Toro 9801 User manual

OPERATOR'S

MANUAL

FORM NO. 3318-402 GB Rev A

MODEL NO. 09801—60001 & OVER

® HYDROJECT®3000 AERATOR

©TheToro Company—1996

2

Foreward

The Hydroject 3000 is a water aerification device that penetrates and breaks up the soil with high-velocity water jets. This

machine operates with minimal disruption to the playing surface since there are no cores to remove after aerification.

After a quick rinse or irrigation cycle, the putting surface is ready for play.

The machine was designed to use water and NOT CHEMICALS. Since so many varieties of chemicals are used in the

Golf environment and since these chemicals react differently with Hydroject components, the Toro Company will not

accept responsibility for equipment or environmental damage caused by using chemicals. Using chemicals in your equip-

ment is done at your own risk!

The Hydroject 3000 releases a tremendous energy through the spray nozzles. DO NOT OPERATE THIS UNIT ON CON-

CRETE OR ASPHALT BECAUSE IT WILL PENETRATE THESE SURFACES.

Since this is a high-quality product, Toro is concerned about the future use of the machine and safety of the user.

Therefore, read this manual to familiarize yourself with safety, operation and maintenance instructions. Certain informa-

tion in this manual is emphasized. DANGER, WARNING and CAUTION identify personal safety-related information.

IMPORTANT identifies mechanical information demanding special attention. Be sure to read this directive because it

deals with the possibility of damaging a part or parts of the machine. NOTE identifies general information worthy of spe-

cial attention.

Service Manual

A service manual is available for the Hydroject 3000 Aerator. This publication provides information for trouble shooting,

testing, adjusting and repairing the machine. To order this publication, contact your local authorized Toro Distributor. Ask

for Form 91-764-SL, Hydroject 3000 service manua1l.

Table of Contents

SAFETY INSTRUCTIONS 3-4

SAFETY INSTRUCTIONS & DECALS .5

SPECIFICATIONS 6-7

FLUID RECOMMENDATIONS 8

IDENTIFICATION AND ORDERING 8

BEFORE OPERATING 10-12

Activate and Charge The battery 10

Check Engine Oil 10

Fill The fuel Tank With Gasoline 11

Check Gear Case Fluid Level 11

Check Pump Case Fluid Level 12

Check Tire Pressure 12

Check Accumulator Charge 12

CONTROLS 13

OPERATING INSTRUCTIONS 14-16

Operating Precautions 14

Starting/Stopping The engine 14

Training Period 14

Operating Procedure 14

Check Interlock System 16

Transport Operation 16

Inspection and Cleanup After Use 16

Pushing or Towing The machine 16

TROUBLE SHOOTING 18-20

MAINTENANCE 17

Servicing The pre- Filter 21

Replacing Main Water Filter 21

Changing Engine Oil and Filter 22

Servicing The Air Cleaner 22

Checking and Replacing The Spark Plug 24

Cleaning Cylinder Head Fins 24

Changing Gear Case Oil and Filter 25

Changing Pump Case Oil 25

Checking Hydraulic Lines and Hoses 25

Adjusting Roller Spray 27

Servicing Spray Wash Nozzles or Strainers 28

Battery Care 28

SEASONAL STORAGE 29

SERVICE INTERVAL CHART 30

3

Hazard control and accident prevention are dependent

upon the awareness, concern, and proper training of the

personnel involved in the operation, transport, mainte-

nance, and storage of the machine. Improper use or

maintenance of the machine can result in injury or

death. To reduce the potential for injury or death, com-

ply with the following safety instructions.

WARNING: Engine exhaust contains carbon monoxide

which is an odorless, deadly poison. Carbon monoxide

is also known to the State of California to cause birth

defects. Do not run the engine indoors or in an enclosed

area.

BEFORE OPERATING

1. Read and understand the contents of this Operator's

Manual before operating the machine. Become

familiar with all controls and know how to stop

quickly.

2. Never allow children to operate the machine. Do

not allow adults to operate the machine without

proper instruction. Only trained operators who have

read this manual should operate this machine.

3. Never operate the machine when under the influ-

ence of drugs or alcohol.

4. Before attempting to start the engine, engage the

parking brake.

5. Remove all debris or other objects that might inter-

fere with operation. Keep all bystanders away from

the work area.

6. Keep all shields and safety devices in place. If a

shield, safety device or decal is defective or dam-

aged, repair or replace it before resuming opera-

tion. Also tighten any loose nuts, bolts and screws

to assure the machine is in safe operating condition.

7. Do not operate the machine while wearing sandals,

tennis shoes, sneakers or shorts. Also, do not wear

loose fitting clothing which could get caught in

moving parts.Always wear long pants and substan-

tial shoes. Wearing safety glasses, safety shoes, ear

protection and a helmet is advisable and required

by some local ordinances and insurance regula-

tions.

8. Fill the fuel tank with gasoline before starting the

engine. Avoid spilling gasoline. Since gasoline is

flammable, handle it carefully.

A. Use an approved gasoline container.

B. Do not fill the tank while the engine is hot or

running.

C. Do not smoke while handling gasoline.

D. Fill the fuel tank outdoors and up to about 25

mm from top of the tank, not the filler neck.

E. Wipe up any spilled gasoline.

9. Check the interlock switches daily for proper oper-

ation. If a switch fails, replace it before operating

the machine. The interlock system is for your pro-

tection, so do not bypass it. Replace all interlock

switches every two years.

WHILE OPERATING

10. DON'T TAKE AN INJURY RISK! When a person

or pet appears unexpectedly in or near the WORK-

ING area, STOPAERATING.

11. Keep your hands and feet away from nozzle and

roller area. High-velocity water jets can penetrate

hands and feet. Penetration by the high-velocity

water jets can cause serious personal injury. If acci-

dental penetration occurs, seek medical attention

immediately.

12. Never use chemicals in the water supply system.

13. Do not operate the water injection system on con-

crete or asphalt because the water jets will perma-

nently damage these surfaces.

Safety Instructions

4

24. Be sure the machine is in safe operating condition

by keeping nuts, bolts and screws tight. Check all

bolts and nuts frequently to be sure they are tight-

ened to specification.

25. If the engine must be running to perform a mainte-

nance adjustment, keep your hands, feet, clothing

and other parts of your body away from any moving

parts.

26. Make sure all hydraulic line connectors are tight, and

all hydraulic hoses and lines are in good condition

before applying pressure to the system.

27. Keep your body and hands away from pin hole leaks

or nozzles that eject water or hydraulic fluid under

high pressure. Use paper or cardboard, not your

hands, to search for leaks. Hydraulic fluid or water

escaping under pressure can have sufficient force to

penetrate your skin and do serious damage. If either

of these fluids are ejected into your skin they must

be surgically removed within a few hours by a doc-

tor familiar with this form of injury or gangrene

may result.

28. Before disconnecting or performing any work on the

hydraulic oil system, all pressure in the system

must be relieved by stopping the engine and open-

ing the by-pass valve.

29. Make sure all water line connectors are tight, and all

hoses and lines are in good condition before apply-

ing pressure to the system.

30. Before disconnecting or performing any work on the

water system, all pressure in the system must be

relieved by stopping the engine and opening the

bleed valve. Opening the bleed valve allows any

trapped water to escape from the system and also

allows the accumulator piston to move to the bot-

tom of the accumulator cylinder.

31. The accumulator in this machine contains high-

pressure dry nitrogen. Accumulator servicing

requires special tools and precautions.

Accumulators do not contain user-serviceable com-

ponents. Improper accumulator servicing can cause

dismemberment or death. Do not attempt to disas-

semble a accumulator; have this work done by a

14. Start the engine with the parking brake engaged.

15. Do not run the engine in a confined area without ade-

quate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

16. Using the machine demands attention, and to prevent

loss of control:

A. Use only in daylight or when there is good artifi-

cial light.

B. Watch for holes or other hidden hazards.

C. Do not transport the machine close to a sand

trap, ditch, creek or other hazard.

17. If the machine starts to vibrate abnormally, shut off

the engine. Remove the wires from the spark plugs to

prevent the possibility of accidental starting. Check

the machine for damage and defective parts. Repair

any damage before restarting the engine and operat-

ing the machine.

18. Do not touch the engine or muffler while the engine is

running or soon after it is stopped. These areas could

be hot enough to cause a burn.

19. Before leaving the operator's position behind the han-

dle engage the parking brake.

20. When leaving the machine unattended, engage the

parking brake , shut OFF the engine and remove the

key from the ignition switch.

MAINTENANCE

21. Disconnect the wires from the spark plugs to prevent

accidental starting of the engine when servicing,

adjusting or storing the machine.

22. If the machine must be tipped to perform maintenance

or an adjustment, close the fuel shut-off valve, drain

gasoline from the fuel tank, oil from the crankcase

and remove the battery.

23. To reduce potential fire hazard, keep the engine free

of excessive grease, grass, leaves and accumulations

of dirt.

5

Authorized Toro Distributor.

32. Do not overspeed the engine by changing the governor

settings. To be sure of safety and accuracy, have an

Authorized T0R0 Distributor check maximum engine

speed with a tachometer.

33. The engine must be shut off before checking oil or

adding oil to the crankcase.

34. Allow the engine to cool before storing the machine in

any enclosure such as a garage or storage shed. Make

sure the fuel tank is empty if the machine is to be stored

longer than 30 days. Do not store the machine near any

open flame or where gasoline fumes may be ignited by

a spark. Always store gasoline in a safety-approved, red

metal container.

35. When storing or transporting the machine (trailering),

make sure the fuel shut-off valve is closed.

36. Perform only those maintenance instructions described

in this manual. If major repairs are ever needed or assis-

tance is desired, contact an Authorized Toro Distributor.

To ensure optimum performance and safety, always

purchase genuine TORO replacement parts and acces-

sories to keep the Toro all TORO. NEVER USE

WILL-FIT" REPLACEMENT PARTS AND ACCES-

SORIES MADE BY OTHER MANUFACTURERS.

Look for the TORO logo to assure genuineness. Using

unapproved replacement parts and accessories could

void the warranty of The Toro Company.

6

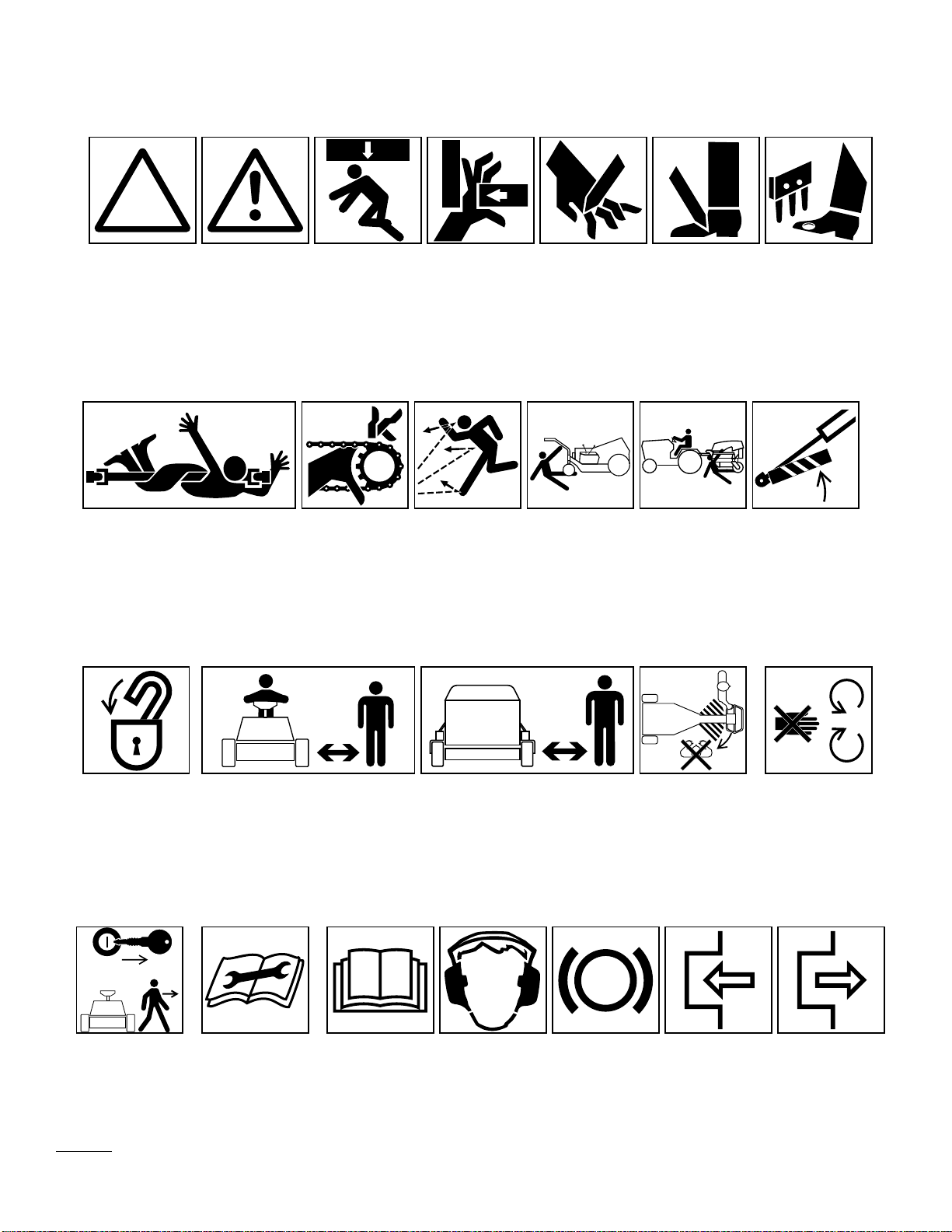

Symbol Glossary

SAFETY ALERT

SYMBOL GENERAL HAZARD

SAFETY ALERT CRUSHING OF

WHOLE BODY,

APPLIED FROM

ABOVE

CRUSHING OF

FINGERS OR HAND,

FORCE APPLIED

FROM SIDE

CUTTING OF

FINGERS OR HAND CUTTING OF FOOT CRUSHING OR

PUNCTURE OF FOOT,

CORING HEAD

WHOLE BODY ENTANGLEMENT,

IMPLEMENT INPUT DRIVE LINE FINGERS OR HAND

ENTANGLEMENT,

CHAIN DRIVE

THROWN OR FLYING

OBJECTS, WHOLE

BODY EXPOSURE

RUNOVER/BACKOVER,

GREENS AERATOR RUNOVER/BACKOVER,

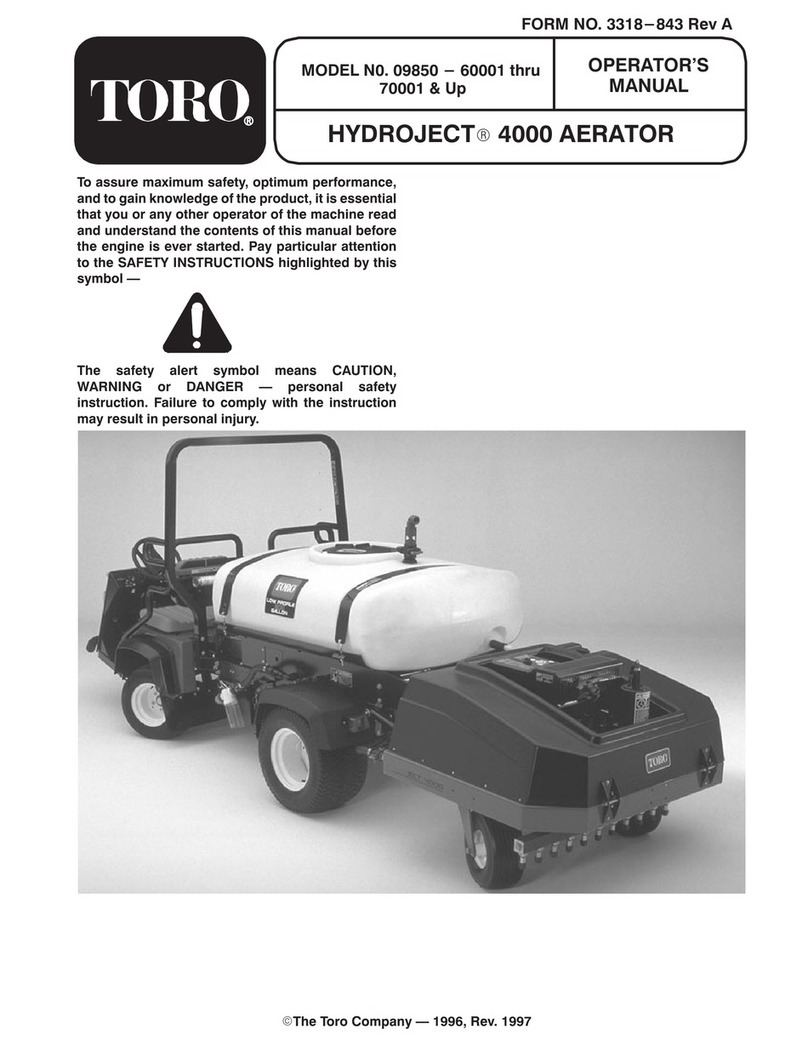

HC 4000 AERATOR SECURE LIFTING CYLINDER WITH

LOCKING DEVICE BEFORE

GETTING IN HAZARDOUS AREA

INSERT SAFETY LOCK

BEFORE GETTING IN

HAZARDOUS AREA

STAY A SAFE DISTANCE FROM MACHINE,

GREENS AERATOR STAY A SAFE DISTANCE FROM MACHINE,

HC 4000 AERATOR

STAY CLEAR OF ARTICULATION

AREA WHILE ENFINE IS RUNNING,

GREENS AERATOR

DO NOT OPEN OR REMOVE

SAFETY SHIELDS WHILE

ENGINE IS RUNNING

SHUT OFF ENGINE & REMOVE

KEY BEFORE LEAVING OPERATOR

POSITION, GREENS AERATOR

CONSULT TECHNICAL MANUAL

FOR PROPER SERVICE

PROCEDURES

READ OPERATOR’S

MANUAL HEARING PROTECTION

MUST BE WORN BRAKE SYSTEM ENGAGE DISENGAGE

7

P

1 INCH (25mm)

P

ON/START OFF/STOP FAST SLOW CONTINUOUS

VARIABLE,

LINEAR

ENGINE START ENGINE STOP

PARK UNLEADED FUEL FUEL TANK FILL

LINE LOCK UNLOCK CORING HEAD

ALWAYS HAVE CORING HEAD

FULLY UP FOR TRANSPORT &

FULLY DOWN FOR CORING

TRACTION DRIVE MANUAL CHOCK WHEELS IN PARKED POSITION,

ALWAYS PARK ON LEVEL SURFACE,

FAIRWAY AERATOR

ALWAYS FORK FROM FRONT OR REAR

OF MACHINE, HC 4000 AERATOR LEVER OPERATION

8

Engine: Onan, 4-cycle, opposed-twin, air-cooled, 17.9

kW (24 hp) @ 3600 rpm, 983 cc displacement.

Electric start. Heavy-duty valve package. Extended

service air cleaner. 2.8 l oil capacity. Solid-state

ignition.

Clutches: Electromagnetic, dual-groove belt drive for

the water pump and driveshaft flange brake/clutch

for the main valve gearbox.

Electrical: 12-volt system with 20-amp circuit breaker

protection. Relays for all high-current switching.

Electronic controller and sensors for automatic

start-up and shut-down sequence of the water injec-

tion system. Group 28 battery with 525 cold-crank

amps.

Traction Drive: Closed-loop hydrostatic drive consist-

ing of Sundstrand variable volume pump and

Parker low-speed, high-torque wheel motor mount-

ed to steering fork. Hydraulic system contains 4.73

l with 25-micron suction line filter and gearbox

reservoir.

Tires/Wheels: Three, smooth-tread 2-ply, 18 x 9.50-8,

pneumatic tubeless, tires. Demountable drop-center

steel wheels with (4) lug nuts mounted to tapered

roller bearing hubs on the transport arms and brake

hub on the wheel motor. All are interchangeable.

Brake: Drum- and shoe-type parking brake mounted to

the wheel motor. Holds unit on a 30% grade.

Transport Lift: 12-volt Warner Electric linear screw

actuator with 15.24 cm stroke. Raises and lowers

lift arm/transport tires and activates hole spacing

control.

Fuel Capacity: 39.75 l gasoline.

Water Injection System:

Pre Filter—Spin-down type with washable cartridge

in clear plastic housing and plastic ball valve for

flushing.

Supply Filter—Replaceable cartridge in plastic

housing with an air bleed button.

Water Pressure Switch—Senses for water pressure

after the filter and turns on when pressure is over

138–193 kPa and turns off when pressure drops

below 48–90 kPa.

Pump—Pump is a Toro exclusive design (patent pend-

ing) with cast stainless steel head and 3 piston

plungers. Vee packing seals and Kevlar guides.

Forged crankshaft with plasma sprayed ceramic on

stainless steel plungers and cast iron connecting

rods. Nominal performance is 4 rpm @ 34,473 kPa

with 1400 rpm input.

Accumulator—Toro exclusive design with low charge

pressure sensor, nitrogen gas charged to a maximum

of 17,237 kPa.

Cam and Gearbox—Reduction gear drive for cam that

actuates the main water valve. Roller cam follower

rides on a cam specifically designed (patent pend-

ing) to control water injection at 5.3 cycles per sec-

ond (320 rpm) and store energy in the accumulator

between injections. Cast iron case also serves as 3.8

l hydraulic reservoir.

Valve—Cast stainless steel valve body functions as a

mounting base for the accumulator, gearbox and

manifold outlet. All high-pressure water flows in

and out through the valve body. Pressure-balanced

valve spool with floating (patent pending), hardened

stainless seat aligns during assembly. Bleed valve in

base allows for bleed-off of high pressure and drain

down for cold weather storage. Bolted flanges and

polyurethane O-rings mate all components to valve

body.

Rollers—Pivoting aluminum rollers uniformly smooth

the turf and provide protection from the nozzle dis-

charge.Adjustable flow (0–3 gpm) spray wash sys-

tem with 6 flood tip nozzles maintain clean rollers.

Pressure Relief Valve—Circle Seal Controls poppet-

type valve preset to 34,473 kPa with corrosion resis-

tant stainless and brass materials.

Specifications

9

Manifold and Nozzles—Extruded stainless steel mani-

fold with 11 flanged nozzle extensions containing

check valves and hardened stainless discharge ori-

fice. Check valves may be reversed in housing to

block unused nozzles.

Controls:

Engine Panel—Throttle, choke, spray wash control, hour

meter, water pressure gauge, spacing control lever,

key switch and circuit breaker reset button.

Steering Tiller Panel— Traction bail, water system

engage and disengage buttons, transport / aerate lift

toggle switch and parking brake with buzzer alarm.

Electronic Control Module—Solid state potted device

for sequencing start and stop of the water system.

Interlocks for water pressure, transport lift and trac-

tion neutral.

Ground Speed:

Aerating: 0–3.2 kmh (both directions)

Transport: 0–6.4 kmh (both directions)

Dimensions:

Length—244.4 cm

Wheelbase—135.1 cm

Width—160 cm

Height—119.9 cm

Weight—429.2 kg

Aeration Width: 83.8 cm with 11 nozzles on 7.6 cm cen-

ters.

Aeration Depth: 10.2–15.2 cm depending on turf condi-

tions and nozzle configuration.

Hole Pattern: Variable from 3.8–15.2 cm spacing in the

direction of travel, and 7.6–15.2 cm increments in width.

Depths and Nozzle Configurations: All nozzles are iden-

tified with numbers indicating the drill size of the orifice.

The standard configuration is 11 nozzles producing depths

of 10.2–15.2 cm depending on turf conditions. Blocked

nozzle locations are obtained by reversing the nozzle

check valve ball and spring. See nozzle size chart and

illustrations below:

IMPORTANT: Use only nozzle configurations shown

or damage to the machine may occur.

Aluminum Washer, Toro Part no. 80-6680 is required with

any nozzle change

Aluminum Washer, Toro Part no. 80-6680 is required with

any nozzle change

**Additional nozzles may be blocked to compensate for pump wear.

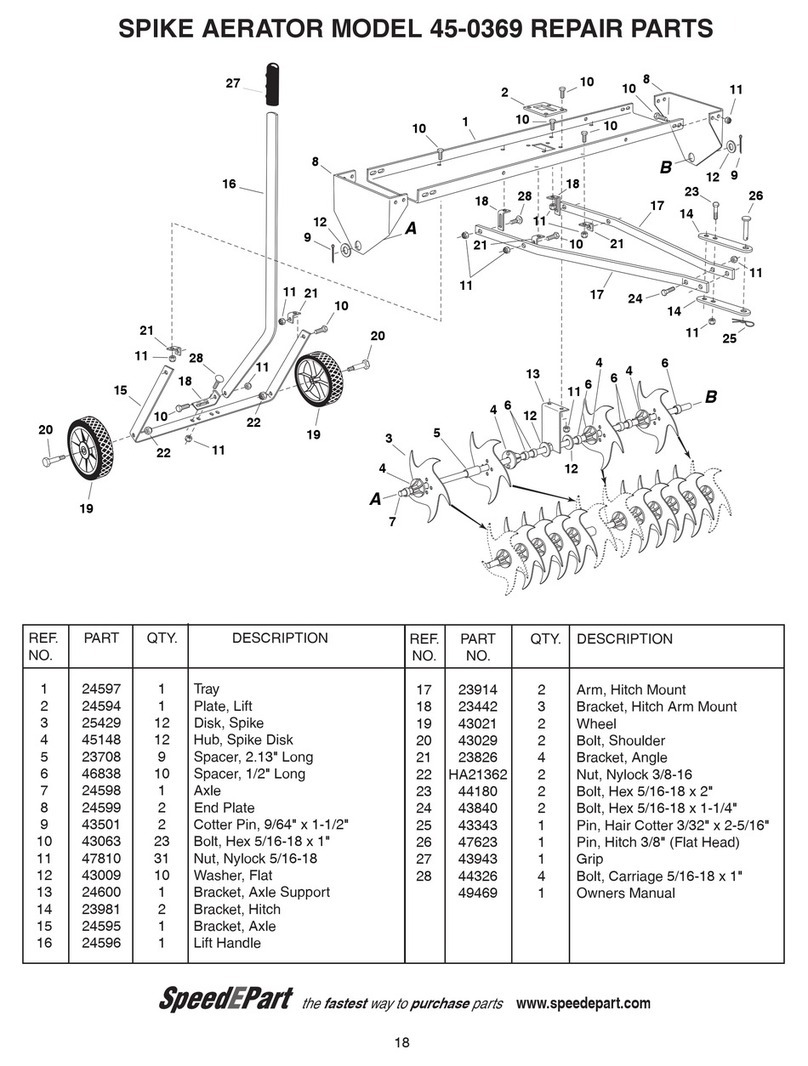

NOZZLE SIZE AND APPROXIMATE DEPTH CHART

Quantity of Nozzles

Part No. Drill Size Metric Size (mm) Open Blocked Depth

86-8130 #56 1.181 * * *

86-8131 #53 1.511 11 0 10.2–15.2 cm

86-8133 #46 2.057 6 5 15.2–20.3 cm

10

OPTIONAL STAGGERED SIZE NOZZLE CONFIGURATION

Quantity of Nozzles

Part No. Drill Size Metric Size (mm) Open Blocked Depth

86-8130 #56 1.181 6 and 0** 7.6–10.1 cm

86-8133 #46 2.057 5 0** 15.2–20.3 cm

Aluminum Washer, Toro Part no. 80-6680 is required with any nozzle change

**Additional nozzles may be blocked to compensate for pump wear.

Check Valve Ball

Check Valve Ball

Spring

Spring

OPEN NOZZLE CLOSED (BLOCKED) NOZZLE

2. Part number, description and quantity of parts

desired.

Note: Do not order by reference number if a parts

catalog is being used; use the part number.

11

Fuel—Unleaded regular gasoline recommended to minimize

engine intake valve and combustion chamber deposits.

Engine Oil—Service classificationAPI SF, SG, SF/CC or

SG/CC in a 30 weight viscosity grade.

Engine Oil Filter—Toro part no. 57-8530

Hydraulic Oil—Mobil DTE 26 or other interchangeable

equivalent. See chart below for equivalent oils.

Mobil DTE 26

Shell Tellus 68

Amoco Rykon Oil #68

Conoco Super Hydraulic Oil 68

Exxon Nuto H 68

Kendall Kenoil R&O 68

Pennzoil Penreco 68

Phillips Magnus A 68

Standard Energol HLP 68

Sun Sunvis 831 WR

Union Unax AW 68

Hydraulic Oil Filter—Toro part no. 67-8110

Water Pump Case Oil—Mobil DTE Extra Heavy or other

interchangeable ISO Grade 150 PE-700-A (Heavy

Inhibited Hydraulic & General Purpose) See following

chart for equivalent oils.

Mobil DTE EH (Extra Heavy)

Shell Turbo 150

Amoco American Ind. Oil 150

Chevron AW Machine Oil 150

Conoco Dectol R & O150

Exxon Terresstic 150

Kendall Ken-Tran 080

Pennzoil Penreco 150/AW150

Phillips Magnus Oil 150

Standard Energol HLP 150

Sun Sunvis 150

Union Unax RX 150/Turbine Oil 150

Valvoline ETC (R&O) #70

Water Supply—Recommend a source with 26.5–30.2 l

per minute. A minimum pressure of 207 kPa at the

machine is required for the pump to engage.

Maximum allowable pressure of 1,379 kPa.

Although irrigation water pumped from ponds or

effluent holding pools can be used, not all condi-

tions can be handled by the machine’s filtration sys-

tem. Additional or alternative filtration may be

required.

Water Filter Cartridge—Toro part no. 86-8630

DO NOT USE CHEMICALS—Concern for environ-

mental issues and corrosive affects on machine

components.

Fluid Specifications

Identification and Ordering

MODEL AND SERIAL NUMBERS

The HYDROJECT 3000 has two identification numbers: a

model number and a serial number. The two numbers are

stamped on a plate which is riveted to the frame. In any

correspondence concerning the HYDROJECT 3000, sup-

ply model and serial numbers to be sure that correct infor-

mation and replacement parts are obtained.

To order replacement parts from an authorized TORO

Distributor, supply the following information:

1. Model and serial numbers of the machine.

ACTIVATE AND CHARGETHE

BATTERY

1. Since the battery is not filled with electrolyte or activated,

bulk electrolyte with 1.260 specific gravity must be pur-

chased from a local battery supply outlet.

2. Release the hood latches and raise the hood.

3. Loosen the capscrew securing the battery clamp to the

machine and remove the battery. Remove the filler caps

from the battery and slowly fill each cell until electrolyte is

just above the plates.

4. Replace the filler caps and connect a 3- to 4-amp battery

charger to the battery posts. Charge the battery at a rate of 3

to 4 amperes for 4 to 8 hours.

5. When the battery is charged, disconnect the charger from

electrical outlet and battery posts.

6. Remove the filler caps. Slowly add electrolyte to each cell

until the level is up to fill ring. Install the filler caps.

IMPORTANT: Do not overfilI the battery. Electrolyte

will overflow onto other parts of the machine and severe

corrosion and deterioration will result.

7. Install the battery and secure it with the battery clamp.

8. Install the positive cable (rubber boot over end) to the posi-

tive (+) terminal and the negative cable (black) to the nega-

12

Figure 1

1. Battery

Before Operating

Electrolyte gases are explosive and can cause serious

injury to eyes, lungs and skin. Wear safety goggles

and rubber gloves when working with electrolyte or

the battery. Charge the battery in a well-ventilated

place so gasses produced while charging can dissipate.

Since the gasses are explosive, keep open flames and

electrical sparks away from the battery; do not smoke.

Nausea may result if the gasses are inhaled. Unplug

the charger from the electrical outlet before connecting

or disconnecting the charger’s leads.

WARNING

tive (-) terminal of the battery and secure with capscrews

and nuts. Slide the rubber boot over the positive terminal to

prevent possible short-out (Fig. 2).

9. Lower the hood and secure the latches.

CHECKTHE ENGINE OIL

The Onan engine is shipped with 3 quarts of oil in the crankcase;

however, the oil level must be checked before and after the

engine is first started.

1. Position the machine on a level surface.

2. Unscrew the dipstick and wipe it with a clean cloth. Screw

the dipstick into the filler neck and make sure it is seated

fully. Unscrew the dipstick out of the filler neck and check

the level of oil. If the oil level is low, add enough to raise

the level to the FULL mark on the dipstick.

Note: If the level of oil is at the ADD mark on the dipstick,

add 1 quart of oil to raise the oil level to FULL. Do not

overfill

3. Pour oil into the filler neck until the level is at the FULL

mark on the dipstick. The Onan engine uses any high-quali-

ty oil having theAmerican Petroleum Institute— APl—

“service classification” SF or SG. Recommended viscosity

(weight) of oil is SAE 30.

IMPORTANT: The Hydroject 3000 operates at very

high engine loads, so check the level of oil every 8 oper-

ating hours or daily. A new engine may consume some

oil until broken in. Initially, change the oil after the first

25 hours of operation; thereafter, under normal condi-

tions, change the oil and filter after every 100 hours of

operation. However, change oil more frequently when

the engine is operated in extremely dusty or dirty condi-

tions.

FILLTHE FUELTANKWITH

GASOLINE

THE TORO COMPANY STRONGLY RECOMMENDS THE

USE OF FRESH CLEAN, UNLEADED REGULAR GRADE

GASOLINE IN TORO GASOLINE POWERED PRODUCTS.

UNLEADED GASOLINE BURNS CLEANER, EXTENDS

ENGINE LIFE, AND PROMOTES GOOD STARTING BY

13

Figure 2

1. Dipstick

Figure 3

1. Fuel tank cap

REDUCING THE BUILD-UP OF COMBUSTION CHAMBER

DEPOSITS.

Note: Do not mix oil with gasoline. Never use methanol, gaso-

line containing methanol, gasohol, gasoline additives, premium

gasoline, or white gas because the engine/fuel system damage

could result.

1. Remove the cap from the fuel tank and fill the 37.85 l tank

to about 2.5 cm from the top of the tank, bottom of the filler

neck with unleaded gasoline. Install the fuel tank cap tight-

ly.

2. Wipe up gasoline that may have spilled to prevent a fire

hazard.

CHECK GEAR CASE FLUID LEVEL

The gear case, which acts as the reservoir for the hydraulic sys-

tem, is filled at the factory with approximately 3.8–4.7 l of

14

Because fuel is flammable, caution must be used when

storing or handling it. Do not fill the fuel tank while

the engine is running, hot or when the machine is in an

enclosed area. Vapors may build up and be ignited by

a spark or flame source many feet away. DO NOT

SMOKE while filling the fuel tank to prevent the pos-

sibility of an explosion. Always fill the fuel tank out-

side and wipe up any spilled fuel before starting the

engine. Use a funnel or spout to prevent spilling, and

fill the tank no higher than 2.5 cm (one inch) below

top of the tank, (bottom of the filler neck). DO NOT

OVER FILL.

Store fuel in a clean safety approved container and

keep the cap on the container. Keep fuel in a cool,

well-ventilated place; never in an enclosed area such

as a hot storage shed. To assure volatility, do not buy

more than a 30-day supply of gasoline, or a 6-month

supply of diesel fuel.

Since many children like the smell of gasoline, keep it

out of their reach because the fumes are explosive and

dangerous to inhale.

DANGER

Mobil DTE 26 hydraulic oil. Check the level of hydraulic oil on

the sight gauge before the engine is first started and daily there-

after. Change the filter initially after 25 hours of operation,

thereafter change the oil and filter every 250 hours of operation.

The oil and filter must be changed immediately when any conta-

mination, sludge, water or condensation appears in the oil or on

sight gauge. Determine and correct oil contamination problem

before restarting the engine and operating the machine.

1. Position the machine on a level surface.

2. Release the hood latches and raise the hood.

3. Check the level of hydraulic oil on the sight gauge. Fluid

level should be up to the middle of gauge window.

4. If the fluid level is low, remove the filler cap and add

enough Mobil DTE 26 hydraulic oil or equivalent oil (refer

to fluid recommendation table) to bring oil up to the proper

level.

5. Lower the hood and secure the latches.

CHECK PUMP CASE FLUID LEVEL

The pump crank case is filled at the factory with 1.8 cl of Mobil

DTE Extra Heavy oil. Check the level of oil on the dipstick

before the engine is first started and daily thereafter. Change the

oil initially after 25 hours of operation, thereafter change every

250 hours of operation. The oil must be changed immediately

when any contamination, sludge, water or condensation appears

in oil. Determine and correct oil contamination problem before

restarting the engine and operating the machine.

1. Position the machine on a level surface.

2. Release the hood latches and raise the hood.

3. Remove the dipstick/filler cap and check the level of oil on

the dipstick. The fluid level should be up to the FULL

mark.

4. If the fluid level is low, add enough Mobil DTE Extra

Heavy oil or equivalent oil (refer to fluid recommendation

table) to bring the oil up to proper level. DO NOT OVER-

FILL.

5. Lower the hood and secure the latches.

15

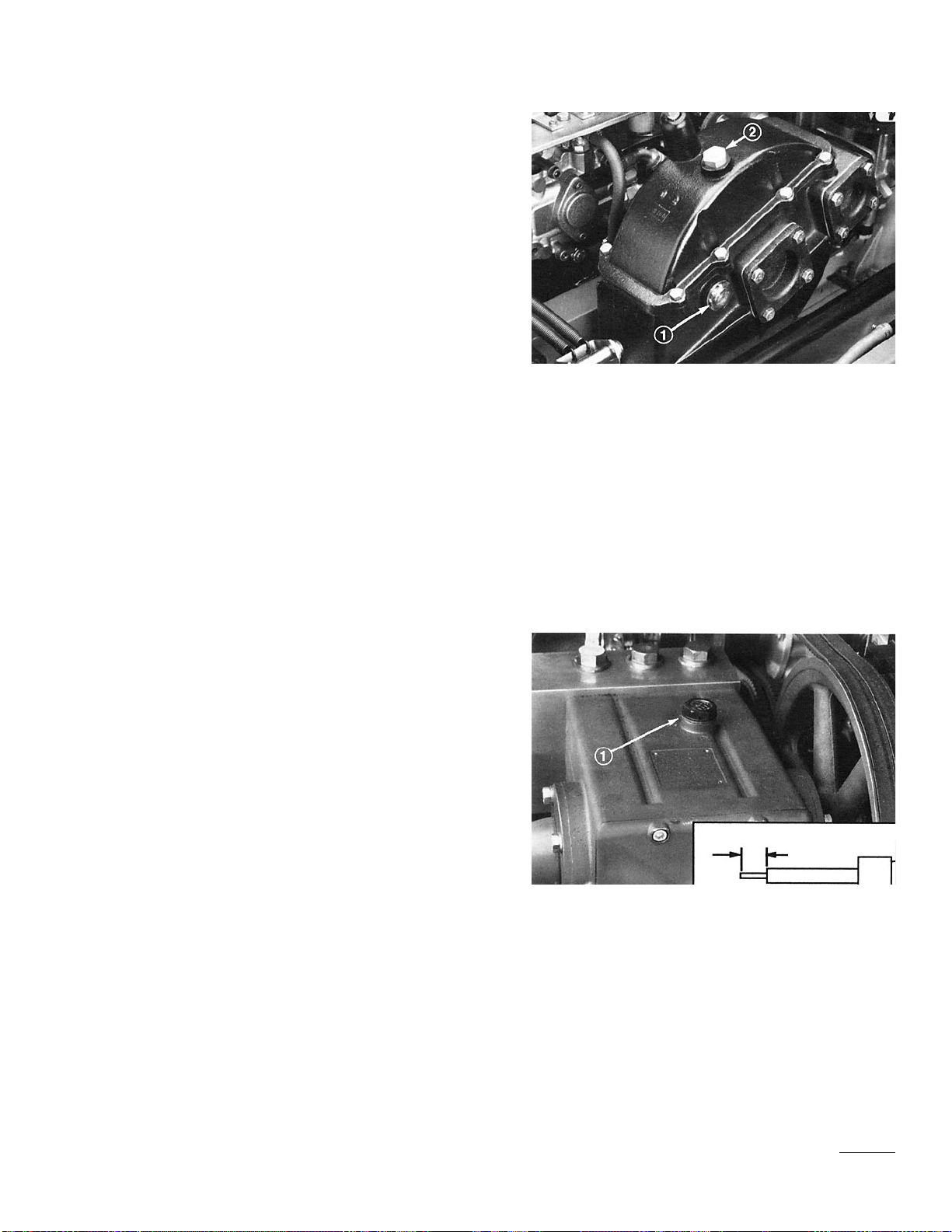

Figure 4

1. sight gauge

2. Filler cap

Figure 5

1. Dipstick/Filler cap

Full

16

CHECKTIRE PRESSURE

Tires are over inflated for shipping. Make sure the front

and rear tires are inflated to 55–82 psi.

CHECKTHE ACCUMULATOR

CHARGE

Have the accumulator charge checked before and after

each operating season by an Authorized TORO

Distributor.

Charged accumulators contain high-pressure nitrogen.

Nitrogen is the only gas to use for accumulator char-

ing. Installing Improper gasses in an accumulator can

cause an explosion and death.

Charging requires special tools and precautions.

Charge accumulators in a well-ventilated area. Have

the accumulator checked and charged by an authorized

TORO distributor.

Wear eye protection. Keep your hands and face away

from the gas valve.

Slowly open the high-pressure water bleed valve

before servicing any component connected to the high-

pressure water system. Opening the high-pressure

bleed valve allows any trapped water to escape from

the system and also allows the accumulator platon to

move the bottom of the accumulator cylinder. Failure

to open the bleed valve before servicing high-pressure

water components can cause personal injury, dismem-

berment or death!

Charged accumulators cannot be shipped via air

freight.

WARNING

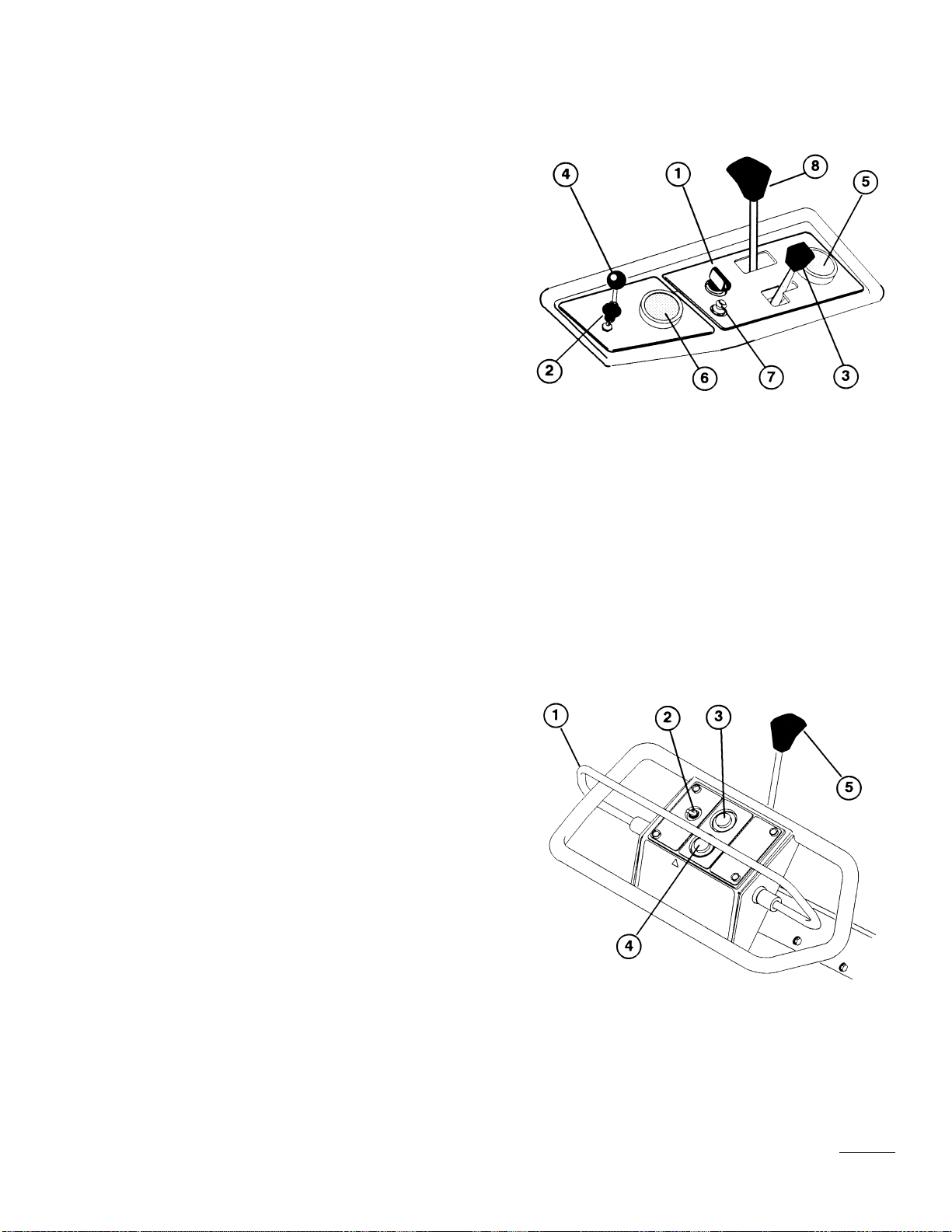

Ignition Switch (Fig. 6)—The ignition switch, which is used to

start and stop the engine, has three positions: OFF, ON and

START.

Choke (Fig. 6)—To start the engine, close the carburetor choke

by pulling the choke control outward to the FULL position.

After the engine starts, regulate the choke to keep the engine

running smoothly. As soon as possible, open the choke by push-

ing it inward to the OFF position.

Throttle (Fig. 6)—The throttle is used to regulate engine speed.

Moving the throttle forward increases engine speed— FAST;

rearward decreases engine speed—SLOW.

Spray Wash Control (Fig. 6)—Pull the handle upward to acti-

vate the roller spray wash system. Move the control knob up or

down to adjust spray rate to keep rollers free of debris.

Hour Meter (Fig. 6)—The hour meter registers accumulated

hours of engine operation. Use the hour meter to determine

intervals for service maintenance and lubrication.

Water Pressure Gauge (Fig. 6)—Registers supply water pres-

sure in the system. Also acts as a interlock switch preventing the

water pump from starting if water pressure is below 138–193

kPa or stopping the water pump if the water pressure drops

below 48–89.6 kPa. Check the gauge frequently to monitor the

water pressure.

Circuit Breaker Reset Button (Fig. 6)—a push button to reset

breaker, after correcting malfunctions in the electrical system.

The button also serves as a switch to interrupt power to the

relays.

Spacing Control Lever (Fig. 6)—Moving the control away

from handle increases the aerating ground speed and distance

between holes. Moving the control toward the handle decreases

aerating ground speed and distance between holes. The setting

will be overridden when the machine is shifted to the transport

position.

Traction Bail (Fig. 7)—Engages and regulates fore and aft trac-

tion operation of the machine. Releasing the bail stops traction

operation and will also stop water injection in 3 to 4 seconds,

unless the bail is engaged. Transport speed is regulated by the

distance the bail is moved.

Transport/Aerate Toggle Switch (Fig.7 )—Lowers the machine

17

Figure 6

1. Ignition switch

2. Choke

3. Throttle

4. Spray wash control

5. Hour meter

6. Water pressure gauge

7. Circuit breaker reset button

8. Spacing control lever

Figure 7

1. Traction Ball

2. Transport/Aerate toggle switch

3. Aeration engagement button

4. Aeration stop button

5. Parking brake

Controls

onto rollers to commence aeration. The switch will override

spacing control setting when it is moved to the transport posi-

tion.

Aeration Engagement Button (Fig. 7)—Depressing the button

starts water injection system only when the water pressure is

above 193 kPa and the rollers are on the ground.

Aeration Stop Button (Fig. 7)—This red button stops the water

injection system. The system continues for a few seconds after

button is pressed.

Parking Brake (Fig. 7)—Push the lever toward the machine to

engage the parking brake. A warning buzzer will sound if you

attempt to move the machine with the parking brake is engaged.

Fuel Shut-Off Valve—Located under the fuel tank. Close the

fuel shut-off valve when storing or transporting (trailering) the

machine.

18

Figure 7

1. Traction Ball

2. Transport/Aerate toggle switch

3. Aeration engagement button

4. Aeration stop button

5. Parking brake

OPERATING PRECAUTIONS

1. Before aerating, inspect the work area for debris and

determine the best direction and pattern in which to

operate the machine.

2. If the machine starts to vibrate abnormally, shut off the

engine. Remove the wires from the spark plugs to pre-

vent possible accidental starting. Check the machine for

damage and defective parts. Repair any damage before

restarting the engine and operating the machine.

3. Use only in daylight or when there is good artificial

light. Watch for holes or other hidden hazards. Do not

transport the machine close to a sand trap, ditch, creek

or other hazard.

4. Always raise the machine to the transport position

when parked on a green to prevent roller marks.

5. Do not operate the water injection system on concrete

or asphalt because water jets will permanently damage

these surfaces. Do not run over hoses because damage

will occur.

6. Do not operate the aerator with its roller or injection

system over the edge of anything that could be hit,

damaged or injured by high-velocity water blasts.

7. Water jets from the injection system should not damage

irrigation heads on one pass of the machine. Do not

allow multiple shots from the injection system to hit

irrigation heads as damage will occur.

8. Use a good, clean, quality water supply in the system.

If good quality water is not available, additional filtra-

tion equipment may be required. DO NOT USE

CHEMICALS IN THE WATER SYSTEM.

9. Do not allow the machine to be subject to freezing tem-

peratures without draining, because damage to the sys-

tem will occur.

19

STARTING / STOPPINGTHE

ENGINE

1. Make sure the wires are installed on the spark plugs

and the fuel shut-off valve is open.

2. Make sure the parking brake is engaged.

3. Pull the choke lever out to the FULL position and

move the throttle lever to the half-throttle position.

Note: When starting a warm the engine, the choke

may not be necessary, but HALF throttle is.

4. Insert the key into the ignition switch and turn it

clockwise to start the engine. Release the key when

the engine starts. Gradually return the choke lever

to the OFF position (lever all the way in) after the

engine starts and warms up.

IMPORTANT: To prevent overheating the

starter motor, do not engage the starter longer

than 30 seconds. After 30 seconds of continuous

cranking, wait 2 minutes before engaging the

starter motor again.

IMPORTANT: The engine is equipped with an

oil pressure interlock switch which interrupts

engine operation if there is not sufficient oil

pressure in the engine during starting or during

engine operation. The engine may start but will

not continue to run due to a lack of oil pressure.

5. To stop the engine, move the throttle control down-

ward to the SLOW position and turn the ignition

key to “OFF".

TRAINING PERIOD

Before aerating with the Hydroject 3000, it is suggested

that you find a clear area and practice starting and stop-

ping, raising and lowering the machine, turning, etc.

This training period will be beneficial in gaining confi-

Operation

dence in the performance of the Hydroject 3000.

OPERATING PROCEDURE

1. Make sure the wires are installed on the spark plugs and the

fuel shut-off valve is open.

2. Uncoil a garden hose making sure there are no kinks or

bends in the hose. Lay out the hose so there are no obstruc-

tions between the machine and the area to be aerated. Turn

on the water supply to purge any air from the hose. Turn off

the water.

3. Connect the hose adapter (Fig. 8) to the garden hose, then

connect the adapter to the quick coupler on the side of the

machine.

4. Turn on the water supply and check the water pressure. The

water pressure must be at least 207 kPa. If system pressure

is not 207 kPa, make sure your hose is not kinked or

obstructed, the water supply is turned on or if the water fil-

ter is plugged.

5. Reach under the fuel tank and press the bleed button on the

top of the water filter head (Fig. 9). Hold the bleed button

down until all air is purged from the filter and water comes

out the opening.

6. Reach under the hood and open the bleed valve on the main

valve at rear of the machine (Fig. 10). Bleed the system

until a steady flow of water comes from the outlet, then

close the valve.

7. If desired, the valve on the pre-filter (Fig. 11) may be

opened slightly (cracked) to provide continuous flushing

during machine operation.

8. Start the engine: refer to Starting/Stopping instructions.

Move the throttle to the FAST position and disengage the

parking brake.

9. Engage the traction bail and approach the area to be aerat-

ed. Make sure there are no obstructions between the aerator

and water supply.

10. Engage and hold the transport/aerate toggle switch to fully

lower the machine onto rollers, release the switch when

fully lowered, then press the engagement button to start

water injection.

20

Figure 8

1. Hose adapter

2. Quick coupler

Figure 9

1. Main water filter head

2. Bleed button

Figure 10

1. Main valve

2. Bleed valve

Other manuals for 9801

1

This manual suits for next models

1

Table of contents

Other Toro Tiller manuals

Toro

Toro 58601 User manual

Toro

Toro Hydroject 3000 User manual

Toro

Toro 09802 HydroJect 3010 User manual

Toro

Toro 23516 User manual

Toro

Toro 09802 HydroJect 3010 User manual

Toro

Toro 58602 User manual

Toro

Toro 09850 User manual

Toro

Toro 22542 User manual

Toro

Toro Soil Cultivator User manual

Toro

Toro 22445 User manual