MERLO CDC User manual

MERLO UK

CDC Quick Guide

THE DYNAMIC

LOAD CONTROL SYSTEM

OPERATING INSTRUCTIONS (SW Version 2.3)

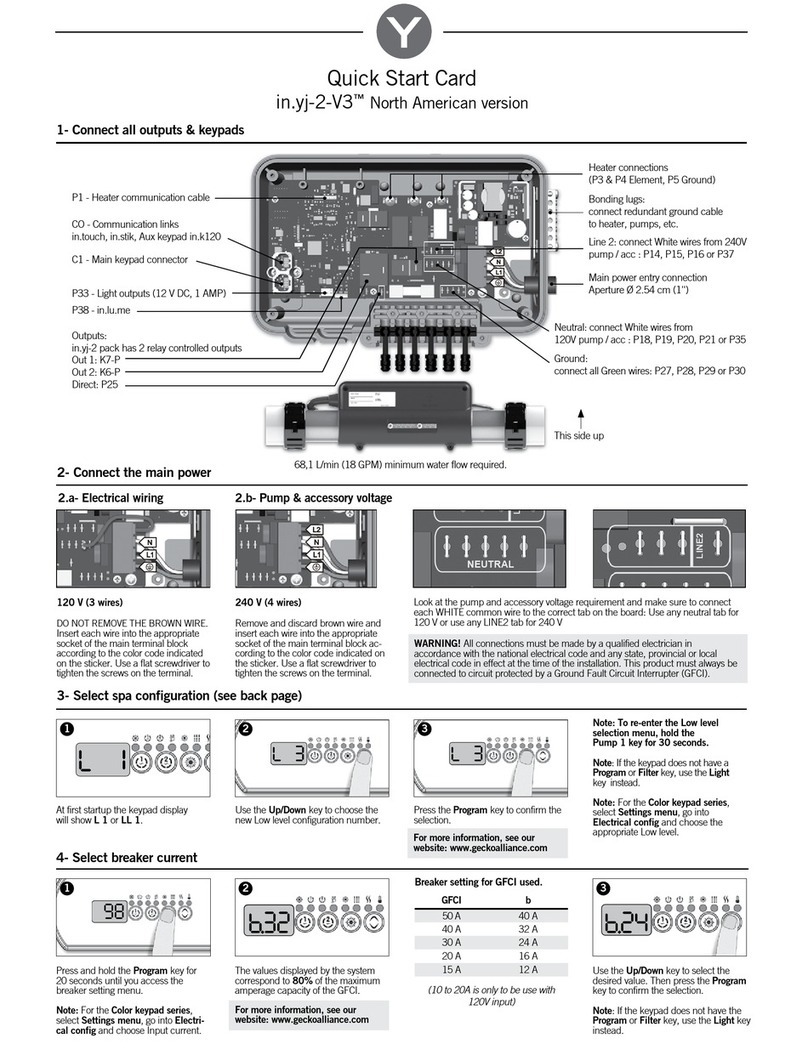

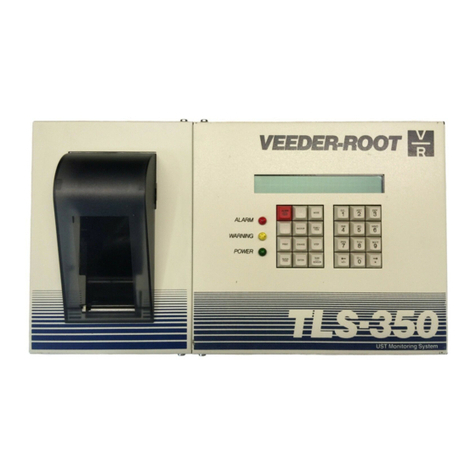

NOMENCLATURE OF DISPLAY

A] Screen

B] Graphic LED bar

C] Keyboard

OPERATING INSTRUCTIONS (SW Version 2.3)

Turn the ignion key to the ‘R’ posion.

SWITCH ON AND MAIN SCREEN

The system displays a screen with the MERLO symbol for 3 seconds and then automacally shis to the main screen.

OPERATING INSTRUCTIONS (SW Version 2.3)

The main screen shows the following informaon:

REF. DESCRIPTION

1 Longitudinal stability limit (percentage)

2Maximum load liable from the spot the telescopic boom is in (shown by the green/amber/red coloured

indicator (9) on the dynamic load chart) depending on the aachment

3Load lied from the spot the telescopic boom is in (shown by the green/amber/red coloured indicator (9) on

the dynamic load chart)

4 Load height from the ground (shown in metres)

5 Distance between the load and the outer limit of tyres shown in metres

6Telescopic boom li angle (shown in degrees)

7Symbol showing the acvaon of the working area for the operaon of the machine as either a telehandler

or a front loader

8Actual working area for the operaon of the machine as either a telehandler or a front loader

9Coloured indicator (green – amber – red) showing the posion of the load lied on the carriage

10 Dynamic load chart depending either on the aachment installed on the carriage (self-idencaon) or on

the posion of selector (D) (manual idencaon)

11 Indicaon that the machine is operang on tyres / stabilizers

12 Image of the aachment installed on the carriage, automacally idened by the system

13 Load being lied net of the tare set by the operator in the WEIGHING SCREEN

14 Informaon on the weighing: operang mode, li angle set by the operator, total weighing

15 In the MAN WEIGHING mode: manual weighing – In the AUTO WEIGHING mode: no command

OPERATING INSTRUCTIONS (SW Version 2.3)

ACTIVATION OF THE GRAPHIC BAR FOR CONTROL SELECTION

Display of the load control system is equipped with a oang bar which shows control buons P1, P2, P3, P4 and P5.

The acvaon of this oang bar depends on the weighing mode selected by the operator:

1) In the ‘AUTO WEIGHING’ mode (see paragraph ‘WEIGHING SCREEN’), when one of the 5 selecon buons (P1, P2,

P3, P4 or P5) is pressed, the system acvates the graphic bar at the boom of display where the executable func-

ons are shown. The operator has 5 seconds to press the buon corresponding to the funcon to be executed. If

no selecon buon is pressed within 5 seconds, the system deacvates the graphic bar.

2) In the 'MAN WEIGHING' mode (see paragraph 'WEIGHING SCREEN'), when one of the 4 selecon buons (P1, P2,

P3 or P4) is pressed, the system acvates the graphic bar at the boom of display where the executable funcons

are shown. The operator has 5 seconds to press the buon corresponding to the funcon to be executed. If no

selecon buon is pressed within 5 seconds, the system deacvates the graphic bar.

If buon P5 is pressed in the manual mode, it does not acvate the graphic bar but it starts a weighing procedure for

the load being lied (see paragraph 'MANUAL WEIGHING' (E)

The funcons corresponding to the selecon buons are the following:

(P1): press buon (P1) to acvate the setup menu for display, where you can adjust both display brightness in the

dayme/night illuminaon mode and the volume of the loudspeaker.

(P2): press buon (P2) to switch on the video camera installed on the machine (available as an opon). Each me

buon (P2) is pressed again, the system goes through all the video cameras available on the machine (check

whether your machine is equipped with oponal video cameras)

(P3): this buon does not acvate any funcon on the machine

(P4): press buon (P3) to acvate the dayme/night illuminaon mode for display

(P5): press buon (P5) to acvate the weighing screen (for further informaon please refer to the instrucons provi-

ded in paragraph 'WEIGHING SCREEN')

OPERATING INSTRUCTIONS (SW Version 2.3)

DISPLAY SETUP (BUTTON P1)

Carry out the following operaons to adjust the brightness

of display (both in a dayme and in a night mode) and the

volume of the loudspeaker:

- acvate the menu bar

- press buon (P1): a screen appears where you can

adjust both display brightness and volume

- press buon (P2) to select the graphic bar correspon-

ding to the seng you need to modify (in this order:

dayme brightness (A), night brightness (B), volume

(C)

- press buons (P3) and (P4) to set the desired values

for both brightness and volume (they can both be ad-

justed from a minimum of 0 to a maximum of 100)

Press buon (P1) to exit the setup screen for display.

SELECTION OF THE VIDEO CAMERA (BUTTON P2)

Carry out the following operaons to view the images from

the video cameras installed on your machine (available as

opons) on the screen of display in the cab:

- acvate the menu bar.

- press buon (P2): the system displays CHANNEL 1.

Press buon (P2) again to change over to CHANNEL 2.

- press buon (P1) to go back to the main screen.

SELECTION OF THE DAYTIME/NIGHT MODE FOR DISPLAY

ILLUMINATION (BUTTON P4)

Carry out the following operaons to select either the day-

me or the night mode for the illuminaon of display:

- acvate the menu bar

- press buon (P4) to change over from the dayme

mode to the night mode for the illuminaon of di-

splay and vice versa.

OPERATING INSTRUCTIONS (SW Version 2.3)

The system informs the operator about the selected mode by displaying either window (dayme mode) or (night

mode) in the middle of display.

dayme mode night mode

WEIGHING SCREEN (BUTTON P5)

From the main screen, acvate the menu bar, then press buon (P5) to enter the weighing screen, where the following

informaon is shown:

OPERATING INSTRUCTIONS (SW Version 2.3)

REF. DESCRIPTION

ANet weight lied by the aachment installed on the carriage (expressed in tonnes)

BTable showing the latest 20 weighings stored in the system, including the total weight

CDeleon of all weighings stored in the system. The total is set back to zero.

DAachment tare

EManual weighing

FSelecon of the weighing mode: either automac or manual

GModicaon of weighings stored in table 'B'

P1 Buon for exing the weighing screen and going back to the main screen

P2 Buon for scrolling the weighing menu

P3 Buon for conrming the item selected from the menu

P4 Buon for decreasing the angle for automac weighing

P5 Buon for increasing the angle for automac weighing

1) INSTRUCTIONS FOR WEIGHING A LOAD

In order for the weighing to be as accurate as possible, please check that the following condions are met:

1) your machine should always be placed on a at, compact surface

2) your machine should be standing sll, with its wheels aligned with the chassis

3) the telescopic boom should be fully retracted and in a horizontal posion

4) the carriage should be in a vercal posion

5) the recommended weighing mode is the manual one (MANUAL WEIGHING)

In these condions the approximate tolerance of the load readout should be about ±5% of the maximum rated load.

The value of the load being lied is to be considered a mere indicaon for the operator. It has no scal signicance and

it is not a cered weight value.

The following part of this paragraph describes the various funcons of the weighing system.

OPERATING INSTRUCTIONS (SW Version 2.3)

2) RESET (C)

The reset control allows you to delete all the weighing values stored in table 'B'. When all the paral weighing values

are deleted, the overall weighing value is set back to zero too.

To carry out the reset procedure you need to scroll the weighing screen with buon (P2) unl you select 'RESET'. Then

press (P3) to conrm.

The overall weighing value is also shown on the main screen in eld (14). When the RESET command is executed, the

value shown in eld (14) is set back to zero too.

Press buon (P1) to go back to the main screen.

OPERATING INSTRUCTIONS (SW Version 2.3)

3) TARE (D)

This control allows you to tare the weighing system. In this way eld (A) will subsequently show only the weight of the

load being lied, without the weight of the aachment.

To carry out the taring procedure you need to scroll the weighing screen with buon (P2) unl you select ‘TARE’. Then

press (P3) to conrm. The value of the measured weight, expressed in tonnes, appears next to the ‘TARE’ inscripon.

Press buon (P1) to go back to the main screen.

OPERATING INSTRUCTIONS (SW Version 2.3)

4) MANUAL WEIGHING (E)

Use this control to manually weigh the load being lied on the aachment. The data measured by the system are

shown in table 'B', from cell number 1 to cell number 20. Aer 20 weighings all the values scroll up, and the next values

are displayed at the boom of the table. The total at the boom of table 'B' is always the sum of all weighings, including

the ones which are not displayed.

To carry out the manual weighing procedure you need to scroll the weighing screen with buon (P2) unl you select

'WEIGHING'. Then press (P3) to conrm. A tone conrms that the weighing procedure was successfully completed, and

the system stores the value in table 'B'.

To know the sum total of all weighings please refer to the gure next to the 'TOT' inscripon, which is shown in the

boom row of the table; this total increases up to a maximum of 9999.99 t.

Press buon (P1) to go back to the main screen.

NOTE!!! You can also carry out a manual weighing procedure from the main screen by pressing buon (P5); a tone

conrms that the weighing procedure was successfully completed, and the system stores the value. On the main

screen you can also see the total of the weighings, whose value is shown under the load chart in eld (14). The

manual weighing procedure can be carried out from the main screen only if you have previously selected the 'MAN

WEIGHING' item on the weighing screen.

OPERATING INSTRUCTIONS (SW Version 2.3)

5) WEIGHING MODES (F)

Use this control to set the weighing mode:

1) MANUAL

2) AUTOMATIC

Is the manual mode selected, symbol 'X' appears with the 'MAN WEIGHING' inscripon next to it. Is the automac

mode selected, the 'Y' symbol appears with the 'AUTO WEIGHING' inscripon next to it. For the manual weighing pro-

cedure please refer to the instrucons provided in the previous step (MANUAL WEIGHING 'E'), while for the automac

weighing please refer to the following instrucons.

Scroll the weighing screen with buon (P2) unl you select 'AUTO WEIGHING', then press buon (P3) to conrm. Now

you can set a boom li angle beyond which the system automacally carries out a weighing. Such angle should be set

using buons P4 (decrease) and P5 (increase), and should range between 0° and 70°. Once these funcons are set you

need to press buon (P1) and to go back to the MAIN SCREEN, because the automac weighing does not work in the

WEIGHING SCREEN.

OPERATING INSTRUCTIONS (SW Version 2.3)

To conrm that the system was correctly set in the automac mode, eld (14) on the main screen shows the 'Y' symbol

and the value you selected for the boom li angle (in degrees).

In this way, whenever the telescopic boom is lied beyond the angle you selected, the system carries out an automac

weighing (eming the corresponding tone), and stores the value in table 'B'. The sum total of the weighings is always

shown on the main screen, under the load chart and next to the 'TOT' inscripon.

In order to have a new automac weighing available you need to lower the telescopic boom unl it is 5° below the

value you set for the li angle; if not, when you raise the telescopic boom again, the system will not carry out any au-

tomac weighing.

OPERATING INSTRUCTIONS (SW Version 2.3)

6) WEIGHING MODIFICATION (G)

Should you need to either modify or delete one or several weighings stored in table 'B' you can do that using the modi-

caon funcon available on the WEIGHING SCREEN. Scroll the weighing screen with buon (P2) unl you select 'EDIT

DATA', then press buon (P3) to conrm.

Now the manual weighing symbol and an eraser appear under buons (P4) and (P5) respecvely.

To select the weighing to be modied press buon (P2) unl this is highlighted in a ashing mode, then press either

buon (P4) to repeat a manual weighing or buon (P5) to delete the weighing.

Press buon (P3) to conrm your selecon.

Press buon (P1) to go back to the main screen.

OPERATING INSTRUCTIONS (SW Version 2.3)

Your machine is equipped with a 4-posion selector switch

(D) which allows the operator to select -either manually or

automacally- the type of aachment installed on the car-

riage, so as to determine the load capacity chart suitable

for the machine/aachment combinaon.

The 4 posions of switch (D) for the selecon of the type

of aachment installed are the following:

AUTO self-idencaon of the aachment installed on

the carriage

0.5/0.6 aachments where the centre of gravity of the

load being lied is 0.5 / 0.6 metres away from

the carriage

1.5 aachments where the centre of gravity of the

load being lied is 1.5 metres away from the car-

riage

4 aachments where the centre of gravity of the

load being lied is 4 metres away from the car-

riage

The graphic representaon of selector (D) is also shown

on display (A) in the cab, in eld (12) , and it is displayed

when:

- no aachment is installed on the carriage.

- no aachment is idened on the carriage.

- an error/a failure occurs in the aachment self-iden-

caon system

When an aachment is installed and idened on the

carriage and the system works correctly, the graphic re-

presentaon of selector (D) in eld (10) changes over to

the symbol of the aachment installed (see below in this

Chapter).

SWITCH FOR THE SELECTION OF THE TYPE OF ATTACHMENT INSTALLED ON THE CARRIAGE (D)

OPERATING INSTRUCTIONS (SW Version 2.3)

When an aachment equipped with a self-idencaon

sensor is installed on the carriage, you need to shi se-

lector (D) to the "AUTO" posion; in this case the system

automacally determines the appropriate working chart

for the machine/aachment combinaon, thus calculang

the correct stability index, the maximum load capacity and

the safe working area. Then the icon of the idened at-

tachment (a bucket in this case) appears in eld (12).

When an aachment equipped with a self-idencaon

sensor is installed on the carriage but selector (D) is not

shied to the "AUTO" posion, the following acvates:

- red indicator of the LED graphic bar (B)

- red indicator showing the posion of the load on the

dynamic load chart

- warning light on instrument panel

- audible alarm in the cab

In this case the system locks machine controls immedia-

tely and window "X" appears in the middle of display (A)

prompng you to turn selector (D) to the "AUTO" posion.

For the operaon modes of selector (D) please refer to the following instrucons:

SELF-IDENTIFICATION OF AN ATTACHMENT (selector (D) in the AUTO posion)

WARNING!!! The aachment self-idencaon system is disabled if operang mode selector (6) is in the "B" posion

(road travel). In this case you need to turn selector (6) to the "A" posion (movements enabled).

OPERATING INSTRUCTIONS (SW Version 2.3)

If the self-idencaon system works correctly but there is

no graphic representaon of the aachment installed on

the carriage, the machine signals it by showing the corre-

sponding symbol in eld (12) of display (A) in the cab.

MANUAL SELECTION OF AN ATTACHMENT (selector (D) in the 0.5/0.6 or 1.5 or 4 posion)

When either an aachment not equipped with a self-idencaon sensor is installed on the carriage or an error/mal-

funconing occurs in the system, you need to manually select the category the aachment belongs to by operang

selector (D) as follows:

- turn selector (D) to the "A" posion (0.5/0.6) when aachments are installed whose centre of gravity is between

0.5 and 0.6 metres ahead of the carriage

- turn selector (D) to the "B" posion (1.5) when aachments are installed whose centre of gravity is within 1.5

metres ahead of the carriage

- turn selector (D) to the "C" posion (4) when aachments are installed whose centre of gravity is within 4 metres

ahead of the carriage

In this way the machine gets ready to be used with the selected aachment based on aachment category, determi-

ning the work chart and calculang the correct stability index, the maximum load capacity and the safe working area.

OPERATING INSTRUCTIONS (SW Version 2.3)

Field (12) shows the graphic representaon of the posion

of selector (D)

If the selector (D) is turned to the AUTO posion and:

- an aachment not equipped with a self-idencaon

sensor is installed on the carriage, or

- an error/malfunconing occurs in the system

The system automacally acvates the work chart corre-

sponding to the “C” posion (centre of gravity of the load

placed 4 metres ahead of the carriage).

For a beer comprehension of both the self-idencaon

system and the manual selecon of aachments a table is

provided, lisng all graphic representaons shown in eld

(12) of display (D), together with their descripon.

SYMBOL SHOWN IN

FIELD (12) DESCRIPTION

CAN bus connecon interrupted – the ECU is not receiving data from the UGS ECU, the-

refore it can’t show reliable informaon. The symbol shown opposite appears in place of

the image of the aachment (or of the selector), the LEDs of the graphic bar ash and all

values (weight, maximum weight, overturning index, height of load from the ground, load

distance and boom angle) are not validated and replaced by a dash.

This symbol only appears when the diagnoscs is acve, because without a CAN BUS the

display switches o.

The aachment installed on your machine was correctly idened by the system, but the

corresponding image is not available in the database.

Make sure that selector (D) is turned to the AUTO posion

The aachment installed on your machine is either not equipped with a self-idencaon

sensor, or it was not automacally idened by the system due to a system failure or

malfunconing.

Manual selecon of the type of aachment installed with selector (D) was necessary.

When selector (D) is in the AUTO posion, mode “C” of the load chart is acve, referring

to aachments whose centre of gravity is 4 metres ahead of the carriage.

The aachment installed on your machine is either not equipped with a self-idencaon

sensor, or it was not automacally idened by the system due to a system failure or

malfunconing.

Manual selecon of the type of aachment installed with selector (D) was necessary.

When selector (D) is in the 0.5/0.6 posion, mode “A” of the load chart is acve, refer-

ring to aachments whose centre of gravity is between 0.5 and 0.6 metres ahead of the

carriage.

OPERATING INSTRUCTIONS (SW Version 2.3)

SYMBOL SHOWN IN

FIELD (12) DESCRIPTION

The aachment installed on your machine is either not equipped with a self-idenca-

on sensor, or it was not automacally idened by the system due to a system failure

or malfunconing.

Manual selecon of the type of aachment installed with selector (D) was necessary.

When selector (D) is in the 0.5/0.6 posion, mode “A” of the load chart is acve, refer-

ring to aachments whose centre of gravity is between 0.5 and 0.6 metres ahead of the

carriage.

The aachment installed on your machine is either not equipped with a self-idenca-

on sensor, or it was not automacally idened by the system due to a system failure

or malfunconing.

Manual selecon of the type of aachment installed with selector (D) was necessary.

When selector (D) is in the 1.5 posion, mode “B” of the load chart is acve, referring to

aachments whose centre of gravity is within 1.5 metres ahead of the carriage.

SYMBOL SHOWN IN

FIELD (12) DESCRIPTION

POSIZIONE SELETTORE

SOLO PER

ATTREZZATURA

SENZA SENSORE

The STANDARD FORK aachment installed on the machine

was correctly idened by the system.

The CONCRETE MIXING BUCKET aachment installed on the

machine was correctly idened by the system.

The

REDUCED-HEIGHT CRANE ARM

TELESCOPIC CRANE ARM

aachment installed on the machine was correctly idened

by the system

The BRICK HANDLER aachment installed on the machine

was correctly idened by the system.

Popular Control System manuals by other brands

Precision Planting

Precision Planting 20/20 SeedSense Operator's guide

Triangle MicroSystems

Triangle MicroSystems PETROSMART EZ installation instructions

Siemens

Siemens BC80 Series product manual

HandyTrac

HandyTrac Key Control Installation and operation

Pentatech

Pentatech GA50 instruction manual

Yaesu

Yaesu SCU-LAN10 Operation manual