

14. How to order ............................................................................

15. Declaration of conformity .......................................................

MISU_UK-0642 - 2.0

WARRANTY

3

4

Pag. 3

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

The warranty

MATERIALSUPPLIEDASSTANDARD

is valid for a period of 12 months from the consignment date and expires at the

end of this period, irrespective of whether the appliance has in fact been used. The guarantee

covers all parts of the device if the materials or assembly of said parts are shown to be faulty and

in respect of the following conditions:

The warranty covers replacement of all those parts shown to be of faulty manufacture

under normal conditions of use.

The warranty is not valid unless accompanied by a copy of the invoice proving purchase.

The warranty is not valid in the following cases:

a if the device has been tampered with in any way;

b use of the device in ways not conforming to the instructions and warnings

given in this manual;

c damage caused by an unsuitable working environment or phenomena not

dependent on normal operation (e.g. an unsuitable mains voltage and/or

frequency values);

d repairs carried out by persons or technical assistance centres not authorised

by the manufacturer.

The resulting costs and risks associated with transport, packing and labour are the

responsibility of the purchaser.

The replacement of the device and/or extension of the period of guarantee validity

following a fault are excluded.

Compensation will not be paid for damages occurring as a result of the device being

inoperative while repairs are carried out.

Where not explicitly specified, reference should be made to 85/374/EEC on the

responsibility for faulty products as incorporated in Italian Decree D.P.R. 224 of 1998.

The "FUTURA" invisible optoelectronic active infrared light curtain consists of the following

elements supplied suitably packed:

Transmitter (TX) complete with M12 5 pole output connector with 5 m long cable

Receiver (RX) complete with M12 8 pole output connector with 5 m long cable

Copy of the present manual including the “ DECLARATION OF CONFORMITY”

Adjustable brackets for installing the Transmitter TX and Receiver RX.

MISU_UK-0642 - 2.0

LEGEND

4

Pag. 4

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

FUTURA

ESPE

OSSD

TX

RX

EDM

=

=

= Trans

)

= R

=

Elettro Sensitive Protective Equipment

Output Signal Switching Device=

=950 nm

name of the device covered by this manual

mitter (section of the “FUTURA

” light curtain emitting IR radiation with

a wavelength of

eceiver (section of the "FUTURA" acting as a sensor and com

and control device and incorporating the two OSSDs).

component monitoring the contacts efficiency of devices connected externally

to the outputs of the light curtain (External Device Monitor).

light curtain

mand

P

W

T

RXTX

PH

PD

PA

DC

WD

=

=

= PH x PD =

=

=

protected by the invisible IR curtain generated by the "FUTURA" device

protected with the declared detection capability (DC)

protected area

detection capability (eg. 14, 38, 76 etc.)

working distance of the two sections: Transmitter TX and Receiver RX

height

distance

Test piece to control

detection capability

To calculate the distance actually

protected with the detection

capability (DC) declared on the

rating plate, use the following

formula, replacing the parameters

with the values corresponding to

your specific application:

where N is a function of the

protected and the detection

capability of the light curtain

according to the formula:

height

Fig.1

VERIFYINGTHEPROTECTEDAREA

RUN ALT

This should be performed using a cylindrical test piece with a diameter corresponding to the

detection capability of the device concerned. This must be intercepted anywhere within the

protected area, causing the green LED to light off and the red LED to light on.

The output signal switching devices (OSSDs) should also open, disabling operation of the

machine. A test piece suitable for the device in use should always be available near the work

station.

MISU_UK-0642 - 2.0

PRECAUTIONS

5

Pag. 5

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

The "FUTURA" device has been designed and produced with the aim of eliminating or reducing

as far as possible all risks for the user. However, could result in unforeseen

conditions with some degree of danger which cannot be completely eliminated. Installation,

testing and maintenance of the "FUTURA" device must be performed exclusively by qualified

personnel following the instructions in this manual faithfully and meticulously.

The and housings are electrically connected to the earth of the internal circuit, thus to the

conductor of the connector. Contact between the housing and the chassis of the machine

(unless free of potential) must therefore be avoided. Failure to observe this precaution could

lead to damage of the units. This danger is totally avoided if the sensor units are correctly fixed by

means of the special adjustable insulating "L" brackets (or by means of optional rear shock

absorbing cylinders).

Connection of other equipment to the power source used to power the "FUTURA" device is not

recommended. This could generate electrical disturbance, jeopardising correct operation of the

various parts of the device itself.

If liquid or foreign bodies of any kind penetrate the device, stop using it immediately and

disconnect it from the power supply.

The “FUTURA” device has been designed and produced in such a way that the housing does not

have to be opened for the device to be used. Given the particular function of the device itself,

removal of the heads of the aluminium housings of the transmitter TX and receiver RX is

prohibited. No attempt should be made to repair them. Always contact the manufacturer only.

improper use

MECHANICALWARNINGS

To prevent shift of the light curtain and consequently also of the protected field, it must be fixed

solidly and precisely respecting the instructions given in paragraph 12 "Mechanical Data".

Connection cables must be arranged so as to avoid accidental contact with, for example,

abrasive, hot or sharp objects which could cause dangerous damage to the cables themselves.

In the event of damage to the connection cables, do not use the device and disconnect

immediately from the power supply. Avoid the connection cables coming into contact with water

or damp surfaces.

For increased safety, shiny surfaces near the light curtain should be opacified. While in

operation, avoid the presence of any infrared diffusing translucent screen in the protected area

as failure to calibrate the light curtain precisely or installation beyond the specified distance

could create detection uncertainty. Mark the extent of the protected area with a material

boundary. If this is not possible, increase the installation distance between the TX and RX to

ensure that the entire area providing access to the danger zone is safely included in the

protected distance PD. Use barriers with a protected height PH such as to prevent the operator

from reaching the danger zone above the upper limit or below the lower limit. In addition, prevent

access to the danger zone with other fixed material barriers where this is not possible by the use

of electro sensitive protective devices.

ELECTRICALWARNINGS

TX RX

GND

MISU_UK-0642 - 2.0

INSTALLATION

6

Pag. 6

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

Ensure the two units, TX and RX, are perfectly parallel and fix using the special adjustable

insulating brackets at the working distance specified when ordering and reported on the rating

plate under the heading "Working Distance". Keep the Receiver out of direct sunlight.

The equipment is turned on by powering the transmitter TX and receiver RX according to the

information given on the rating plate. After about one second the device should be ready for

operation. The meaning of the light indicators is described and illustrated in detail in paragraph 7

".

After turning power to the two units on and aligning them correctly, make sure that at least the

yellow indicator on the TX and the green indicator on the RX are on. The red

indicator on the RX lights on in the presence of an obstacle inside the protected area or if the units

are not perfectly aligned. To prolong the connections, use shielded cable to avoid all

interference.

If there are shiny reflectant surfaces near the light curtain, they should ideally be coated with matt

black paint to reduce the risk of undesirable reflections.

The sensor units are normally factory calibrated for the distance requested. However, in certain

cases it may be necessary to recalibrate on site using the " " buttons on the front panel

of the top head of the emitter TX. This should be done starting from the lowest value, repeatedly

pressing the button while holding the button down until all three LEDs on the buttons

light off. At this point, without intervening in the protected zone and in the total absence of obsta

cles, repeatedly press the button only for just the number of times necessary for the green

indicator on the RX to lights on steadily. This must be performed at least twice together with

reciprocal alignment of the two sensor units. The final position of the digital compara

tor will therefore be that nearest to the GREEN RED switch point of the indicators.

Finally press the button to confirm and store the new calibration. This operation produces

the best calibration obtainable for the distance considered.

This procedure must be performed by specialist accident prevention personnel supervised by

the company safety manager who will previously have contacted the manufacturer.

stan

dard

"Light indicators and setting controls

DISTANCE

MIN RUN ALT

DISTANCE

INC DEC

INC

RUN

RUN ALT-

Also verify correct operation using the test piece to ensure it is intercepted at all points of the area

to be protected. The minimum diameter of the test piece unequivocally intercepted at all points of

the protected area is known as the Maximum Detection Capability (from IEC EN 61496

) of the light curtain. For example, for the FUTURA 38 system this is 38 mm.

The choice between the two models must be made on the basis of the risk category attributed to

the machine, assessed in accordance with European standard . The model

is suitable for all applications with maximum accident risk, both in terms of the frequency with

which the operator is exposed to said risk and the gravity of the danger (machines listed in annex

IV of Directive 98/37). The model is suitable for all other applications where the severity

and frequency of exposure to the risk of accident is less.

EN954-1 FUTURA4

FUTURA3

SET

FUTURA3 -FUTURA4

MISU_UK-0642 - 2.0

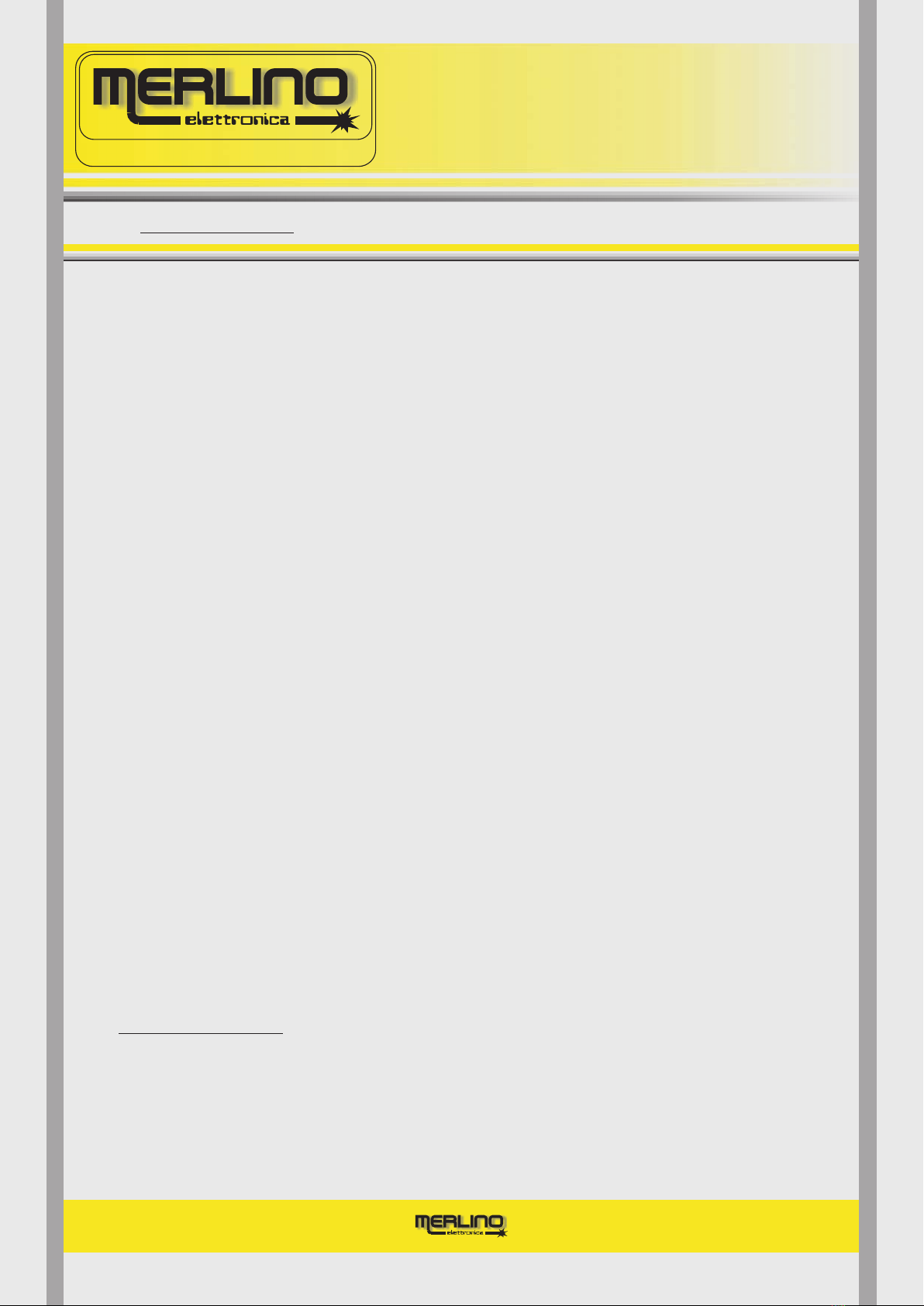

LIGHT INDICATORS and SETTING CONTROLS - TX

7

Pag. 7

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

The "FUTURA" active optoelectronic light curtain has a number of light indicators providing

rapid and unequivocal information on its operating status. In particular, there are three LEDs

on the top head of the transmitter (TX) and five on the top head of the receiver (RX).

There are also a number of controls to set and regulate the emitter and receiver. To ensure their

correct use, they are identified and described below.

INC

SET

DEC

button: modifies the working distance. Press repeatedly a maximum of 30 times to increase or decrease (if the button is held down at the

same time) the distance up to the maximum or down to the minimum allowed for that specific model.

button: confirms the working distance. Press once to maintain the set working distance (until pressed again) also after having disconnected

from the power supply.

button: decreases the working distance. If held down while the button is pressed, reducesthe working distance to the minimum allowed for

that specific model.

DEC

INC

Setting controls (absent in the /AUTO model)

T

NA

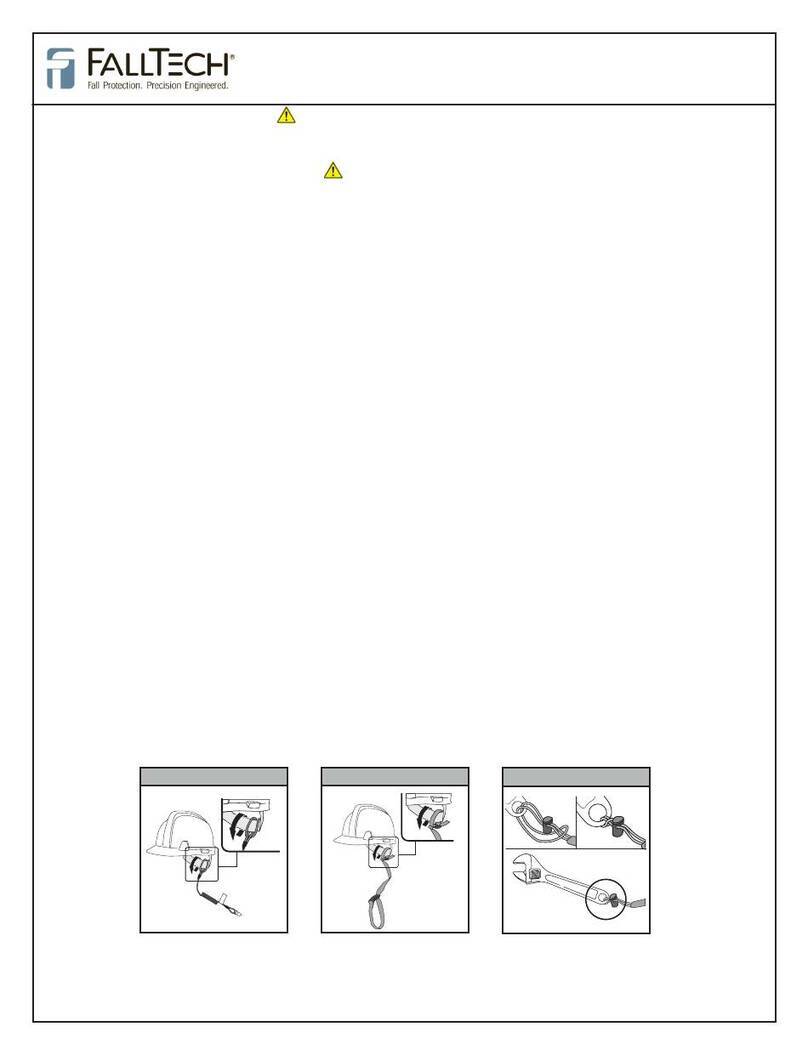

Fig.2

INC DEC

SET

MIN Distance MAX

Indicates short

distance calibra.

light-curtain

Indicates medium

distance calibrated

l i g h t - c u r t a i n Indicates long

distance calibra.

light-curtain

Push-button to

increase and

decrease distance

Push-button

to confirm

distance

Psh-button

to decrease

distance

Fig.3

CHECK AND

SOLUTION

A

B

C

DEVICE STATUS

D

LEDs STATUSCASE

No power.

Possible internal fault

Calibrated for minimum

working distance

Check the suitability of

the installation distance

Calibrated for medium

working distance

Calibrated for maximum

working distance

OFF

OFF

OFF

MAX

MIN

OFF

OFF

ON

MAX

MIN

OFF

ON

ON

MAX

MIN

ON

ON

ON

MAX

MIN

Check power supply

and connections.

If persist return to factory

Check the suitability of

the installation distance

Check the suitability of

the installation distance

E

TEST input activeted

MAX

MIN

I.R. emission

inhibited

SLOW

SIMULTANEOUS

BLINKING

{

TROUBLESHOOTING

TX - TOP HEAD

MISU_UK-0642 - 2.0

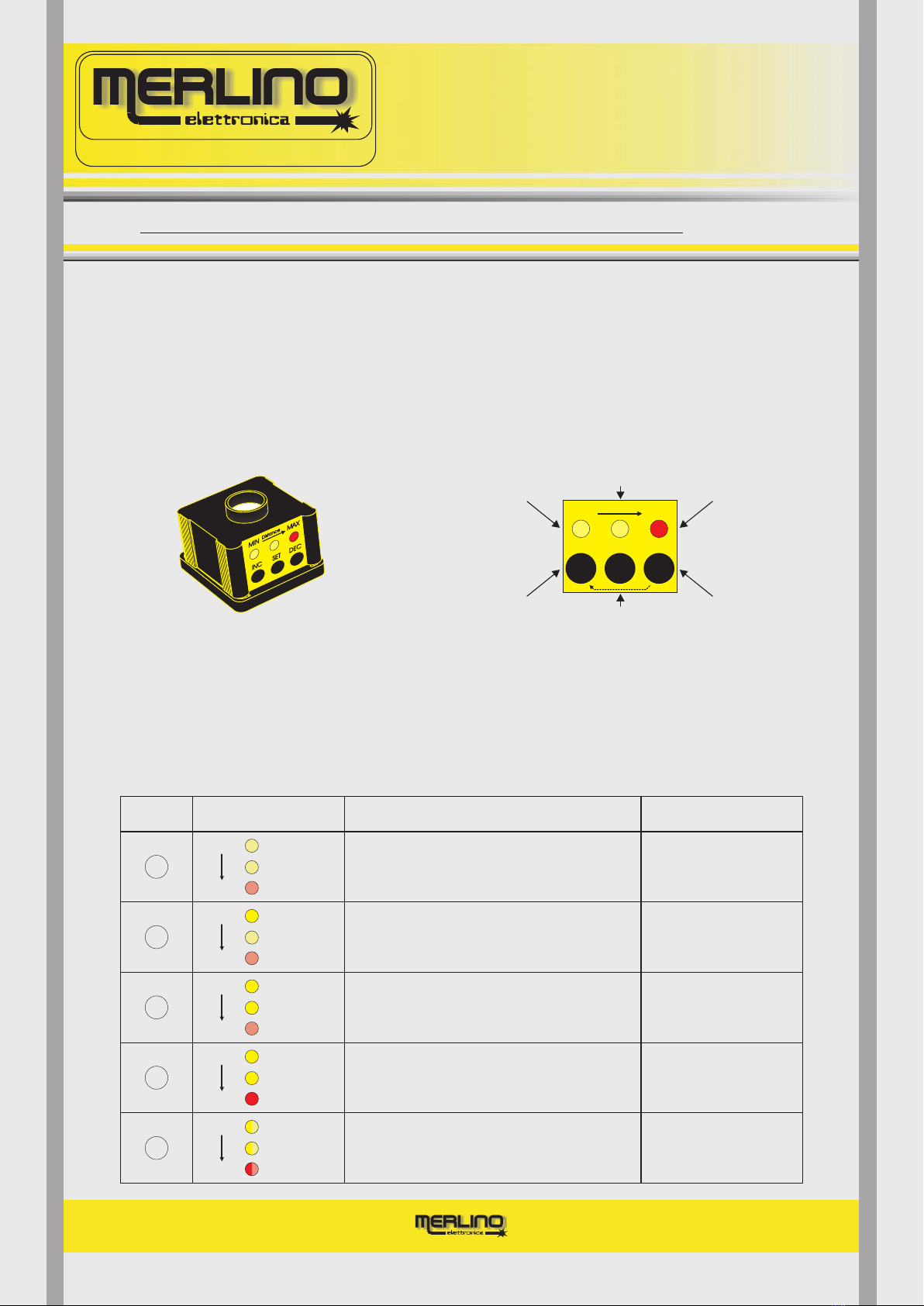

LIGHT INDICATORS and SETTING CONTROLS - RX

7.1

Pag. 8

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

RX - TOP HEAD

MODE

SRI

MODE

function mode selector: taking of the jumper located under

the black cap the light-curtain switches from the automatic to

the manual restart operation (start/restart interlock)

manual restart operation selection indicator

(start/restart interlock), it lights on taking of the jumper

U

TROUBLESHOOTING

Fig.4

Indicates

curtain

manual

restart operation

light-

MUTE MODE

SRI

RUN BLK

ALT

Indicates aligned

with

no

light-curtain

obstacles

Indicates misaligned

light-curtain or

obstacles presence Indicates

for failure

lockout

state light-curtain

Indicates

light-curtain

muting

state

(FUTURA4 only)

Light-curtain

selector

function mode

Fig.5

CHECK AND

SOLUTION

A

Disparity between the

inside driving channels

Block briefly

the protective curtain,

if persist send to factory

Load sinking current connected

to the OSSD1 or OSSD2 higher than 0,7A,

OSSD1 or OSSD2 short-circuited to GND

(FUTURA4 model only)

FAST

SIMULTANEOUS

BLINKING

B

C

{

DEVICE STATUS

OSSD1 or OSSD2 connected to the +24Vcc

or OSSD1 short-circuited with OSSD2

(FUTURA4 model only)

OSSD1 or OSSD2 connected to the +24V

during power-on

(FUTURA4 model only)

D

LEDs STATUSCASE

BLINKING

ON

OFF

BLK

ALT

RUN

OFF

MUTE

E

F

G

H

OFF

OFF

ON

BLK

ALT

RUN

OFF

MUTE

OFF

ON

OFF

BLK

ALT

RUN

OFF

MUTE

OFF

OFF

ON

BLK

ALT

RUN

BLINKING

MUTE

BLINKING

ON

OFF

BLK

ALT

RUN

BLINKING

MUTE

ON

ON

OFF

BLK

ALT

RUN

OFF

MUTE

OFF

BLK

ALT

RUN

OFF

MUTE

OFF

BLK

ALT

RUN

OFF

MUTE

Optical alignment O.K.,

no obstacles

No failures

SLOW

ALTERNATE

BLINKING

{

No optical alignment

or obstacles presence

Possible internal fault

Improve the alignment,

remove probable obstacles.

If persist send to factory

MUTING activated, protective action

temporarely neutralized

(FUTURA4 model only)

Warning,

possible unsafe

situation

Disparity state between the

inputs, or inputs activated

with obstacles presence

MUTING Check MUTING sources,

remove probable obstacles.

If persist send to factory

Switch-off power supply,

remove the factor,

switch-on power supply

Check if the

are in the ON state

OSSDs

Remove the factor

and block briefly the

protective curtain

Remove the factor

and block briefly the

protective curtain

MISU_UK-0642 - 2.0

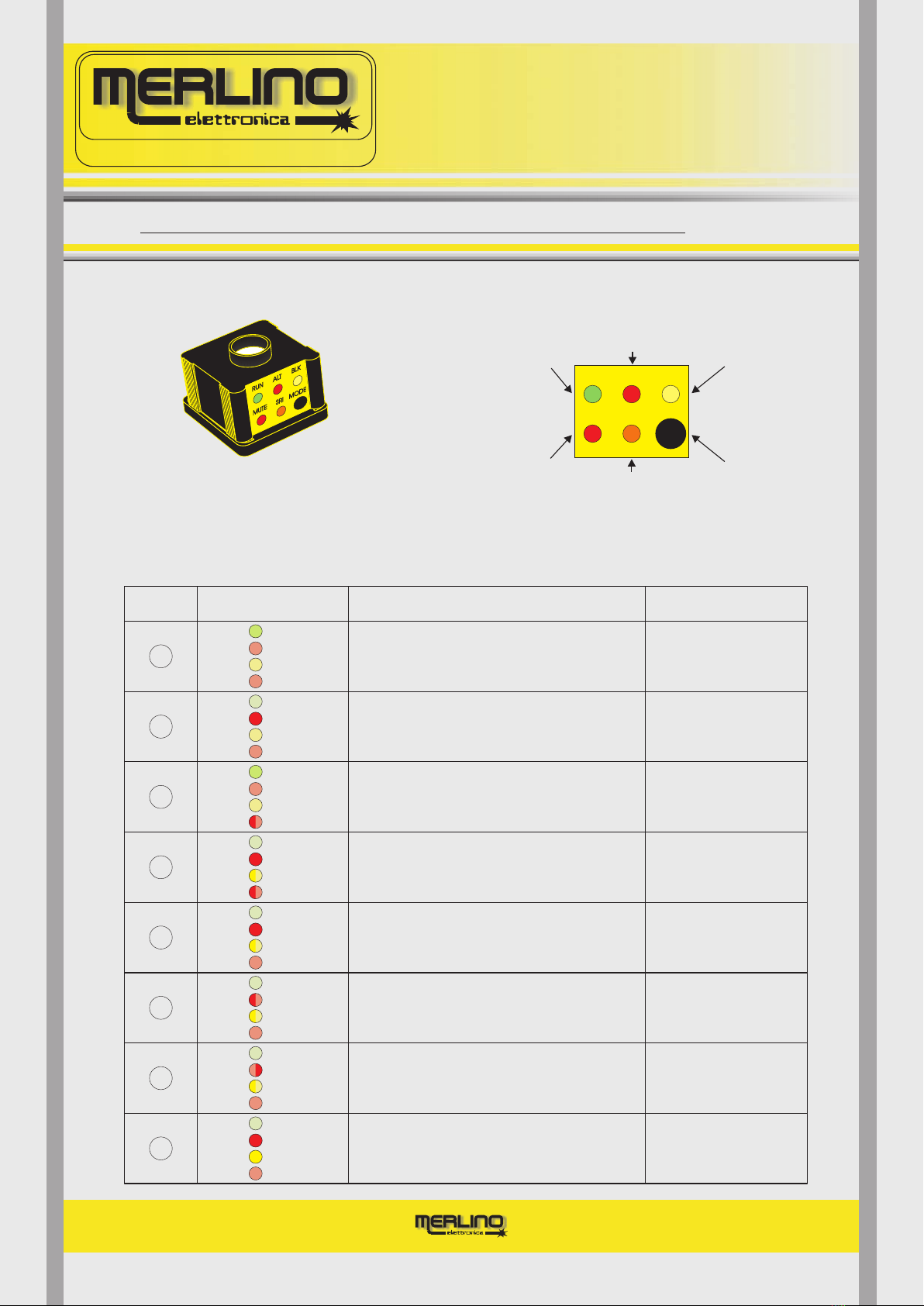

RATING PLATE

8

Pag. 9

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

M12 5 poles male plug M12 5 poli spina maschio

If the function TEST is not used short circuit the conductors 4-5

Se la funzione TEST non viene utilizzata cortocircuitare i conduttori 4-5

1)

2)

3) /Blu

4) /Nero

Brown

White

Blue

Black

/Marrone

/Bianco

=

= Ref.

= GND

= Test

+ 24V 5) /GrigioGrey = Test

1 2

3

4

5

M12 8 poles male plug M12 8 poli spina maschio

If the functions E.D.M. and START/RESTART are not used short circuit the conductors 3-4

Se le funzioni E.D.M. e START/RESTART non vengono utilizzate cortocircuitare i conduttori 3-4

1) /Bianco

2) /Marrone

3) /Verde

4) /Giallo

White

Brown

Green

Yellow

= SW1

= SW1

=

=}E.D.M. /

Start-Restart

5) /Grigio

6) /Rosa

7) /Blu

8) /Schermo

Grey

Pink

Blue

Shield

= SW2

= SW2

= + 24V

= GND

12

3

4

5

6

7

8

On both Transmitter (TX) and Receiver (RX) there is a label showing all the technical data

typical of the device according to the Machinery Directive 98/37/EEC Annex l° § 1.7.3

concerning safety components.

Following with reference to a specific model of light curtain called “FUTURA4/14” there is an

example of rating plate

A second label, located on the aluminium housing, shows on how to carry out electrical

connections useful for a correct use of the device.

It identified all the conductors with reference to their colouring and to the corresponding

function.

TX FUTURA

Power consumption

Progressive Num.

Month: February

Year: 2002

Protected height

Via Como 33/A LISSONE (MI) ITALY Serial number

Numero di serie

Detection capab.

Capacità di rilev.

Model

Modello

14 mm

2020001

FUTURA 4

RX Safety category

Categoria di sic.

Working range

Gamma esercizio

Protected height

Altezza protetta

TYPE 4

415 mm

PH - 6m Power consumption

Assorbimento

Response time

Tempo di risposta

40 70 mA

÷

5 - 48 ms Working temp.

Temp. esercizio

Protection degree

Grado protezione

0..+55°C

Working distance

Distanza esercizio 1200 mm

Supply voltage

Tensione aliment.

24V +/- 10%

0..+55°C

IP 65

{

{

Range

Working temperature

Protection degree

Safety category

Setting distance

Responce time

Supply voltage

Device model

Detection capability

RX FUTURA3

RX FUTURA4

1)

2)

3) /Blu

4) /Nero

Brown

White

Blue

Black

/Marrone

/Bianco

=

= Ref.

= GND

= Test

+ 24V 5) /Grigio

Grey = Test

Section

Company Logo

Marking

Fig.6

Fig.7

Fig.8

Fig.9

M12 8 poles male plug M12 8 poli spina maschio

If the functions E.D.M. and START/RESTART are not used short circuit the conductors 3-4

Se le funzioni E.D.M. e START/RESTART non vengono utilizzate cortocircuitare i conduttori 3-4

1) /Bianco

2) /Marrone

3) /Verde

4) /Giallo

White

Brown

Green

Yellow

= OUT1

= OUT2

=

=}E.D.M. /

Start-Restart

5) /Grigio

6) /Rosa

7) /Blu

8) /Schermo

Grey

Pink

Blue

Shield

= Mute1

= Mute2

= + 24V

= GND

12

3

4

5

6

7

8

1) /Bianco

2) /Marrone

3) /Verde

4) /Giallo

White

Brown

Green

Yellow

= SW1

= SW1

=

=}E.D.M. /

Start-Restart

5) /Grigio

6) /Rosa

7) /Blu

8) /Schermo

Grey

Pink

Blue

Shield

= SW2

= SW2

= + 24V

= GND

1) /Bianco

2) /Marrone

3) /Verde

4) /Giallo

White

Brown

Green

Yellow

= OUT1

= OUT2

=

=}E.D.M. /

Start-Restart

5) /Grigio

6) /Rosa

7) /Blu

8) /Schermo

Grey

Pink

Blue

Shield

= Mute1

= Mute2

= + 24V

= GND

MISU_UK-0642 - 2.0

DETERMINING THE SAFE DISTANCE

9

Pag. 10

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

To ensure the device fulfils its accident prevention functions correctly, it must be installed at a

safe distance from the point actually dangerous for the operator of the machine in such a way as

to stop the dangerous movement before that point is actually reached.

The procedure for calculating this distance is established in the harmonised European standard

EN999 which gives a number of formulas using parameters dependent on various factors

discussed below (for more detail see the standard itself).

For information only, a number of examples to calculate the installation distance from the danger

point for vertically installed light curtains with a detection capability of no more than 40 mm are

given below.

is the safe distance to be respected when installing the device

is a constant establishing the speed at which the operator approaches the danger point,

established at 2 m per second

is the time in milliseconds deriving from the sum of the time t1 taken by the machine to stop

its dangerous movement after an ALT command and the time t2 taken by the light curtain to

open the OSSDs after an obstacle has been introduced into the protected area.

is the detection capability of the in millimetres

If the result of this formula exceeds 500 mm, the value of the constant K may be reduced to 1.6 m

per second.

As is obvious, when the has a detection capability of 14 mm, the additional factor C is

zero, considerably reducing the distance in absolute value of the installation from the danger

point, in fact:

For vertically installed light curtains with a detection capability of between 40 and 70 mm, accor

ding to EN999, the formula to be used is the following:

light curtain

light curtain

For accesses protected by normally vertically installed multiple light beam device with a detec

tion capability of more than 70 mm used, the formula to be used is:

where T = t1 + t2 while C = 8 x (d 14)

C=8 x (14 14) = 0

S=KxT+C

S

K

T

d

S= 1,6x(t1+t2)+850

S= 1,6x(t1+t2)+1200

MISU_UK-0642 - 2.0

10 TECHNICAL CHARACTERISTICS - FUTURA 14 FUTURA 38

Pag. 11

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

PROTECTED HEIGHT (PH) 125 270 415 560

DETECTION CAPABILITY (DC) 14mm

WORKING RANGE

RESPONSE TIME 18 - 78msec

TX INDICATORS

OSSDs TYPES

PROTECTION FEATURES

SUPPLY VOLTAGE 24Vdc 10% on request 12Vdc±

CURRENT CONSUMPTION TX 70mA RX 50mA

WORKING TEMPERATURE 0 to +50°C

UMIDITY 25 85%÷

INTERFERENT LIGHT IMMUNITY 50.000 lux

FUTURA - 14 MODEL

PROTECTION DEGREE IP65

L= PH 5 Meters÷ H = 5 15÷ Meters

705

RX INDICATORS

TOTAL HEIGHT (TH) 195 340 485 630 775

MAX. LOAD CAPACITY 0,1 uF

WAVELENGHT = 950 nm

DISTANCE SETTING MANUAL / AUTOMATIC

OUTPUT CONNECTION

5 METERS CABLE LENGHT M12 CONNECTOR TX = 5 POLE - RX = 8 POLE

HOUSING YELLOW RAL 1021 ALUMINIUM - CROSS SECTION 41 x 46 mm

AVAILABLE FUNCTIONS

2 PNP OPEN COLLECTORS 0,7A@ 24Vdc (F4)

POLARITY INVERSION - OUTPUTS SHORT CIRCUIT - CURRENT THRESHOLD(F4) (F4)

YELLOW=LOW RANGE YELLOW=MEDIUM RANGE RED=HIGH RANGE

GREEN=ALERT RED=ALARM YELLOW=BLOCK

BLK. RED=MUTING (F4) ORANGE=MANUAL RESTART

2 VOLTAGE FREE SWITCHES 0,7A @ 40Vdc/ac

E D MXTERNAL EVICE ONITOR - START/RESTART INTERLOCK - MUTING (F4)

150

38mm

10,5 - 63msec

FUTURA - 38 MODEL

220 1739

1522

1305

1088871654

437

367 584 801 1018 1235 1452 1669

TX 70mA RX 50mA

0 to +50°C

25 85%÷

50.000 lux

IP65

0,1 uF

= 950 nm

24Vdc 10% on request 12Vdc±

L = PH 5 Meters÷ H = 5 15÷ Meters

MANUAL / AUTOMATIC

5 METERS CABLE LENGHT M12 CONNECTOR TX = 5 POLE - RX = 8 POLE

YELLOW RAL 1021 ALUMINIUM - CROSS SECTION 41 x 46 mm

2 PNP OPEN COLLECTORS 0,7A@ 24Vdc (F4)

POLARITY INVERSION - OUTPUTS SHORT CIRCUIT - CURRENT THRESHOLD(F4) (F4)

YELLOW=LOW RANGE YELLOW=MEDIUM RANGE RED=HIGH RANGE

GREEN=ALERT RED=ALARM YELLOW=BLOCK

BLK. RED=MUTING (F4) ORANGE=MANUAL RESTART

2 VOLTAGE FREE SWITCHES 0,7A @ 40Vdc/ac

E D MXTERNAL EVICE ONITOR - START/RESTART INTERLOCK - MUTING (F4)

PROTECTED HEIGHT (PH)

DETECTION CAPABILITY (DC)

WORKING RANGE

RESPONSE TIME

TX INDICATORS

OSSDs TYPES

PROTECTION FEATURES

SUPPLY VOLTAGE

CURRENT CONSUMPTION

WORKING TEMPERATURE

UMIDITY

INTERFERENT LIGHT IMMUNITY

PROTECTION DEGREE

RX INDICATORS

TOTAL HEIGHT (TH)

MAX. LOAD CAPACITY

WAVELENGHT

DISTANCE SETTING

OUTPUT CONNECTION

HOUSING

AVAILABLE FUNCTIONS

MISU_UK-0642 - 2.0

TECHNICAL CHARACTERISTICS - FUTURA 76 FUTURA 114

10.1

Pag. 12

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

295

76mm

10,5 - 33msec

FUTURA - 76 MODEL

365 799 1233 1667

729 1163 1597

TX 70mA RX 50mA

0 to +50°C

50.000 lux

IP65

0,1 uF

= 950 nm

25 85%÷

PROTECTED HEIGHT (PH)

DETECTION CAPABILITY (DC)

WORKING RANGE

RESPONSE TIME

TX INDICATORS

OSSDs TYPES

PROTECTION FEATURES

SUPPLY VOLTAGE

CURRENT CONSUMPTION

WORKING TEMPERATURE

UMIDITY

INTERFERENT LIGHT IMMUNITY

PROTECTION DEGREE

RX INDICATORS

TOTAL HEIGHT (TH)

MAX. LOAD CAPACITY

WAVELENGHT

DISTANCE SETTING

OUTPUT CONNECTION

HOUSING

AVAILABLE FUNCTIONS

24Vdc 10% on request 12Vdc±

L = PH 5 Meters÷ H = 5 15÷ Meters

MANUAL / AUTOMATIC

5 METERS CABLE LENGHT M12 CONNECTOR TX = 5 POLE - RX = 8 POLE

YELLOW RAL 1021 ALUMINIUM - CROSS SECTION 41 x 46 mm

2 PNP OPEN COLLECTORS 0,7A@ 24Vdc (F4)

POLARITY INVERSION - OUTPUTS SHORT CIRCUIT - CURRENT THRESHOLD(F4) (F4)

YELLOW=LOW RANGE YELLOW=MEDIUM RANGE RED=HIGH RANGE

GREEN=ALERT RED=ALARM YELLOW=BLOCK

BLK. RED=MUTING (F4) ORANGE=MANUAL RESTART

2 VOLTAGE FREE SWITCHES 0,7A @ 40Vdc/ac

E D MXTERNAL EVICE ONITOR - START/RESTART INTERLOCK - MUTING (F4)

657

114mm

13 - 23msec

FUTURA - 114 MODEL

727 15951161

1091 1525

TX 70mA RX 50mA

0 to +50°C

50.000 lux

IP65

0,1 uF

= 950 nm

25 85%÷

24Vdc 10% on request 12Vdc±

L = PH 5 Meters÷ H = 5 15÷ Meters

MANUAL / AUTOMATIC

5 METERS CABLE LENGHT M12 CONNECTOR TX = 5 POLE - RX = 8 POLE

YELLOW RAL 1021 ALUMINIUM - CROSS SECTION 41 x 46 mm

2 PNP OPEN COLLECTORS 0,7A@ 24Vdc (F4)

POLARITY INVERSION - OUTPUTS SHORT CIRCUIT - CURRENT THRESHOLD(F4) (F4)

YELLOW=LOW RANGE YELLOW=MEDIUM RANGE RED=HIGH RANGE

GREEN=ALERT RED=ALARM YELLOW=BLOCK

BLK. RED=MUTING (F4) ORANGE=MANUAL RESTART

2 VOLTAGE FREE SWITCHES 0,7A @ 40Vdc/ac

E D MXTERNAL EVICE ONITOR - START/RESTART INTERLOCK - MUTING (F4)

PROTECTED HEIGHT (PH)

DETECTION CAPABILITY (DC)

WORKING RANGE

RESPONSE TIME

TX INDICATORS

OSSDs TYPES

PROTECTION FEATURES

SUPPLY VOLTAGE

CURRENT CONSUMPTION

WORKING TEMPERATURE

UMIDITY

INTERFERENT LIGHT IMMUNITY

PROTECTION DEGREE

RX INDICATORS

TOTAL HEIGHT (TH)

MAX. LOAD CAPACITY

WAVELENGHT

DISTANCE SETTING

OUTPUT CONNECTION

HOUSING

AVAILABLE FUNCTIONS

MISU_UK-0642 - 2.0

ELECTRICAL CONNECTIONS

11

Pag. 13

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

RXTX

5

12

34

12

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1) Brown

2) White

3) Blue

4) Black

5) Grey

= + 24V

= Ref.

= GND

= Test

= Test

1) White

2) Brown

3) Green

4) Yellow

5) Grey

6) Pink

7) Blue

8) Red

Shield

= OSSD1................. SW1

= OSSD2 SW1

=

=

= MUTE1 SW2

= MUTE2 SW2

= + 24V

= GND

................

.................

.................

= GND

}E.D.M./

Start-Restart

FUTURA3

1 2

3

5

4

Male plug

5 CONDUCTORS M12

FEMALE CONNECTOR

Female socket Female socket

Male plug

If the function TEST is not used, short

circuit the conductors 4 5 and connect

them to the “0V” of power supply blue (3)

If the functions E.D.M. and START RESTART

are not used, short circuit the conductors

3 4 and connect them to the “0V” of power

supply red/shield (8)

3

2

1POWER SUPPLY

24Vdc +/- 10%

BROWN

BLUE

BLACK

WHITE

GREY

5

4

TEST INPUT

NORMALLY CLOSED

CONTACT

Jumper

If the function TEST is not used, short

circuit the conductors 4 5 and connect

them to the “0V” of power supply blue (3) 5m standard

cable length

Reference voltage (useful for testing)

connect it to the “0V” of power supply blue (3)

TX FUTURA

5 conductors cable

8 CONDUCTORS M12

FEMALE CONNECTOR

5 CONDUCTORS M12

FEMALE CONNECTOR

Fig.10 Fig.11

Fig.12

+24V

0V

MISU_UK-0642 - 2.0

ELECTRICAL CONNECTIONS - RX

11.1

Pag. 14

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

D1

D2

K1

K2

RX FUTURA4

8 conductors shielded cable

RX FUTURA3

8 conductors shielded cable

5

6

BROWN

WHITE

PINK

YELLOW

GREY

GREEN

2

1

SW1

SW2

SW1

SW2

Imax = 0,7A

Imax = 0,7A

Vmax = 40Vdc/ac

Vmax = 40Vdc/ac

5m standard

cable length

F1

F2

F1=F2= fuses of a higher value

than the current sinking

into the load (suggested)

Fig.13

D1=D2= rectifier diodes to suppress

“spike” generated by the an

inductive load that reduced

life of the output switches of

the light-curtain (recommended)

8 CONDUCTORS M12

FEMALE CONNECTOR

SCR = extra-voltages discharger to

suppress possible high energy

discharge (recommended)

5

6

BROWN

WHITE

PINK

YELLOW

GREY

GREEN

D1

2

1

3

4

D2

E D Mxternal evice onitor

K2

I =max 0,7A

K1

OSSD1

MUTE1

Control devices of the MUTING function.

: when activated, temporarely, they

neutralize the light-curtain protective action.

WARNING

OSSD2

Jumper

MUTE2

5m standard

cable length

8 CONDUCTORS M12

FEMALE CONNECTOR

F1F2

Fig.14

If the functions E.D.M. and START-RESTART

are not used, short circuit the conductors

3-4 and connect them to the “0V” of power

supply red/shield (8)

P.N. : the E.D.M. function works

only if loads K1, K2, … Kn are

with forced interlocked contacts

operation. E.D.M. must be used to

reach the safety caegory declared.

I =max 0,7A

INTERLOCK

PUSH-BUTTON

START/RESTART

F1=F2= fuses of a higher value

than the current sinking

into the load (suggested)

D1=D2= rectifier diodes to suppress

“spike” generated by the an

inductive load that reduced

life of the output switches of

the light-curtain (recommended)

+24V POWER SUPPLY

24Vdc +/- 10%

SCR

SCR = extra-voltages discharger to

suppress possible high energy

discharge (recommended)

P.N. : if the sinking current is less than

100mA than connect the load to the

conductor, if it is higher to

the “0V” of power supply

green (3)

red/shield (8)

NC SWITCH

K1

NC SWITCH

K2

NC SWITCH

Kn

3

4

E D Mxternal evice onitor

Jumper

If the functions E.D.M. and START-RESTART

are not used, short circuit the conductors

3-4 and connect them to the “0V” of power

supply red/shield (8)

INTERLOCK

PUSH-BUTTON

START/RESTART

NC SWITCH

K1

NC SWITCH

K2

NC SWITCH

Kn

0V

+24V POWER SUPPLY

24Vdc +/- 10%

SCR

0V

P.N. : the E.D.M. function works

only if loads K1, K2, … Kn are

with forced interlocked contacts

operation. E.D.M. must be used to

reach the safety caegory declared.

BLUE

SHIELD

RED

7

8

{

7

8

BLUE

RED

SHIELD

{

MISU_UK-0642 - 2.0

MECHANICAL DATA

12

Pag. 15

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

14

3

20

16

24

1,5

1

18

2

7

8,5 1,5

0,5

1,5 1,5

44

6,5 3,5 3,5

41

6,5

15,5

3

5,5

TOP HEAD

SECTION VIEW

3

20

24

1,5

6

2

7

8,5 1,5

0,5

1,5 1,5

44

41

13,5

3

Fig.15

Fig.16

Fig.17

Fig.18

7

13

4MA

15

46

41

15

HOUSING CROSS

SECTION

41x46

Osmall

shock absorbing cylinders

ptional

O second

frontal black filter

ptional

Tighten the hexagonal

head screw to block

Tighten the hexagonal

head screw to block

H

BOTTOM HEAD

SECTION VIEW

HOUSING CROSS

SECTION VIEW

MISU_UK-0642 - 2.0

MAINTENANCE AND CONTROLS

13

Pag. 16

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

The transmitter and receiver units require no particular maintenance. However, the black front

screens protecting the optics should be cleaned daily to remove large quantities of dust.

Avoid rubbing the screens with abrasive cloths as rubbing causes static electricity and attracts

dust. To clean, use alcohol. Avoid plastic solvents.

When the device is used for the first time, to guarantee safe conditions, the correct setting of the

functions must be controlled. When using the device for the first time, operation of the device in

the particular application must first be verified. This must be done by specialist personnel. Acci

dent prevention legislation specifies that this control should be performed daily.

Before beginning any form of work, it is good practice to verify that:

with the machine stationary and power to the on (no obstacle in the protected

area), the green indicator is lit.

with the machine stationary and power to the on in the presence of an obsta

cle in the protected area, the red indicator is lit.

moving parts are not accessible to personnel. Any extraordinary maintenance must

therefore be carried out under the strict supervision of the safety manager. All accesses

not pro tected by electro sensitive protective devices must be equipped with fixed material

barriers or other.

A sheet indicating the daily checks must be compiled by the operator of the machine and must

be clearly visible near the workstation.

DAILYCONTROLSANDPERIODICALTESTS

RUN

ALT

light curtain

light curtain

with the machine running, introduction of the test piece at any point in the protected area

switches the green indicator to the red indicator, shutting down the machine within the

specified time.

The "FUTURA" invisible optoelectronic active infrared light curtain consists of the following ele

ments, provided on request as spare parts:

M12 5 pole output connector for TX with 5 m long cable....................

M12 8 pole output connector for RX with 5 m long cable..................

Manual with duplicate of the “ DECLARATION OF CONFORMITY

Adjustable brackets for installing the TX and RX ............................

ALT

MATERIALSUPPLIEDASSPAREPARTS

a)

b)

d)

c)

code

....... CON M12 5P 5M

......... CON M12 8P 5M

”........... MISU FUTURA

......... SSO 49 28,5

MISU_UK-0642 - 2.0

HOW TO ORDER

14

Pag. 17

PROGETTAZIONE E PRODUZIONE

APPARECCHIATURE ELETTRONICHE

MERLINO elettronica s.a.s. di Meroni N.

Via Como, 33/A - 20035 Lissone - MI

E-mail: [email protected]

Web-site: www.merlinoelettronica.it

REFERENCE CODE FOR ORDERING

All models of the "FUTURA" active infrared light curtains are calibrated during

factory testing according to the specified by the customer in the last part of

the order code. Should it be necessary to modify this distance at a later date, you should

contact the manufacturer who will modify the calibration for the new working distance.

Alternatively, contact the factory telephonically for instructions on how to proceed. For all

those models ordered with the optional function of

(AUTO), calibration takes place completely automatically for the specific distance concerned

each time power to the device is turned on.

optoelectronic

working distance

automatic working distance calibration

Below are a number of examples of order codes (with relative comments) for different models of

the "FUTURA" optoelectronic light curtains.

model designed to protect from risks up to category 3 ac

cording to EN954 1, with a maximum detection capabi

lity of 76 mm, protected height of 729 mm and range of

between 5 and 15 m.

Calibrated working distance 7,5 m.

model designed to protect from risks up to category 4 ac

cording to EN954 1, with a maximum detection capabi

lity of 14 mm, protected height of 560 mm and range of

between 560 and 5000 mm.

Calibrated working distance 900 mm.

model designed to protect from risks up to ca

tegory 4 according to EN954 1, with a maxi

mum protection capability of 38 mm and pro

tected height of 801 mm, with automatic cali

bration for a distance of between 801 and

5000 mm.

.

FUTURA3/76 - PH729/H/7,5

FUTURA4/14 - PH560/L/900

FUTURA4/38/AUTO - PH801/L

Automatic calibration

SAFETY CATEGORY ( )3 OR 4

RANGE

PROTECTED HEIGHT

(mm)

H5÷15m

AUTOMATIC CALIBRATION

WORKING DISTANCE

AUTO LPH÷5m

FUTURA / / - PH / /

DETECTION CAPABILITY (mm)

(14 - 38 - 76 - 114)

Optional WORKING DISTANCE

(m)

(mm)

Fig.19

MISU_UK-0642 - 2.0

This manual suits for next models

6

Table of contents

Other Merlino Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Trinity Highway

Trinity Highway QuadGuard Elite M10 Product Description Assembly Manual

Syntech

Syntech MAXAIR CAPR 2272PB-100 User instructions

KidKusion

KidKusion 4680 instructions

Metacon-Next

Metacon-Next FirePro V4 user manual

Guardian Fall Protection

Guardian Fall Protection Cable LE Lanyard instruction manual

Harken

Harken SNATCHET INSN65R manual