Trinity Highway QuadGuard Elite M10 User manual

QuadGuard

®

is a registered trademark of Energy Absorption Systems, Inc.

Part No. 620076

© 2021 Trinity Highway Products, LLC

TrinityHighway.com 1 Revision C September 2021

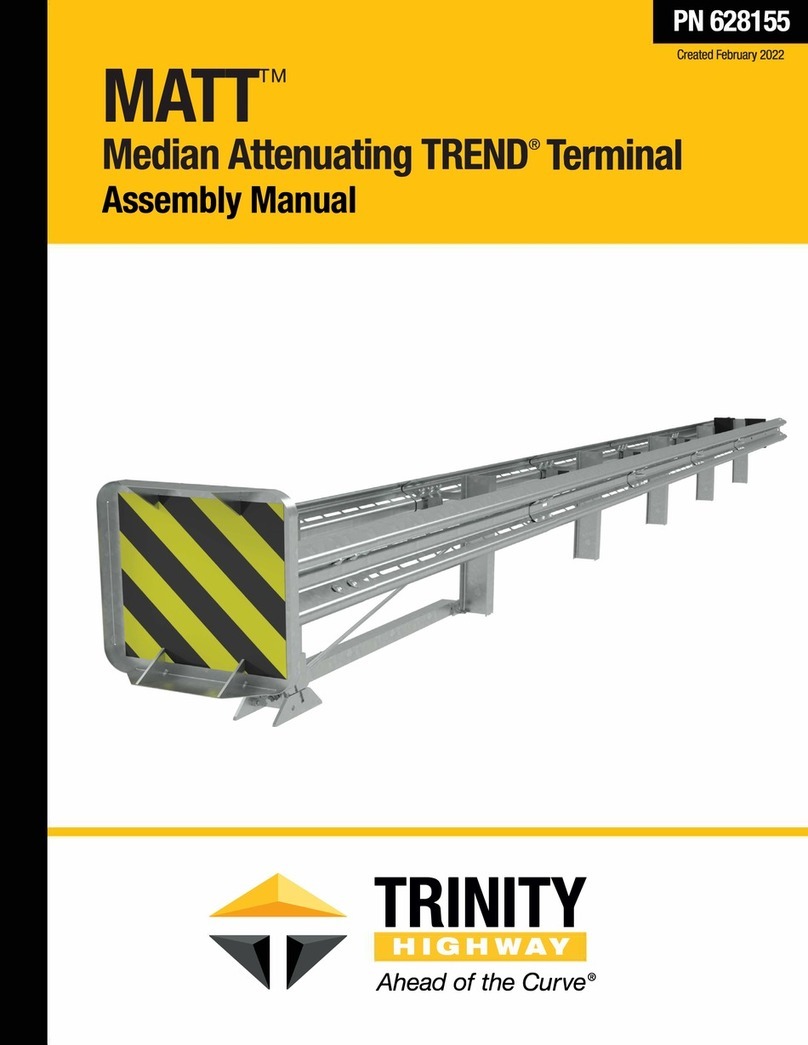

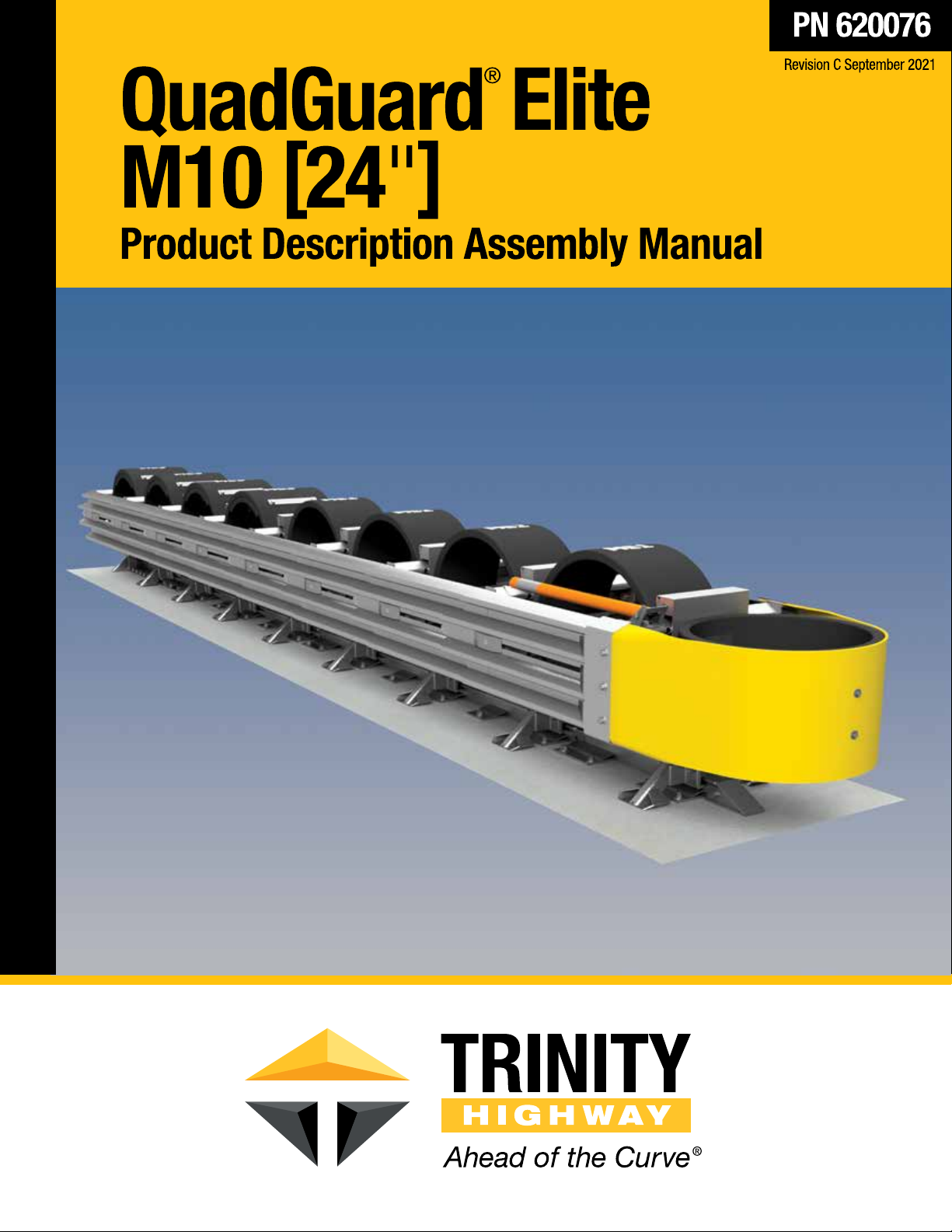

QuadGuard® Elite M10 [24”]

The QuadGuard

®

Elite M10 has been tested pursuant to AASHTO MASH specifications. This system

has been deemed eligible for Federal-aid reimbursement on the NHS by the FHWA.

Product Description

Assembly Manual

15601 Dallas Parkway

Suite 525

Addison, Texas 75001

Warning:

The local highway authority, distributors, owners, contractors,

lessors, and lessees are RESPONSIBLE for the assembly, maintenance, and

repair of the QuadGuard

®

Elite M10. Failure to fulfill these

RESPONSIBILITIES with respect to the assembly, maintenance, and repair

of the QuadGuard

®

Elite M10 could result in serious injury or death.

Important:

These instructions are for standard assembly specified by the

appropriate highway authority. In the event the specified system assembly,

maintenance, or repair would require a deviation from standard assembly

parameters, contact a Trinity Highway representative. This system has been

deemed eligible by the FHWA for use on the NHS under strict criteria utilized by

that agency.

This manual must be available to the worker overseeing and/or assembling the product at

all times. For additional copies, contact Trinity Highway directly at (888) 323-6374 or visit

TrinityHighway.com.

The instructions contained in this manual supersede all previous information and manuals. The

information, illustrations, and specifications in this manual are based on the latest QuadGuard

®

Elite M10 system information available to Trinity Highway at the time of printing. We reserve the

right to make changes at any time. Please contact Trinity Highway to confirm that you are referring

to the most current instructions.

TrinityHighway.com 2 Revision C September 2021

Table of Contents

Customer Service Contacts .......................................................................................................... 3

Abbreviations ................................................................................................................................ 3

Important Introductory Notes ........................................................................................................ 3

Safety Symbols ............................................................................................................................. 4

Safety Rules for Assembly............................................................................................................ 4

Limitations and Warnings.............................................................................................................. 5

System Overview .......................................................................................................................... 6

Inspect Shipping...................................................................................................................... 6

System Assemblies................................................................................................................. 7

Select Transition ................................................................................................................... 15

Recommend Tools...................................................................................................................... 16

Site Preparation/Foundation ....................................................................................................... 18

Foundation/Anchoring................................................................................................................. 19

Trinity Highway Approved Adhesive Anchoring System ............................................................. 20

Vertical Anchors.................................................................................................................... 20

Anchor Assembly Cautions for Steel Rebar.......................................................................... 21

Horizontal Anchors................................................................................................................ 22

Measuring the Width ............................................................................................................. 25

Assembly Procedures ................................................................................................................. 26

Tension Strut Backup............................................................................................................ 26

Pre-Assembled System Installation Instructions......................................................................... 40

QuadGuard®Elite M10 Final Inspection Checklist...................................................................... 41

Maintenance and Repair............................................................................................................. 42

Visual Drive-By Inspection .................................................................................................... 42

Walk-Up Inspection............................................................................................................... 42

Post-Impact Instructions........................................................................................................ 44

Parts Ordering Procedure ..................................................................................................... 47

Maintenance Flow Chart ....................................................................................................... 47

Drawings ..................................................................................................................................... 48

QuadGuard®Elite M10 QGEMTSCVR-U .......................................................................... 48

TS Concrete Pad618686 ................................................................................................... 49

TS Concrete Pad 8” w/Rebar618686 ................................................................................ 50

TS Concrete Pad 8” wo/Rebar618686 .............................................................................. 51

4” Offset Safety Shape TransitionQGEMTSCVR-T4LR .................................................... 52

6” Offset Single Slope TransitionQGEMTSCVR-T6LR...................................................... 53

Thrie-Beam TransitionQGEMTSCVR-TTLR..................................................................... 54

End Shoe TransitionQGEMTSCVR-ESLR ....................................................................... 55

Extended End Shoe TransitionQGEMTSCVR-SPE ......................................................... 56

31” W-Beam TransitionQGEMTSCVR-TWLR ................................................................... 57

TrinityHighway.com 3 Revision C September 2021

Customer Service Contacts

Trinity Highway is committed to the highest level of customer service. Feedback regarding the

QuadGuard

®

Elite M10 system, its assembly procedures, supporting documentation, and

performance is always welcome. Additional information can be obtained from the contact

information below:

Trinity Highway

Telephone (888) 323-6374 (USA)

+1 312 467 6750 (International)

Contact Link TrinityHighway.com/Contact

Abbreviations

AASHTO American Association of State Highway and Transportation Officials

FHWA Federal Highway Administration

MASH Manual for Assessing Safety Hardware

MUTCD

Manual on Uniform Traffic Control Devices

NHS National Highway System

Important Introductory Notes

The performance of the QuadGuard

®

Elite M10 as designed, and approved for reimbursement by

the FHWA pursuant to its MASH standard, is dependent upon the proper assembly, deployment

and future maintenance of the system. These instructions should be read in their entirety and

understood before assembling the QuadGuard

®

Elite M10. These instructions are to be used in

conjunction with the assembly of QuadGuard

®

Elite M10 system and are for standard assemblies

only as specified by the applicable highway authority. If you need additional information, or have

questions about the QuadGuard

®

Elite M10, please contact the highway authority that has

planned and specified this assembly and, if needed, contact Trinity Highway Customer Service.

This product must be assembled in the location specified by the appropriate highway authority. If

there are deviations, alterations, or departures from the assembly protocol specified in this

manual, the device may not perform as tested.

Important:

DO NOT use any component part that has not been specifically

approved for this system during the assembly or repair of this system.

This product has been specified for use by the appropriate highway authority and has been

provided to that user who has unique knowledge of how this system is to be assembled. No

person should be permitted to assist in the assembly, maintenance, or repair of this system that

does not possess the unique knowledge described herein. These instructions are intended for

an individual qualified to both read and accurately interpret them as written. These instructions

are intended only for an individual experienced and skilled in the assembly of highway products

that are specified and selected by the highway authority.

A Manufacturer’s Drawing Package will be supplied by Trinity Highway upon request. Each

system will be supplied with a specific drawing package unique to that system. Such drawings

take precedence over information in this manual and shall be studied thoroughly by a qualified

individual who is skilled in interpreting them before the start of any product assembly.

TrinityHighway.com 4 Revision C September 2021

Safety Symbols

This section describes the safety symbols that appear in this QuadGuard

®

Elite M10 manual.

Read the manual for complete safety and assembly information.

Symbol Meaning

Safety Alert Symbol:

Indicates Important, Caution, Warning, or Danger. Failure

to read and follow the Important, Caution, Warning, or Danger indicators could

result in serious injury or death to workers and/or bystanders.

Warning:

Read safety instructions thoroughly and follow the assembly directions

and suggested safe practices before assembling, maintaining, or repairing the

QuadGuard

®

Elite M10. It is the responsibility of the installer to follow the

instructions contained in this manual. Failure to comply with these warnings could

result in increased risk of serious injury of death in the event of a vehicle impact.

Important:

Please keep up-to-date instructions for later use and reference by

anyone involved in the assembly of the product.

Safety Rules for Assembly

* Important Safety Instructions *

This manual must be kept in a location where it is readily available to persons who are skilled and

experienced in the assembly, maintenance, or repair of the QuadGuard

®

Elite M10. Additional

copies of this manual are available from Trinity Highway by calling (888) 323-6374 or at

TrinityHighway.com/Contact. Please contact Trinity Highway if you have any questions

concerning the information in this manual or about the QuadGuard

®

Elite M10.

It is the responsibility of the installer to use appropriate safety precautions when operating power

equipment, mixing chemicals, and when moving heavy equipment or QuadGuard

®

Elite M10

components. Safety articles including but not necessarily limited to work gloves, eye protection,

safety-toe shoes, and back protection should be used.

Warning:

It is the responsibility of the installer to use all safety measures

incorporating appropriate traffic control devices specified by the highway authority.

These measures must be used to protect all personnel while at the assembly,

maintenance, or repair site.

Warning:

Failure to comply with these warnings could result in increased risk of

serious injury or death in the event of a vehicle impact with a system that has not

been accepted by the FHWA.

Warning:

Use only Trinity Highway parts on the QuadGuard

®

Elite M10 for

assembly, maintenance, or repair. The use of component parts not specified herein

is strictly prohibited. The QuadGuard

®

Elite M10 assembled with Trinity Highway

Parts has been tested, approved, and accepted for state use by the FHWA. A

QuadGuard

®

Elite M10 Assembly using parts other than those specified herein has

not been tested, approved, or accepted for state use by the FHWA. Failure to follow

this warning could result in increased risk of serious injury or death in the event of

a vehicle impact.

Other manuals for QuadGuard Elite M10

2

Table of contents

Other Trinity Highway Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual