Chapman AH200 User manual

Page 2

English

Introduction

THIS MANUAL MUST BE HANDED TO THE OPERATOR BEFORE USE. THE OPERATOR MUST UNDERSTAND FULLY THE CONTENT OF THIS

HANDBOOK BEFORE USING THE MACHINE FOR THE FIRST TIME. OF THE IMPLEMENT IS RESOLD, THIS MANUAL MUST ACCOMPANY THE

MACHINE.

NOTE: The information contained in this manual is correct at the time of going to press. However, in the course of development, changes in

specification are inevitable. Should you find the information given differs from your machine, please contact Chapman Machinery Ltd direct

for advice. Use only Chapman Genuine Service Parts on Chapman Machinery and Machines.

HSE Information

The safe use of all-terrain vehicles (ATVs) & Side by Sides (UTVs) in agriculture and forestry must be

adhered to at all times with machinery attached or not. The HSE information, AIS Sheet 33, gives advice on

the safe use of ATVs/UTVs. It covers the two main types used in off-road working in agriculture and

forestry. The Full HSE information sheet can be found here or using the QR Code to the right

https://www.hse.gov.uk/pubns/ais33.pdf and must be read prior to any ATV/UTV use.

REMEMBER - GET PROPERLY TRAINED AND ALWAYS WEAR HEAD PROTECTION

Important Safety Information

Always read this manual before fitting or operating the machine –whenever any doubt exists contact your

dealer or the Chapman Machinery Service Department for advice and assistance.

•Do not operate this equipment unless you have studied this manual in full

•Only use this machine for its designated task - improper use is both highly dangerous and damaging to machine components

•Both operators & maintenance fitters should be familiar with the machine and fully aware of dangers surrounding improper

use or incorrect repairs

•Before starting, carry out a visual check on both machine & towing vehicle as regards functionality,road safety & accident

prevention rules

•Even when using the machine correctly, accidents can occur. It is imperative that nobody stand withinthe danger area. If working

near roads, buildings or animals, special attention must be taken to ensure safety.

•Never wear loose clothing which could get caught in rotating equipment

•Never carry passengers on the towing vehicle

•Do not stand near the machine when operating

•Damaged or missing safety decals must be replacedimmediately

Transportation Safety

•When transporting, especially over rough ground, reduce speed to prevent damage to machine.

•This machine is not road legal in its standard form. DO NOT tow on public highways.

Operating Safety

•Pay special attention when working not to harm livestock if crowding around the machine occurs.

•If anything should become entangled in the mechanism, or blocked, stop the machine and disconnect the power before

attempting to clear the blockage.

Page 3

English

Description

The AH200 is the ultimate tool for a professional finish on your arenas or sand schools. The 2.0m working width and heavy duty fixed spring tines

on a steel frame give the AH200 exceptional performance in levelling and rejuvenating surfaces, along with a rear consolidation roller to give a

great finish. Arenas and gallops are becoming more sophisticated in their construction with synthetic materials being added to the surfaces to

provide superior, stable riding surfaces.

40 8mm tines offset over 4 rows means no missed spots. Easily adjust the aggressiveness of the tines with three tine settings and simple

adjustment. Six front mounted ‘S’ Tines allow the AH200 to loosen and lift the surface to give a greater mix of more fibre and synthetic materials.

The Spring Tines that follow smooths out the surface before the rear consolidation roller compacts and orientates fibres across the surface. A 12v

electric lift actuator is fitted which lets you simply raise & lower the machine into work mode or travelling mode with a remote switch on the

back of your ATV/UTV.

These machines should however only be used to perform tasks for which they were designed - use of the machine for any other function may be

both dangerous to persons, and potentially damaging to components. Use of the machine beyond the stated usage may invalidate any applicable

warranty, as well as being potential in breach of applicable safety regulations.

Note: This machine is for off-road use only and is not designed or approved for highway travel

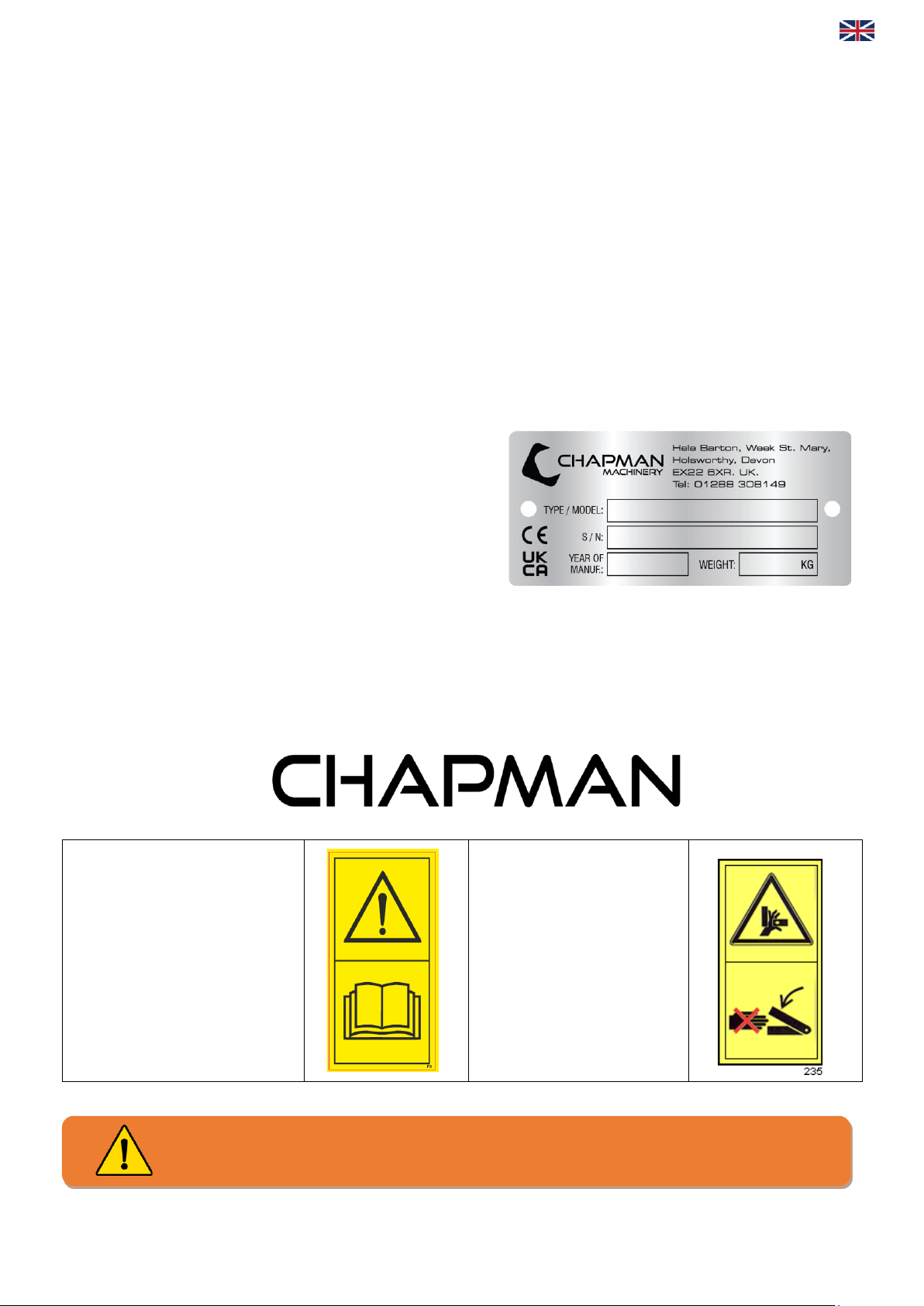

Identification

Each machine is fitted with a serial plate (shown below) which details the

following:

1. Model

2. Date of Manufacture (DOM)

3. Serial Number

4. Mass

When enquiring regarding spares or additional equipment, ensure you have this information to hand.

Implement Decals

If your implement does not contain all of the decals shown below, please contact Chapman Machinery for replacement decals before use.

Note: All decals must be present and visible. It is imperative that these are replaced if damaged to prevent potential harm to users.

ENSURE CONTROL EQUIPMENT IS SECURELY ATTACHED TO THE TOWING

CAUTION - Read operators

manual before handling this

machine. Observe

instructions and safety rules

when operating.

WARNING –Crush Hazard

Never reach into crush area

as parts may move trapping

appendages

ENSURE CONTROL EQUIPMENT IS SECURELY ATTACHED TO THE TOWING

VEHICLE BEFORE USE

Page 4

English

Attachment

Before attachment, ALWAYS ensure the following:

•All safety guards & decals are in good working order and correctly fitted

•Lubrication points have been lubricated as per scheduled maintenance period

•The tyres are free of damage and inflated to the correct pressure

•Electrical connections are free of dirt and moisture

NOTE: This machine is designed to attach to the towing vehicle through a 50mm diameter ball hitch.

1. Reverse the towing vehicle up to the machine.

2. Attach the machine onto the towing vehicle’scoupling. Adjust drawbar angle as necessary to ensure main frame of machine is parallel

with ground when in working height, this ensures even tine contact across the 4 rows of tines.

3. Attach the control cable to the control socket fitted on the towing machine, ensuring a secure connection.

4. If required, adjust tine angle setting before lowering machine into work mode.

Initial Set-up

Towing Vehicle Wiring

Initially the towing vehicle must be wired using the supplied two core power cable to be wired directly to the vehicle battery terminals. Failure

to wire the supplied dedicated feed directly to the battery may cause issues with towing vehicle electrics. Ensure the supply is suitably routed to

protect from heat and mechanical damage.

Battery Specification

12V DC Nominal, Minimum 18Ah battery

Tine Angle

The tines on the AH200 can be set to three settings of aggressiveness, using the black tine bar adjuster located just behind the machine

drawbar. Pulling the adjuster forwards (towards the towing vehicle) will make the tines less aggressive and pushing the adjuster rearwards will

make the tines more aggressive. The adjuster is fixed in place once set using a pin and retaining clip. *We recommend you begin operation with

the tines in the middle setting and adjust as required thereafter*

Height

The working height of the machine is set using the electronic actuator and control box. Pressing the relevant up / down arrow will raise or

lower the main frame accordingly. The AH200 should only be transported across fields with the height at it’s maximum, and then lowered into

use as required. The AH200 should be lowered to allow weight onto the tines, such that consistent ground contact is achieved by the tines. The

wheels will always carry some weight, to ensure the unit tows easily and travels over rough terrain smoothly.

Initial Test Operation

In order to familiarise the operator(s) with the machine, first adjust the tines and machine height in the yard, before commencing work. This will

ensure the operator is fully familiar with the operation of the machine. During this period the angle of the drawbar should be adjusted to suit

the towing vehicle, such that the main frame of the AH200 runs level with the ground when the unit is in a working height.

Operating Limits

Minimum / Maximum Temperature: -5°C / +40°C

Maximum Speed: 10 km/h

Battery Voltage: 12V DC Nominal

Maximum Speed 8km/h (5mph)

DO NOT OPERATE BEYOND OPERATING LIMITS, DAMAGE TO MACHINERY OR INJURY TO

OPERATOR MAY OCCUR.

Page 5

English

Operation

Ensure that the operator is suitably qualified to use a machine of this nature and that they have fully read and understood this manual - they

should be aware of all safety aspects relating to the safe use of the machine.

AFTER APPROXIMATELY ONE HOUR OF WORK WITH A NEW MACHINE, ALL NUTS AND BOLTS SHOULD BE CHECKED FOR TIGHTNESS AND

ADJUSTED AS NECESSARY!

Operation

1. Set desired tine angle with machine in transport position (ie. height at maximum). Recommended start position is middle hole on tine

adjustment.

2. Drive onto surface and using control box lower tines onto ground until all the axle lifts off the surface. Continue to raise the axle fully.

The working height of the AH200 is set by the level of the rear roller at the back of the machine and the spring tines at the front. You

should aim for the main frame of the AH200 to be level when working as a starting point.

3. Drive around the surface and examine the results –if the S tines are too deep and aggressive then adjust the drawbar to raise the front

of the machine slightly (and as such reduce the working depth of the S tines slightly) Conversely, if the S Tines are not being aggressive

enough, adjust the drawbar height down accordingly.

4. Following first adjustments, again drive around the surface and examine the results, re-adjusting as necessary. If needed you can also

adjust the setting of the 4 rows of following tines to be more of less aggressive as required by moving the black lever located just

behind the drawbar.

5. If you find that the front row and rear rows of following tines are doing an uneven amount of work then raise or reduce the level of the

rear roller accordingly to adjust this.

6. Once a suitable height setting is found it generally does not need to be changed, however it is advisable to make a mark on the frame of

the machine using an indelible pen or similar such that this setting can easily be recalled if changes are required in the future.

Forward Speed

A forward speed of up to 10km/h will typically produce the best results, however this may need to be reduced depending on the surface

conditions and any obstacles that may be present in the arena.

Storage

Machines should always be stored under cover and protected from the elements accordingly.

For extended periods of storage, it is advisable that the machine be kept in a clean dry environment protected from the elements to avoid risk of

corrosion.

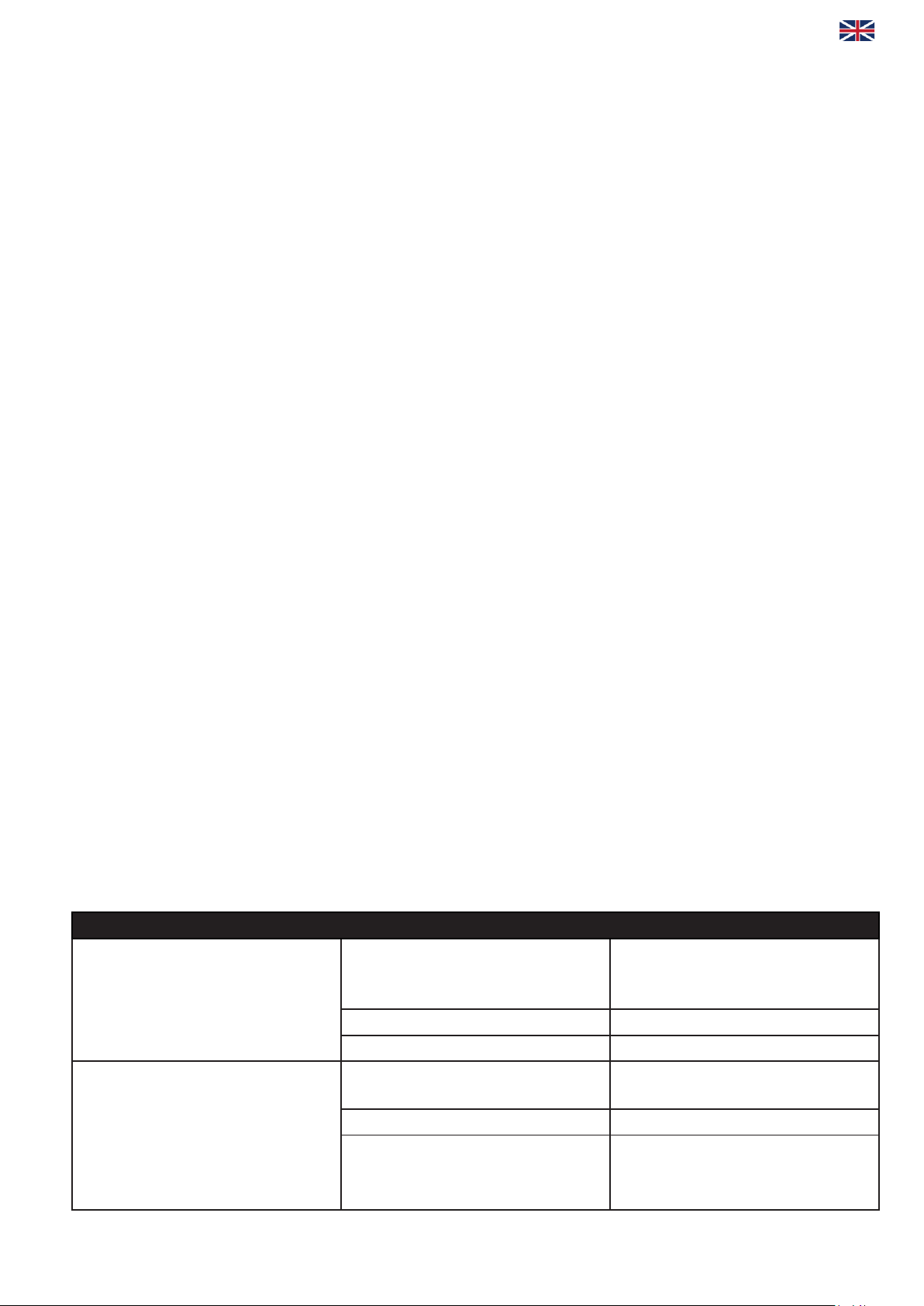

Troubleshooting

Problem

Possible Causes

Remedies

Unit will not raise or lower

Shortage in wiring (may be

indicated by unit losing powerwhen

run button pressed)

Check plug and battery connection

are free from dirt and making good

contact

Actuator Fault

Replace motor, contact distributor

Switch Fault

Replace switch, contact distributor

Poor tine contact with ground

Working height too high

Lower unit

Tines worn

Inspect tines, replace if worn

Drawbar angle incorrect

Adjust drawbar adjuster so that

main frame is parallel with ground

when at working height

Table of contents

Languages:

Other Chapman Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions