3

2Safety Information

•A careful operator is the best operator. Most accidents can be avoided by observing necessary

precautions. To help prevent accidents, read the following precautions before operating this

equipment. Equipment should be operated only by those who are responsible and instructed to do

so. Carefully review the procedures given in this manual with all operators. It is important that all

operators be familiar with and follows safety precautions. Improper use of the equipment can cause

serious injury or death.

•Read the operator’s manual before operating equipment.

•Only allow properly trained persons to operate the equipment.

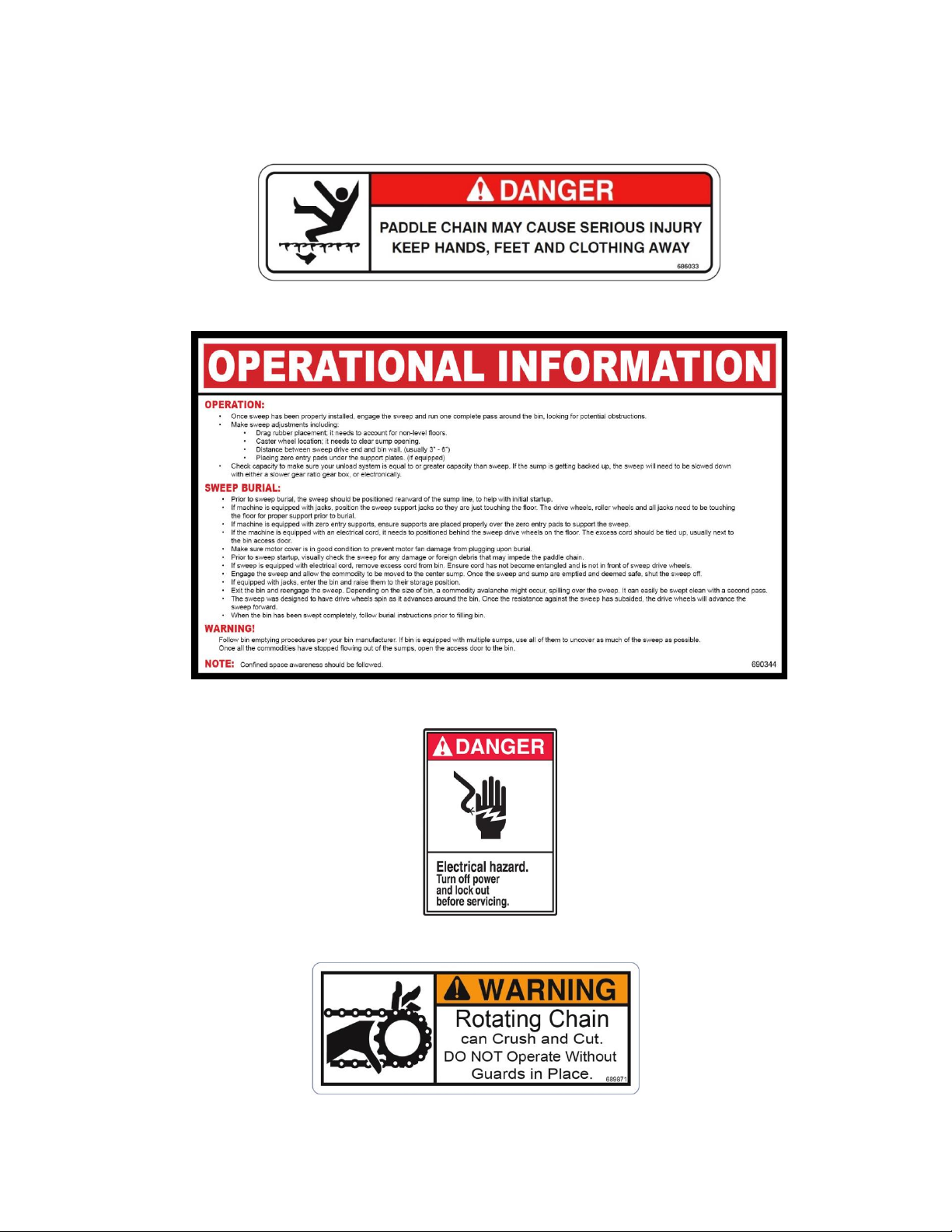

•Keep hands and feet away from all pinch points.

•Keep bystanders away during operation. In an empty bin/silo, keep everyone rearward of the

sweep during operation to validate installation or maintenance.

•Do not contact (i.e., push, stand, touch, etc.) any portion of the sweep during operation.

•Since the installation of this sweep takes place within a confined space. Confined space awareness

should be followed. Lockout/tag out awareness should be followed.

•A licensed electrician is recommended to wire the unit in accordance with local federal codes.

•DO NOT clean, lubricate, or adjust the equipment while it is running. Disengage the machine prior

to doing so.

•Install and ground slip collector ring and the entire unit in accordance with the National Electric

Code (NEC) and local codes and/or ordinances.

•Always disconnect and lock out all power sources from the collector ring before attempting to

perform any service function. Follow lockout/tag out procedures as outlined in OSHA section

1910.147 where appropriate.

•An explosion proof motor is required for use in a Class II, Group E, F, G dust environment.

•Refer to maintenance chart to check all fasteners and hardware to assure tightness.

•CAUTION: Too much oil will cause overheating and too little will result in gear failure. Check oil level

regularly. More frequent oil changes are recommended when operating continuously, at high

temperatures or under conditions of extreme dirt or dust. Check that the vent plug is clear.

•Contact the bin manufacturer for anchor design on grain bins 72 feet in diameter and larger for

single pass sweep utilization. Failure to do so may cause damage to the grain bin.

•REMEMBER: The manufacturer includes or provides all reasonable means for accident prevention

except a safe and careful operator.