4

TRANSPORT 108

6.7 EXCLUDING A METERING UNIT....................................................................................................................................66

6.7.1 MANUAL EXCLUSION OF THE TRANSMISSION .............................................................................66

6.7.2 AUTOMATIC ROW EXCLUSION (OPTIONAL)..................................................................................67

6.7.3 RAISING THE UNIT.............................................................................................................................. 68

6.8 PLANTING DEPTH...........................................................................................................................................................69

6.8.1 ADJUSTING PROSEM K......................................................................................................................69

6.8.2 ADJUSTING PROSEM P .....................................................................................................................70

6.9 SCRAPER PROSEM K.......................................................................................................................................................71

6.10 PRESSURE OF THE METERING UNIT ONTO THE GROUND 6.10 PRESSURE OF THE METERING

UNIT ONTO THE GROUND..........................................................................................................................................72

6.10.1 PRESSURE OF THE UNIT PROSEM K / P.........................................................................................72

6.10.2 PRESSURE OF THE UNIT PROSEM BASIC .....................................................................................72

6.11 CLOSING THE FURROWS..............................................................................................................................................73

6.11.1 V-SHAPED PRESS WHEELS – PROSEM K .......................................................................................73

6.11.1.1 WHEEL’S WORKING WIDTH .............................................................................................74

6.11.1.2 PRESSURE ONTO THE SEED ............................................................................................75

6.11.1.3 BEARING ANGLE ...............................................................................................................75

6.11.2 FURROW-COVERER – PROSEM P ...................................................................................................76

6.11.2.1 ADJUSTING THE FURROW-COVERER PROSEM P HIGH SHARE ................................76

6.11.2.2 ADJUSTING THE FURROW-COVERER PROSEM P........................................................77

6.12 OPENING COMPONENTS.............................................................................................................................................78

6.12.1 ADJUSTING THE BLADE AND THE CLOD REMOVER ..................................................................78

6.12.2 ADJUSTING THE DISC FURROW OPENER IN UNIT PROSEM K (OPTIONAL)...........................79

6.12.3 ADJUSTING THE FURROW-OPENER BLADE ................................................................................79

6.12.4 ADJUSTING THE FURROW’S RESIDUE ROTARY CLEANER IN PROSEM K

METERING UNITS (OPTIONAL)......................................................................................................80

6.13 FURROW’S RESIDUE ROTARY CLEANERS WITH PARALLELOGRAM (OPTIONAL)..............................................81

6.14 TURBO DISC OPENER (OPTIONAL) ............................................................................................................................82

6.15 SEED PRESSING WHEEL PROSEM K (OPTIONAL) ....................................................................................................84

6.16 TRACK ERASER (OPTIONAL) .......................................................................................................................................85

6.17 HYDRAULICAL TRACK MARKERS...............................................................................................................................86

6.17.1 ADJUSTING TRACK MARKER’S LENGTH .......................................................................................86

6.17.2 ADJUSTING TRACK DISC’S ORIENTATION....................................................................................88

6.18 FERTILISING EQUIPMENT (OPTIONAL) .....................................................................................................................89

6.18.1 REPLACING THE FERTILISER’S TRANSMISSION.......................................................................... 91

6.18.2 FERTILISER’S DOUBLE DISC ...........................................................................................................92

6.18.3 FERTILISER’S SHARE........................................................................................................................93

6.19 INSECTISIDE MICROGRANULATOR (OPTIONAL) ....................................................................................................94

6.19.1 CHANGING THE MICROGRANULATOR’S TRANSMISSION ........................................................96

6.19.2

EXCLUDING THE MICROGRANULATOR................................................................................................ 97

6.20 HELICIDE MICROGRANULATOR (OPTIONAL)..........................................................................................................98

6.21 INSECTISIDE MICROGRANULATOR AND HELICIDE MICROGRANULATOR (OPTIONAL) ................................

101

6.21.1 CHANGING THE TRANSMISSION OF THE INSECTISIDE MICROGRANULATOR WITH DOUBLE HOPPER . 105

6.21.2 CHANGING THE TRANSMISSION OF THE HELICIDE MICROGRANULATOR WITH DOUBLE HOPPER....... 106

6.21.3 EXCLUDING THE INSECTISIDE AND HELICIDE MICROGRANULATORS ..........................................................107

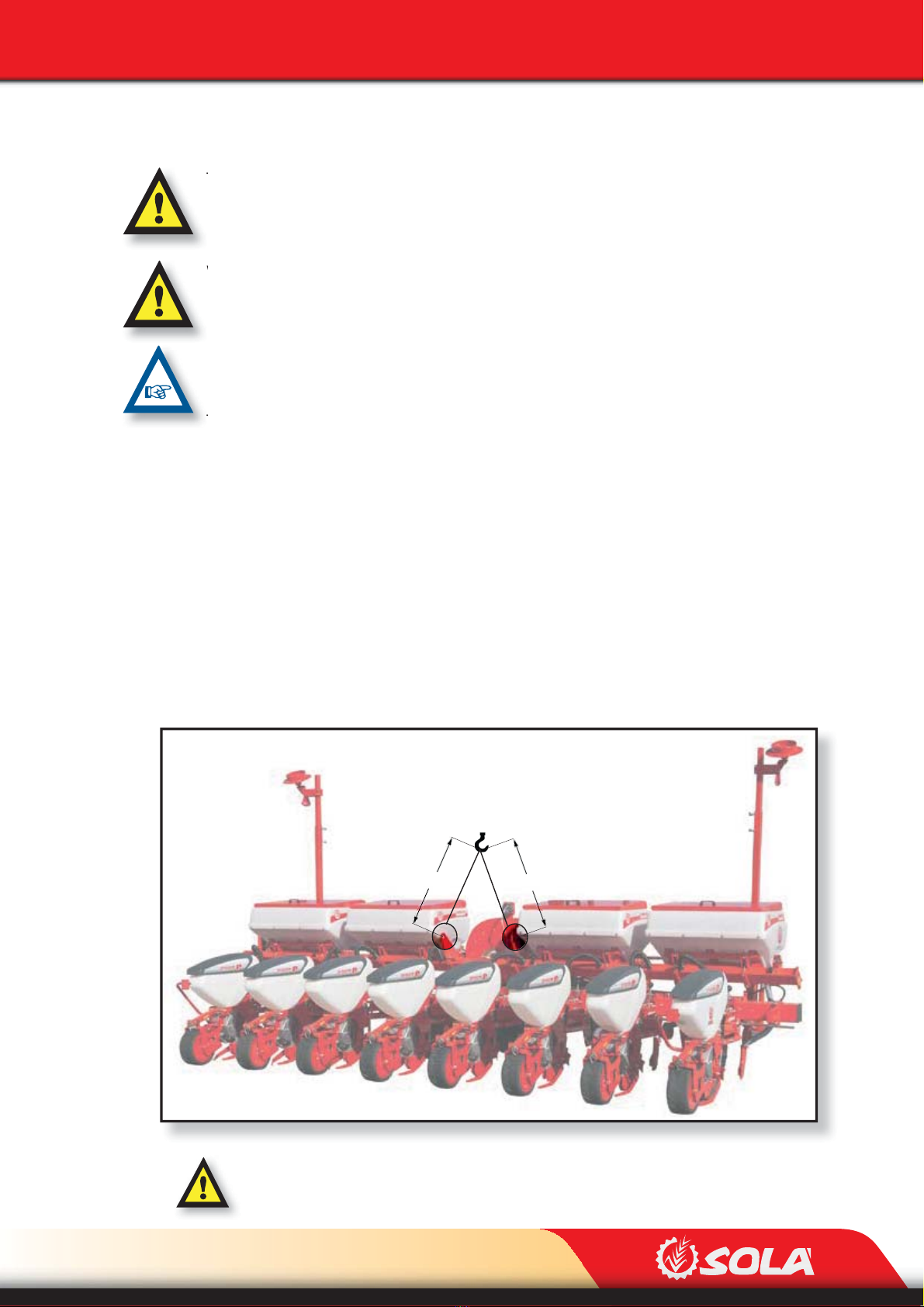

7- TRANSPORT.................................................................................................................................................. 108

7.1 FIXED FRAME .................................................................................................................................................................108

7.2 VARIANT MANUAL FIXED FRAME..............................................................................................................................109

7.3 TELESCOPIC, VARIANT AND VARIANT IDRA FRAME ..............................................................................................109

7.4 FOLDING FRAME........................................................................................................................................................... 110

8- FILLING AND EMPTYING THE HOPPERS .......................................................................................................111

8.1 SEED HOPPER................................................................................................................................................................ 111

8.2 FERTILISER HOPPER..................................................................................................................................................... 112

8.3 INSECTISIDE MICROGRANULATOR’S AND/OR HELICIDE MICROGRANULATOR’S HOPPERS ........................ 112

9- MAINTENANCE..............................................................................................................................................113

9.1 CHECKING FREQUENCY............................................................................................................................................... 114

9.2 GREASING AND LUBRICATION................................................................................................................................... 116

9.3 FANS................................................................................................................................................................................ 118

9.4 TRANSMISSION CHAIN................................................................................................................................................ 119

9.5 AUTOMATIC GEARBOX................................................................................................................................................120

9.6 MACHINE CLEANING....................................................................................................................................................120

9.7 SCREWS ..........................................................................................................................................................................122

9.8 TYRE PRESSURE ............................................................................................................................................................122

10- WARRANTY ................................................................................................................................................ 123