EN

CONTENT

1. Introduction ......................................................................................4

2. Safety instructions ...........................................................................5

2.1 Warnings per machine ...................................................................................... 5

3. Overview machine Overview ...........................................................9

4. Technical data .............................................................................. 10

5. Assembly ...................................................................................... 11

6 Fuel and oil supply. ........................................................................ 18

6.1 Oil supply ........................................................................................................ 18

6.2 Fuel supply ..................................................................................................... 20

7. Pre-operative checks .................................................................... 20

8. Run in period ................................................................................ 21

9 Commissioning. ............................................................................. 21

10. Symptomatic starting problems .................................................. 24

11. Maintenance ............................................................................... 24

12. Packing and storage of equipment ............................................. 25

12.1 Packing .........................................................................................................25

12.2 Storage ......................................................................................................... 25

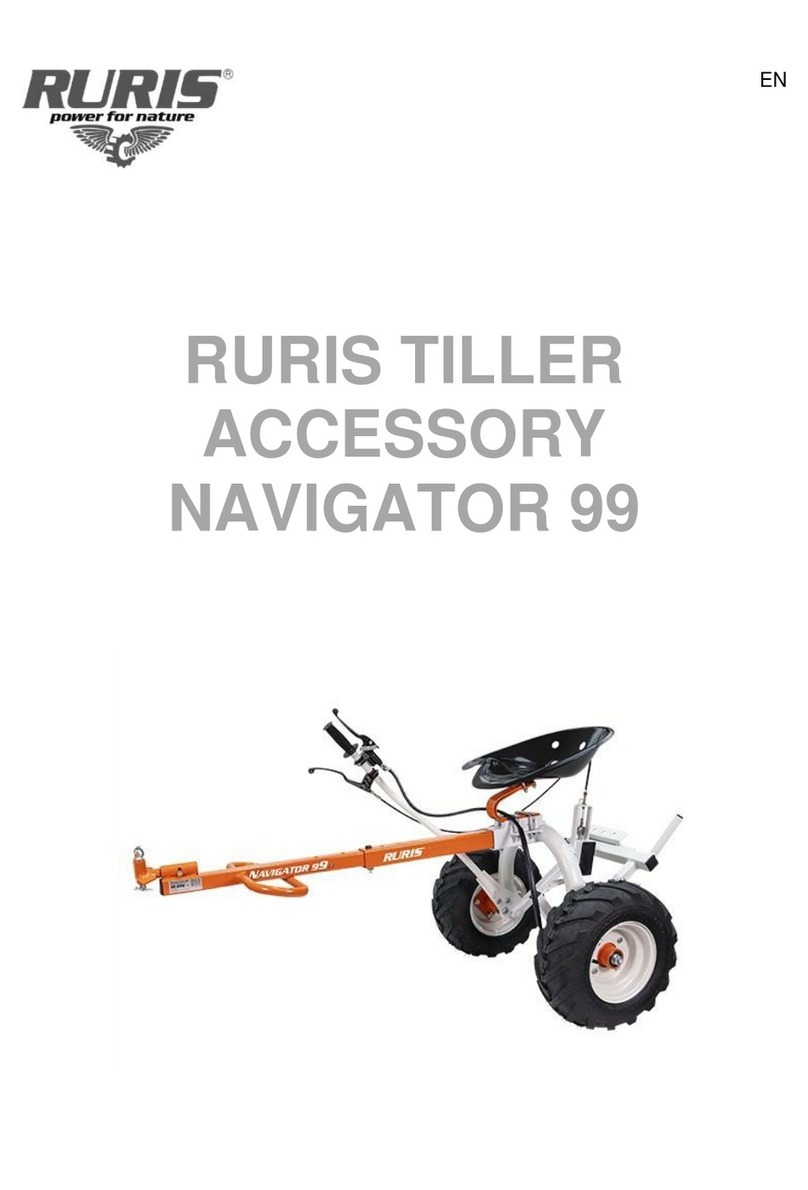

13. Accessories compatible with the machine .................................. 26

14. Coupling accessories .................................................................. 28

14.1 Plow coupling ................................................................................................ 28