Merry Tiller ST5 5H Series User manual

OWNER’S MANUAL

Suburban Merry Tiller

Models: ST5.5H ST750IC ST6.5V

CAUTION:

Before using this product, read this

manual and follow all Safety Rules and

Operating Instructions.

MACKISSIC, INC. P.O. BOX 111, PARKER FORD, PA 19457-0111

www.mackissic.com

PART # 709-3400

05/18/2020

2

TABLE OF CONTENTS

Accessories .....................................

2

I. Safety ..............................................

3

General Preparation ............................

5

Repair and Maintenance Safety ..........

6

II. Assembly Instructions ....................

7

III. Lubrication & Engine Start Up ........

8

IV. Operation .......................................

10

V. Service - Maintenance - Repair ......

11

Belt and Clutch Adjustment .................

11

Belt Installation ....................................

12

Service Notes ......................................

12

Inspection of Transmission .................

12

Engine Maintenance

............................

13

VI. Storage ..........................................

13

Transmission Assembly Drawing ....

14

Tiller Drawing ..................................

15

Parts List

..............................................

16

Warranty .........................................

17

MERRY TILLER ACCESSORIES

AVAILABLE WHEREVER MERRY TILLER PRODUCTS ARE SOLD

MT-951

MT-952

MT-956

MT-1701

MT-1702

MT-1703

MT-1812

MT-1813

MT-2492

MT-2857

MT-7801

MT-7802

MT-7875

Finger Tine Assemblies - Right and Left Inside

Finger Tine Assemblies - Right and Left Outside

Pick Tine Assemblies (1 set)

Slasher Tine Assemblies - Right and Left Inside

Slasher Tine Assemblies - Right and Left Outside

Slasher Tine Extension Assemblies - Right and Left

Bolo Tine Assemblies - Right and Left Inside

Bolo Tine Assemblies - Right and Left Outside

Aerator Assemblies (3 spoons) Set of 4

Finger Tine Extension Assemblies (1 complete set)

8” Furrower

10” Furrower

Adjustable Plow Bar

3

SECTION I - SAFETY

This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read

and follow all instructions in this manual before attempting to operate your tiller.

Failure to comply with these instructions may result in personal injury. When you

see this symbol - heed its warning.

INTENDED USE

Never use your tiller for any other purpose than cultivating soil and use only approved

attachments and accessories. It is designed for this use and any other use may cause

injury.

DANGER: Rotating tines and belt.

Keep hands and feet out of tines and belt area while machine is running.

DANGER: This machine can CRUSH, CUT, and SEVER parts of your body if they enter

the operating areas of the garden tiller.

Make certain that all safety labels on this equipment are kept

clean and in good condition.

If you need replacement labels, please order by part number

091-0423.

4

DANGER: Your tiller was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. If you violate any of these rules, you may cause

serious injury to yourself or others.

WARNING: The Engine Exhaust from this product contains

chemicals known to the state of California to cause cancer,

birth defects or other reproductive harm.

OPERATORS INSTRUCTIONS

STARTING:

1. Remove or rotate wheels to up position.

2. Adjust drag bar for desired depth.

3. Stand between handlebars.

4. Allow clutch lever to drop into disengaged position.

5. Move throttle lever to run position.

6. Reach forward to set choke lever to choke position.

7. Hold left handlebar with left hand and pull starter

rope with right hand.

8. As engine starts, return choke lever to run

position and adjust throttle for desired speed.

TILLING:

Squeeze clutch lever to start tilling. Apply downward

pressure on handles to allow drag bar to control

forward motion of tiller. Certain tilling conditions

require tiller to be run at a reduced throttle speed.

STOPPING:

Release clutch lever and move throttle to stop position.

5

GENERAL PREPARATION

•Read the owner’s manual carefully and in its

entirety before attempting to assemble this

machine. Be thoroughly familiar with the

controls and the proper use of the equipment

before operation. Know how to stop the unit

and disengage the controls quickly.

•Your tiller is a powerful tool, not a plaything.

Therefore, exercise extreme caution at all

times.

•Never allow children to operate the

equipment. Only responsible adults who are

familiar with these rules of safe operation

should be allowed to use your unit.

•Keep the area of operation clear of all

persons, particularly small children, and pets.

Thoroughly inspect the area where the

equipment is to be used and remove all

foreign objects.

•Wear sturdy, rough-soled work shoes and close

fitting slacks and shirt. Slacks that cover the legs

and steel-toed shoes are recommended. Secure

hair above shoulders and do not wear loose

clothes that can be caught in moving parts.

Never operate a unit in bare feet, sandals or

sneakers.

•Do not operate while under the influence of

alcohol or drugs.

•If the tines strike a foreign object or if your

machine should start making an unusual noise or

vibration, immediately stop the engine and allow

the machine to come to a complete stop.

Disconnect the spark plug wire and move it away

from the spark plug.

Take the following steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to assure

continued safe operation.

•Handle fuel with care; it is highly flammable.

•Refer to engine manual for safety and

service instructions.

•Disengage clutch before starting the engine

(motor).

•Never attempt to make any adjustments

while the engine (motor) is running (except

where specifically recommended by the

manufacturer).

•DO NOT put hands or feet near or under rotating

parts.

•Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay

alert for hidden hazards of traffic. Do not carry

passengers.

•Stop the engine (motor) when leaving the

operating position. Disconnect the spark plug

before unclogging the tines, and when making

any repairs, adjustments, and inspections.

•Periodically check tines and remove any vines or

garden debris that may be wrapped around the

tine shaft. Before cleaning, repairing, or

inspecting, shut off the engine and make certain

all moving parts have stopped. Disconnect the

spark plug wire, and keep the wire away from the

plug to prevent accidental starting.

•Do not run the engine indoors; exhaust fumes are

dangerous.

•NEVER operate the tiller without proper guards,

plates, or other safety protective devices in place.

•Do not overload the machine’s capacity by

attempting to till too deep at to fast a rate.

•Only operate your tiller in good daylight. Do not

operate tiller at night or in dark areas where your

vision may be impaired.

•Be careful when tilling in hard soil or frozen

ground. The tines may catch in the ground and

propel the tiller forward. If this occurs, release

clutch lever to stop forward motion.

CHILDREN

•Tragic accidents can occur if the operator is not alert to the presence of small children.

•Keep children out of the work area and under the watchful eye of a responsible adult other than the operator.

•Be alert and turn the unit off if a child enters the area.

•Never allow children under the age of 16 to operate the tiller.

6

•REPAIR AND MAINTENANCE SAFETY

•Use extreme care in handling gasoline and other

fuels. They are extremely flammable and the

vapors are explosive.

•Store fuel and oil in approved containers, away

from heat and open flame, and out of the reach

of children. Check and add fuel before starting

the engine. Never remove gas cap or add fuel

while the engine is running. Allow engine to cool

at least three minutes before refueling.

•Replace gasoline cap securely and wipe off any

spilled gasoline before starting the engine as it

may cause a fire or explosion. Extinguish all

cigarettes, cigars, pipes and other sources of

ignition.

•Never refuel unit indoors because flammable

vapors will accumulate in the area.

•Never store the machine or fuel container inside

where there is an open flame or spark, such as

a gas hot water heater, space heater, clothes

dryer or furnace.

•Never run this machine in an enclosed area as

the exhaust from the engine contains carbon

monoxide, which is an odorless, tasteless, and

deadly poisonous gas.

•To reduce fire hazard, keep engine and muffler

free of debris build-up. Clean up fuel and oil

spillage. Allow unit to cool at least five minutes

before storing.

•Before cleaning, repairing, or inspecting, make

certain the tines and all moving parts have

stopped. Disconnect the spark plug wire and

keep wire away from spark plug to prevent

accidental starting. Do not use flammable

solutions to clean air filter. NOTE: If the engine

is equipped with a fuel shut off valve, be sure to

turn it to the off position.

•Check the belt and engine mounting screws at

frequent intervals for proper tightness. Also

visually inspect tines for wear or damage. Use

only replacement tines which meet original

manufacturer’s specifications.

•Never tamper with safety devices. Check their

proper operation regularly. Be sure all safety

guards and shields are in proper position.

These safety devices are for your protection.

•Never operate your tiller in poor mechanical

condition or when in need of repair. Periodically

check and keep all nuts, bolts, and screws tight

to be sure the equipment is in safe working

condition.

•Inspect the belt each time you use the unit.

Look for damage, worn areas, or tears. Do not

use the unit if this condition exists.

•If your machine strikes any foreign object or

starts making an unusual noise or vibration,

immediately shut off engine, disconnect spark

plug wire from spark plug, and allow all moving

parts to come to a complete stop. Inspect for

damage and repair and or replace damaged

parts. Check for and tighten any loose parts.

•Do not tamper with the engine’s governor

setting. The governor controls the maximum

safe operation speed and protects the engine.

Over revving the engine is dangerous and will

cause damage to the engine and to the other

moving parts of the machine. See your

authorized dealer for engine governor

adjustments.

YOUR RESPONSIBILITY

•Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

HAZARD: This unit is equipped with an internal combustion engine

and should not be used on or near any unimproved forest-covered,

brush-covered or grass-covered land unless the engine’s exhaust

system is equipped with a spark arrester meeting applicable to local or

state laws (if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

In the State of California, the above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A

spark arrester for the muffler is available through your engine manufacturer’s servicing dealer.

7

SECTION II - ASSEMBLY INSTRUCTIONS

PACKAGE CONTENTS

BOX

POLYBAG

BOLT BAG

•TILLER

•OWNER’S MANUAL

•1 EA CLUTCH SPRING

•2 EA 10-32 X 1 1/4 RHMS

•HANDLE BARS (2)

•ENGINE MANUAL

•1 EA PULL CORD HOLDER

•5 EA 1/4 X 20 NYLOCK NUT

•TIE BARS (2)

•WARRANTY CARD

•2 EA CABLE GUIDE

•2 EA 5/16-18 X 3/4 HHCS

•OUTSIDE TINES (2)

•CLUTCH CABLE

•2 EA 3/8 X 2 1/4 CLEVIS PIN

•2 EA 5/16 X 1 3/4 HHCS

•POLYBAG

•CROSS BRACE

•2 EA 1/8 HAIR SPRING COTTER

•4 EA 5/16-18 X 1 HHCS

•CLUTCH CONTROL LEVER

•2 EA 10-32 KEP NUT

•8 EA 5/16-18 NYLOCK NUT

•BOLT BAG

•1 EA 1/4-20 X 1 ½ HHCS

•

NOTE: All items in this section refer to the item numbers on assembly drawings on page 16

TOOLS REQUIRED FOR ASSEMBLY

•1/2”, 7/16”, 3/8” Wrench or Socket

STEP I - Unpacking and Checking Contents

1. Remove all parts and liners from carton

2. Slit carton ends, leaving the tiller available for assembly without lifting it.

3. After unpacking the shipping carton, compare items with list above. Use the parts lists and assembly

drawings on pages 17-19 for additional identification assistance.

4. If any parts are missing or damaged, contact your local dealer, distributor, or call the factory.

5. Assembly should be done on a clean, level surface

STEP II - Attaching Handles, Cross Brace and Tie Bars

1. Attach lower ends of handles (item #31 & # 34, pg. 16/17) to frame rails

(item #17 & #18, pg. 16/17). Use the 5/16-18 x 1” HHCS (item #51, pg.

16/17) and the 5/16-18 nylock nut (item #41, pg. 16/17) to attach each

handle. Do not completely tighten the bolts and nuts at this time.

2. Remove the three bolts and whiz nuts on the transmission where the tie

bars (item #28 & #29, pg. 16/17) will connect. Discard the whiz nuts.

Place the tie bars on both sides of the transmission case flange and put

the 1/4-20 x 1 1/4 bolts you just removed through the three holes in the

tie bars and transmission and hand tighten with three 1/4-20 nylock

nuts from the bolt bag.

3. To attach the cross brace, place a 5/16-18 x 1 3/4 HHCS (item #10, pg.

16/17) through the upper holes of the handle, tie bar, and cross brace.

Hand tighten a 5/16-18 nylock nut (item #41, pg. 16/17) to these bolts.

Attach two cable guides (item #50, pg. 16/17) to the inside of the cross

brace by placing a 5/16-18 x 3/4 HHCS (item #48, pg. 16/17) through

the lower hole in the tie bar, cross brace, and then through the cable

guide. Hand tighten a 5/16-18 nylock nut on both sides.

4. Tighten all nuts and bolts in the same order as installation of steps 1-3.

8

STEP III - Attaching the Throttle Control Cable, Clutch Cable and Starter Rope

1. Insert throttle control (item #52, pg. 16/17) through cable guide (item #50, pg. 16/17). Attach throttle control to

handlebar with 2 ea. 10-32 x 1 1/4 machine screw (item #33, pg. 19) and 2 ea. 10-32 Kep nut (item #32, pg.

19) provided in the bolt bag.

2. Insert clutch cable through the cable guides (item #50, pg. 16/17) on the cross brace and the transmission.

Slip lower cable loop (end without chain attached) over adjustment link (item #25, pg. 16/17). Attach clutch

control lever (#31B, pg. 16/17) to right hand handlebar with a 1/4-20 x 1 ½ HHCS (#31D, pg. 16/17) and a

1/4-20 nylock nut (#31D, pg. 16/17). Attach clutch spring (item #43, pg. 16/17) to the clutch control lever

(item #31B, pg. 16/17). Now attach the clutch cable chain to the spring.

3. Disconnect the spark plug. Grasp the starter pull cord and pull it 6” past the cross brace. String the cord into

the eye of pull cord holder (item #54, pg 16/17) from the bolt bag. Put the pull cord holder through the hole

below the cross brace. Secure with a 1/4-20 nylock nut from the bolt bag.

NOTE: Models with Honda engines do not provide an extended rope pull. This engine is equipped with

an on/off switch that requires the engine to be stated and stopped from the engine position

9

SECTION III - LUBRICATION & ENGINE START UP

FOR INFORMATION ABOUT:

❑OIL

❑FUEL

❑STARTING

❑STOPPING

❑RECOMMENDED MAINTENANCE

❑SERVICE

❑STORAGE

❑ENGINE WARRANTY INFORMATION

REFER TO THE ENGINE OWNER’S MANUAL.

THE ENGINE ON YOUR SUBURBAN TILLER HAS BEEN SHIPPED DRY.

BE SURE TO SERVICE THE ENGINE ACCORDING TO THE

ENGINE OWNER’S MANUAL PRIOR TO STARTING.

FAILURE TO DO SO CAN RESULT IN DAMAGE NOT WARRANTIED BY THE

ENGINE MANUFACTURER.

WARNING: Do not fill closer than ½” from the top of the fuel tank to prevent spills and to allow for fuel expansion.

If gasoline is accidentally spilled, move the mower away from the area of the spill. Avoid creating any source of

ignition until gasoline vapors have disappeared.

CAUTION: Experience indicates that alcohol blended fuels (gasohol, ethanol, methanol) can attract moisture

which leads to separation and formation of acids during storage. Acidic gas can damage the fuel system or an

entire engine while in storage. To avoid engine problems, the fuel system should be empty before storage for

periods over 30 days. For more information, refer to the engine owner’s manual. Use fresh fuel each season.

Never use engine or carburetor cleaner products in the fuel tank or permanent damage may result.

THE TRANSMISSION HAS BEEN FACTORY SERVICED WITH “00” GREASE.

NO ADDITIONAL LUBRICATION IS NECESSARY OR RECOMMENDED.

ALWAYS CHECK OIL LEVEL PRIOR TO

STARTING THE TILLER.

10

SECTION IV - OPERATION

TILLING - This tiller is equipped with a set of rear wheels. These wheels are designed only for transporting

the tiller to and from the tilling area. They should never be used during the tilling process. When at the

tilling site, lean the tiller forward until resting on the frame rails. Grab the ring on the pin holding the wheels in

place, pull it out and swing the wheels up and out of the way. Pull the upper pin out and lock the wheels into the

upper position with this pin. Adjust the dragbar by pulling the third pin out and raising or lowering it to the desired

tilling depth. The drag bar acts as an anchor, which forces the tiller to dig rather than walk over the area to be

tilled, and controls the forward motion of the tiller. By adjusting the downward pressure on the handlebars, the

operator controls the drag bar depth and the tiller will perform properly with a minimum of assistance.

1. NEVER allow bystanders near the unit.

2. DO NOT put hands or feet near or under rotating parts.

3. Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert for

hidden hazards of traffic. DO NOT carry passengers.

4. Exercise caution to avoid slipping or falling.

5. Never operate the machine at high transport speeds on slippery surfaces.

6. Do not overload the machine’s capacity by attempting to till TOO DEEP at too FAST a rate.

7. Be careful when tilling in hard soil or frozen ground. Certain soil conditions require the engine to be run at a

reduced speed or the tines may catch in the ground and propel the tiller forward. If this occurs, release clutch

lever to stop forward motion.

8. After striking a foreign object, STOP the engine, remove the wire from the spark plug, thoroughly inspect the

tiller for any damage before restarting and operating the machine.

9. If the unit should start to VIBRATE abnormally, STOP the engine (motor) and check immediately for the

cause. Vibration is generally a warning of trouble.

10. STOP the engine (motor) when leaving the operating position. Disconnect the spark plug wire before

unclogging the tines, and when making any repairs, adjustments, and inspections.

11. Take all possible precautions when leaving the machine unattended. Release the clutch lever and stop the

engine.

12. Periodically check tines and remove any vines or garden debris that may be wrapped around tine shaft.

BEFORE cleaning, repairing, or inspecting, shut off the engine and make certain all moving parts have

stopped. Disconnect the spark plug wire, and keep the wire away from the plug to prevent accidental starting.

13. Do NOT run the engine INDOORS; exhaust fumes are dangerous.

14. NEVER operate the tiller without proper guards, plates, or other safety protective devices in place.

15. Use only attachments and accessories APPROVED by the manufacturer of the tiller.

16. Never operate the tiller without good visibility of light.

11

SECTION V - SERVICE - MAINTENANCE - REPAIR

The transmission has been factory serviced with “00” grease. No additional lubrication

is necessary or recommended.

Belt tension should be checked, and adjusted if necessary, after initial 20 to 30 minutes

of operation. Follow directions below.

Belt and Clutch Adjustment

CAUTION: DO NOT ADJUST BELT OR CLUTCH WITH THE ENGINE RUNNING!

•For proper belt tightness and tiller operation, the distance from the center

of the engine crankshaft (A), to the center of the transmission input shaft

(B), should measure 14 3/4”.

•Proper clutch adjustment is very important. The idler type clutch may

need adjusting as the belt stretches.

•To check belt and clutch adjustment, start the tiller, press down on the

handle bars to raise the tines into the air, and squeeze the clutch lever. If

adjusted correctly, the tines will rotate while the clutch lever is squeezed

and stop when it is released. When the lever is squeezed tight, the clutch

spring (item #43, pg. 15) should be slightly stretched (about 1/4 inch).

If your tines fail to operate as described above, adjustment can be made in the following ways.

1. Switch the link on the end of the clutch cable (item #53, pg. 15) which is attached to the clutch spring (item

#43, pg. 15). A link closer to the cable will tighten the adjustment, a link further away from the cable will

loosen the setting.

2. Loosen the nut holding the adjustment link (item #25, pg. 15). While holding idler arm and pulley

(item #20 & #22, pg.15) firmly, adjustment link can be moved up (counterclockwise) to loosen

clutch, or moved down (clockwise) to tighten clutch. After making any change in position of

adjustment link, re-tighten nut.

3. Additional adjustment can also be made by loosening the four bolts (item #10, pg. 15) holding the engine to

the engine mounts (items #17 & #18, pg. 15) and sliding the engine forward or backward as needed. Re-

tighten engine mount bolts. This adjustment is almost never needed and should not be made unless all

other adjustments fail.

Belt Installation and Alignment of Pulleys

1. Whenever a new belt is installed be sure to examine the grooves of the pulleys for wear. A wide groove of a

worn engine pulley will cause slippage of the belt when the clutch is engaged. Replace the pulley if worn.

2. The pulleys must be aligned by sliding the engine pulley in or out so that the belt will travel in a straight line.

3. Be sure to install the belt inside the two pins of the belt release bracket. If improperly installed on the outside

of the belt release pins, the belt will be quickly damaged, and/or jump off pulleys.

4. Start the engine and test the clutch for proper operation.

5. Reinstall the belt cover.

6. Check belt tension after initial 20 to 30 minutes of operation with a new belt. Be sure your tiller operates as

per the directions in this section.

NOTE: The purpose of the belt release bracket is to force the belt out of the engine pulley groove, allowing it to

slip when clutch lever is not engaged.

•Proper maintenance includes periodic inspection and lubrication of the tiller by the operator, using the correct

lubricants. This will ensure long life of the tiller.

•Keep machine, attachments, and accessories in safe working condition.

•Check engine mounting bolts, and other bolts at frequent intervals for proper tightness to be sure the

equipment is in safe working condition.

12

Service Notes

1. The transmission has been factory serviced with “00” grease. NO additional lubrication is necessary

or recommended.

2. Service the engine according to the engine operating and maintenance instructions furnished with the tiller.

Special attention should be given to the proper installation and service of the engine air filter assembly.

3. Regularly check tines for wear. Tine clevis pin holes should be checked for wear or elongation. Tine

assemblies should be replaced when lead corner on cutting edge has become rounded, therefore reducing

tilling efficiency.

4. Proper maintenance includes periodic inspection and lubrication by the operator, using the correct lubricants.

This will ensure long life of the tiller.

5. Keep the machine, attachments, and accessories in safe working condition.

6. Check engine mounting bolts, and other bolts at frequent intervals for proper tightness to be sure the

equipment is in safe working condition.

7. Never store the machine with fuel in the fuel tank inside a building where ignition sources are present, such

as hot water and space heaters, clothes dryers, and the like. Allow the engine to cool before storing in any

enclosure.

8. Always refer to the engine operating instructions for important details if the tiller is to be stored for an

extended period.

Inspection of the Transmission Case Assembly

When it is necessary to make internal repairs to the transmission, it is advisable to take your tiller to an

authorized MERRY TILLER dealer, especially if there are signs of excessive wear. Following are some

suggestions that will help to determine the amount of wear.

1. Before removing the transmission case from the tiller, turn the large pulley by hand and observe whether or

not the rotor shaft also turns. If it does not, or if the pulley turns freely, check to be certain the square key

securing the pulley to the drive shaft is not missing or damaged. This could cause the pulley to slip on the

shaft.

2. Turn the large pulley in either direction until all the slack is removed from the chains and sprockets within the

transmission. Make a mark on the tine shaft and the outer edge of the large pulley. Then, while observing

both the mark on the pulley and the mark on the tine shaft, turn the large pulley in the opposite direction until

all internal slack is removed and the mark on the tine shaft just begins to move. The mark on the large pulley

should not travel a distance of more than 3 inches (7.6 centimeters) before the mark on the tine shaft begins

to move.

Any travel of the mark in excess of this indicates excessive wear inside the case of either one or both chains,

sprockets, shafts, or bearings. The case should be removed and disassembled for internal inspection.

Engine Maintenance

CHECK THE ENGINE OWNER’S MANUAL FOR RECOMMENDED REGULAR MAINTENANCE.

By following the engine maintenance schedule, you will obtain maximum engine and tiller life. The four-cycle

engine of your tiller will normally consume some oil, so check engine oil level regularly and before each use.

13

MERRY TILLER SERVICE BULLETIN

TIME TO CHANGE THE TINE SHAFT SEALS

Tine Shaft Seal Replacement Instructions

It is extremely important that the oil seals on the tiller transmission be inspected and replaced regularly to ensure proper lubrication and to

prevent dirt from entering the transmission. Both sides of the tine shaft have two oil seals. These seals are inserted back to back over the tine

shaft. The inner seal faces into the transmission and is designed to keep lubricant from escaping from the transmission. The outer seal faces

outward and is designed to keep dirt out of the transmission. The Merry Tiller transmission is lubricated with heavy “00” grease. If the seals

fail, it may not be noticed due to the heavy consistency of the grease. This is the best possible

lubricant available and will add years of life to your Merry Tiller. Seals should be inspected

regularly and replaced as needed or before periods of expected extended use.

To replace the seals proceed as follows.

1. Take a screwdriver or awl and hammer along the tine shaft until you can pry the first

seal out.

2. Repeat and take the second seal out.

3. Place the new seal on the tine shaft with smooth side facing out, and press into place.

(Note: A 1 ½” ID piece of plastic pipe works great to do this).

4. Place the second seal on the tine shaft with the smooth side facing in, and press into

place.

5. Repeat to other side of the transmission.

Note: It is very important that the smooth side of the two seals be against each other.

Replacement Parts

PART #

QTY

WHERE USED

DESCRIPTION

708-3241

1

MINNIE

OIL SEAL

708-3241-10

10

MINNIE

OIL SEAL –10 PACK

708-3241-50

50

MINNIE

OIL SEAL –50 PACK

706-0344

1

SUBURBAN/INTERNATIONAL

OIL SEAL

706-0344-10

10

SUBURBAN/INTERNATIONAL

OIL SEAL –10 PACK

706-0344-50

50

SUBURBAN/INTERNATIONAL

OIL SEAL –50 PACK

MAINTENANCE SCHEDULE

Frequency

Service required

After every use

Inspect belts & pulleys for proper alignment and excessive wear

Check operation of belt and idler, make sure tines stop & start correctly

Inspect transmission for any leakage, check all bolts for tightness. Pay particular attention to

center bolt that secures the transmission to the frame rails

Check tines for wear and excessive play, make sure no pins are missing

Perform normal engine maintenance

Every 150 hours

Inspect transmission case assembly, conduct test for excessive travel, (see attached). Check for

excessive wear on case halves

Check tine shaft and drive shaft for up and down play, if loose replace bearings.

If transmission is OK replace tine shaft and drive shaft seals

Inspect tines for wear, if cutting corner is rounded replace tines. Check pin holes for elongating

and wear, make sure no pins are missing

Anytime the transmission is unbolted from the frame rails it is necessary to secure the internal

sprockets with a 5/16" rod cut to the same width of the transmission case. It is possible for the

internal sprockets to move if not secured during service

Every 600 hours

Remove transmission for internal inspection. Disassemble and inspect all parts for wear. Clean

all parts, replace worn parts as needed, relubricate with approx. 9 oz.“00” grease. Reassemble

with new case gasket and reinstall on tiller.

Anytime the transmission is unbolted from the frame rails it is necessary to secure the internal

sprockets with a 5/16" rod cut to the same width of the transmission case. It is possible for the

internal sprockets to move if not secured during service

14

SECTION VI - STORAGE

•Clean the tiller thoroughly.

•Wipe down the tiller with an oiled rag to prevent rust (use a light oil or silicone).

•Store the unit in a clean, dry area. Do not store next to corrosive material, such as fertilizer.

NOTE: If storing in an unventilated or metal storage shed, rustproof the equipment by coating with a light

oil or silicone.

Engine

It is important to prevent gum deposits from forming in essential fuel system parts such as the carburetor, fuel

hose, or fuel tank during storage. Experience indicates that alcohol blended fuels (e.g. gasohol, ethanol or

methanol) can attract moisture which leads to separation and formation of acids during storage. Acidic gas can

damage the fuel system of an engine while in storage.

•Empty the fuel tank before storing the tiller for 30 days or longer.

•Start the engine and let it run until the fuel lines and carburetor are empty.

•Never use engine or carburetor cleaner products in the fuel tank or permanent damage may occur.

•Remove the spark plug, pour approximately one tablespoon of engine oil into cylinder and crank slowly to

distribute oil. Replace the spark plug.

•Use fresh fuel next season. Do not store gasoline from one season to another.

NOTE: Fuel stabilizer is an acceptable alternative in minimizing the formation of fuel gum deposits during storage.

Fuel Stabilizer

•Follow the mix ratio found on stabilizer container when mixing stabilizer to gasoline in fuel tank or storage

container.

•Run the engine at least ten minutes after adding stabilizer to allow the stabilizer to reach the carburetor.

Do not drain the gas tank and carburetor if using fuel stabilizer.

Oil

Drain all the oil from the crankcase and refill the crankcase with fresh oil each season (this should be done after

the engine has been operated and is still warm).

DANGER: Your tiller was built to be operated according to the rules for safe

operation in this manual. As with any type of power equipment, carelessness or

error on the part of the operator can result in serious injury. If you violate any of

these rules, you may cause serious injury to yourself or others.

BEFORE STARTING ENGINE, ALWAYS CHECK OIL LEVEL!

15

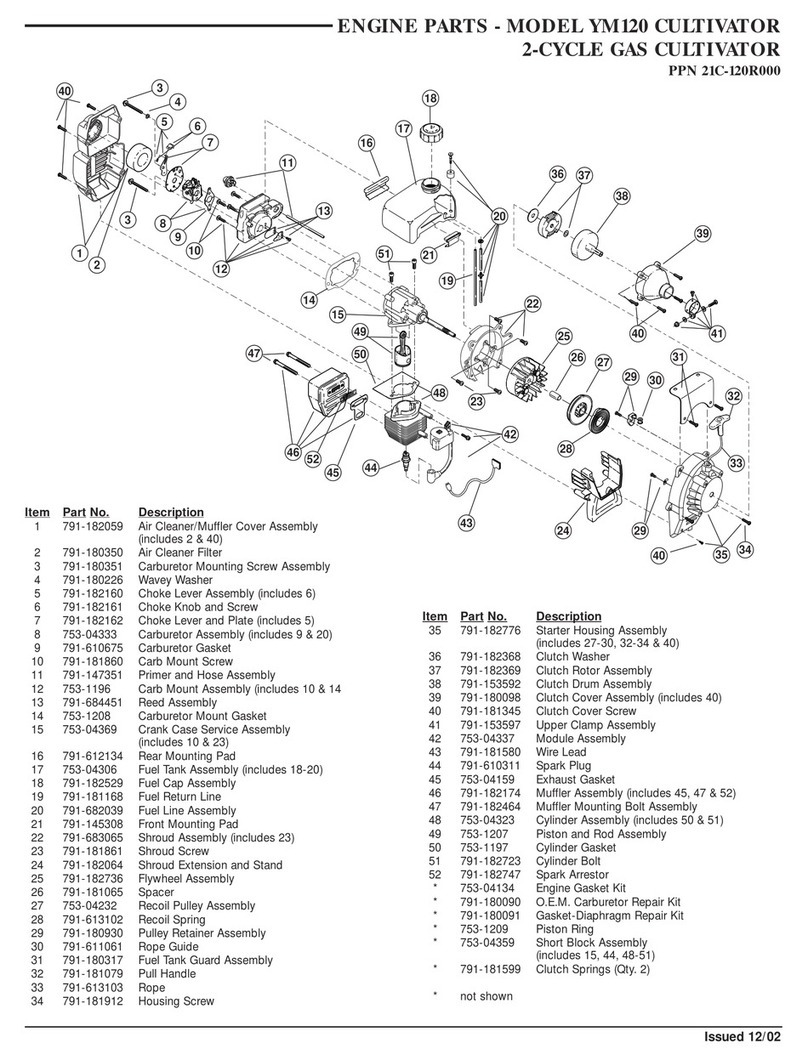

709-1933 TRANSMISSION ASSEMBLY

ITEM NO.

PART NO.

DESCRIPTION

QTY.

1

1A

1B

1C

1D

2

2A

2B

2C

2D

3

4

5

6

7

8

9

10

10A

11

12

13

14

15

16

--

709-1934

706-0342

706-0343

706-0344

706-0345

709-1935

020-0014

706-0343

706-0344

706-0345

709-0147

706-0347

706-0348

709-0352

709-0651

706-2500

706-3411

709-1615

030-0093

709-1654

706-2788

706-3096

090-0453

090-0419

090-0460

060-0034

L.H. Case Half Assembly (includes 1A-1D)

Drive Shaft Seal

Tine Shaft Bearing

Oil Seal

Bearing

R.H. Case Half Assembly (includes 2A-2D)

Soft Plug

Tine Shaft Bearing

Oil Seal

Bearing

Tine Shaft Weldment

Roller Chain #50-40 Pitches

Roller Chain #35-50 Pitches

Idler Sprocket Inner Race

Tine Shaft Spacer

Drive Shaft Assembly

Caplug

Idler Sprocket Assembly (includes 10A)

Idler Sprocket Bearing

Transmission Case Gasket

1/4 x 3/4” Self Tapping Screw

1/4-20 x 1/2” HH Whiz Lockscrew

1/4-20 Whiz Locknut

5/16-18 x 2-3/4” HHCS

5/16-18 Nylock Locknut

“OO” Grease

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

17

17

1

1

1

16

17

SUBURBAN PARTS LIST

ITEM NO.

PART NO.

DESCRIPTION

QTY.

1

2

2

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

25

26

27

28

29

30

31

31B

31C

31D

31D

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

57

---

---

---

---

709-1933

030-0623

706-3404

030-0658

500-0058

090-0232

090-0470

030-0109

090-0060

090-0419

090-0093

090-0091

706-1368

100-0018

080-0053

709-2502

090-0408

030-0131

709-2205

709-2208

709-2647

706-3417

090-0233

030-0111

709-3409

706-0137

706-1826

100-0018

709-3136

709-3137

090-0394

706-2637

706-3254

706-0630

090-0057

090-0470

706-1539

090-0400

706-2632

706-0895

706-3419

706-3347

709-2658

709-2659

709-3080

090-0460

090-0207

706-0152

706-0924

090-0089

706-1024

090-0461

090-0066

705-0056-2

706-2243

090-0088

030-0662

706-2250

090-0467

090-0012

707-1338-A

707-1339-A

707-1704-A

707-1705-A

Transmission Assembly

ST750IC - B&S Engine

ST5.5H - Honda Engine

ST6.5V –Vanguard Engine

Guide ¾”L

1/4” Flat Washer

1/4-20 Nylock Locknut

Pulley - Transmission

1/4-20 x 1” HHCS

5/16-18 x 2-3/4” HHCS

5/16-18 x 3” HHCS

5/16-18 x 1-3/4” HHCS

Pulley - Engine

3/16 x 3/16 x 1” Shaft Key

5/16-18 x 5/16” Set Screw

Hitch-Rear

5/16-24 x 3/4” HHCS

V-Belt

L.H. Engine Mount Weldment

R.H. Engine Mount

Belt Release Bracket Weldment

Idler Arm Weldment

5/16 Flat Washer

Idler Pulley

Idler Arm Compression Spring

Adjustment Link

Cross Brace

3/16 x 3/16 x 1 Key

Tie Bar L.H.

Tie Bar R.H.

5/16” Split Lock Washer

R. H. Handle Assembly (includes 31C)

Clutch Control Lever

Handle Grip

¼-20 x 1-1/2 HHCS

¼-20 Nylock Locknut

10-32 Nut

10-32 x 1 1/4 Rd Hd Machine Screw

L.H. Handle Assembly (includes 32B)

Rear Skid Weldment

Wheel Frame Weldment

Wheel

Belt Cover

Trans. Case to Belt Cover Bracket

Engine Mount to Belt Cover Bracket

5/16-18 Nylock Locknut

3/8-16 Hex Nut

Clutch Control Spring

1/8” Hair Spring Cotter

5/16-18 x 1-1/4” HHCS

Clevis Pin

3/8 Nut Nylock

5/16-18 x 3/4” HHCS

1/2 Shoulder Bolt

Cable Guide

5/16-18 x 1” HHCS

Throttle Control

Clutch Cable Assembly

Pull Cord Holder

1/4-20 x 3/4” HHCS

L.H. Inside Slasher Tine –Not Shown

R.H. Inside Slasher Tine –Not Shown

L.H. Outside Slasher Tine –Not Shown

R.H. Outside Slasher Tine –ot Shown

1

1

1

1

2

4

7

1

3

2

1

6

1

1

4

1

2

1

1

1

1

1

4

1

1

1

1

1

1

1

2

1

1

1

1

1

2

2

1

1

1

2

1

1

1

17

2

1

7

2

7

2

2

2

2

4

1

1

1

1

3

1

1

1

1

18

19

LIMITED WARRANTY

Any product manufactured by MacKissic, Inc. and found, in the judgment of MacKissic, Inc., to be

defective in material or workmanship, will be repaired or replaced by an Authorized MacKissic Service Dealer

without charge for parts and labor to the original owner of the MacKissic product.

The MacKissic product including any defective part must be returned to an Authorized MacKissic Service

Dealer within the warranty period. The expense of delivering the product to the dealer for warranty work and the

expense of returning it back to the owner after repair or replacement will be borne by the owner. MacKissic’s

responsibility is limited to making the required repairs or replacements only. No claim of breach of warranty shall

be cause for cancellation or rescission of the sales contract of any MacKissic product. Proof of purchase will be

required by the dealer to substantiate any warranty claim. All warranty work must be performed by an Authorized

MacKissic Service Dealer.

This warranty is limited to two years from the date of original retail purchase for any MacKissic product

that is used for consumer purposes or one year for commercial and rental use.

This warranty does not cover any product that has been subject to misuse, abuse, neglect, negligence, or

accident, or that has been operated in any way contrary to or inconsistent with the operating instructions as

specified in the owner’s manual. The warranty does not apply to any damage to the product that is the result of

improper maintenance, or to any product or parts that have not been assembled or installed as specified in the

owner’s manual.

The warranty does not cover any product that has been altered or modified. In addition, the warranty

does not extend to repairs made necessary by normal wear, or by the use of parts or accessories which, in the

judgment of MacKissic, Inc., are either incompatible with the MacKissic product or adversely affect its operation,

performance or durability. This warranty does not cover engines, electric starters, batteries, and tires which are

warranted separately by their manufacturer and for a different period of time.

MacKissic, Inc. reserves the right to change the design of any product without assuming any obligation to

modify any product previously manufactured.

THE DURATION OF THE LIMITED WARRANTY IS TWO YEARS CONSUMER, ONE YEARCOMMERCIAL AND

RENTAL USE. REPAIR OR REPLACEMENT AS PROCEEDED UNDER THIS LIMITED WARRANTY IS THE EXCLUSIVE

REMEDY OF THE PURCHASER. MacKissic, INC., SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES, EXCEPT THE LIMITED WARRANTY DESCRIBED ABOVE, ALL IMPLIED WARRANTIES (MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE) ARE SPECIFICALLY DISCLAIMED.

MacKissic, INC. ASSUMES NO RESPONSIBILITY FOR INCIDENTAL, CONSEQUENTIAL OR OTHER DAMAGES

INCLUDING, BUT NOT LIMITED TO, EXPENSE FOR GASOLINE, OIL, EXPENSE OF DELIVERING THE PRODUCT TO AN

AUTHORIZED MacKissic SERVICE DEALER AND EXPENSE OF RETURNING IT BACK TO THE OWNER, MECHANIC’S

TRAVEL TIME, TELEPHONE OR TELEGRAM CHARGES, RENTAL OF A LIKE PRODUCT DURING THE TIME WARRANTY

REPAIRS ARE BEING PERFORMED, TRAVEL, LOSS OR DAMAGE TO PERSONAL PROPERTY, LOSS OF REVENUE,

LOSS OF USE OF THE PRODUCT, LOSS OF TIME OR INCONVENIENCE.

This warranty gives you specific legal rights, and you may also have other rights that vary from state to

state.

5/18/20

This manual suits for next models

2

Table of contents

Other Merry Tiller Tiller manuals

Popular Tiller manuals by other brands

Hyundai power products

Hyundai power products HMTB55 instructions

Troy-Bilt

Troy-Bilt TB154E Operator's manual

Senix

Senix TL4QL-L1 Operator's manual

Craftsman

Craftsman 917.299850 owner's manual

Craftsman

Craftsman 917.293302 owner's manual

Parkside

Parkside PGK 1400 A1 Translation of the original instructions