Tool Tethers

User Instrucon Manual

Please read and understand the manufacturer’s instrucons for each component or part of the complete system. Manufacturer’s instrucons must be followed for

proper use, care, and maintenance of this product. These instrucons must be retained and be kept available for the worker’s reference at all mes. Alteraons or

misuse of this product, or failure to follow instrucons, may result in serious injury or death.

PLEASE READ - IMPORTANT SAFETY INFORMATION

WARNINGS AND LIMITATIONS

1.0 Descripon - The FallTech For Tools™ Tool Tethers are used to connect to the tool or tool aachment to FallTech® Wrist Aachments and Tool Anchors.

2.0 Applicaon - The FallTech For Tools™ Tool Tethers are designed to be used as a component in a dropped object prevenon program. The tool tethering system

is an assembly of components and subsystems to arrest a tool from an accidental drop. The system typically consists of tool aachment, a tool tether, and a tool

anchor. See product labels for maximum load capacity and maximum tether length.

3.0 System Requirements - The FallTech For Tools™ Tool Tethers is designed for use by a single tool with a combined weight no greater than 15 lbs (6.8 kg), based

on the rang of the aachment. DO NOT exceed the capacity of the lowest rated component in the system.

3.1 Compability of Components: Equipment is designed for use with approved components and subsystems only. Substuons or replacements made

with non-approved components or subsystems may jeopardize compability of equipment and may aect the safety and reliability of the complete system.

3.2 Making Connecons: Only use locking connectors with this equipment. Only use connectors that are suitable to each applicaon. Ensure all connecons

are compable in size, shape, and strength. Do not use equipment that is not compable. Visually ensure all connectors are fully closed and locked.

4.0 Installaon

4.1 Pre-Use Inspecon: Inspect the tool tethers thoroughly for missing or damaged parts before aaching it to the tool. Inspect the webbing, looped ends,

and stching for cuts, fraying, and signs of damage to the materials from excessive wear or abrasion. Inspect the carabiners and speed clips for excessive wear,

cracks, or deformies. If any of these condions exist, remove from service.

4.2 Installaon Procedure: Ensure the tool aachment is clean and free of oil, grease, or debris, which could prevent adequate aachment onto the tool or

tool aachment. The Tool Tether should be placed away from the funconal parts of the tool and the connecon point should face away from the center of

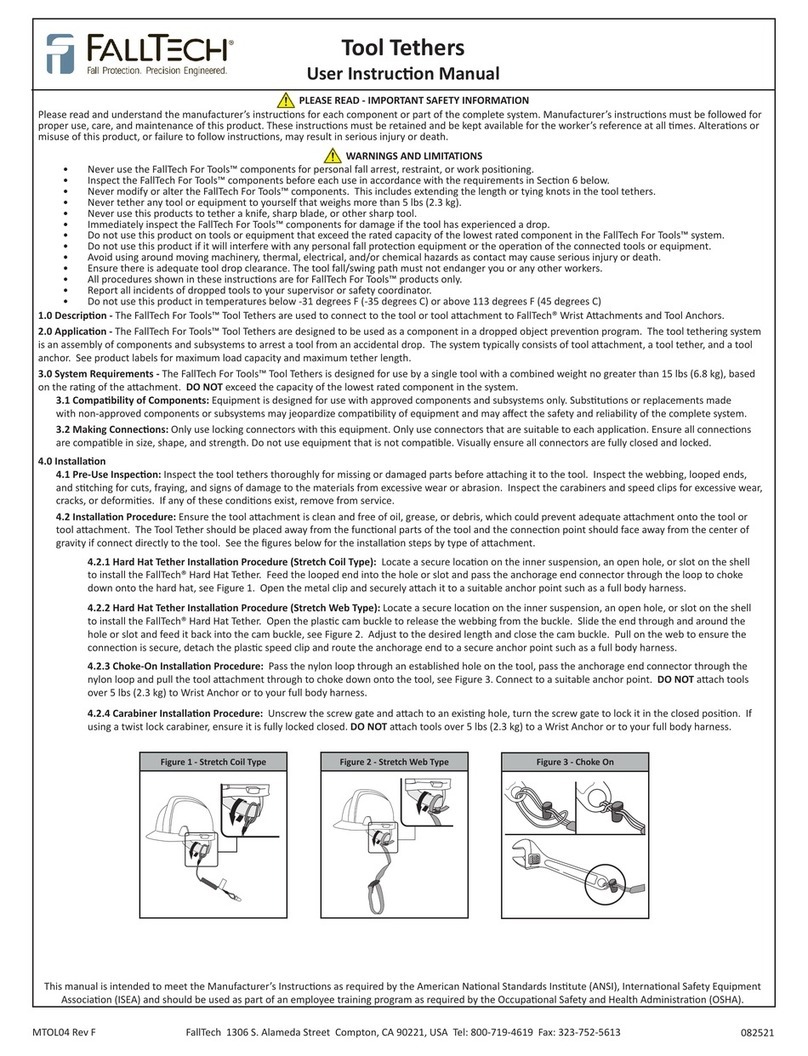

gravity if connect directly to the tool. See the gures below for the installaon steps by type of aachment.

4.2.1 Hard Hat Tether Installaon Procedure (Stretch Coil Type): Locate a secure locaon on the inner suspension, an open hole, or slot on the shell

to install the FallTech® Hard Hat Tether. Feed the looped end into the hole or slot and pass the anchorage end connector through the loop to choke

down onto the hard hat, see Figure 1. Open the metal clip and securely aach it to a suitable anchor point such as a full body harness.

4.2.2 Hard Hat Tether Installaon Procedure (Stretch Web Type): Locate a secure locaon on the inner suspension, an open hole, or slot on the shell

to install the FallTech® Hard Hat Tether. Open the plasc cam buckle to release the webbing from the buckle. Slide the end through and around the

hole or slot and feed it back into the cam buckle, see Figure 2. Adjust to the desired length and close the cam buckle. Pull on the web to ensure the

connecon is secure, detach the plasc speed clip and route the anchorage end to a secure anchor point such as a full body harness.

4.2.3 Choke-On Installaon Procedure: Pass the nylon loop through an established hole on the tool, pass the anchorage end connector through the

nylon loop and pull the tool aachment through to choke down onto the tool, see Figure 3. Connect to a suitable anchor point. DO NOT aach tools

over 5 lbs (2.3 kg) to Wrist Anchor or to your full body harness.

4.2.4 Carabiner Installaon Procedure: Unscrew the screw gate and aach to an exisng hole, turn the screw gate to lock it in the closed posion. If

using a twist lock carabiner, ensure it is fully locked closed. DO NOT aach tools over 5 lbs (2.3 kg) to a Wrist Anchor or to your full body harness.

MTOL04 Rev F 080621

FallTech 1306 S. Alameda Street Compton, CA 90221, USA Tel: 800-719-4619 Fax: 323-752-5613

This manual is intended to meet the Manufacturer’s Instrucons as required by the American Naonal Standards Instute (ANSI), Internaonal Safety Equipment

Associaon (ISEA) and should be used as part of an employee training program as required by the Occupaonal Safety and Health Administraon (OSHA).

Figure 3 - Choke On

Figure 1 - Stretch Coil Type Figure 2 - Stretch Web Type

• Never use the FallTech For Tools™ components for personal fall arrest, restraint, or work posioning.

• Inspect the FallTech For Tools™ components before each use in accordance with the requirements in Secon 6 below.

• Never modify or alter the FallTech For Tools™ components. This includes extending the length or tying knots in the tool tethers.

• Never tether any tool or equipment to yourself that weighs more than 5 lbs (2.3 kg).

• Never use this products to tether a knife, sharp blade, or other sharp tool.

• Immediately inspect the FallTech For Tools™ components for damage if the tool has experienced a drop.

• Do not use this product on tools or equipment that exceed the rated capacity of the lowest rated component in the FallTech For Tools™ system.

• Do not use this product if it will interfere with any personal fall protecon equipment or the operaon of the connected tools or equipment.

• Avoid using around moving machinery, thermal, electrical, and/or chemical hazards as contact may cause serious injury or death.

• Ensure there is adequate tool drop clearance. The tool fall/swing path must not endanger you or any other workers.

• All procedures shown in these instrucons are for FallTech For Tools™ products only.

• Report all incidents of dropped tools to your supervisor or safety coordinator.

• Do not use this product in temperatures below -31 degrees F (-35 degrees C) or above 113 degrees F (45 degrees C)