The STXP Series is a Type 1 SPD and suitable for use in

all locations. Type 1 SPDs are evaluated more rigorously

by UL for NEC®Article 285 compliance. Type 1 SPDs have

been evaluated for line side applications without need

for supplemental overcurrent protection. Type 1 SPDs

include internal overcurrent protection. There are practical

maintenance reasons for installing on load side of the

main overcurrent device (i.e. Type 2 installation). When

connected on load side of main disconnect, its recommend

connecting a 30A circuit breaker to protect the 10 AWG

conductors. The circuit breaker serves as a disconnect

switch and provides NEC®imposed short circuit protection

to the conductors in Type 2 or 4 applications.

The STXP Series is a high quality, high energy surge

suppressor designed to protect equipment from

damaging transient overvoltages. The STXP Series

is parallel connected device. Proper installation is

important for maximize product performance. These

installation instructions do not replace national or

local electrical codes.

Compliance:

The STXP Series SPD fully complies with latest UL 1449

and NEC®regulatory changes. There has been recent

emphasis on installation location, identied as types 1, 2, 3

or 4 locations. They are outlined below:

Type 1: Installation on the line side or load side of the

service disconnect overcurrent device, and

may be used in Type 2 or Type 4 installations.

Examples: Surge arresters, lightning arresters,

meter hubs, metering cabinets, ran out of breaker

positions, etc.

Type 2: Downstream of service disconnect; probably will

connect via breaker. Examples: Switchboards,

power panels, panelboards, equipment, motors,

pumps, etc.

Type 3: Plug-in SPD

Type 4: Usually treated as a UL Recognized component

in a larger UL Listed nished product. Examples:

UL 508 control panels, medical equipment, wind

turbines, signage, conveyers, elevators, etc.

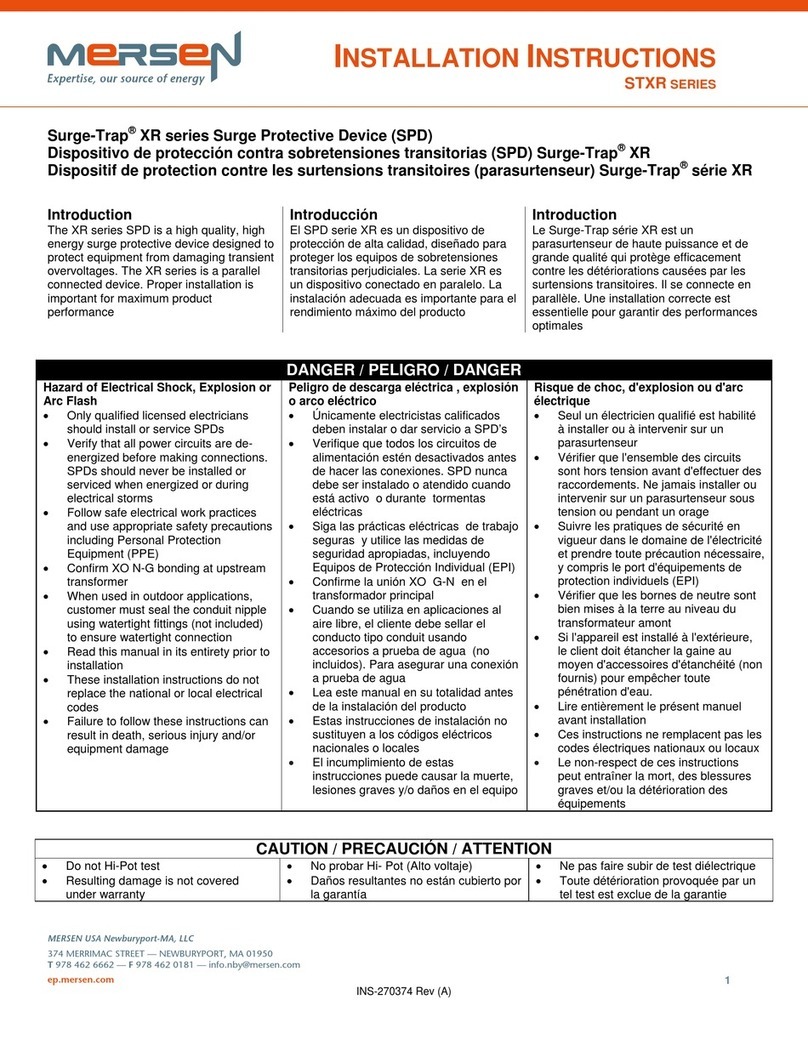

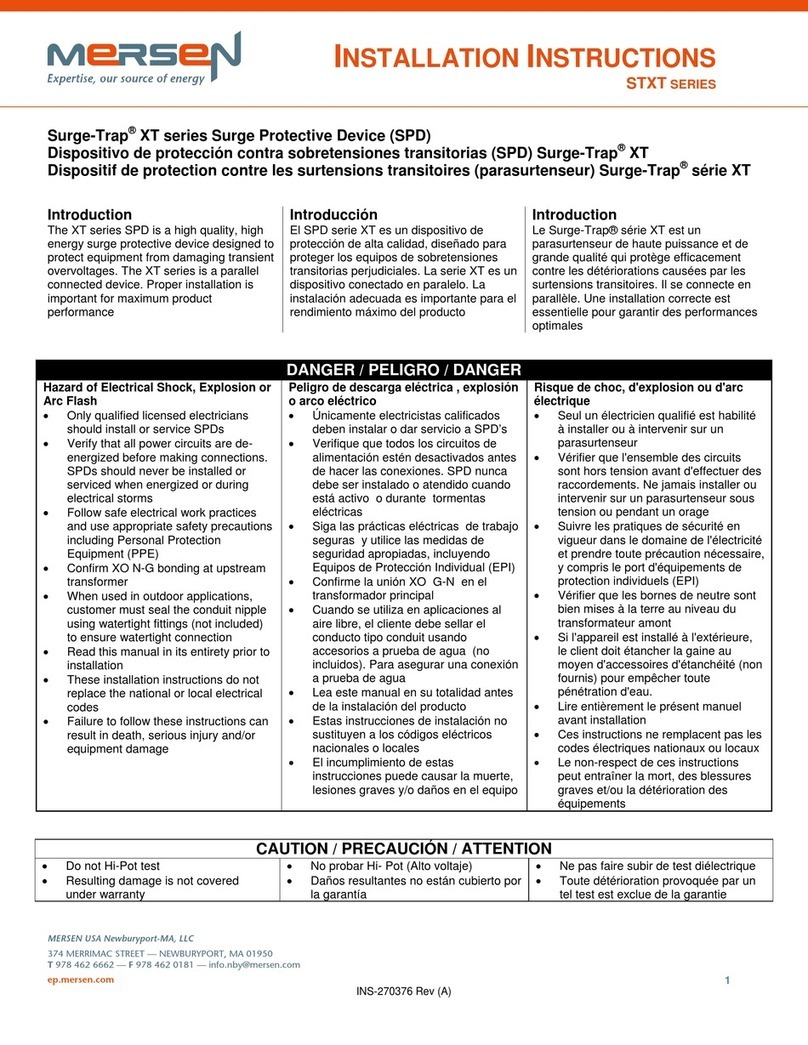

WARNING – Risk of Electric Shock

• Only qualied licensed electricians should install or service

SPDs

• SPDs should never be installed or serviced when energized

or during electrical storms

• Use appropriate safety precautions including Personal

Protection Equipment

• Failure to follow these instructions can result in death,

serious injury, and/or equipment damage

• When used in outdoor applications, customer must seal

the conduit nipple using watertight ttings (not included) to

ensure a watertight connection

• Read this manual in its entirety prior to installing

NEC®Art 285 & UL 1449

SPD Types: Type 1, 2, 3, & 4

Based on location within electrical distribution

system (also coincides with ANSI/IEEE C62.41.2 - 2002

Categories C, B &A)

Surge-Trap®Type 1 XP Series SPD

INSTALLATION INSTRUCTIONS