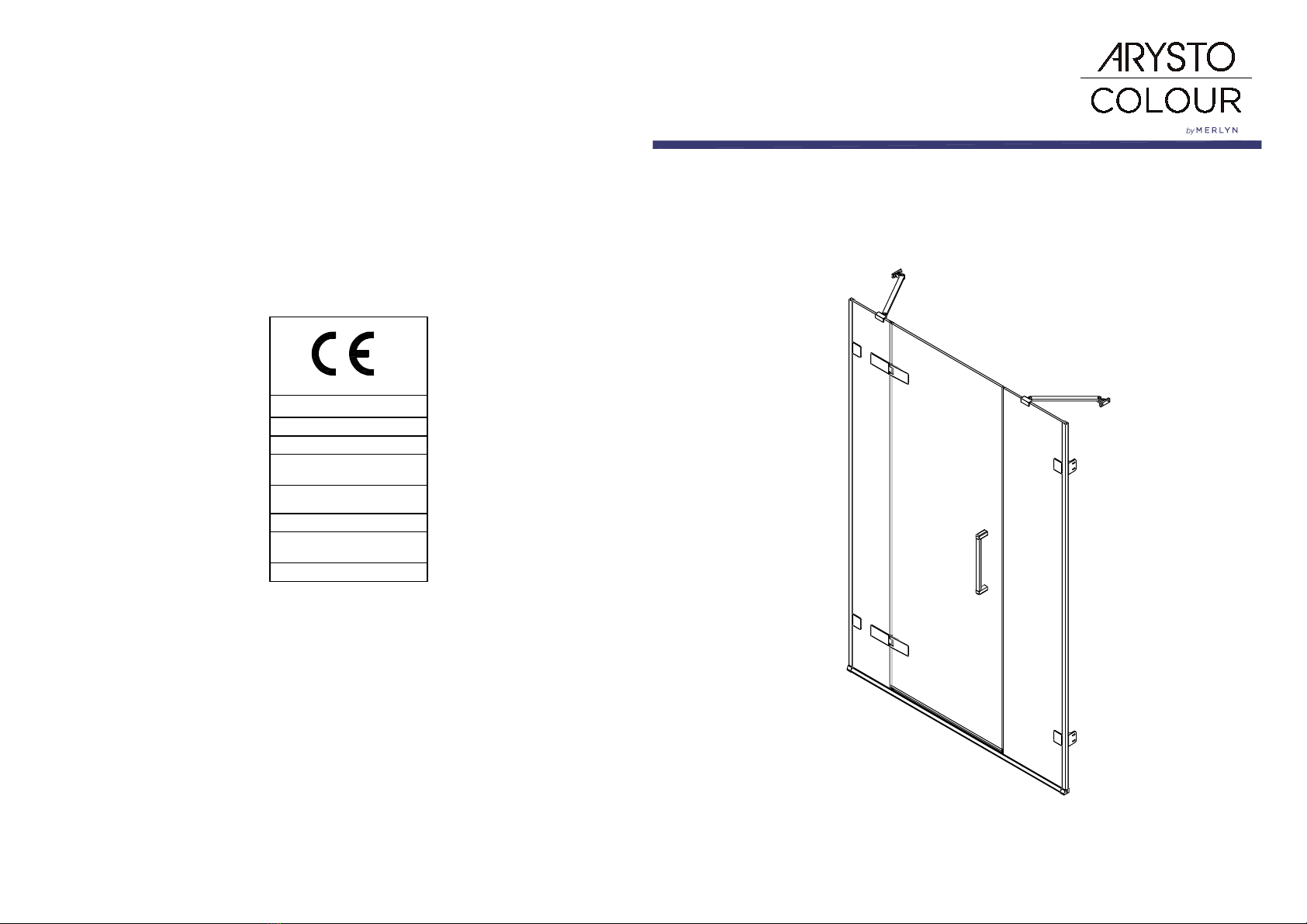

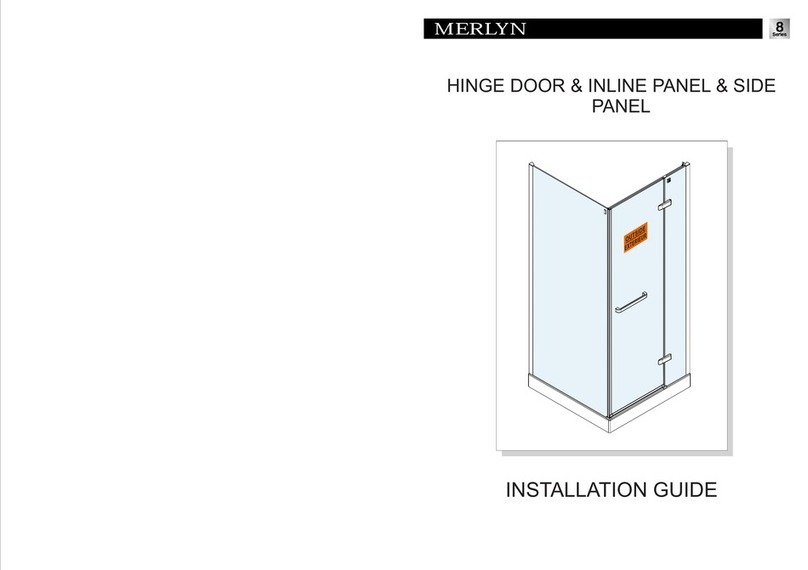

MERLYN ARYSTO COLOUR User manual

Other MERLYN Shower Cabin manuals

Popular Shower Cabin manuals by other brands

Grandform

Grandform ESSENTIAL Assembly instructions

Coram Showers

Coram Showers PREMIER installation instructions

ERLIT

ERLIT ER 10109V Installation and operation instruction

KERRA

KERRA P 135 Assembly and maintenance instructions

Novellini

Novellini NEW HOLIDAY A80 Installation, use and maintenance manual

Kermi

Kermi Raya RA EPR/L TWD installation instructions

Samo

Samo B6811 Assembly instruction

OVE

OVE OWS-607 Installation and user guide

Dreamline

Dreamline MYSTERIE SHDR-61AMZ48 Series installation instructions

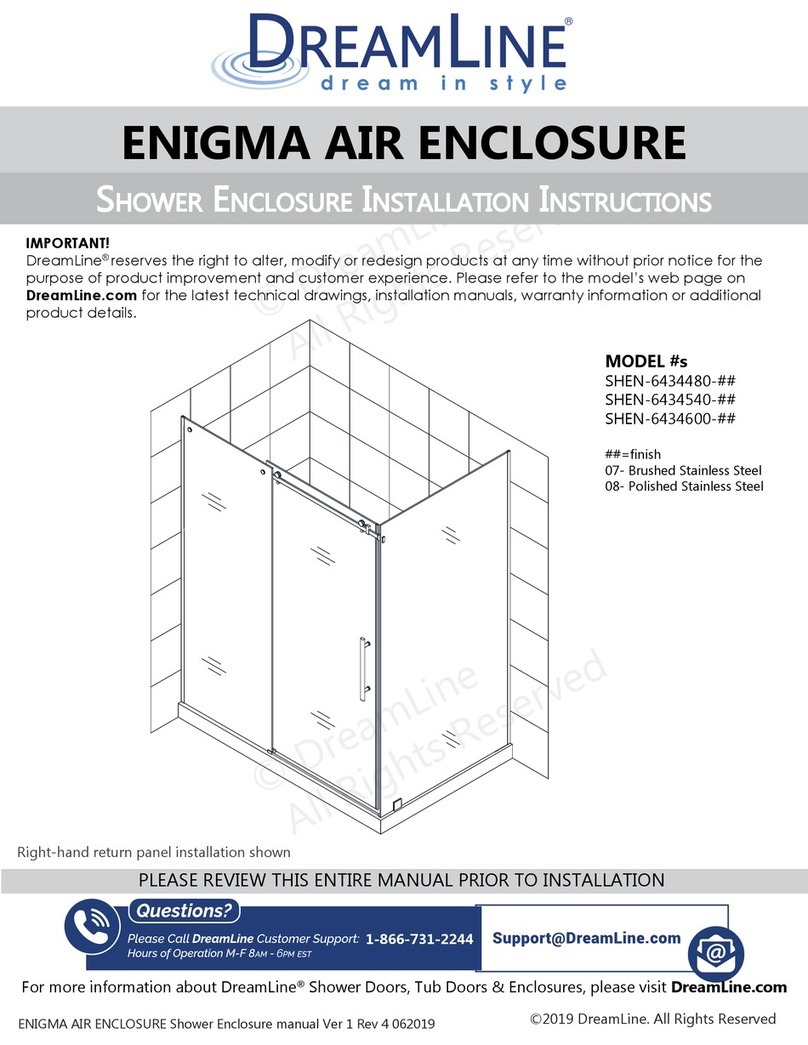

Dreamline

Dreamline ENIGMA AIR SHEN-6434480 Series installation instructions

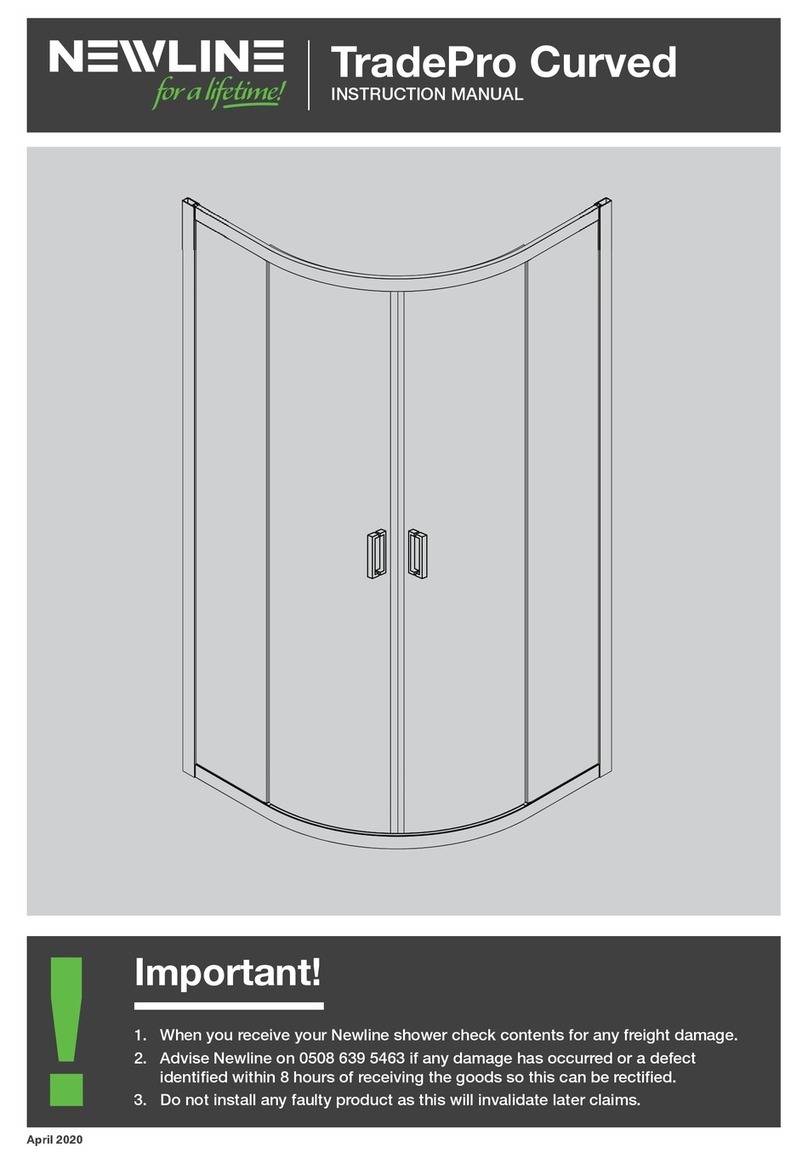

NewLine

NewLine TradePro Curved instruction manual

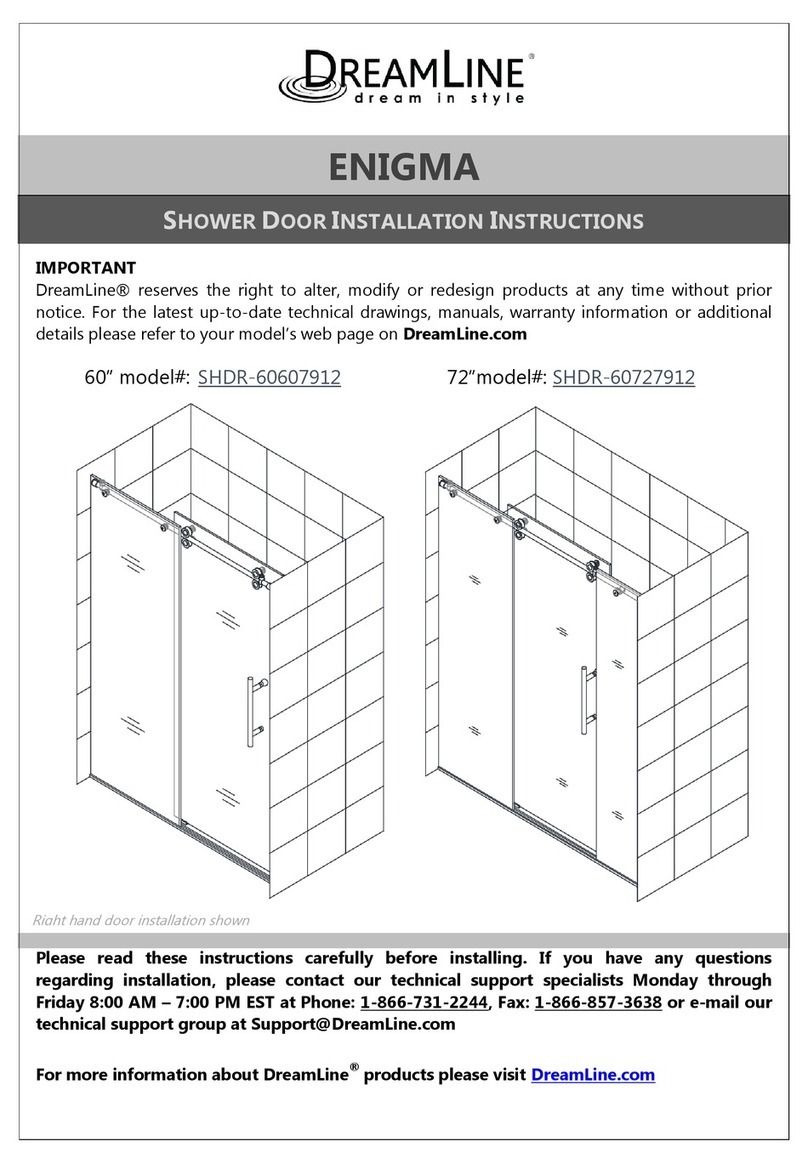

Dreamline

Dreamline ENIGMA SHDR-6060791272 installation instructions