5

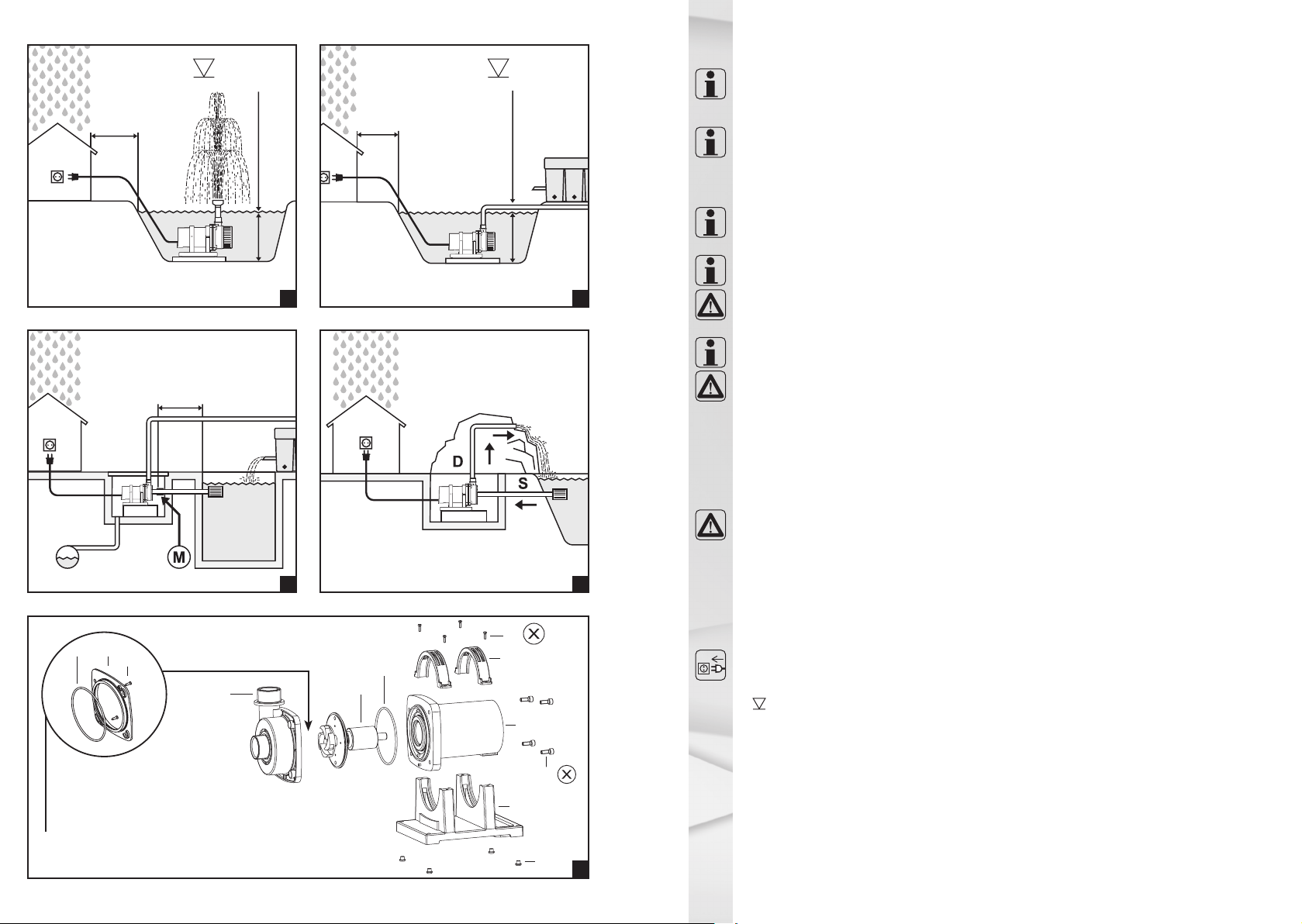

“Non submersible use” (see fig. 3 + 4)

The pump can be used in a nonsubmerged type application.

- Position the pump below the surface of the water, at the side of the pond so that the water can flow into

the pump (not self-priming).

- Connect suction hose (S) and pressure hose (D) to the pump. Connection should be watertight.

- Suction hose and pump must be filled with water before switching-on.

-TIP! To prevent the pump becoming clogged, provide the suction hose with a pre filter

Art.-No. 168 / 009137 - 168 / 009140 or 168 / 009050 covered in our range of accessories.

Overload protection

In case the pump is becoming overheated the built-in thermal overload trip switches it off.

The pump must cool down.

The pump will not start automatically without the necessary controlling when it is cool.

Check the following operating conditions:

- Is there a sufficient water supply?

- Has the filter become clogged?

- Has dirt entered the pump housing (Follow the cleaning instructions below)?

- Have hoses or jets become clogged?

- Has the pump cooled down?

As soon as you have solved the problems, you can switch on the pump again by pulling the plug out of the

socket and putting it in again after a short time (1 min.)

Dismantling (see fig. 5)

1. Follow the safety measures. Disconnect pump from mains!

2. Loosen the 4 screws (18).

3. Pull apart pump housing (12) and motor housing (10) .

4. Remove rotor assembly (15) from motor housing (10). Take care of the O-ring (16) on the motor

housing (10).

5. Clean all parts with clear water and a soft sponge. Note! In case of massive calcination please use

Messner decalcifier for pumps Art.-No. 168 / 009115.

Assembly (see fig. 5)

1. Push the O-ring (16) onto the starting point on the motor housing (10).

2. Carefully slide the rotor assembly (15) into the motor housing (10) and twist the bearing cover so that

the two holes fit onto the pins on the motor housing (10).

3. Check whether the rotor assembly can be rotated easily.

4. Check the position of the O-ring (16) on the motor housing (10).

5. Put the pump housing (12) on the motor housing (10) and attach it firmly and evenly with the

4 screws (18) .

Maintenance

In order to prolong the service life of your pump significantly and to keep it in sound operating condition, it is

recommended to carry out maintenance and cleanup regularly.

This can be done by everyone, quickly and easily. See „Dismantling/Assembly“

Servicing intervals

- In the beginning check proper performance of your pump every day. If necessary, clean the filters.

- Since servicing intervals (complete cleaning) will vary depending on the level of pond pollution, repeat the

periodic service to your pump in accordance with the pollution of the pond water .

Should you determine that there are damaged or worn parts, replace them. See „Spare parts“

Important! When used in calcareous water, the rotor assembly (15) and the stainless steel can split

tube in the motor housing (10) should be cleaned at regular intervals.

Pump care in wintertime

Protect your pump from freezing-up!

Take the pump out of your pond in autumn.

Clean the pump completely according to the instructions.

During the winter months store the pump in a tank filled with water to prevent the bearings from drying out.

Store the tank in a frostproof room.

6

Spare parts

To order spare parts, please indicate the pump type, the designation and the Art.-No. from the table below

(see also fig. 5).

Item Designation Art.-No. Number

1 Pump stand 104 / 003506 1

2 Clip 104 / 003505 2

104 / 003279 112 Pump housing G 1¼˝

Pump housing G 1½˝ 104 / 003280 1

104 / 003570 1

104 / 003409 1

104 / 003508 1

104 / 004627 1

Pump housing

G 1½˝ - Ø 35

Pump housing G 2˝

Pump housing

G 2˝ - Ø 45

Pump housing

G 2˝ - Ø 109

13 Connection flange 104 / 003410 1

Pump Type

eco-Tec2 4500 - 20000

eco-Tec2 plus 10000 - 25000

eco-Tec2 4500 - 20000

eco-Tec2 plus 10000 - 25000

eco-Tec2 4500, eco-Tec2 7500

eco-Tec2 10000, eco-Tec2 13000

eco-Tec2 16000

eco-Tec2 plus 10000

eco-Tec2 20000

eco-Tec2 plus 15000

eco-Tec2 plus 20000

eco-Tec2 plus 25000

eco-Tec2 20000

eco-Tec2 plus 15000, eco-Tec2 plus 20000

eco-Tec2 plus 25000 104 / 004612 1

C3 G 2˝

Connection flange

C3 Ø 109

15 Rotor assembly 168 / 009156 1

168 / 009157 1

eco-Tec2 4500

eco-Tec2 7500

eco-Tec2 10000 168 / 009158 1

168 / 009159 1

168 / 009160 1

eco-Tec2 13000

eco-Tec2 16000

eco-Tec2 20000 168 / 009161 1

168 / 009162 1

168 / 009163 1

168 / 009164 1

Rotor assembly

Rotor assembly

Rotor assembly

Rotor assembly

Rotor assembly

Rotor assembly

Rotor assembly

Rotor assembly

Rotor assembly

eco-Tec2 plus 10000

eco-Tec2 plus 15000

eco-Tec2 plus 20000

eco-Tec2 plus 25000 168 / 009175 1

16 O-ring 96 x 3 112 / 000030 1

112 / 000047 1

112 / 000069 1

114 / 000048 4

114 / 000079 4

114 / 000078 2

114 / 000042 4

114 / 000172 4

eco-Tec2 4500 - 20000

eco-Tec2 plus 10000 - 25000

eco-Tec2 20000

eco-Tec2 plus 15000, eco-Tec2 plus 20000

eco-Tec2 plus 25000

eco-Tec2 4500 - 16000

eco-Tec2 plus 10000

eco-Tec2 20000, eco-Tec2 plus 15000

eco-Tec2 plus 20000, eco-Tec2 plus 25000

eco-Tec2 20000

eco-Tec2 plus 15000 - 25000

eco-Tec2 4500 - 20000

eco-Tec2 plus 10000 - 25000

eco-Tec2 4500 - 20000

eco-Tec2 plus 10000 - 25000

17 O-ring 105 x 3

O-Ring 105 x 2,5

18 Screw M 6 x 16

Screw M 6 x 20

19 Screw Ø 3,5 x 13

20 Screw Ø 3,9 x 16

21 Rubber buffer

Guarantee conditions

This pump comes with a 72-month guarantee that is effective from the date of delivery. The invoice will be

the proof of the date. In case of damages due to defects in material or manufacturing, we shall either do a

free repair during the guarantee period or replace the damaged part, the choice being ours’.

Damages that occur due to installation and operating errors, lime deposits, insufficient care, frost action,

normal wear and tear or improper repair attempts will not come under this guarantee. The guarantee will

not be valid in case of modifications to the pump, e.g. cutting off the line connection or the line cord. We

will not accept responsibility for consequential damages resulting from breakdown of the pump or improper

operation.

When making use of the guarantee, please send us the pump, along with the corresponding invoice, free of

charge via the specialist dealer who sold you the pump.

Waste disposal

waste disposal of electronic devices by the user in private households of the EU

It is not allowed to dispose the product along with the regular waste disposal, instead it has to be collected

separately. It is your responsibility to dispose and recycle the device in a proper place and protect the

environment through this. More information, where to dispose your devices can be obtained at the local

departments.